Tension resisting and twisting resisting combined shock isolation device with self-restoring function

A self-resetting and torsion-resistant technology, applied in earthquake-proof, bridge parts, building components, etc., can solve the problem of high tensile force, overturning force, low strength of friction-slip vibration isolation bearings and rolling vibration isolation bearings, complex processing technology, etc. problem, to achieve the effect of large stiffness adjustment range, significant isolation effect, and obvious effect of cycle extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

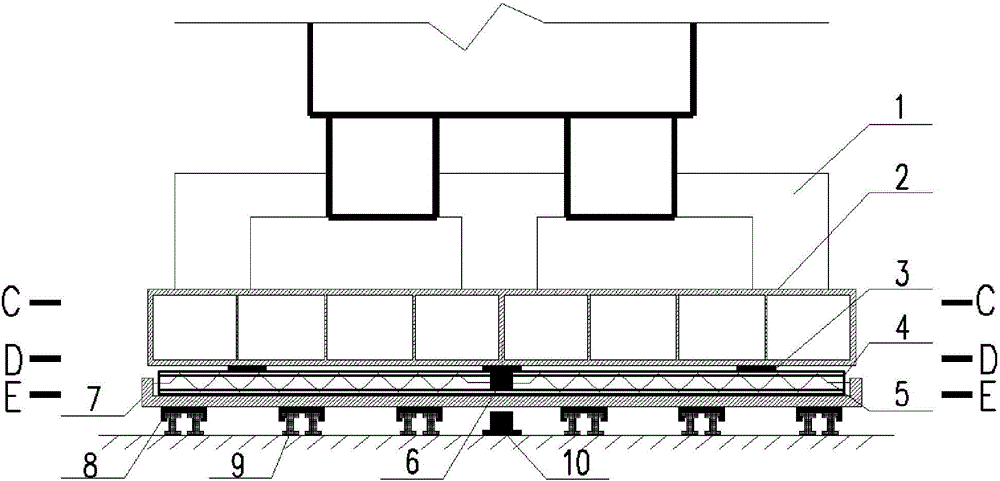

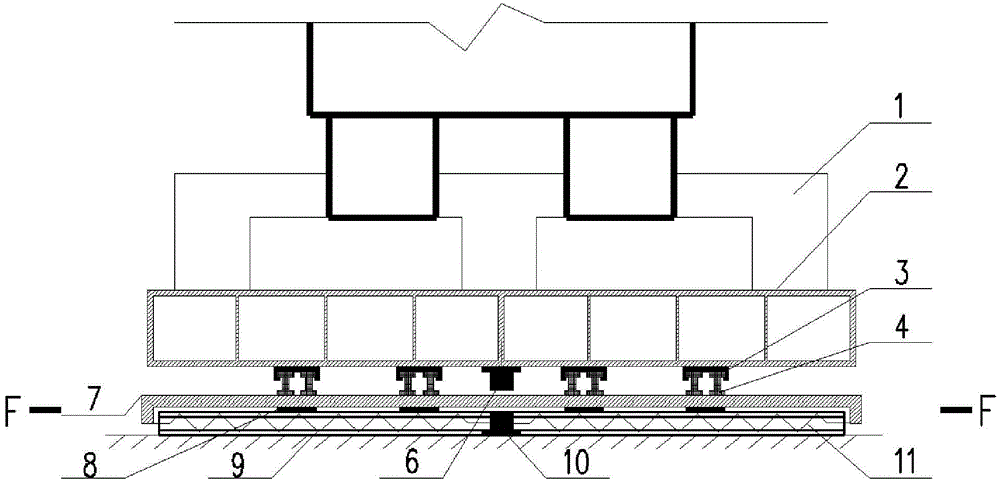

[0029] The technical requirements for the overall shock isolation device are as follows:

