Roller repairing method

A repair method and roll technology, which is applied in the field of roll repair and can solve problems such as broken pin holes on rings and falling off of rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

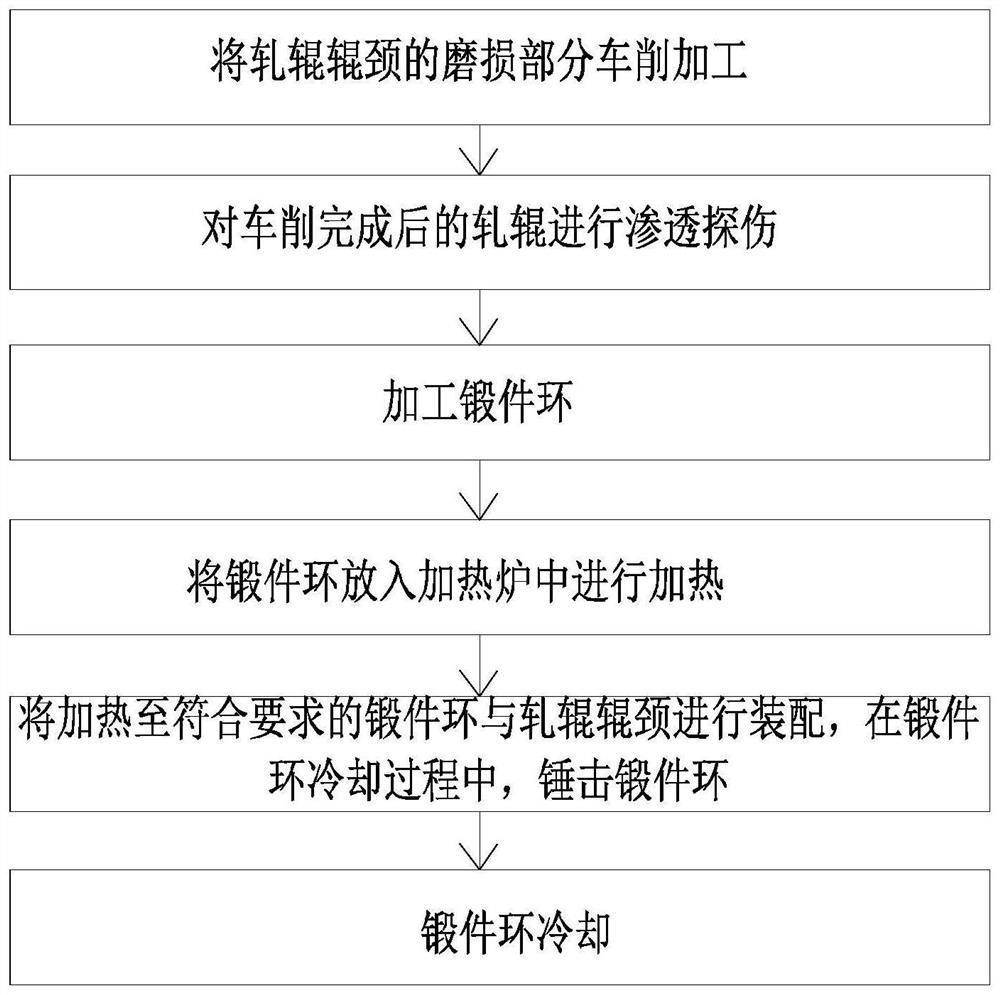

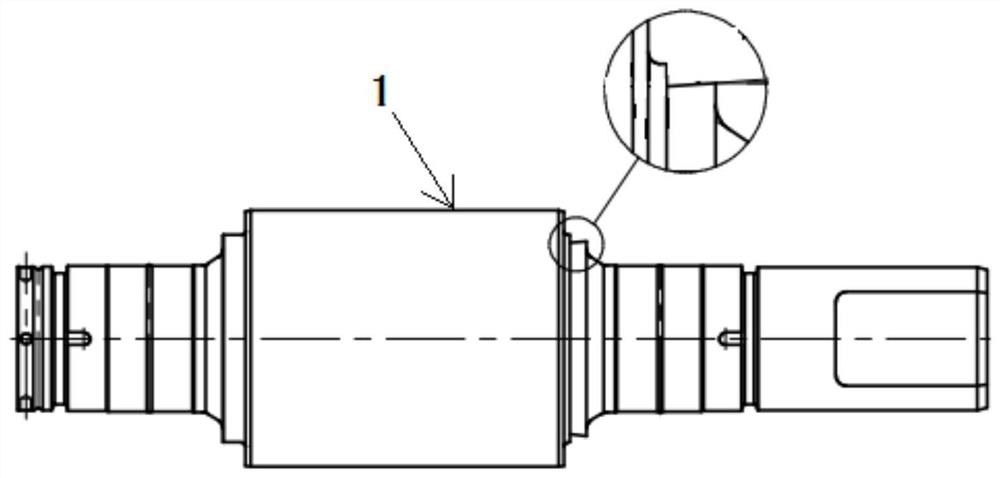

[0032] Please refer to figure 1 , the present invention provides a repair method for roll 1,

[0033] Step 1: Carry out turning processing on the surface of the roll neck of the roll 1, and remove the worn parts on the surface, so as to obtain a clean surface of the roll 1. In detail, the roll 1 described in this application can be made of cast steel, semi-steel, ductile iron, or cast iron, and its size and taper should be processed according to the drawing requirements during turning. The surface of roll 1 after turning generally does not need to be polished. The surface of roll 1 is processed with high surface roughness. When necessary, it will be processed by grinding. The surface of roll neck in roll 1 that is used for assembly does not need to be cleaned. But it should be kept as clean as possible. It is worth noting that this repair method is best used for the repair of the roll neck of roll 1. After removing the defects, the strength of roll 1 needs to be checked. Onl...

