A numerical control machining method for super-large complex thin-walled parts of titanium alloy

A technology of thin-walled parts and processing methods, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as surface springback, increased processing difficulty, and complex overall structure of parts, so as to control the deformation of parts , Great reference, the effect of high-quality and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

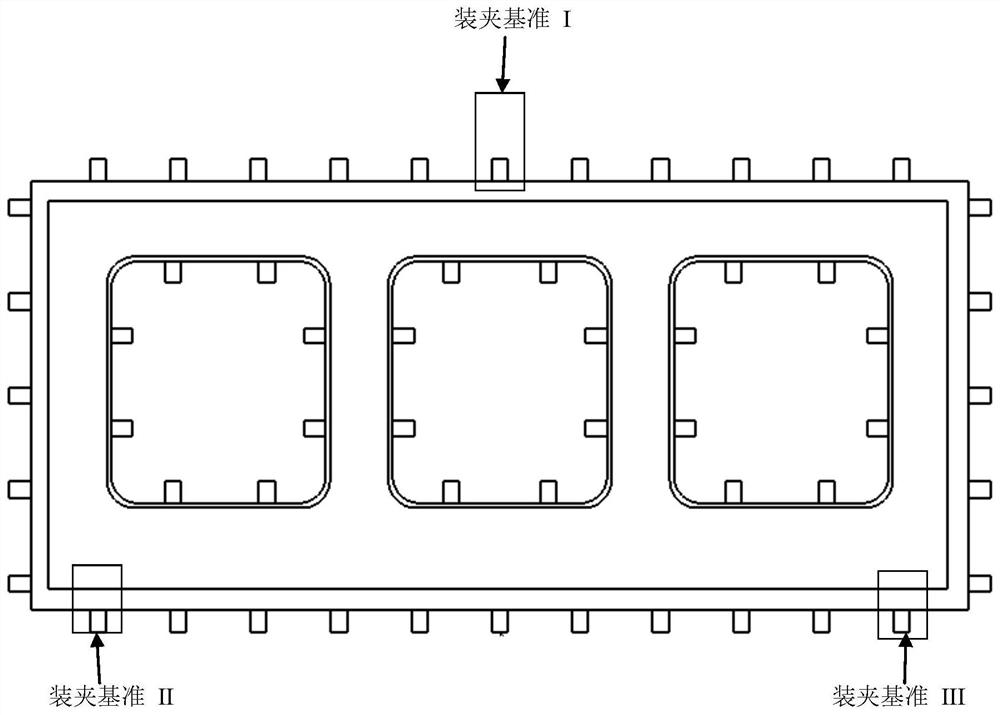

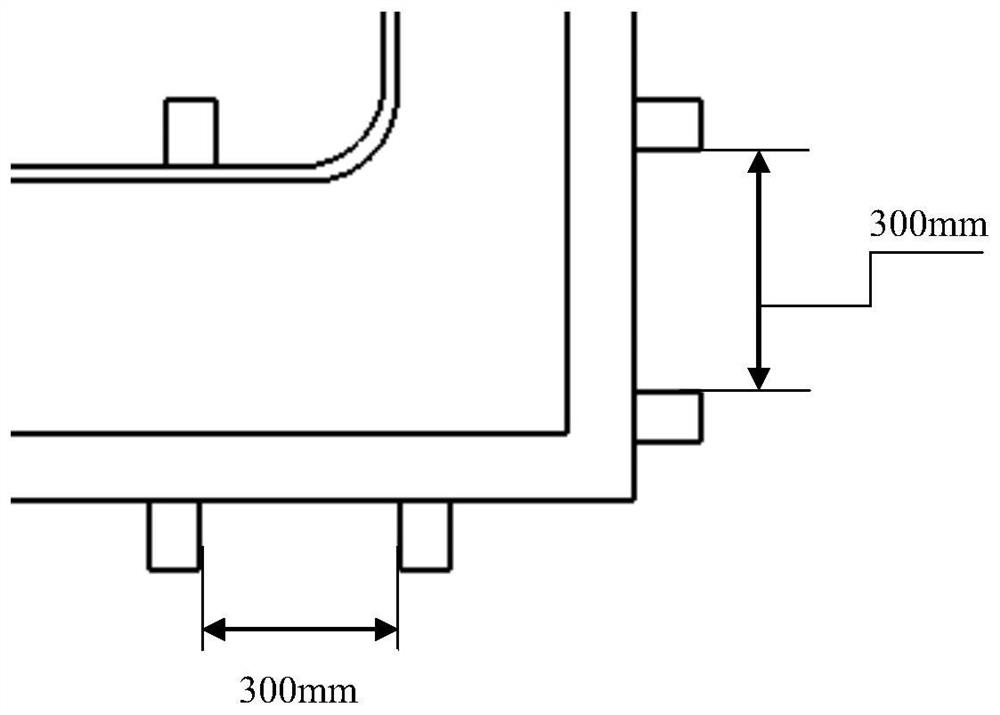

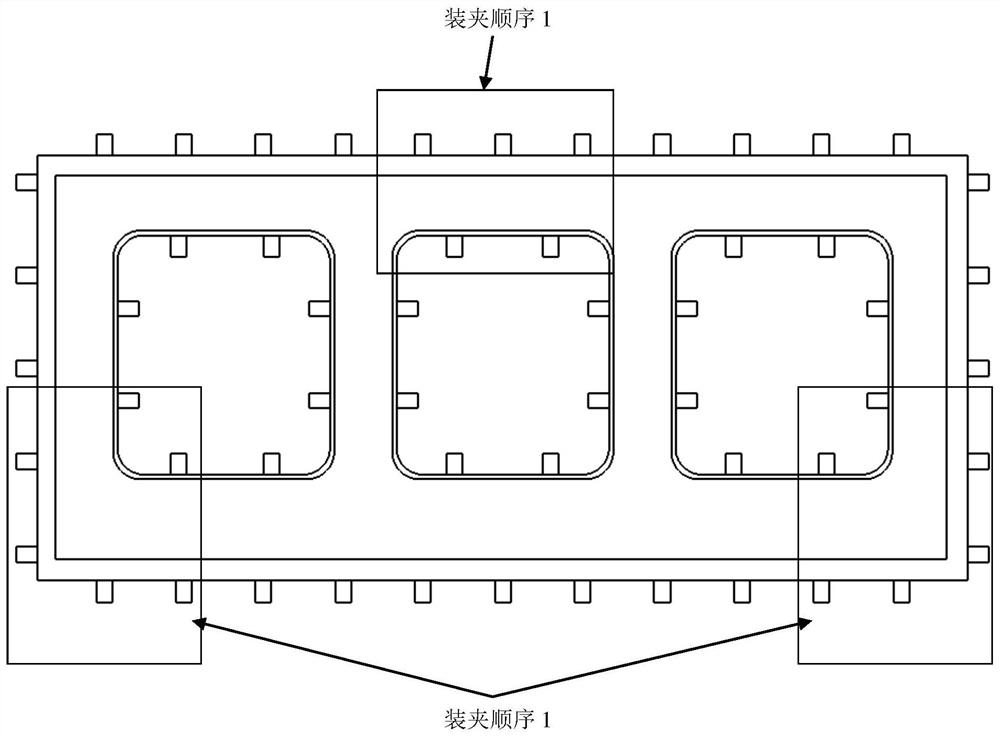

[0074] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0075] It should be understood that the appended drawings are not to scale, presenting a suitably simplified representation of various features illustrative of the basic principles of the invention. The specific design features of the invention disclosed herein, including, for example, specific dimensions, orientations, locations and shapes will be determined in part by the particular intended application and use environment.

[0076] In the accompanying figures, the same or equivalent parts (elements) are designated with the same reference numerals.

[0077] In the description of the present invention, it should be noted that the terms "center", "longitudinal", "transverse", "upper", "lower", "front", "rear", "left", "right", " The orientations or positional relationships indicated by "vertical", "horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com