Real-time adjustable coil winding structure

A wire winding and wire clip technology is applied in the field of real-time adjustable wire winding structure, which can solve the problems of low efficiency of production equipment, difficulty in changing the wire wrapping better, and difficulty in improving winding quality, etc., and achieves the effect of high-quality and high-efficiency processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

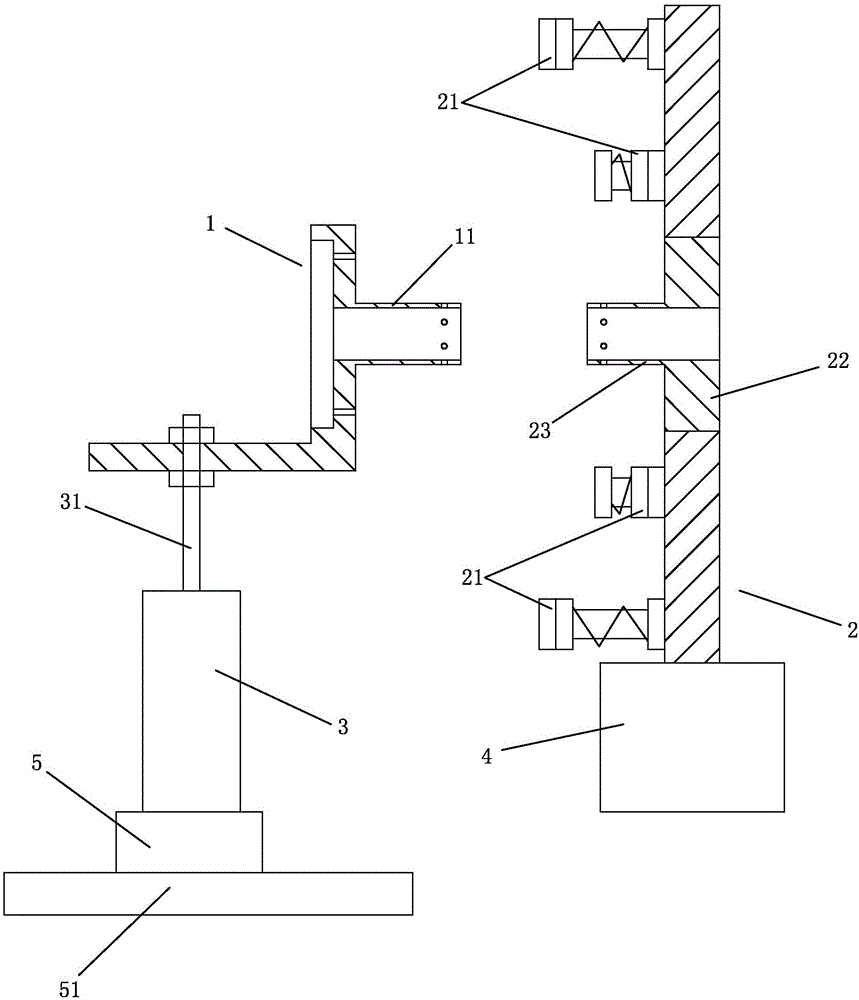

[0014] refer to figure 1 , a real-time adjustable wire winding structure of the present invention, comprising a front guide frame 1 and a lead frame 2, the front guide frame 1 is provided with a guide tube 11 guiding through the pipe material, and the front guide frame 1 is installed on the lifting mechanism 3, the The lifting mechanism 3 is fastened on the translation mechanism 5, the guide tube 11 protrudes toward the lead frame 2, the lead frame 2 is provided with a wire clamp 21 for stably winding the wire, and an inner frame 22 located at the center of the lead frame 2, The center of the inner frame 22 is provided with a winding tube 23 that is coaxial and protrudes toward the guide tube 11. The tube wall of the winding tube 23 is provided with a through hole corresponding to the wire clamp 21. The lead frame 2 is connected with a rotating motor 4 , the pipe blank passes through the guide tube 11 of the front guide frame 1 and enters the winding tube 22 of the lead frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com