Quasi-zero stiffness vibration isolator based on magnetorheological elastomer

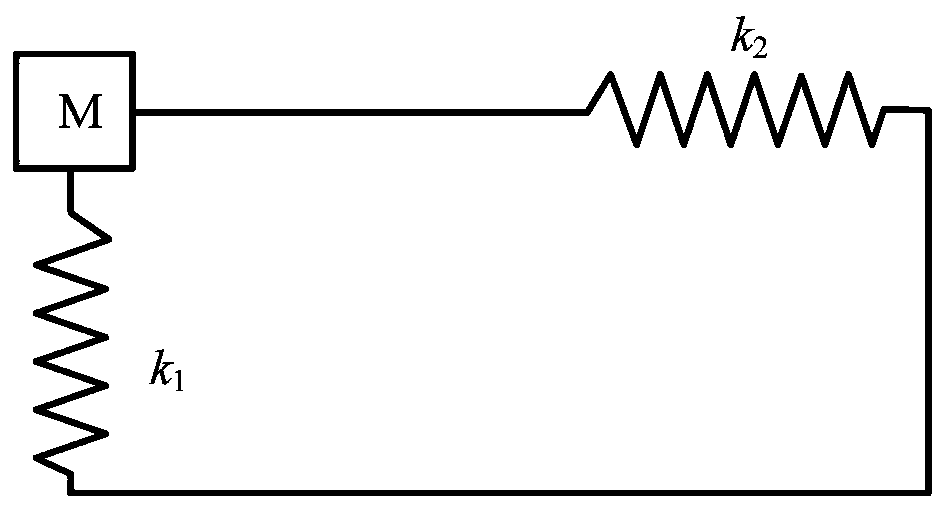

A magnetorheological elastomer and quasi-zero stiffness technology, which is applied in the design characteristics of spring/shock absorber, functional characteristics of spring/shock absorber, shock absorber, etc., can solve the problem of inability to achieve vibration isolation effect and slow adjustment response speed , Stiffness can not be adjusted and other problems, to achieve the effect of being beneficial to engineering applications, rapid response, and expanding the range of stiffness adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

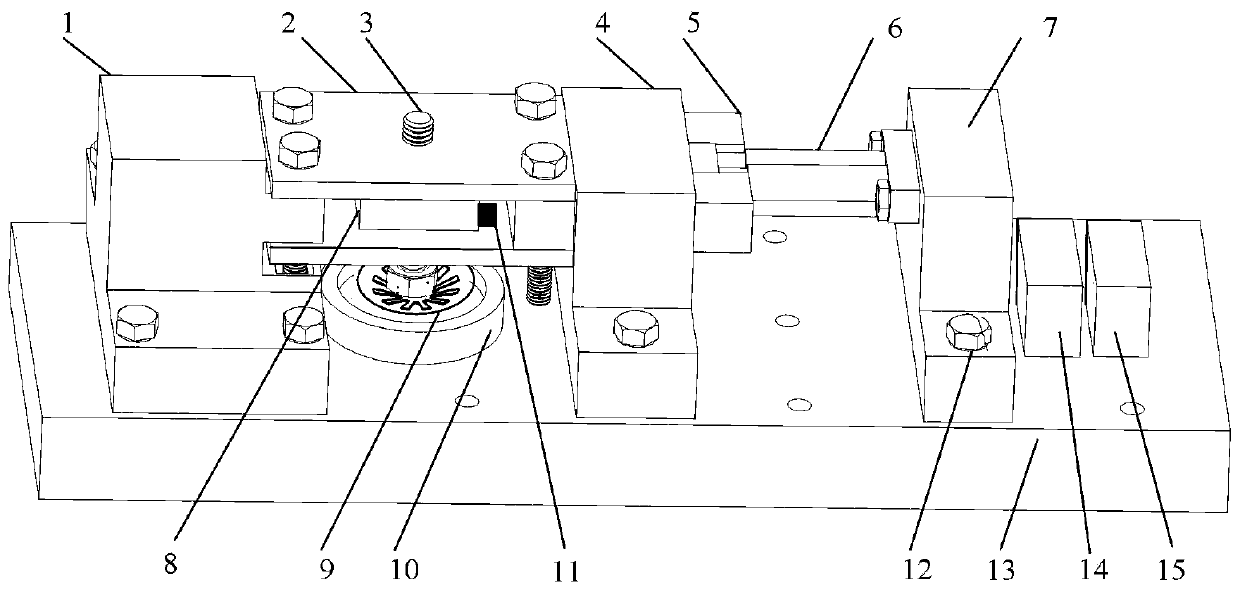

[0023] In this example, if figure 2 As shown, a quasi-zero stiffness vibration isolator based on a magnetorheological elastomer is sequentially fixed with a first fixed platform 1, a second fixed platform 14 and a third fixed platform 7 on the vibration isolator base 13;

[0024] Between the first fixed platform 1 and the second fixed platform 14, two layers of flexible boards 2 are arranged; between the two layers of flexible boards 2, a vibration isolation mechanism 8 is provided through connecting bolts 3; The side is provided with an acceleration sensor 11;

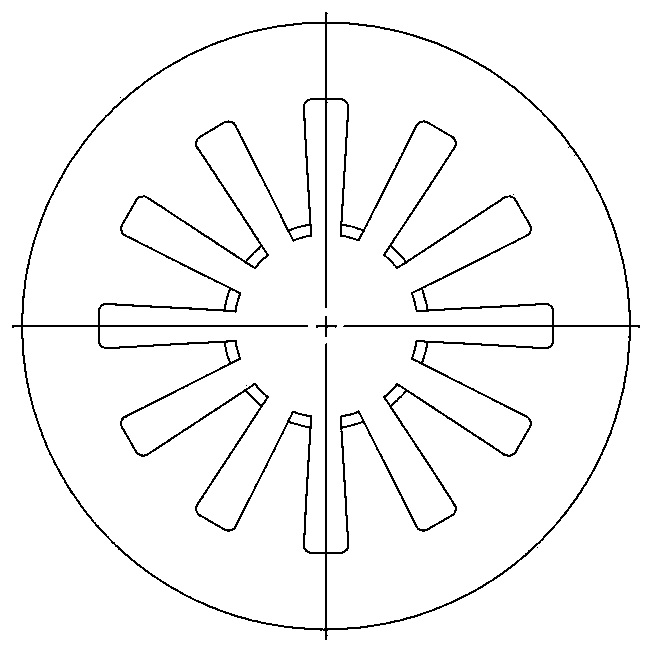

[0025] Below the two-layer flexible plate 2, a disc spring support platform 10 is arranged on the vibration isolator base 13; image 3 The disc spring 9 shown; and the disc spring 9 is against the end of the connecting bolt 3, and provides vertical support to the vibration isolation mechanism 8;

[0026] On the second fixed platform 14, a connection key plate 5 is penetrated, and the connection key plate 6 is a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com