Automobile side frame inner panel part die

A technology for side panel inner panel and parts is applied in the field of automobile side panel inner panel parts mold, which can solve the problems of low production efficiency, long manufacturing cycle and high manufacturing cost, saving manpower and material resources, low production cost and convenience. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

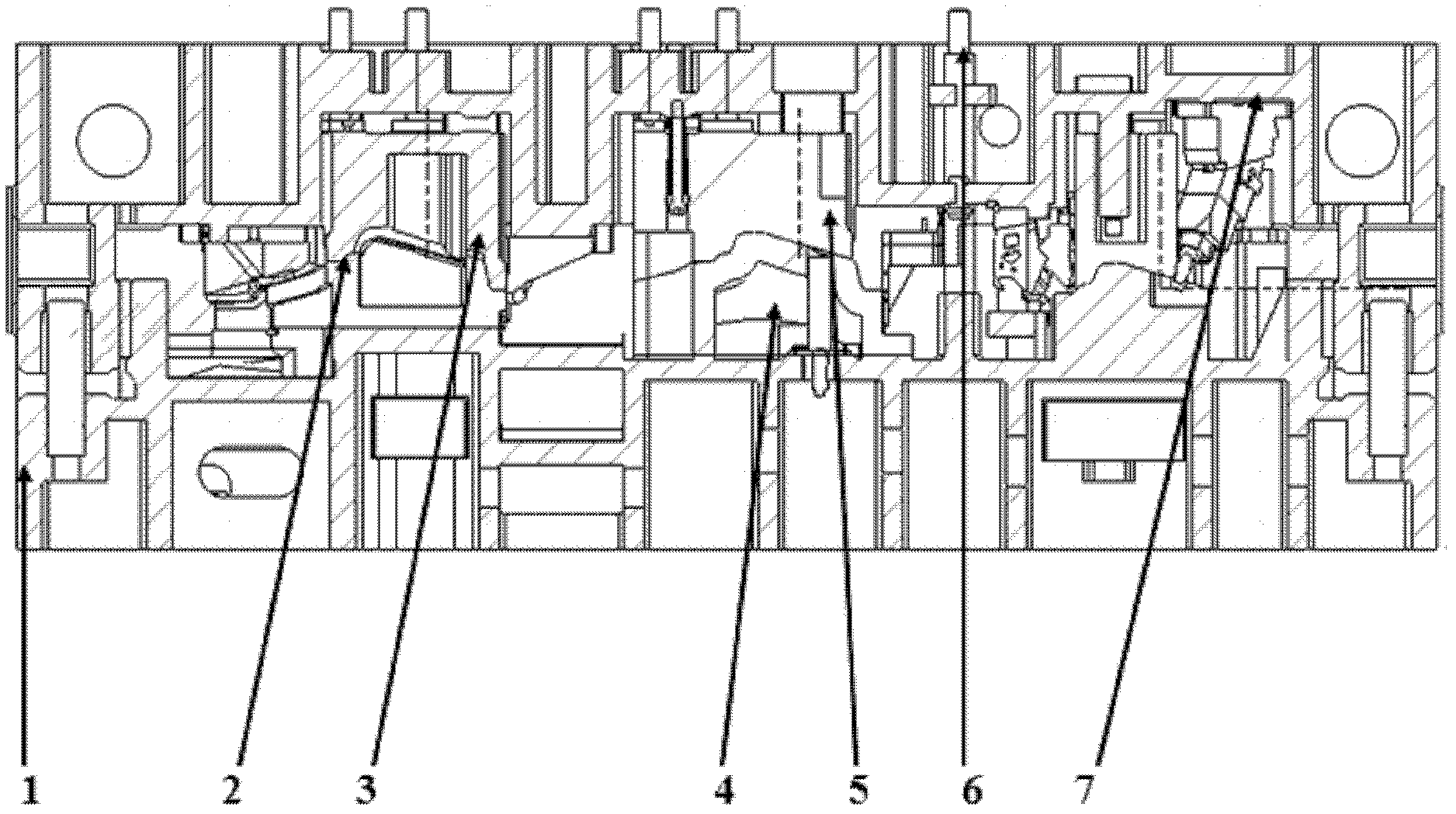

[0015] like figure 1 As shown, a mold for an automobile side wall inner panel part includes an upper mold assembly and a lower mold assembly.

[0016] The upper mold assembly includes an upper mold base 7 and an upper mold core arranged on the upper mold base 7, an upper mold insert, an upper mold presser and eight upper ejector pins 6, and the upper mold core is positioned under the upper mold base 7, The upper mold core is provided with a trimming punching die 3 and a flanging shaping die 5, the trimming punching die 3 is located on the left side of the flanging shaping die 5, and the upper ejector pin 6 passes through the upper die base 7 to reach Connected to the top of the upper core.

[0017] The lower mold assembly includes a lower mold base 1 and a lower mold core and an ejector arranged on the lower mold base 1. The lower mold core is located above the lower mold base 1. Side punching punch 2, flanging shaping punch 4.

[0018] The working process of the mold is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com