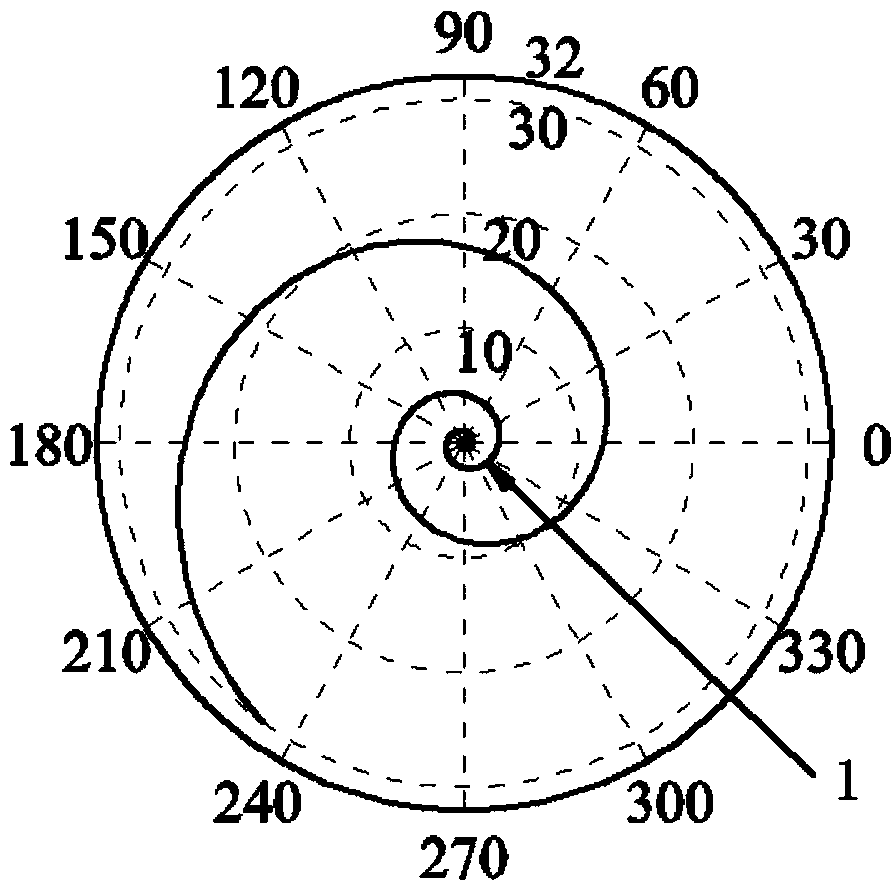

Equiangular spiral line partition variable parameter control precision machining method

A technology of equiangular spiral and precision machining, which is applied in the direction of digital control, metal processing, metal processing equipment, etc., can solve the problems of low processing efficiency and low processing quality of equiangular spiral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

