Woodenware water paint and preparation method thereof

A water paint and woodware technology, applied in the field of wood water paint and its preparation, can solve the problems of insufficient hiding power and easy cracking, and achieve the effects of good sealing, increased hardness, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

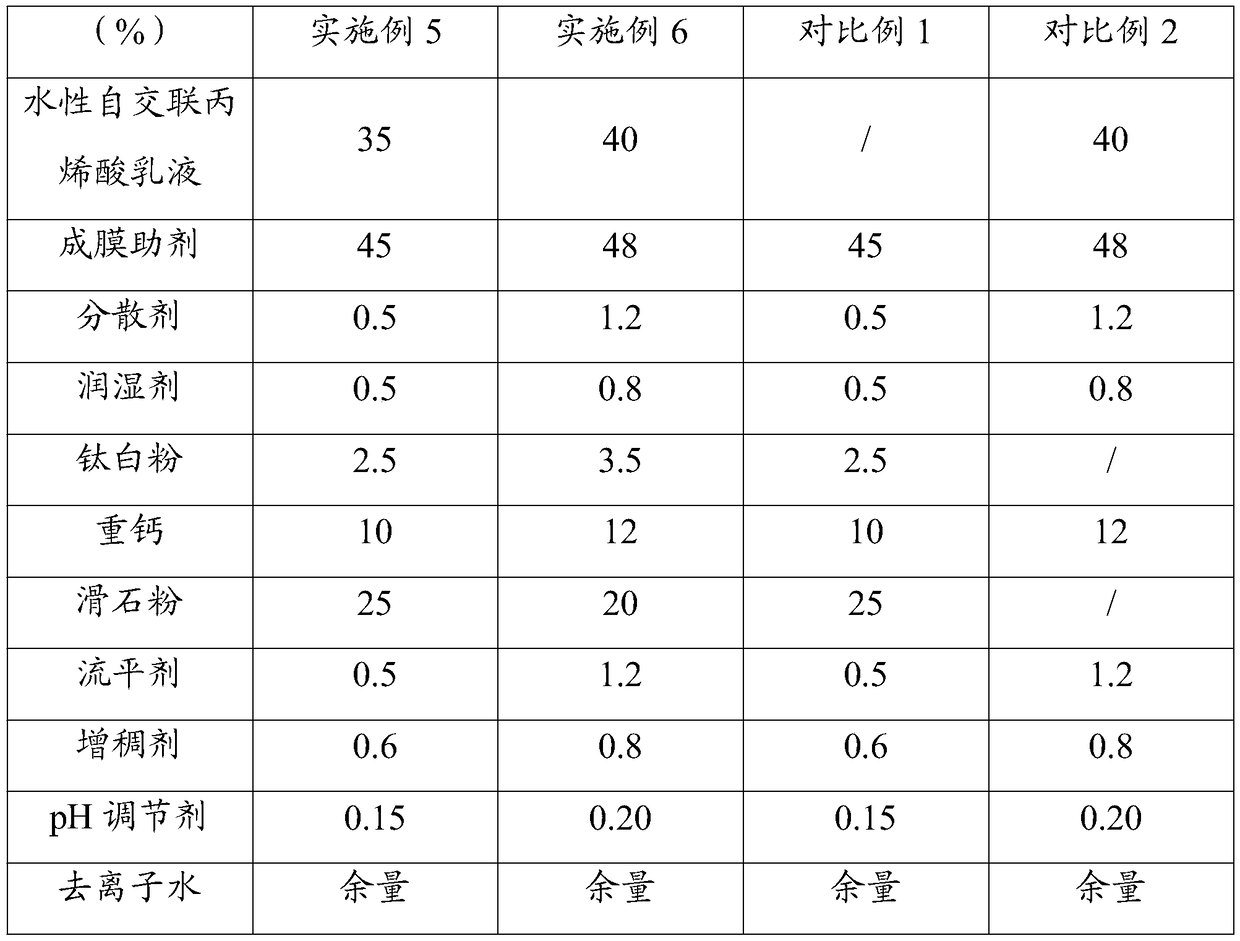

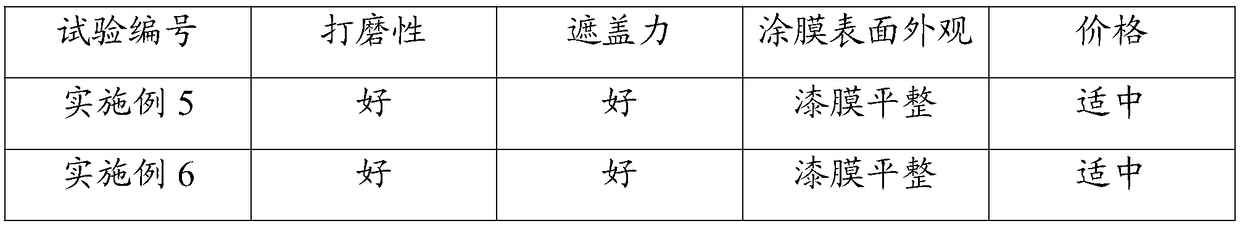

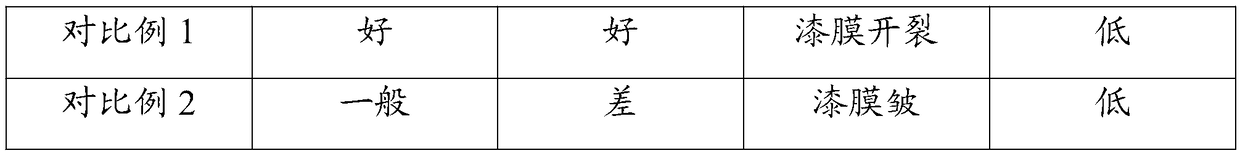

Examples

preparation example Construction

[0045] The invention also discloses a preparation method of wood water paint, specifically comprising the following steps:

[0046] (1) Preparation of pre-cured paddle: weigh according to the formulation amount of the high-solid wood white primer described in any one of claims 1 to 6, first add water-based self-crosslinking acrylic acid emulsion to the container and start stirring, then Slowly add film-forming aids into the container under low-speed stirring, and start to disperse them at high speed after the addition is completed, and the dispersion time is 5-10 minutes;

[0047] (2) Add deionized water, pH adjuster and dispersant sequentially under low-speed stirring state. After the addition is completed, start to disperse them at a high speed. The dispersion time is 5-10 minutes. 800-mesh heavy calcium stirring at high speed, the stirring time is 15-20 minutes, and the mixed material paddle is obtained;

[0048] (3) Add the above-mentioned mixed slurry components into a g...

Embodiment 1