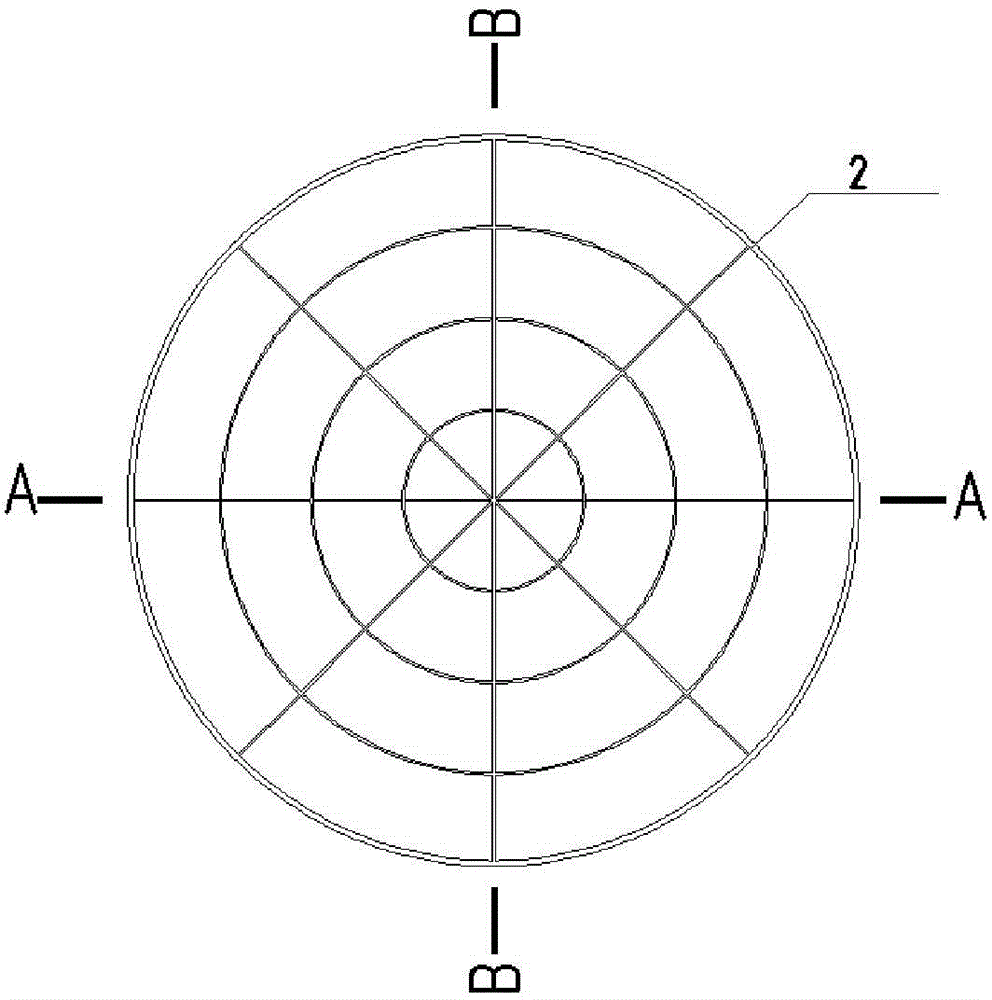

[0030]First, determine the cross-sectional size of the rigid support pedestal 2 according to the load of the upper high-flexible equipment 1, so that it can have a large enough load-bearing capacity, and adopt a combined steel structure to make it have sufficient rigidity to improve the rigid support pedestal itself The natural vibration frequency (30-50HZ) is far away from the frequency of the upper high-flex equipment (0.1-2HZ), thereby reducing the impact of the pedestal on the upper high-flex equipment 1.

[0031] According to the sum of the load of the upper high-flexible equipment 1 and the self-weight of the rigid support pedestal 2, determine the cross-sectional dimensions of the bottom horizontal vibration-isolation linear guide 4, the bottom longitudinal vibration-isolation linear guide 9, the layered partition 7, and the lateral limit slider 3 and the number of longitudinal li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com