Method for machining AF1410 steel part before quenching

A pre-processing and parts technology, which is applied in the field of AF1410 steel parts before quenching, can solve the problems of low material thermal conductivity, high temperature in the processing area, and low processing efficiency, so as to achieve high-quality and efficient processing, improve processing efficiency, and reduce cutting temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] see Figure 1 to Figure 4 , in the present embodiment, the processing method of AF1410 steel parts before quenching comprises the following steps:

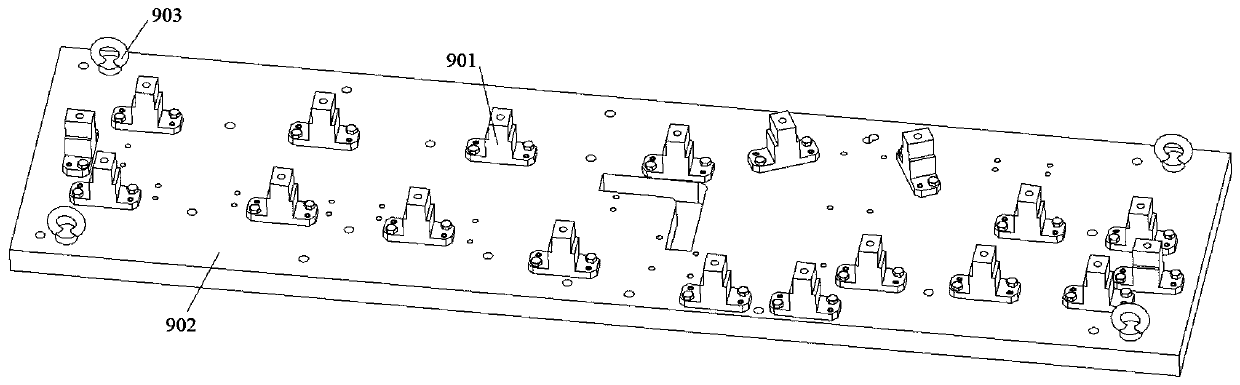

[0026] Step 1, manufacture the tooling of milling parts, such as image 3 shown. A plurality of process lugs 1 and tooling 9 are connected by bolts 10 to position the pressing parts, such as Figure 4 shown. In an optional embodiment, if the part has a double-sided structure, two sets of tooling need to be designed for two-sided processing.