[0055] A kind of water-based paint for wood, which is prepared by the following raw material ratio in parts by mass: 32% of water-based self-crosslinking acrylic emulsion, 41% of film-forming aid, 45% of pigment, 0.5% of dispersant, and 0.3% of wetting agent , Leveling agent 0.3-1.5%, thickener 0.5%, pH regulator 0.15%, titanium dioxide 2.5%, 800 mesh heavy calcium 6%, deionized water balance;

[0056] Among them, the water-based self-crosslinking acrylic emulsion is self-crosslinking acrylic acid with a solid content of 45%, the leveling agent is an associative polyurethane thickening and leveling agent, and the thickener is a polyurethane thickener and dipropylene glycol methyl ether in a mass ratio of 2:1 uniform mixture, the dispersant is a wetting and dispersing agent, the wetting agent is a fluorosurfactant, and the film-forming aid is dipropylene glycol methyl ether.

Embodiment 2

[0058] A kind of water-based paint for wood, which is prepared by the following raw material ratio in parts by mass: 35% of water-based self-crosslinking acrylic emulsion, 45% of film-forming aid, 50% of pigment, 1.0% of dispersant, and 0.6% of wetting agent , leveling agent 0.8%, thickener 0.6%, pH regulator 0.1%, titanium dioxide 3.0%, 800 mesh heavy calcium 10%, deionized water balance;

[0059] Among them, the water-based self-crosslinking acrylic emulsion is self-crosslinking acrylic acid with a solid content of 45%, the leveling agent is an associative polyurethane thickening and leveling agent, and the thickener is a polyurethane thickener and dipropylene glycol methyl ether in a mass ratio of 2:1 uniform mixture, the dispersant is a wetting and dispersing agent, the wetting agent is a fluorosurfactant, and the film-forming aid is alcohol fat twelve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com