Tuned passive damper with two degrees of freedom

A technology with passive damping and degrees of freedom, applied in the fields of non-rotational vibration suppression, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of narrow frequency band of vibration suppression, achieve wide frequency band of vibration suppression, easy parameter adjustment, and environment-free pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

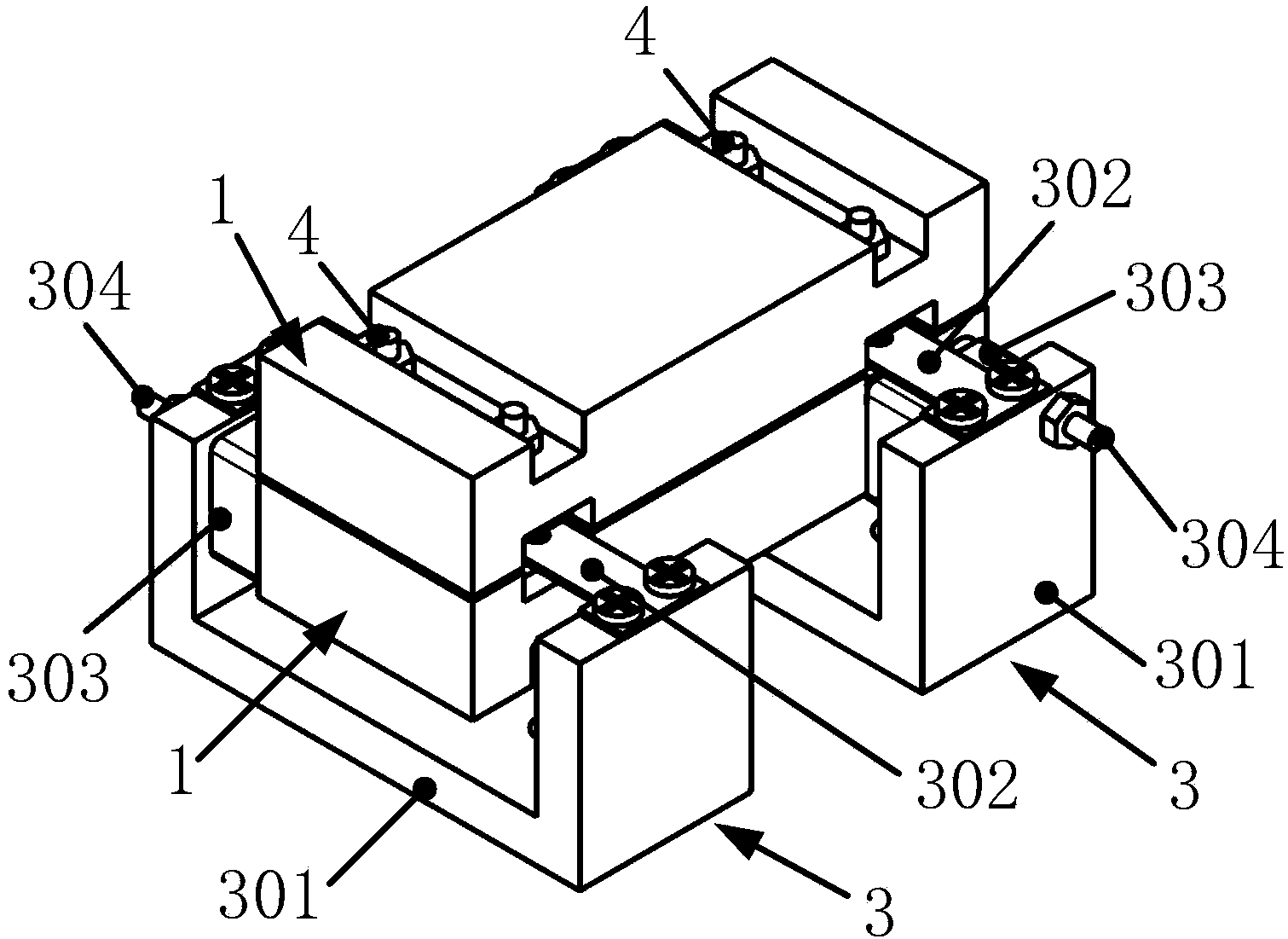

