Multi-adaptive quick mounting type attached air cooling dedusting device

A dust-removing equipment and quick-loading technology, applied in the field of machining, can solve the problem of powder chips being difficult to collect quickly, and achieve the effects of improving quality stability, machine tool life, light weight, and reducing processing hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

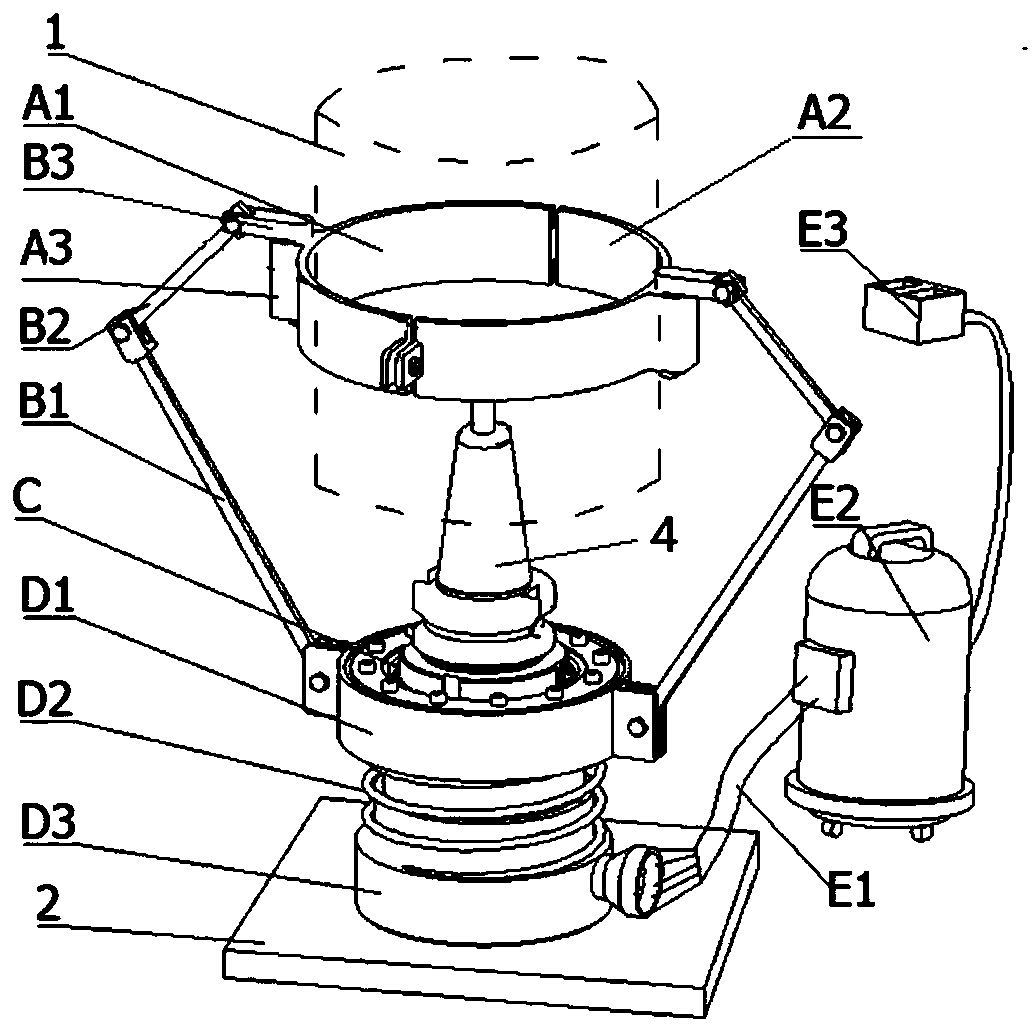

[0020] The technical solution adopted in the present invention is a multi-adaptive quick-installed accompanying cooling and dust removal equipment. parts, such as figure 1 , 2 shown.

[0021] The spindle clamping mechanism is connected and fixed with the machine tool spindle 1 by the left and right clamping rings A1 and A2 through bolts and nuts. The left and right clamping rings A1 and A2 are semi-cylindrical thin-walled structures. The middle part is processed with a pin hole A3.

