A kind of preparation method of anti-ultraviolet polymer coated nano-alumina pigment

A nano-alumina, anti-ultraviolet technology, applied in the field of pigments, can solve the problems of not having anti-ultraviolet performance and fabrics that cannot be prepared, and achieve the effects of improving anti-ultraviolet performance, high color fastness, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

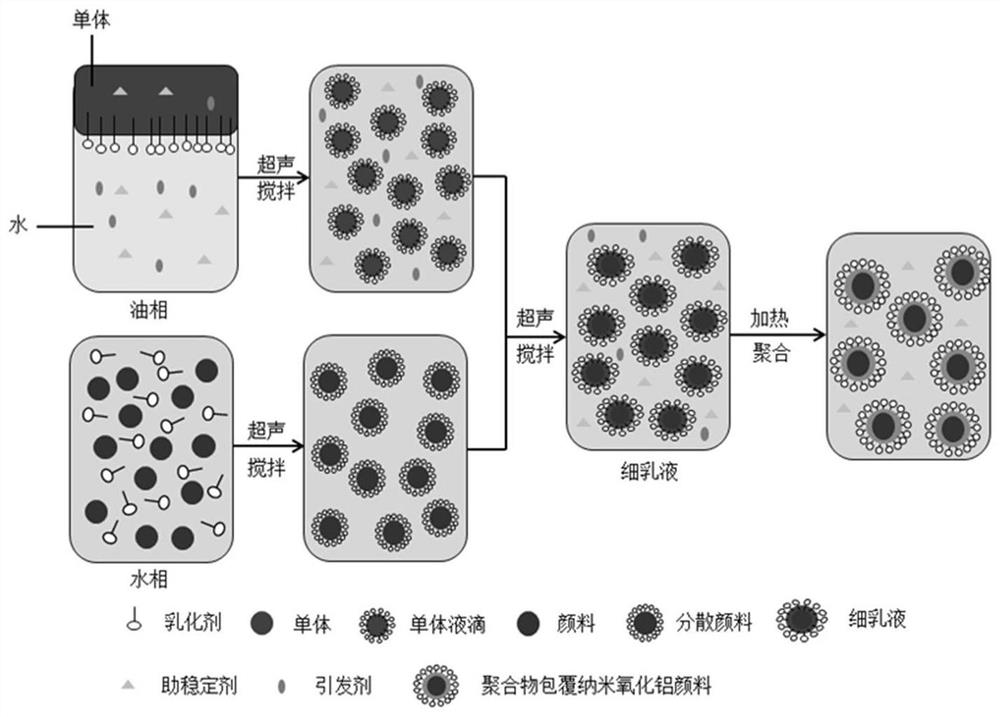

[0031] A preparation method of UV-resistant polymer-coated nano-alumina pigment, comprising the following steps:

[0032] (1) 9-12gAl(NO 3 ) 3 9H 2 Dissolve O and 1-3g urea in 200mL deionized water, stir for 1-3h, transfer the solution into a polytetrafluoroethylene-lined stainless steel reactor and heat at 140-160°C for 6-10h, collect the white precipitate at the bottom of the inner substrate , washed several times with deionized water and alcohol, and dried to obtain the product γ-AlOOH.