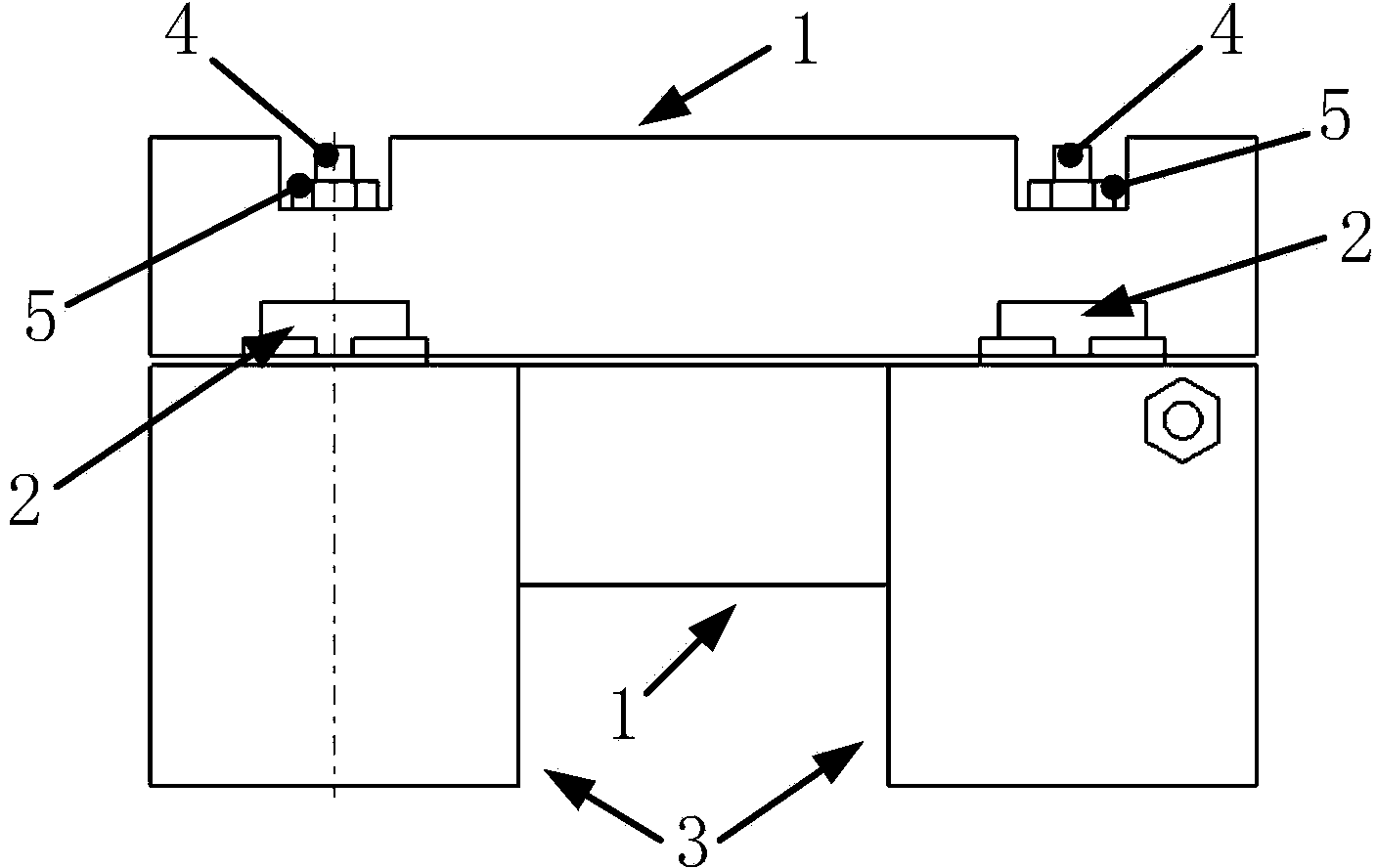

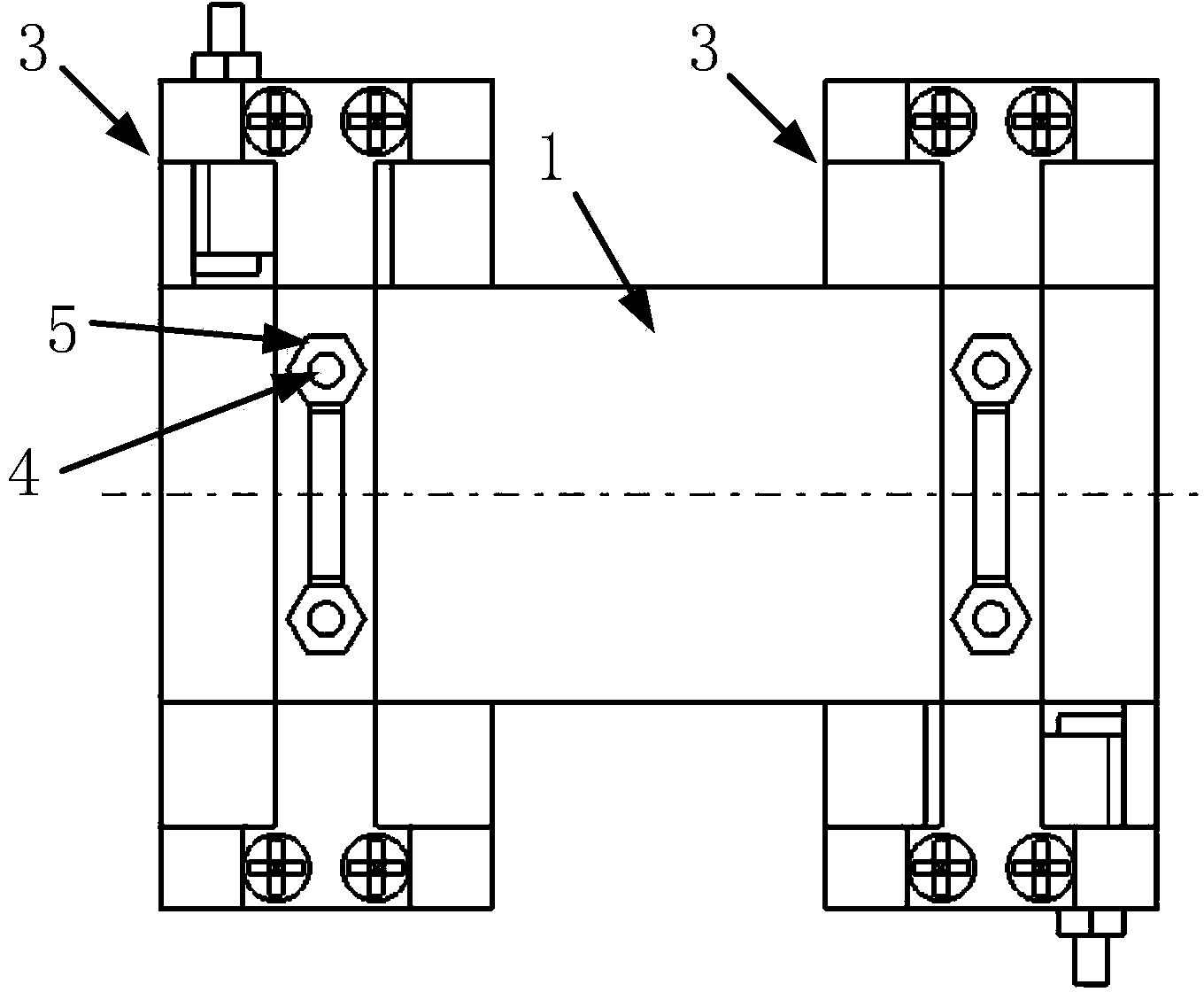

[0031] The present invention is a tuned two-degree-of-freedom passive damper, such as figure 1 , figure 2 , image 3 As shown, it includes a mass block 1, a slider 2, an elastic-damping unit 3, a stiffness adjusting bolt 4, and a stiffness adjusting nut 5.

[0032] Such as Figure 4 , Figure 5 As shown, the mass 1 consists of two pieces, namely an upper mass and a lower mass, which have the same structure and both have a rectangular cross-section. The upper mass block and the lower mass block are located at upper and lower positions respectively and are symmetrical to each other. Such as Figure 4 As shown, the lower surface of the upper mass block and the upper surface of the lower mass block are symmetrically located at the left and right ends, and grooves 101 that penetrate front and rear are designed; and the bottom surface of each groove 101 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com