Quartz hemispherical resonator in-situ shape detection ion beam polishing atom manufacturing equipment and method

A technology of hemispherical resonators and ion beams, applied in electron beam welding equipment, manufacturing tools, measuring devices, etc., can solve the problems of large stress removal, small wall thickness of resonators, damage, etc., and achieve high-quality and efficient precision machining and processing The effect of stable environment and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

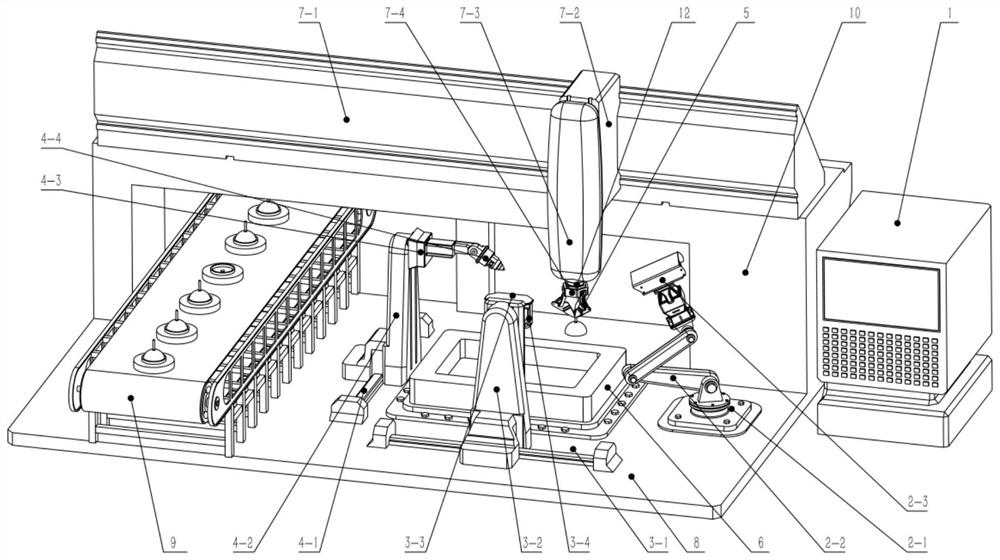

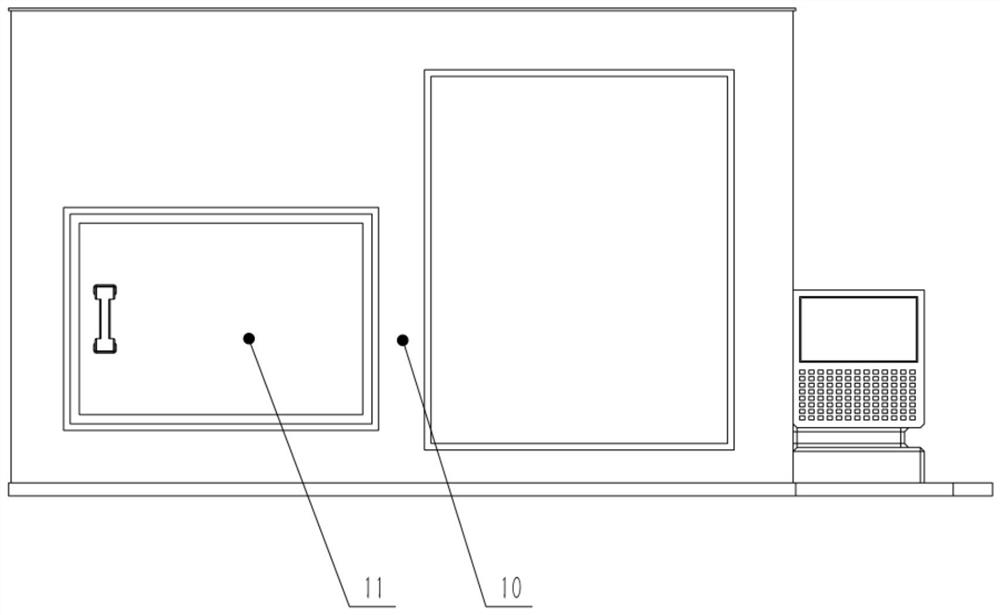

[0036] After the traditional quartz hemispherical resonator is ground and polished, the shape and position accuracy and performance are directly tested, and those that are unqualified are directly scrapped, and the scrap rate is high. The current ultra-precision grinding and polishing of quartz hemispherical resonators is difficult to reduce the coaxiality to 300nm, and the general coaxiality is >1.5μm. In order to solve the problems existing in the existing technology, such as Figure 1-2 As shown, the present invention provides a quartz hemispherical resonator in-situ shape detection ion beam polishing atom manufacturing equipment, including: a numerical control system 1, a micro-scale mobile platform device installed on a machine tool, and a prototype installed on a machine tool base 8 A configuration detection device, a frequency difference detection device, an ion beam processing device, a transmission device 9 , a fixture 5 , a workbench 6 and a vacuum chamber 10 . The ...

Embodiment 2

[0045] On the basis of Embodiment 1, the present invention also provides a method for using the quartz hemispherical resonator to detect ion beam polishing atom manufacturing equipment and process the quartz hemispherical resonator in situ, including the following steps:

[0046] Step 1. After the transmission device 9 transports the quartz hemispherical resonator to be finished to the inside of the machine tool, the micro-scale mobile platform device moves to the clamping station at the transmission device 9, and clamps the quartz hemispherical resonator through the clamp 5;

[0047] Step 2: The clamp 5 clamps the quartz hemispherical resonator and moves to the top of the workbench 6 within the detection range of the in-situ shape detection device, and the in-situ shape detection device starts to work to detect the outline size of the quartz hemispherical resonator, as well as the roundness, The shape and position accuracy such as the coaxiality of the spherical convex center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com