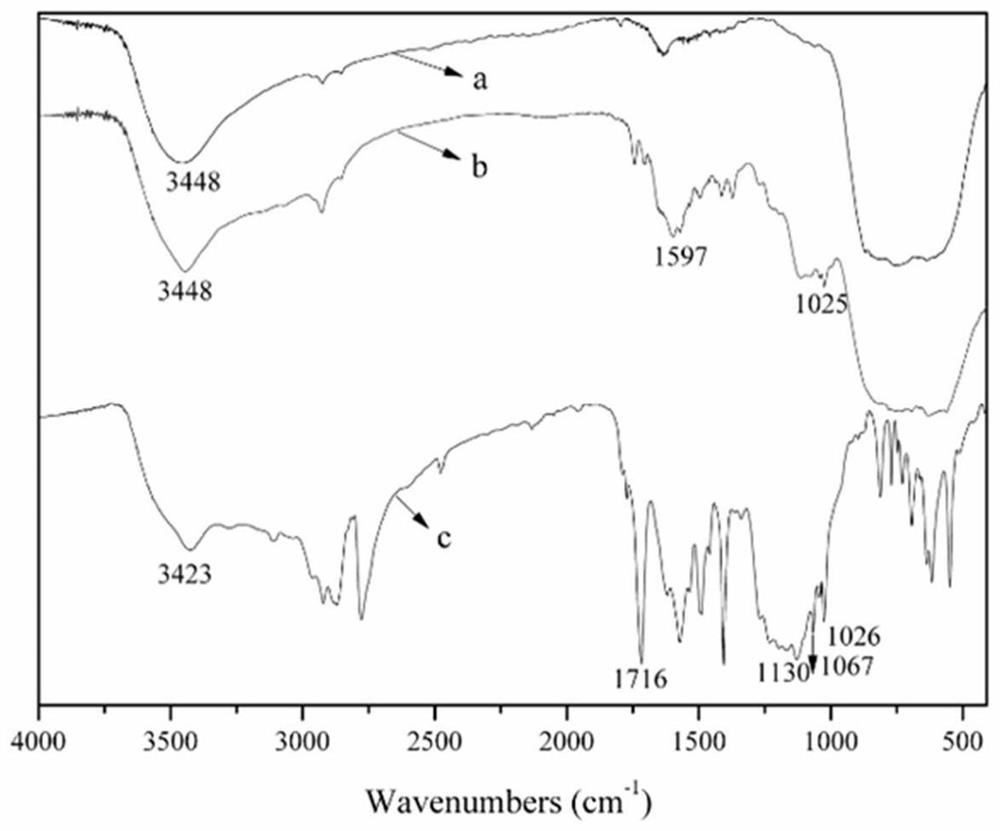

[0033] (2) Add 3-6g of γ-AlOOH and 3-6mL of 3-aminopropyltriethoxysilane to the mixed solution of deionized water (30-50mL) and ethanol (40-60mL), and after ultrasonic dispersion, place in In the agate jar, use a planetary ball mill with a speed of 200-300r / min. After high-energy ball milling for 20-30 hours, open the jar and add 10-15mL of ammonia water and 2-3g of dichloro-s-triazine-type reactive dyes, and continue ball milling for 5-10 hours. ; Finally, the product was centrifuged,...

Embodiment 1

[0039] (1) 9gAl(NO 3 ) 3 9H 2 O and 1g of urea were dissolved in 200mL of deionized water, stirred for 3 hours, then transferred to a polytetrafluoroethylene-lined stainless steel reactor and heated at 150°C for 6 hours, and the white precipitate at the bottom of the inner substrate was collected and washed with deionized water and alcohol After several times, it was dried to obtain the product γ-AlOOH.

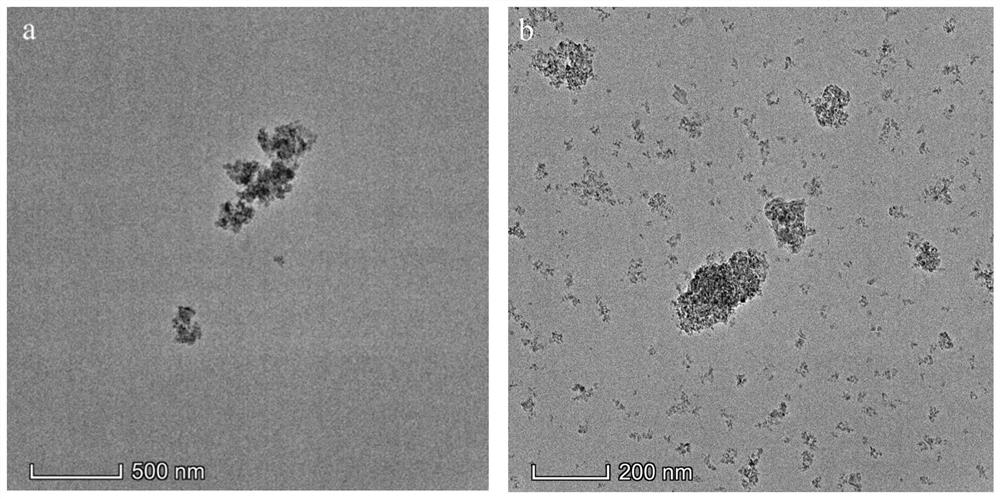

[0040] (2) Add 3g of γ-AlOOH and 3mL of 3-aminopropyltriethoxysilane to a mixed solution of deionized water (30mL) and ethanol (40mL). After ultrasonic dispersion, place it in an agate jar and use a planetary ball mill to , rotating speed 250r / min, after high-energy ball milling for 20h, open the tank and add 10mL ammonia water and 2g dichloro-s-triazine reactive dye, continue ball milling for 5h; finally centrifuge the product, wash with ethanol, and dry at 60°C to obtain Al 2 o 3 / NH 2 / dye. Wherein, the dichloro-s-triazine type reactive dye is C.I. reactive brilliant...

Embodiment 2

[0045] (1) 12g Al(NO 3 ) 3 9H 2 Dissolve O and 1g urea in 200mL deionized water, stir for 3h, transfer the solution into a polytetrafluoroethylene-lined stainless steel reactor and heat at 150°C for 10h, collect the white precipitate at the bottom of the inner substrate, wash it with deionized water and alcohol After several times, it was dried to obtain the product γ-AlOOH.

[0046] (2) Add 6g of γ-AlOOH and 6mL of 3-aminopropyltriethoxysilane to a mixed solution of deionized water (50mL) and ethanol (50mL). After ultrasonic dispersion, place it in an agate jar and use a planetary ball mill to , rotating speed 250r / min, after high-energy ball milling for 30h, open the tank and add 15mL ammonia water and 3g dichloro-s-triazine reactive dye, and continue ball milling for 10h; finally, the product is centrifuged, washed with ethanol, and dried at 60°C to obtain Al 2 o 3 / NH 2 / dye. Wherein, the dichloro-s-triazine type reactive dye is C.I. reactive brilliant blue 4.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com