Screws and screw-type mechanical components with shock-resistant, vibration-resistant and tightening force-enhanced structures

A technology for strengthening structures and mechanical components, applied in the directions of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of reduced tightening force, unfavorable expansion of mutual friction area, difficulty in improving mutual tightening force, etc. , to achieve the effect of prolonging the life, suppressing the reduction of the loosening torque (torque) value, and outstanding anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

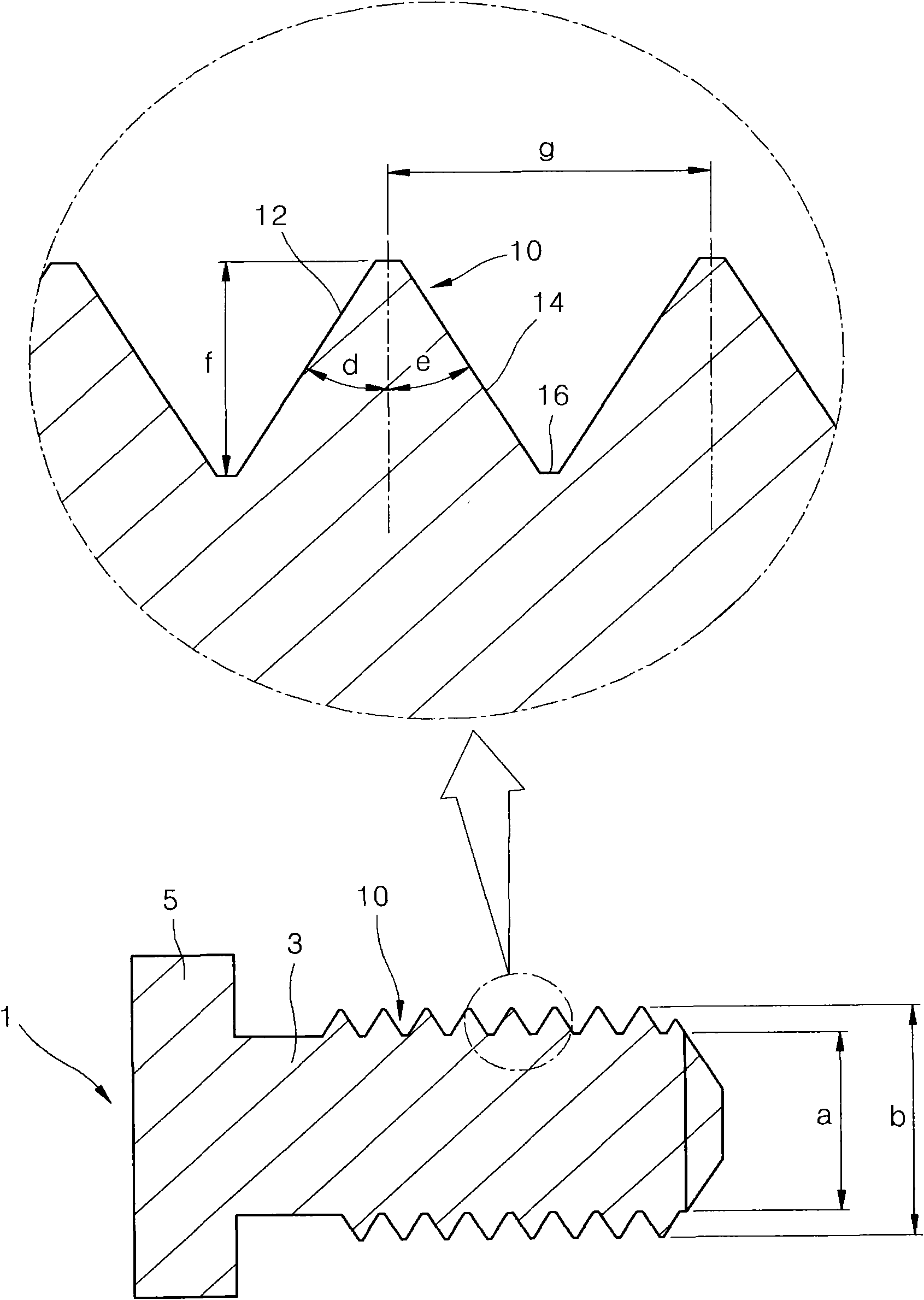

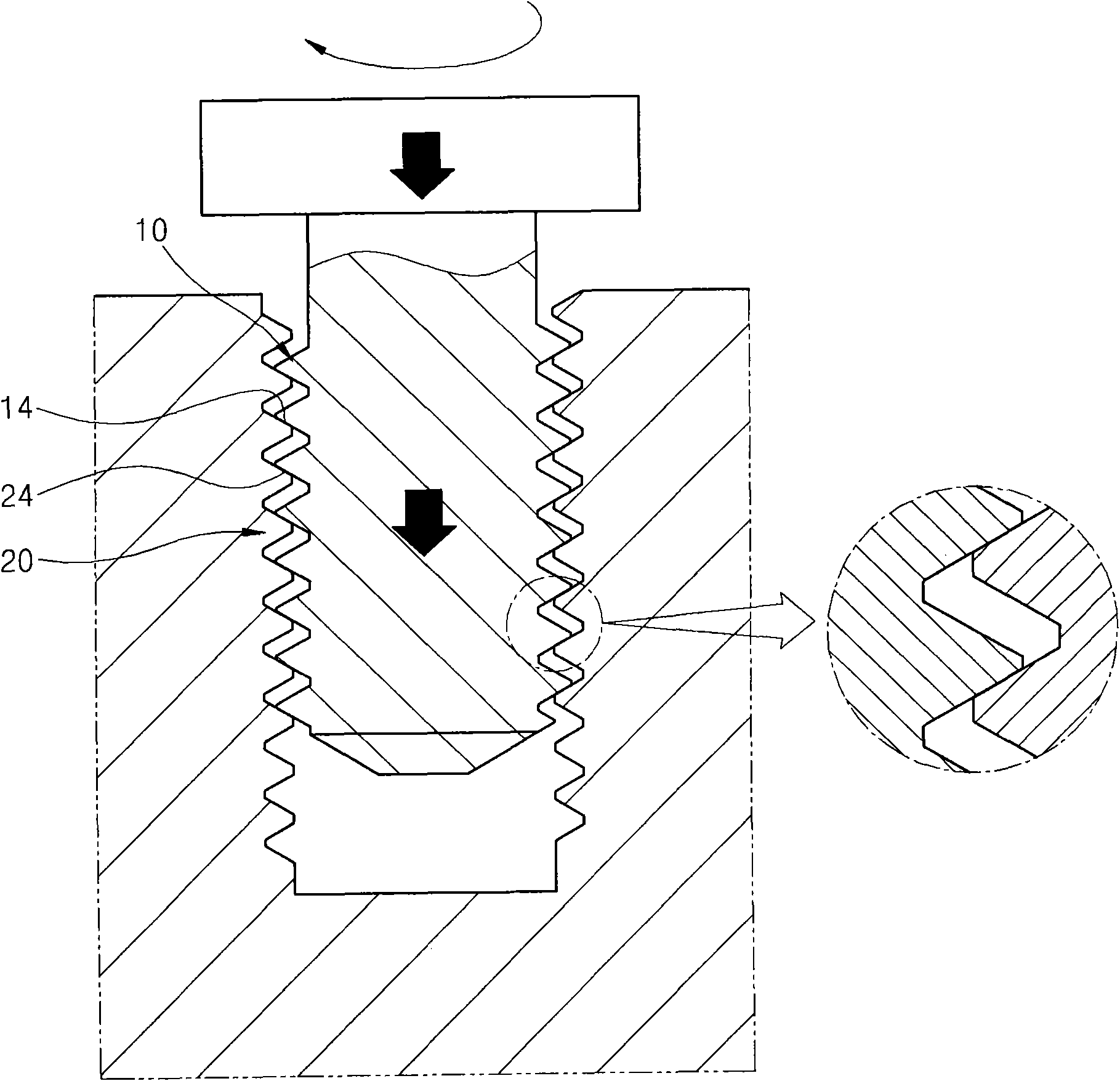

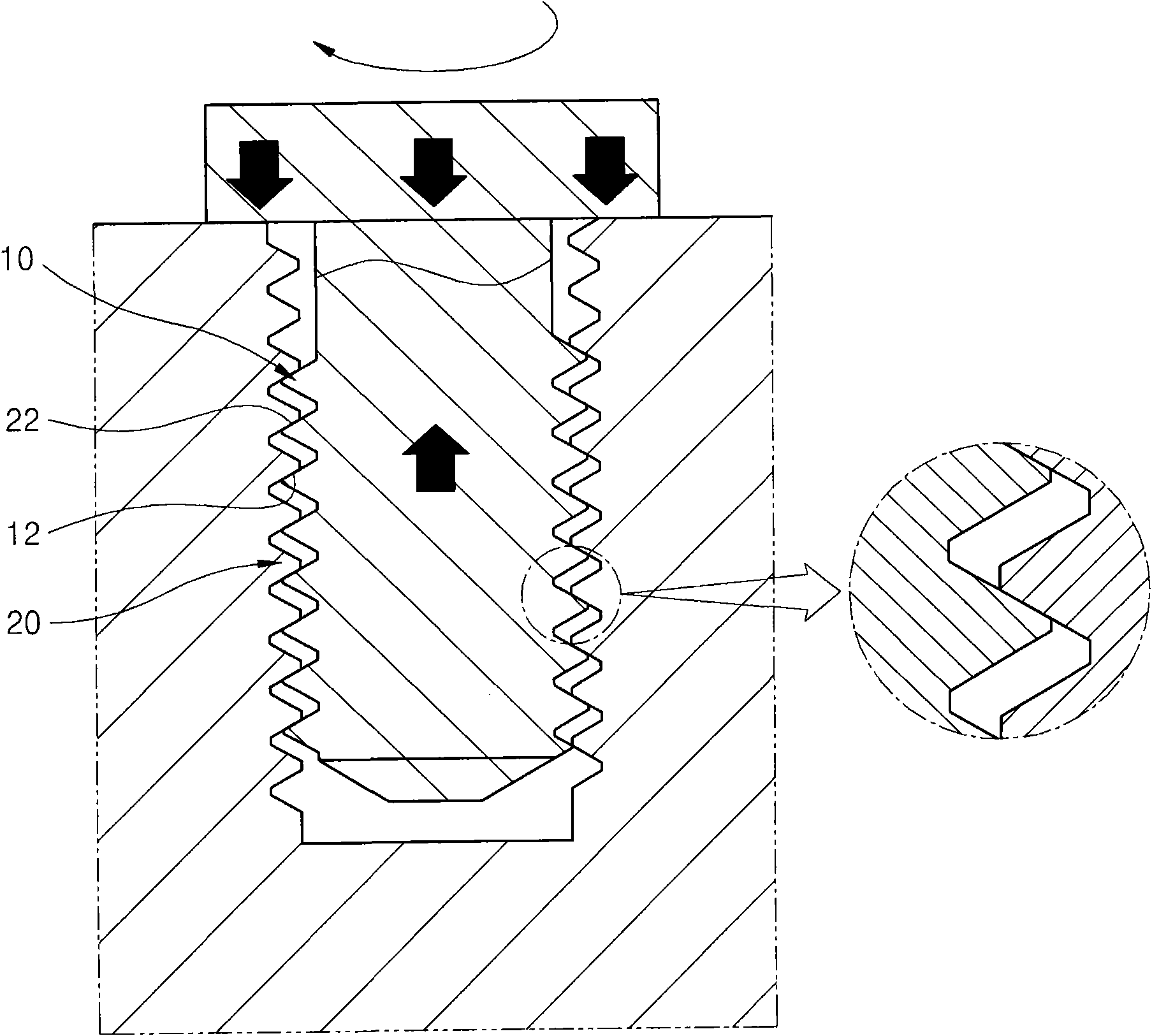

[0035] Next, preferred embodiments of the screw and the screw-type mechanical member having an impact-resistant, vibration-resistant, and fastening force-enhanced structure in the present invention will be described.

[0036] Advantages and features of the present invention, and methods for implementing the advantages and features will become more apparent with reference to the accompanying drawings and embodiments described in detail below. However, the present invention is not limited to the embodiments disclosed below, but will be implemented in a variety of forms different from each other. This embodiment is only to make the disclosure of the present invention more perfect, and to fully provide the present invention for those skilled in the art to which the present invention belongs. The scope of the invention, the present invention is defined by the scope of claims. In addition, in the process of describing the present invention, if it is judged that related known technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com