Cascadable variable-stiffness robot joint

A robot joint and variable stiffness technology, applied in the field of robotics, can solve the problems of large joint rotational inertia, limited use occasions, and lack of consistent standards, etc., and achieve the effect of large stiffness adjustment range, reduced rotational inertia, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described below with reference to the drawings.

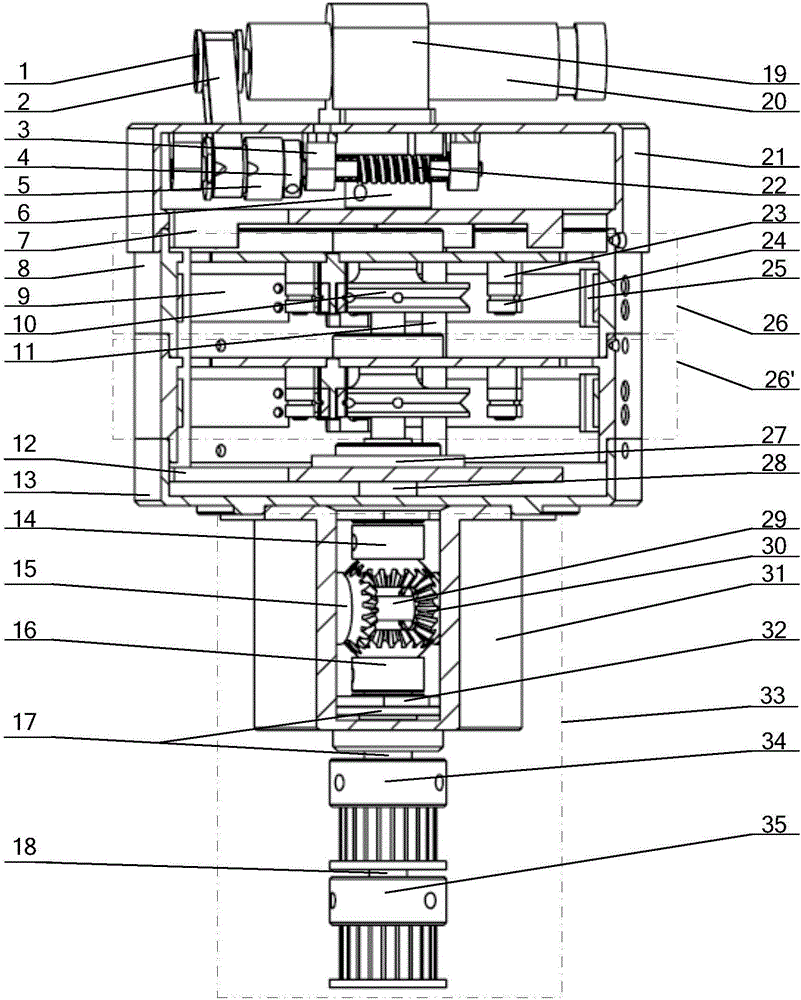

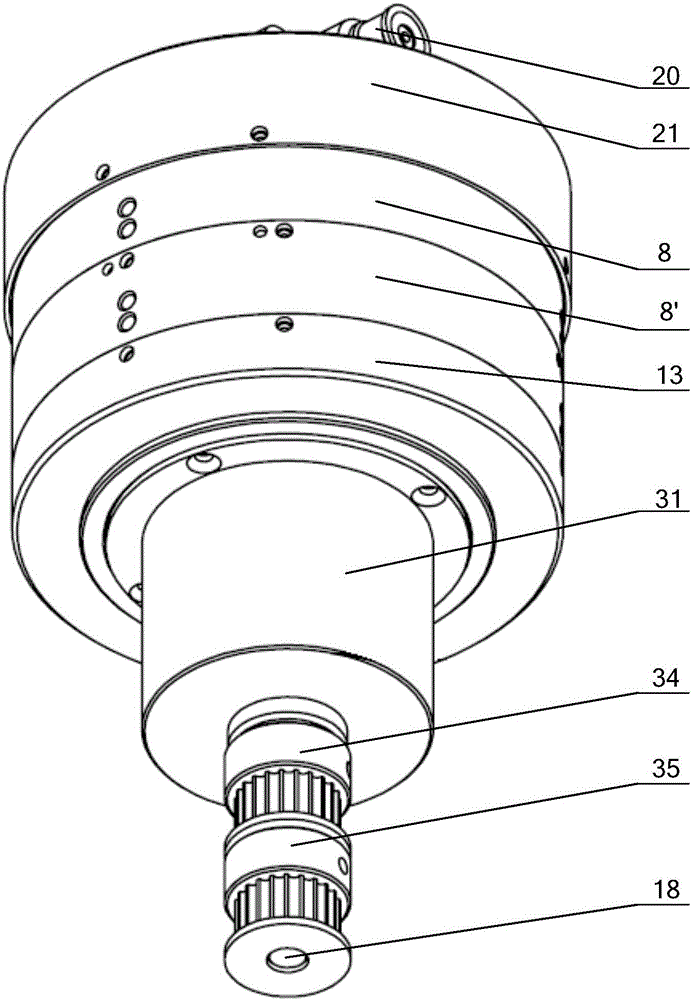

[0020] Such as figure 1 , 2 , 3, 4, and 5, the variable stiffness robot joint that can be cascaded and expanded in the present invention includes a flexible shaft-disk mechanism 26, a differential gear mechanism 33, a rotating