Processing device and process for ultraviolet-assisted chemical mechanical polishing of diamond wafer

A technology of chemical machinery and processing equipment, applied in metal processing equipment, grinding equipment, grinding/polishing equipment, etc., can solve processing damage, chemical action cannot meet the needs of diamond processing, and surface roughness is difficult to reach sub-nanometer level and other problems, to achieve the effect of high-quality and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

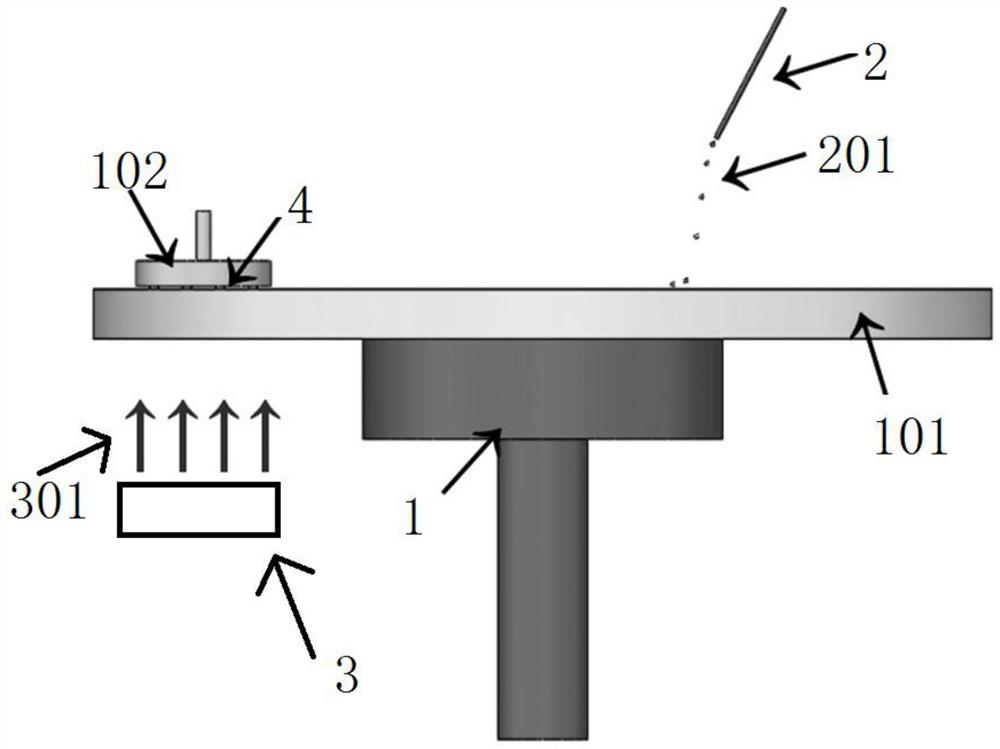

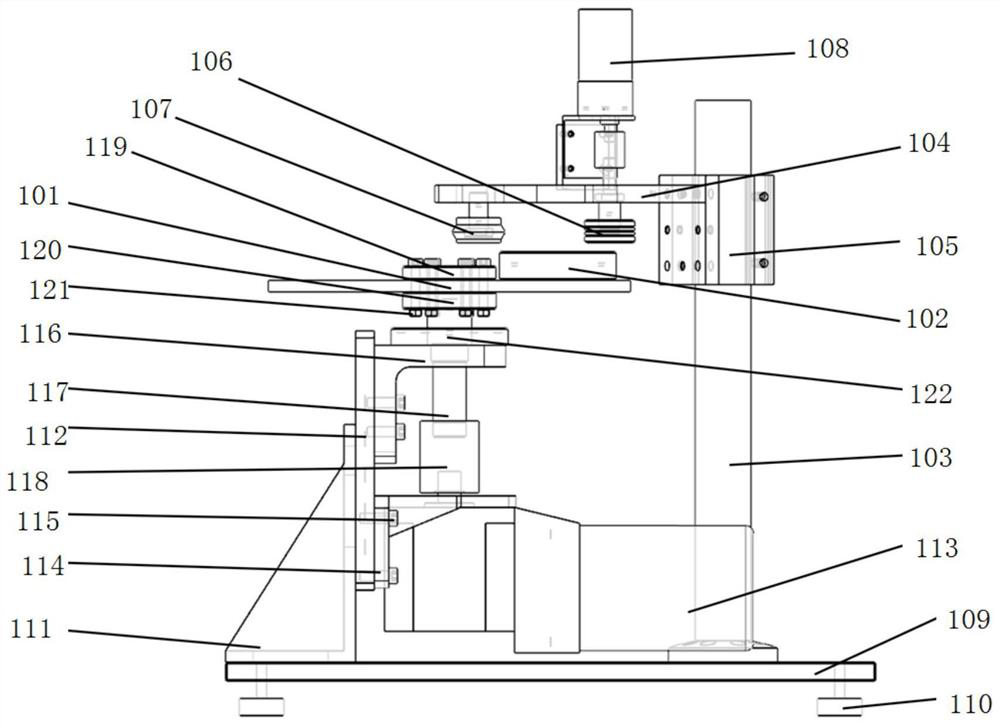

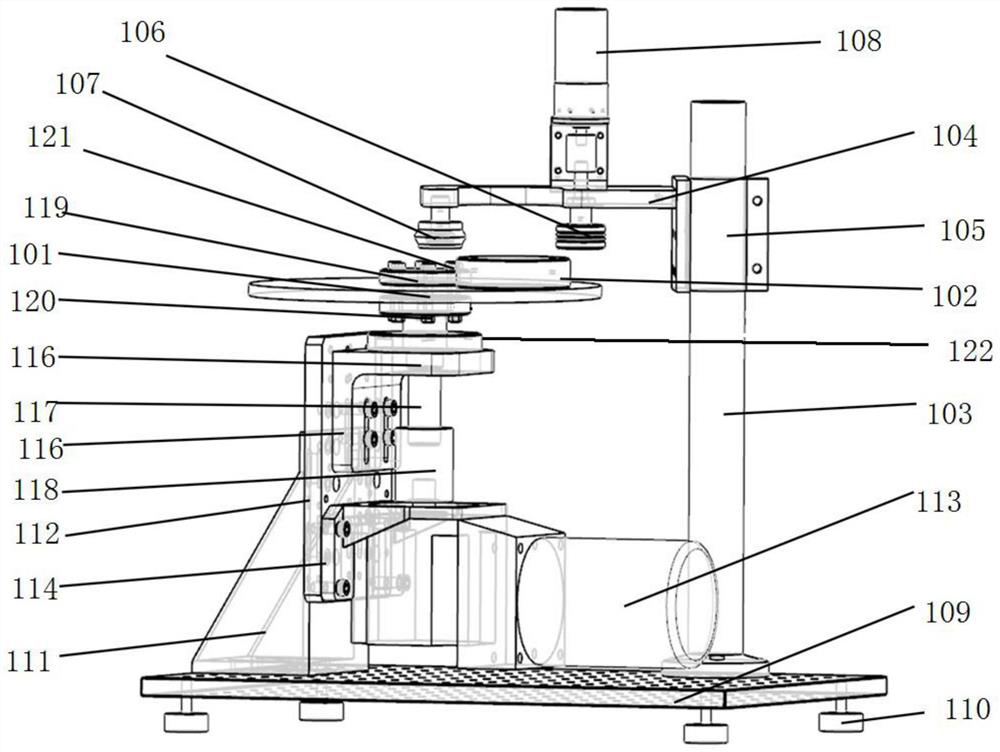

[0046] Such as Figure 1~3 As shown, a processing device for UV-assisted chemical mechanical polishing of a diamond wafer includes a polishing device 1, a polishing liquid supply device 2 and an ultraviolet light irradiation device 3;

[0047] The polishing device 1 includes a horizontally arranged polishing disc 101 and a first driving mechanism, the first driving mechanism is located below the polishing disc and is connected to the polishing disc 101 for driving the polishing disc 101 around it. The axis rotates; the polishing disc 101 is made of a material that allows ultraviolet light to pass through, and the polishing disc 101 is used to polish the single crystal diamond wafer 4 arranged on the upper surface of the polishing disc 101; the polishing liquid supply device 2 is located above the polishing disc 101, and is used to supply polishing liquid 201 to the polishing disc 101; the ultraviolet light irradiation device 3 is located below the polishing disc, and the ultra...

Embodiment 2

[0064] Such as Figure 1~3 As shown, the present invention also discloses a single crystal diamond processing technology, which adopts a processing device for UV-assisted chemical mechanical polishing of a diamond wafer described in Example 1, comprising:

[0065] The single crystal diamond wafer 4 is fixed on the counterweight 102 by paraffin, and the polishing pressure is controlled by adjusting the weight of the counterweight 102. The counterweight 102 is driven by the second driving mechanism 108, and the driving guide wheel 106 and Under the auxiliary of passive guide wheel 107, single crystal diamond wafer 4 rotates together with counterweight 102;

[0066] Under the effect of the first driving mechanism, the polishing disc 101 rotates with the main shaft 117, and the single crystal diamond wafer 4 bonded on the counterweight 102 is placed on the JGS1 quartz glass polishing disc 101, and the JGS1 quartz glass polishing disc 101 is connected with the single The surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com