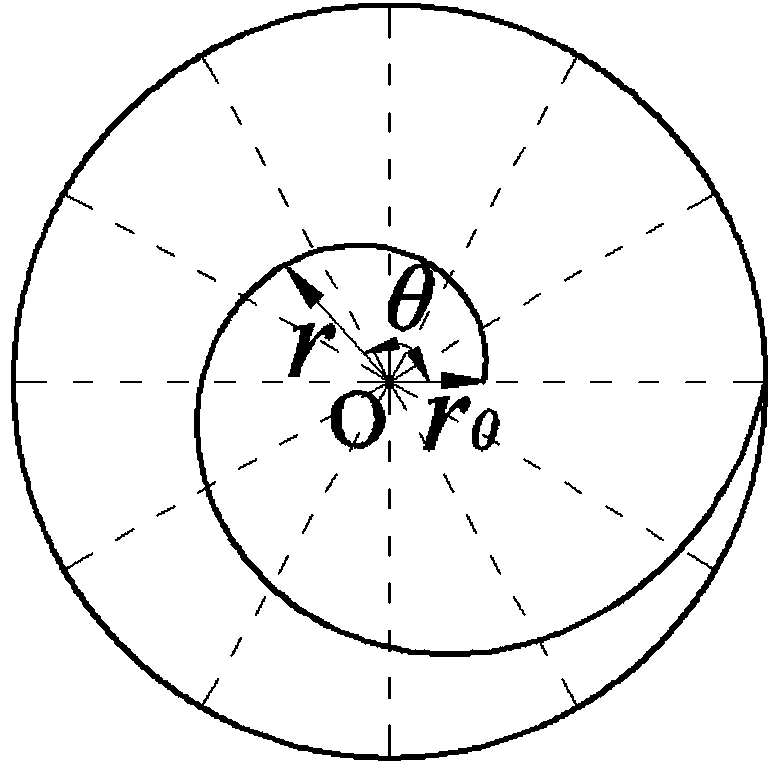

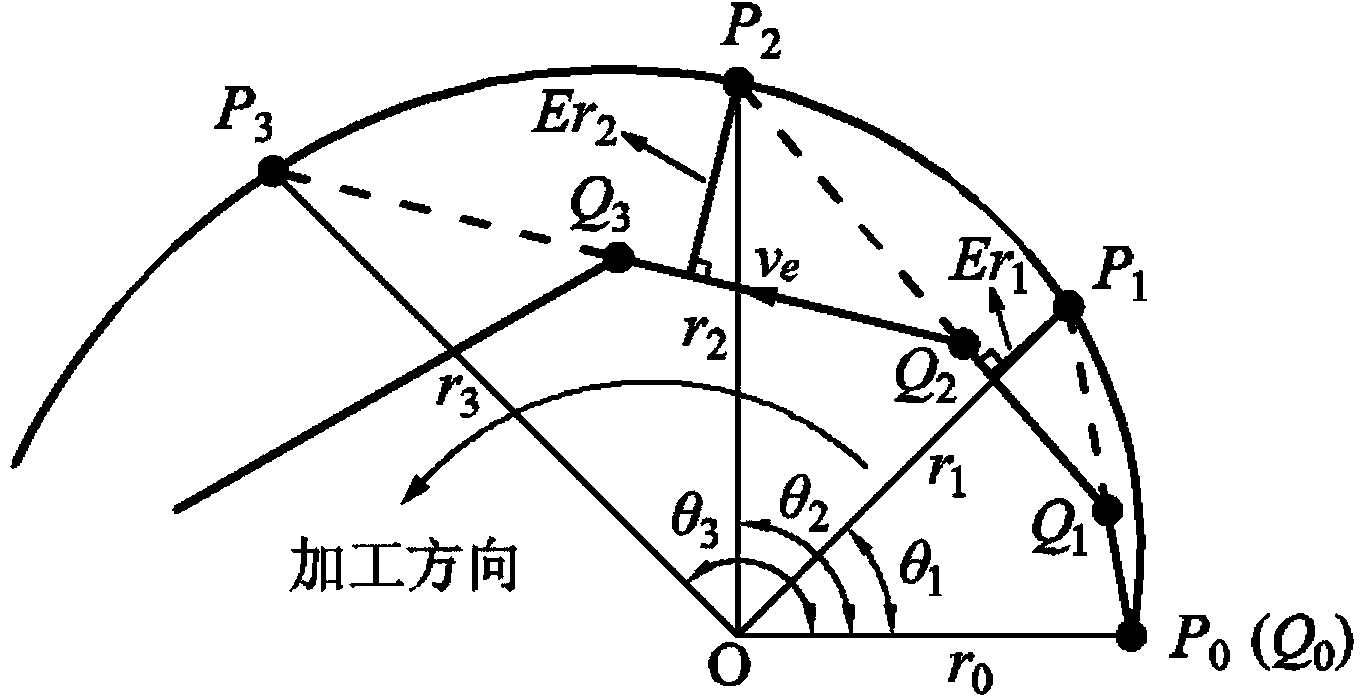

[0072] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and accompanying drawings. Due to the small feature size and large curvature changes in the central area of the equiangular helix, the local geometric features have abrupt changes, resulting in large changes in the dynamic characteristics of the feed axis of the machine tool during the CNC machining process. Limited by the dynamic characteristics of the machine tool, there is a deviation between the actual moving position of the feed axis of the CNC machine tool and the theoretical position programmed by the NC program, which leads to an increase in the contour error of the central area of the equiangular helix, making it difficult to guarantee the machining accuracy. In addition, the change of the dynamic characteristics of the CNC machine tool caused by the change of the geometric characteristics of the equiangular helix leads to the aggr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com