support mechanism 36, a top cover 21, a bottom shell 13, and a gear holder shell 31. Among them, the number of 26 flexible shaft disk mechanisms can be greater than 1, and the number is determined by the energy storage requirements of the system. figure 1 , 2 The illustrated embodiment employs two identical flexible disc mechanisms 26 and 26' mounted in cascade.

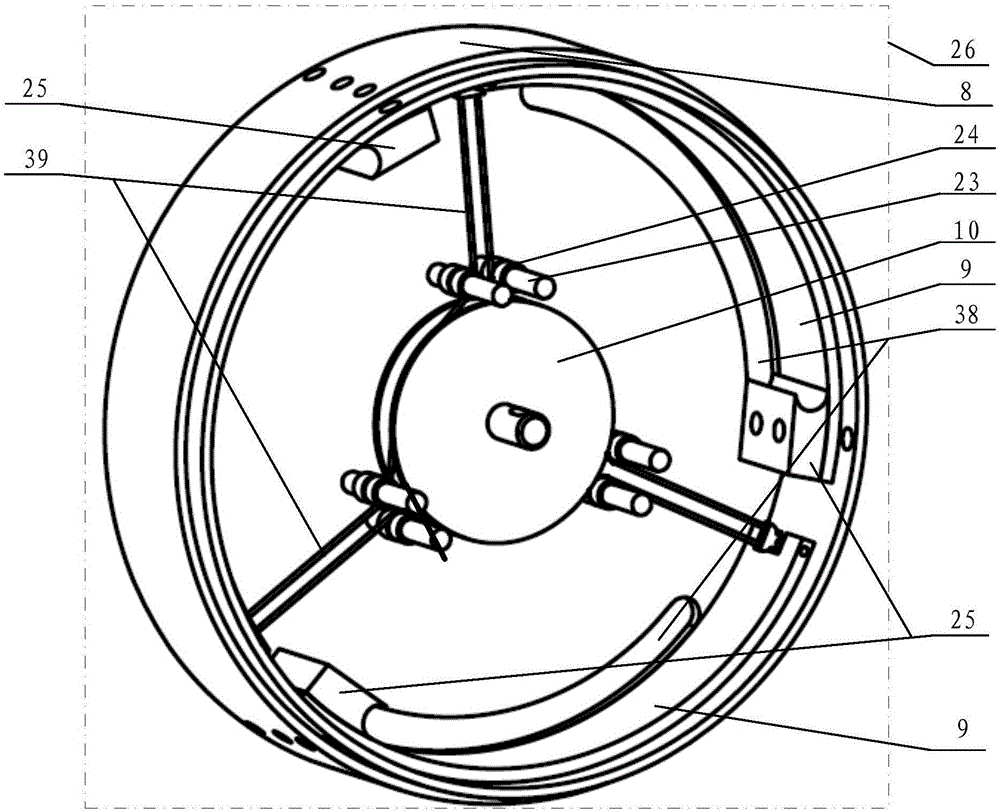

[0021] Such as image 3 As shown, the structural main body of the flexible shaft-disc mechanism 26 is an arc leaf spring mounting seat 8, and three arc leaf springs 9 symmetrically distributed are installed on the inside of the arc leaf spring mounting seat 8, and one end of each arc leaf sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com