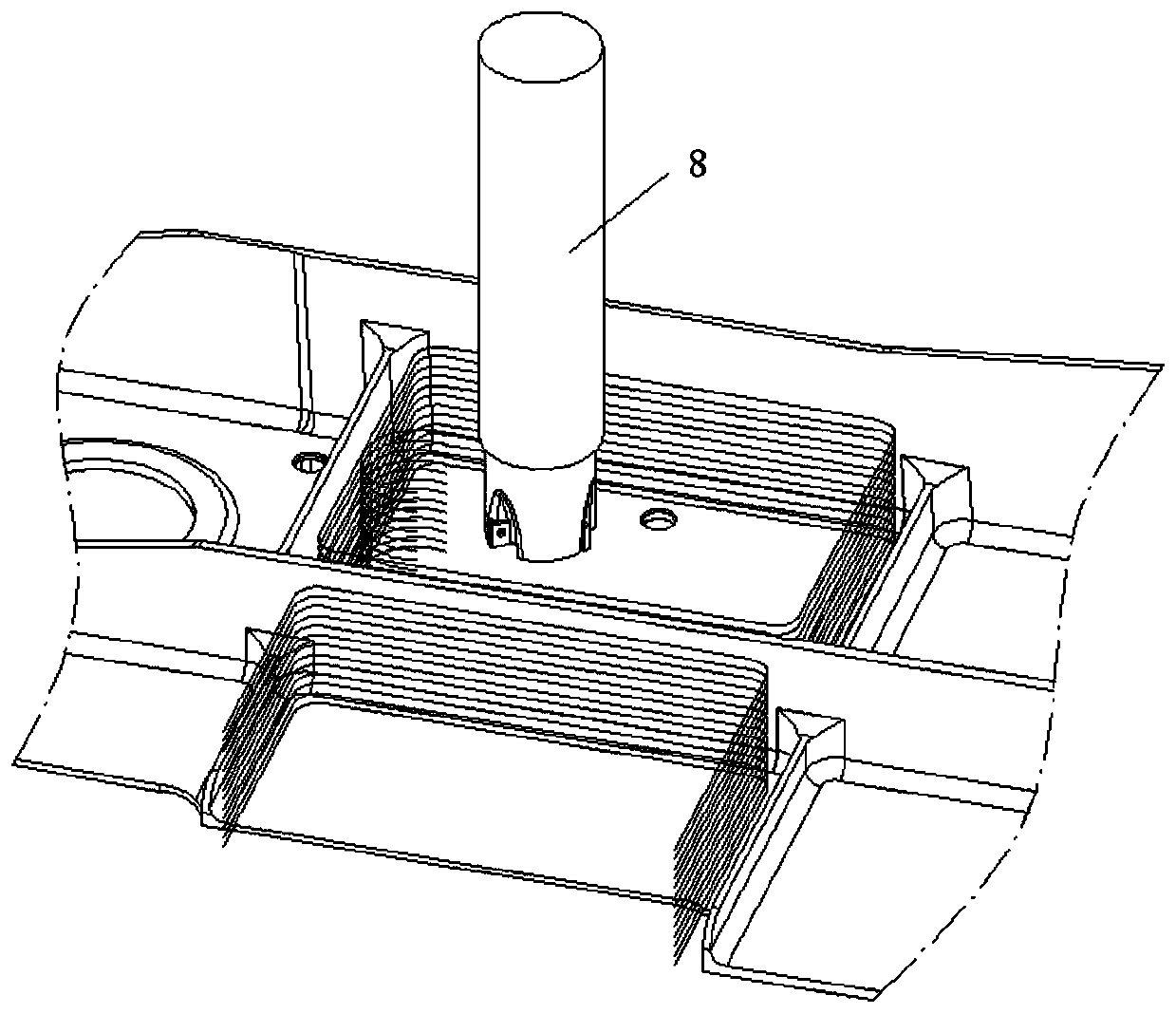

[0027] Step 2. Using a five-axis machine tool with a high-pressure cooling system, place the parts and tooling 9 in step 1) on the machine tool. Machine tools with a high-pressure cooling system ensure sufficient coolant during milling and effectively reduce the temperature in the cutting area.

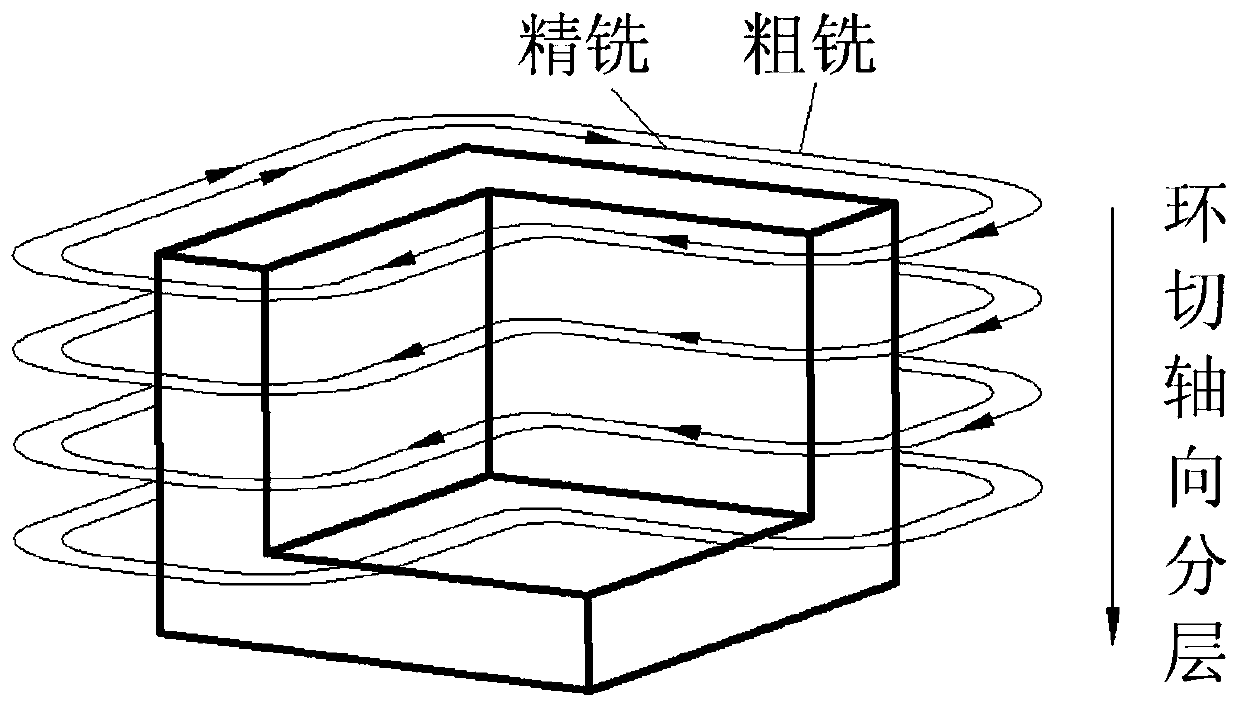

[0028] Step 3. Use the indexable milling cutter 8 to remove the part allowance evenly at equal intervals from top to bottom in the shallow cutting-fast feed cutting method. Specifically, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com