Ultrasonic vibrating trepanning reamer machining device applied to pneumatic drill

An ultrasonic vibration and processing device technology, applied in reaming device, reaming device, metal processing equipment and other directions, can solve the problems of poor portability of vibration device, limited application of vibration technology, complex structure, etc. The effect of machining accuracy and surface quality, simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

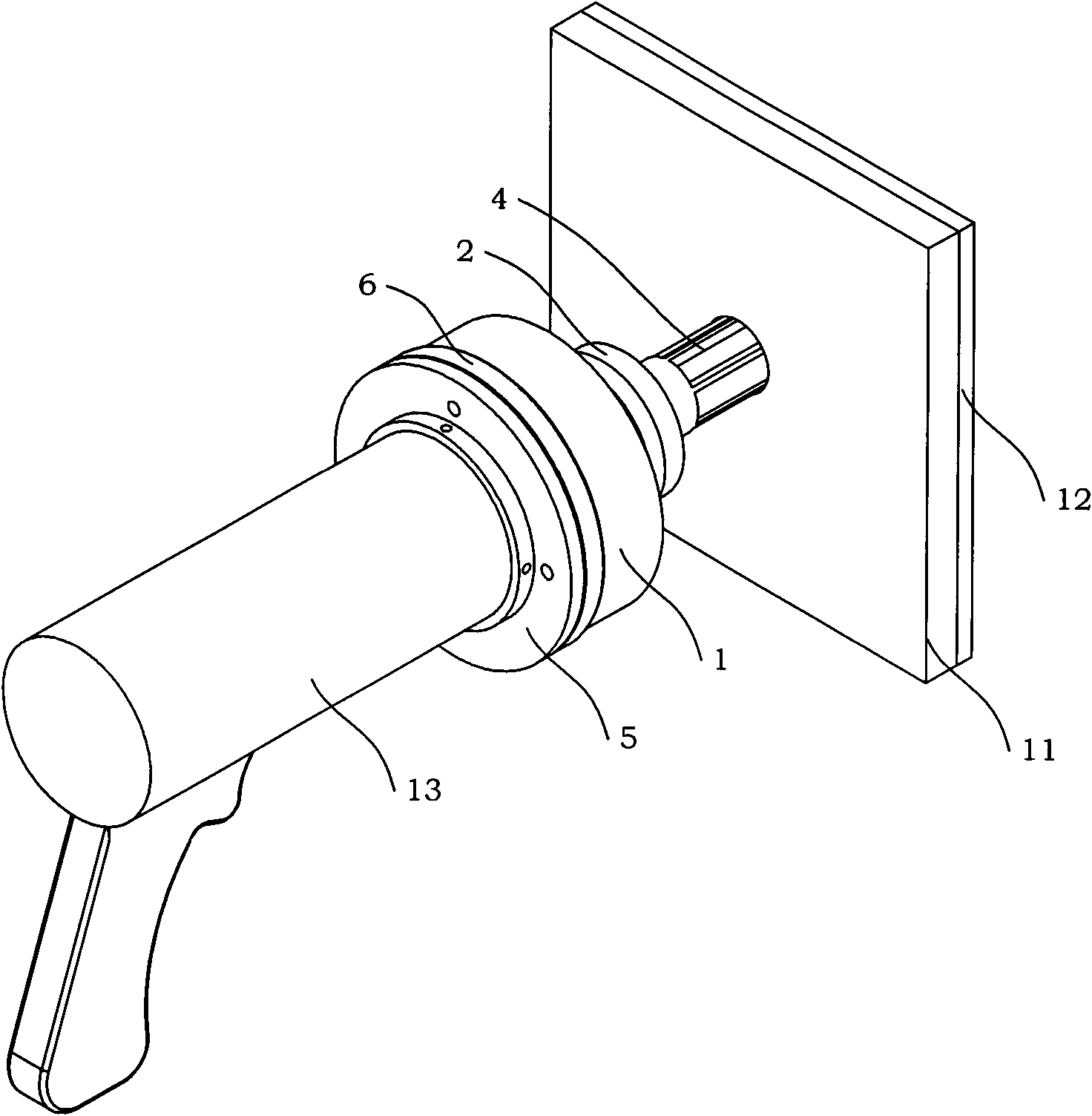

