Heavy car engine rear suspension cushion assembly

A technology of automobile engine and rear suspension, which is applied in the direction of power plant, vehicle parts, jet propulsion device, etc. It can solve the problems of labor-intensive installation, poor vibration damping effect, etc., and achieve reliable structure, good vibration damping effect and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

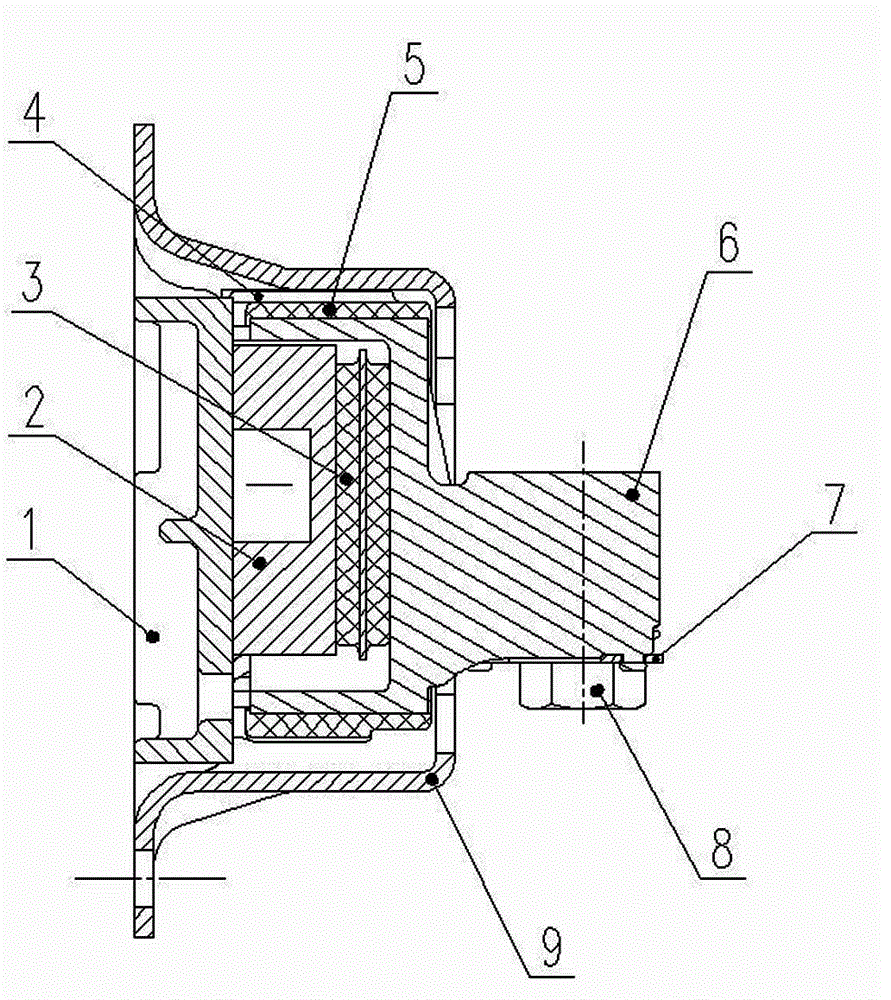

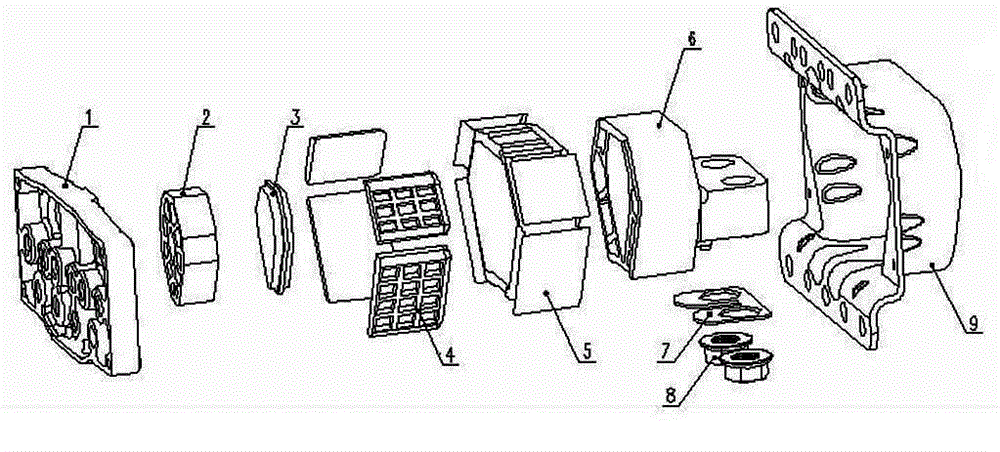

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: as figure 1 , figure 2 The rear suspension cushion assembly of the automobile engine shown includes a hollow conical outer casing 9 with holes at both ends and an inner skeleton 6 arranged in the cavity of the outer casing 9, and the large end of the outer casing 9 faces outwards. Flanging, small end inward flanging, the shape of one end of the inner skeleton 6 is a hexahedral hollow cavity, the other end is a cuboid, and one end of the cuboid of the inner skeleton 6 stretches out from the hole at the small end of the outer shell 9; the inner skeleton 6 The main rubber block 5 and the plastic plate 4 are arranged radially between the hollow cavity of the outer body and the inner cavity of the outer shell 9, wherein the plastic plate 4, the main rubber block 5 and the hexahedron of the inner skeleton 6 are vulcanized together, and then passed through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com