Embodiment 2

[0040] On the basis of embodiment 1, the technical scheme of the present invention is further improved, specifically:

[0041] The repair method of roll 1 comprises the following steps:

[0042] Step 1: Carry out turning processing on the surface of the roll neck of the roll 1, and remove the worn parts on the surface, so as to obtain a clean surface of the roll 1.

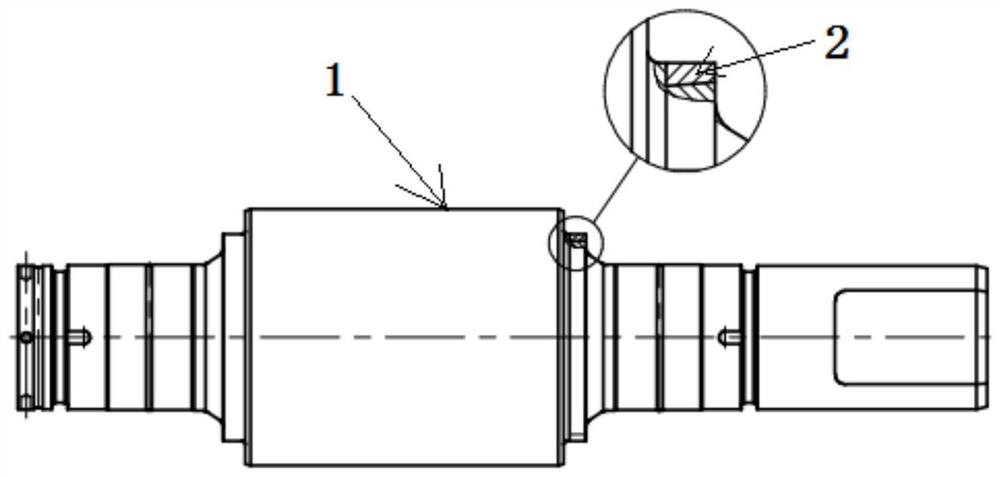

[0043] Both the roll neck of the roll 1 and the forging ring 2 have a taper, the directions of the two tapers are the same and matched, and the small end of the taper is on the inner side. Specifically, such as image 3 As shown, the small taper head is at the inner end, the inner circle of the forging ring 2 is a tapered hole, and the outer circle of the roll neck of roll 1 is also tapered, and the small taper end is at the inner end, that is, the diameter of the outer end surface of the roll neck of roll 1 is larger than this The diameter at the shaft diameter where the segment is connected to the adjacent one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com