Pipeline anti-damage hose clamp with high fastening forces

An anti-damage and fastening force technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as decreased tightening force of hose clamps, scratched or damaged pipes, shortened service life, etc. , to achieve scientific and reasonable structural design, avoid pipeline damage and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

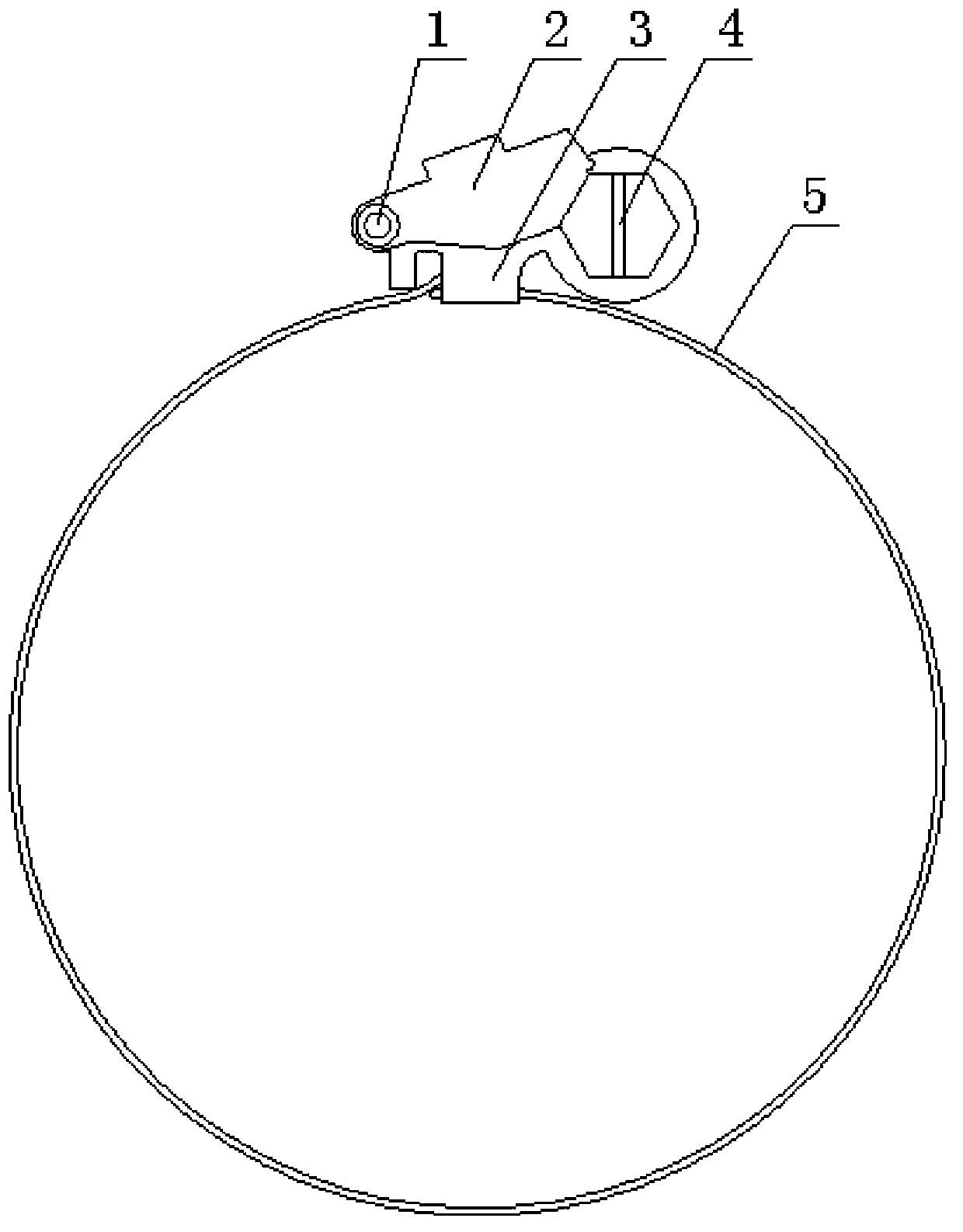

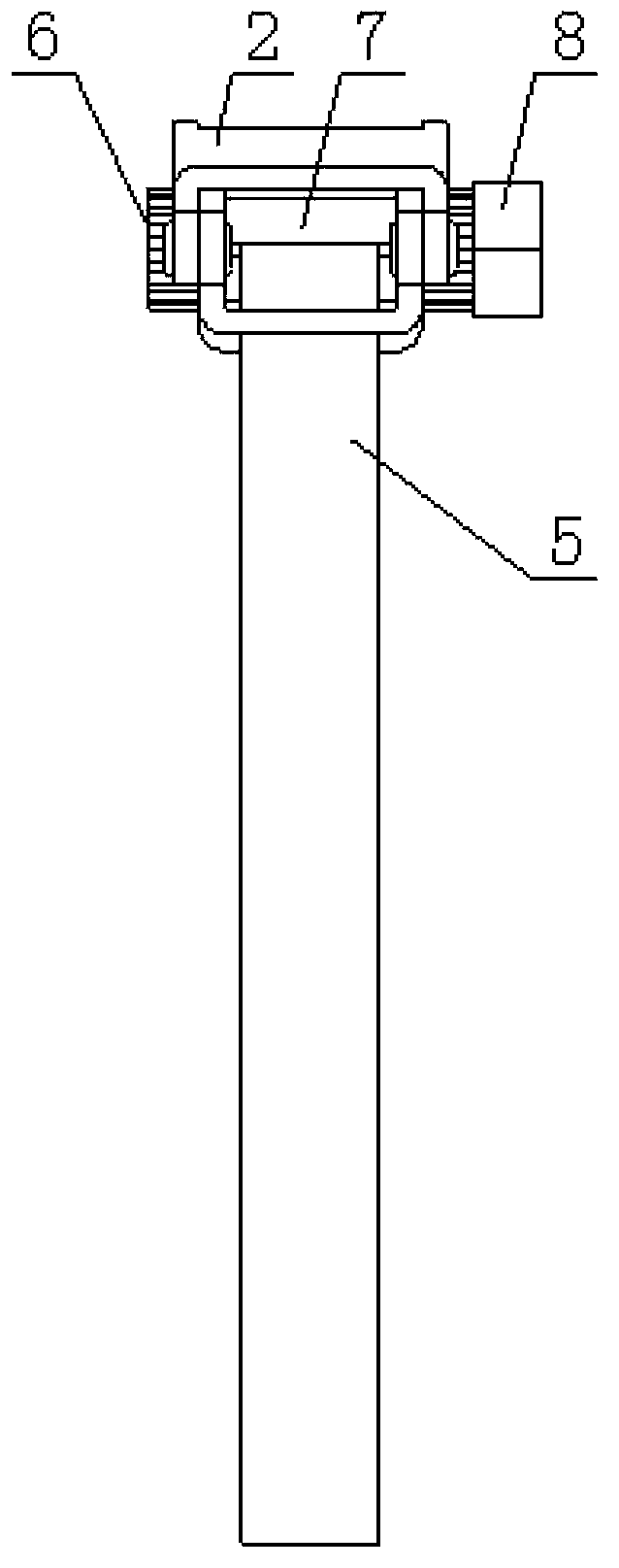

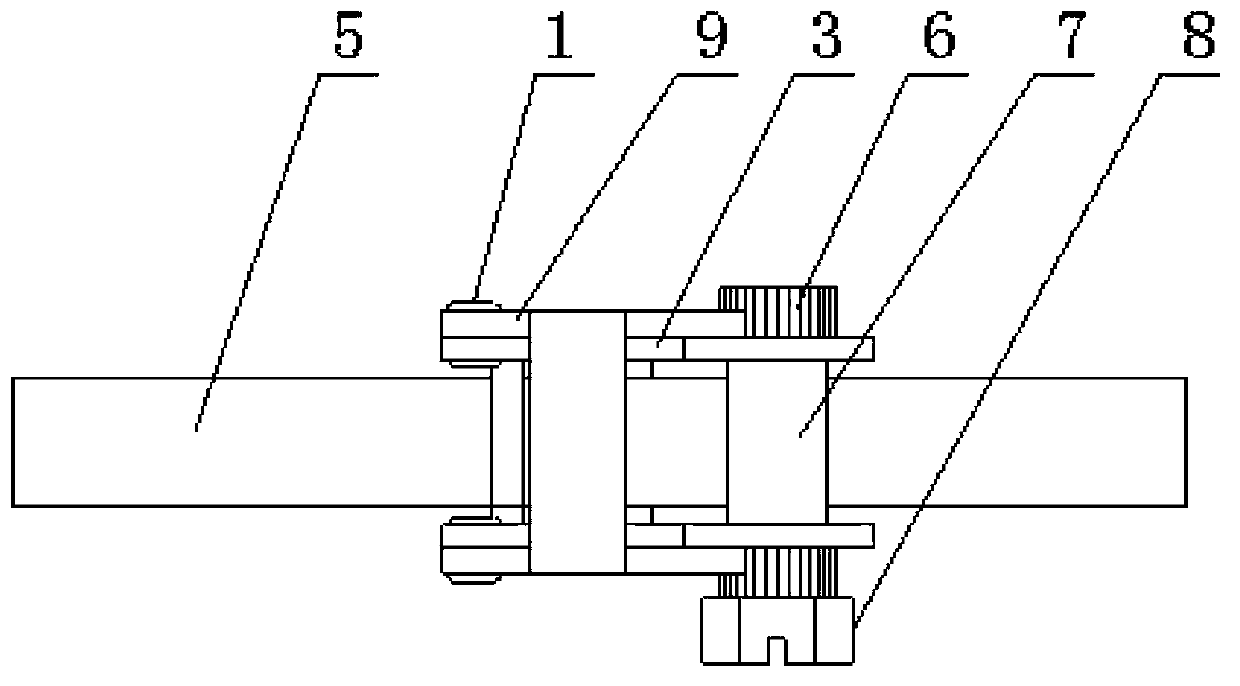

[0027] An anti-damage throat clamp for pipelines with strong fastening force, including a clamp 5, and its innovation is that it also includes a connecting bracket 3, a backstop baffle group 2, a rivet 1, and a tightening rod 4, and the clamp is fixed on the clamp. The connecting bracket is firmly installed at the end, the head of the connecting bracket is shaped on a tightening rod mounting hole 12, and the afterbody of the connecting bracket is shaped on a rivet mounting hole 10, and the screwing rod mounting hole of the connecting bracket is installed. Tighten the rod, on the rod body of the tightened rod, the free end of the strap is axially formed with a slit 13, and the rod body 7 of the tightened rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com