Connection structure of refrigerant tube

A refrigerant pipe and connection structure technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, heating method, etc., can solve the problems of impossibility of airtightness, refrigerant gas leakage, and difficulty in ensuring airtightness, etc. , to achieve the effect of improving the efficiency of cooling/heating and preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

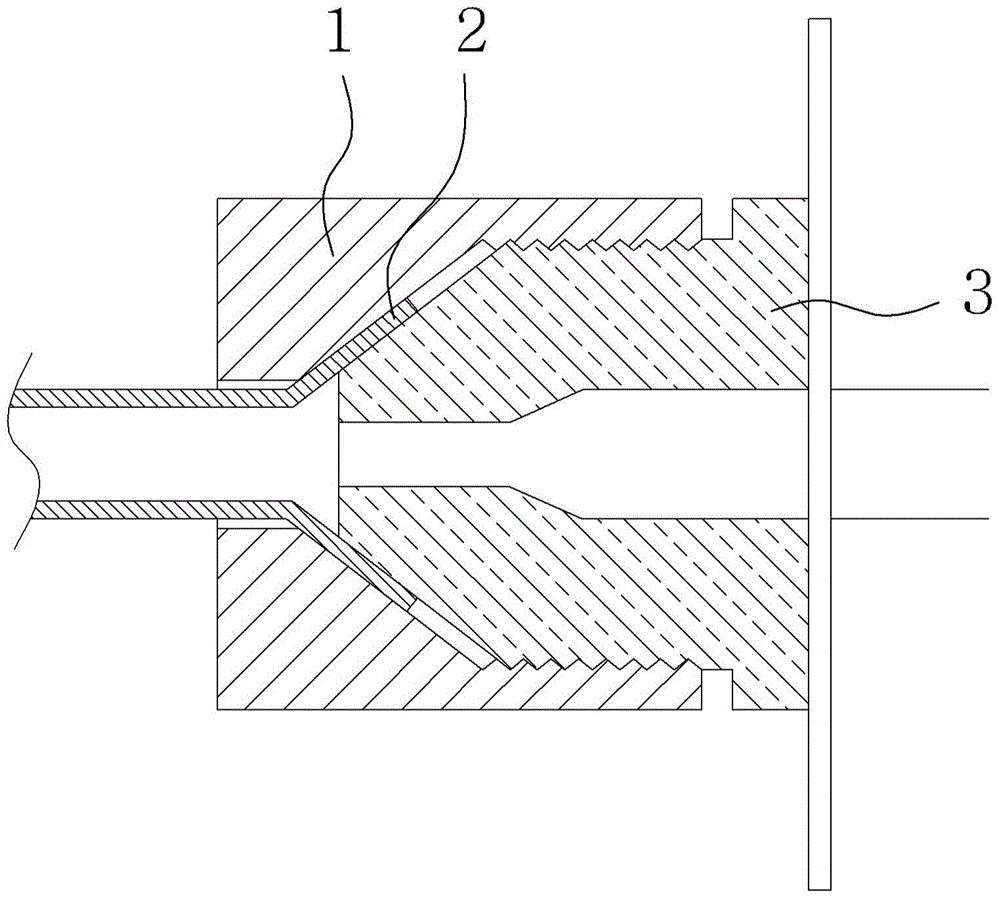

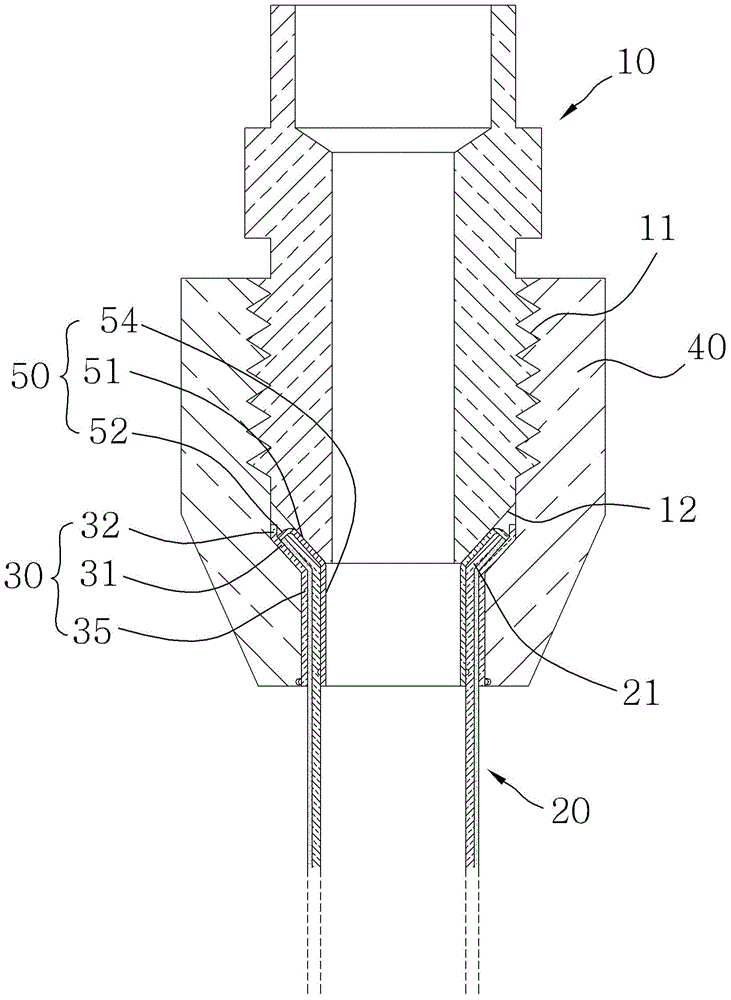

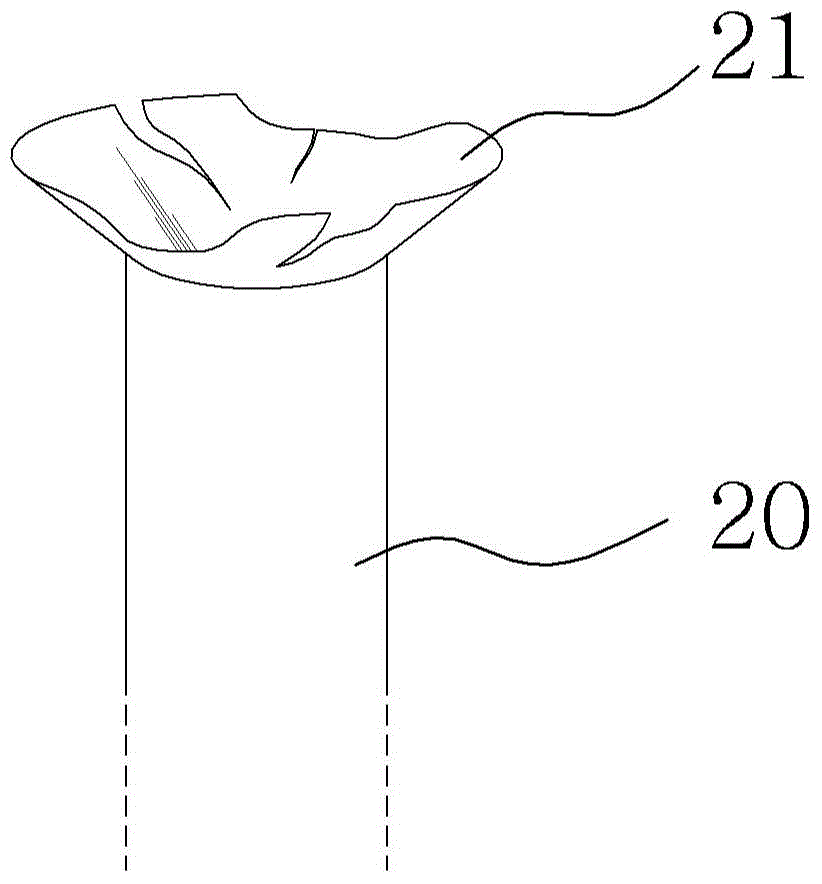

[0049] Combine below Figure 4 to Figure 6 Embodiments of the refrigerant pipe connection structure of the present invention will be described.

[0050] In the refrigerant pipe connection structure of the present invention, the nut 170 is inserted into the refrigerant pipe 140 and then the bolt 110 and the nut are combined in order to closely combine the expanded portion 141 of the refrigerant pipe 140 with the tapered portion 113 of the valve 110 to maintain airtightness. 170 and fasten the thread, the male thread 112 of the valve 110 and the female thread 172 of the nut 170 can be screwed together so that the expansion part 141 of the refrigerant tube 140 is firmly fastened to the tapered part of the valve 110 113.

[0051] At this time, the material of the refrigerant pipe 140 on which the above-mentioned expanded portion 141 is formed is aluminum and the valve 110 is one of copper, iron, or stainless steel. Therefore, if the nut 170 is tightened excessively, the expanded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com