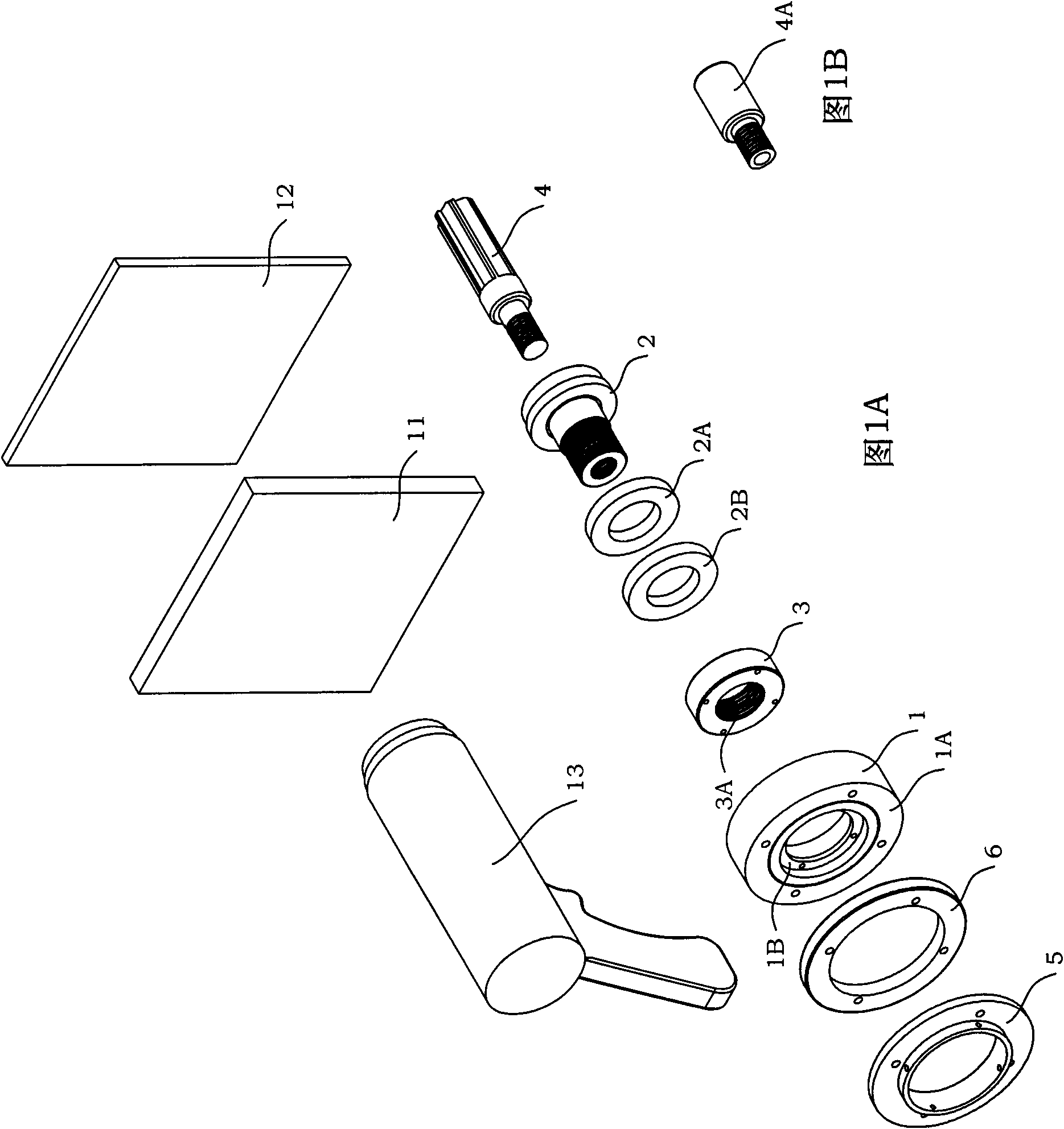

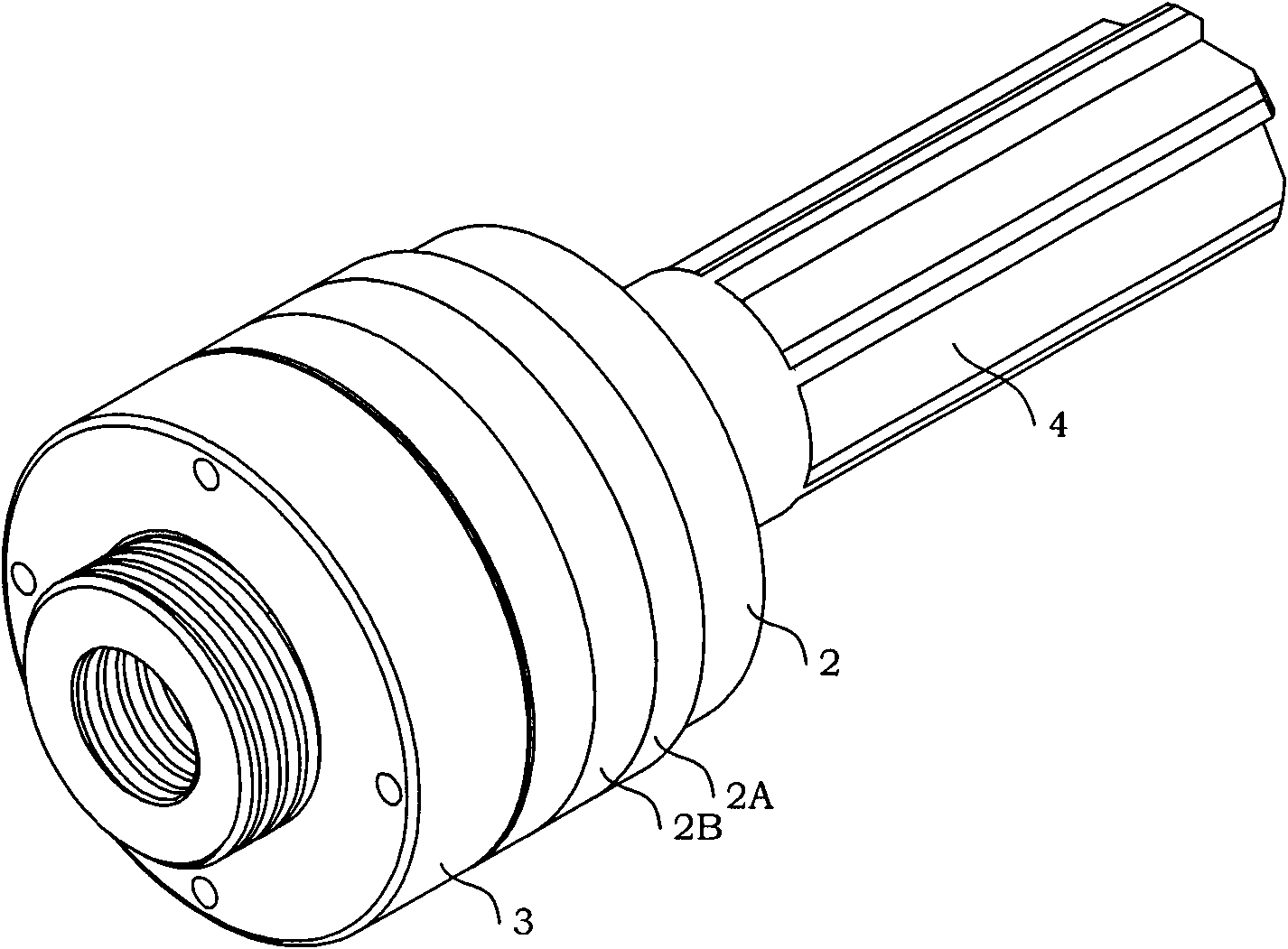

[0026] See figure 1 , Figure 1A , Figure 1B As shown, an ultrasonic vibrating sleeve reaming device applied to a gas drill of the present invention includes a slip ring 1, a front cover 2, A ceramic sheet 2A, B ceramic sheet 2B, a back cover 3, and a flange. 5 and retaining ring 6; one end of the front cover 2 can be used to connect the reamer 4 ( Figure 1A Shown) or nesting drill 4A ( Figure 1B Shown). In the present invention, the housing of the air drill 13 is connected to the flange 5, and the main shaft of the air drill 13 is connected in the internal threaded hole 21 of the front cover 2. In order to achieve mobility on the construction site, the air drill 13 adopts a manual air drill. The threaded interface assembly of the cutter (reamer or nesting drill) and the air drill spindle in the present invention not only facilitates the disassembly of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com