Method and device for preparing silicon-based three-dimensional (3D) microstructure

A three-dimensional structure, silicon-based technology, used in the manufacture of microstructure devices, microstructure devices, microstructure technology, etc. Effect of surface quality, good aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

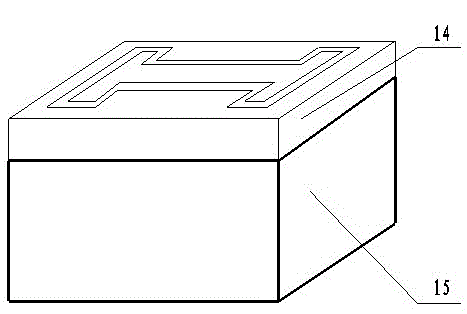

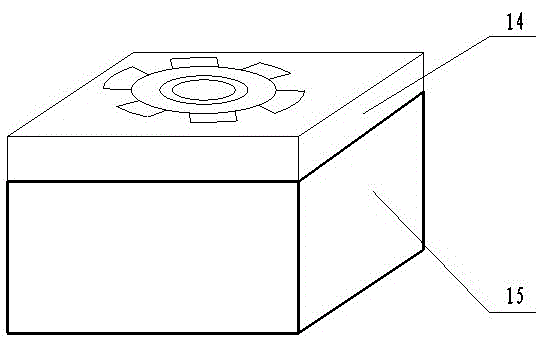

[0029] This example is in figure 2 Make the I-shaped micro-three-dimensional structure as shown on the pattern mask 14 on the silicon chip 15 shown, or as image 3 As shown, the tooth-shaped micro three-dimensional structure as shown on the pattern mask 14 is fabricated on the silicon wafer 15 .

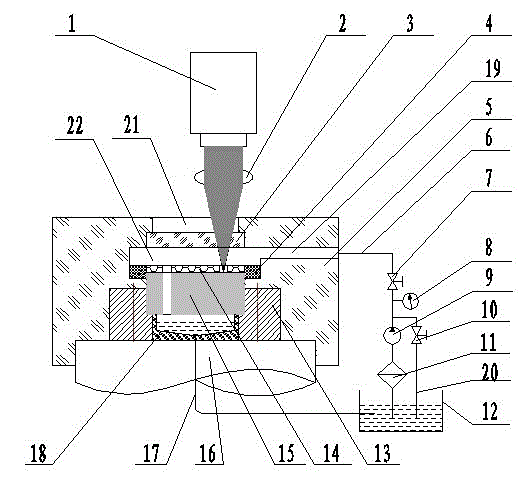

[0030] Silicon wafers are in such figure 1 The setup shown is for the fabrication of micro-3D structures. The device is mainly composed of a laser 1, a focusing lens 2, a graphic mask 14, a work box 5, a workbench 16, a liquid collection tank 18 and a chemical solution circulation filtration system. Working box 5 upper end is provided with window 21, and the inboard of window 21 is provided with optical safety mirror 3, and window 21 below is a cavity 22, and one side of cavity 22 is provided with the liquid inlet cavity 19 that vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com