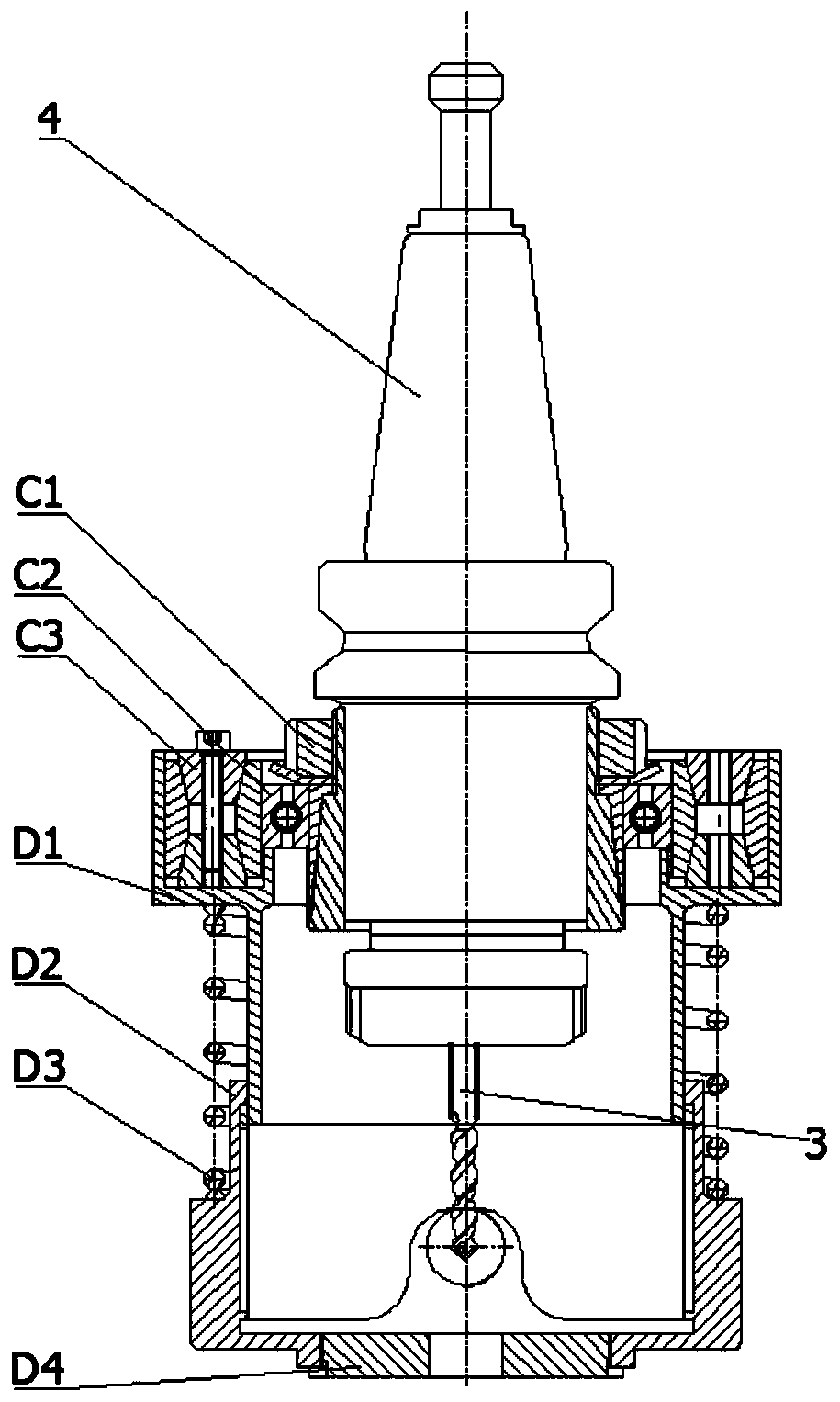

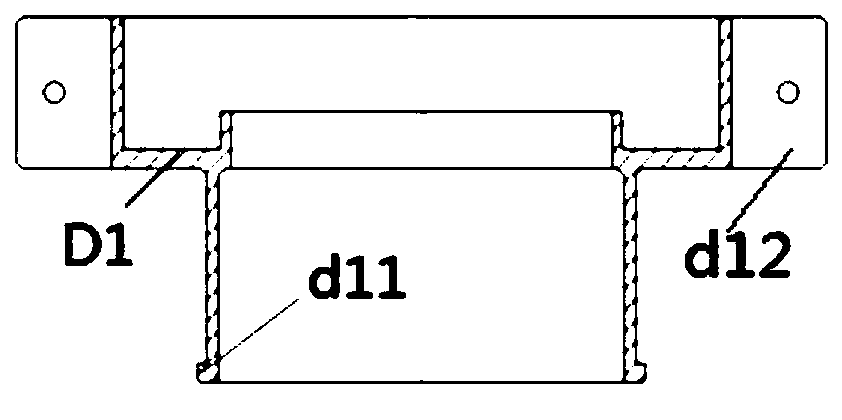

[0022] The bearing connection mechanism C is a mechanism that connects the tool handle 4 and the axial telescopic mechanism D, wherein the tool handle 4, the expansion sleeve C1, the rolling bearing C2, the expansion sleeve C3 and the axial expansion mechanism D are sequentially arranged from inside to outside Carry out assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com