Lattice magneto-rheological intelligent vibration reduction structure, magneto-rheological vibration isolating device and manufacturing method of lattice magneto-rheological intelligent vibration reduction structure

An intelligent vibration reduction and magnetorheological technology, which is used in shock absorbers, shock absorbers, vibration suppression adjustment, etc., can solve the problems of high manufacturing difficulty and cost, limited application scope, complex processing methods, etc., and achieve great practicality. Application value, simple and effective preparation method, strong anti-impurity pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

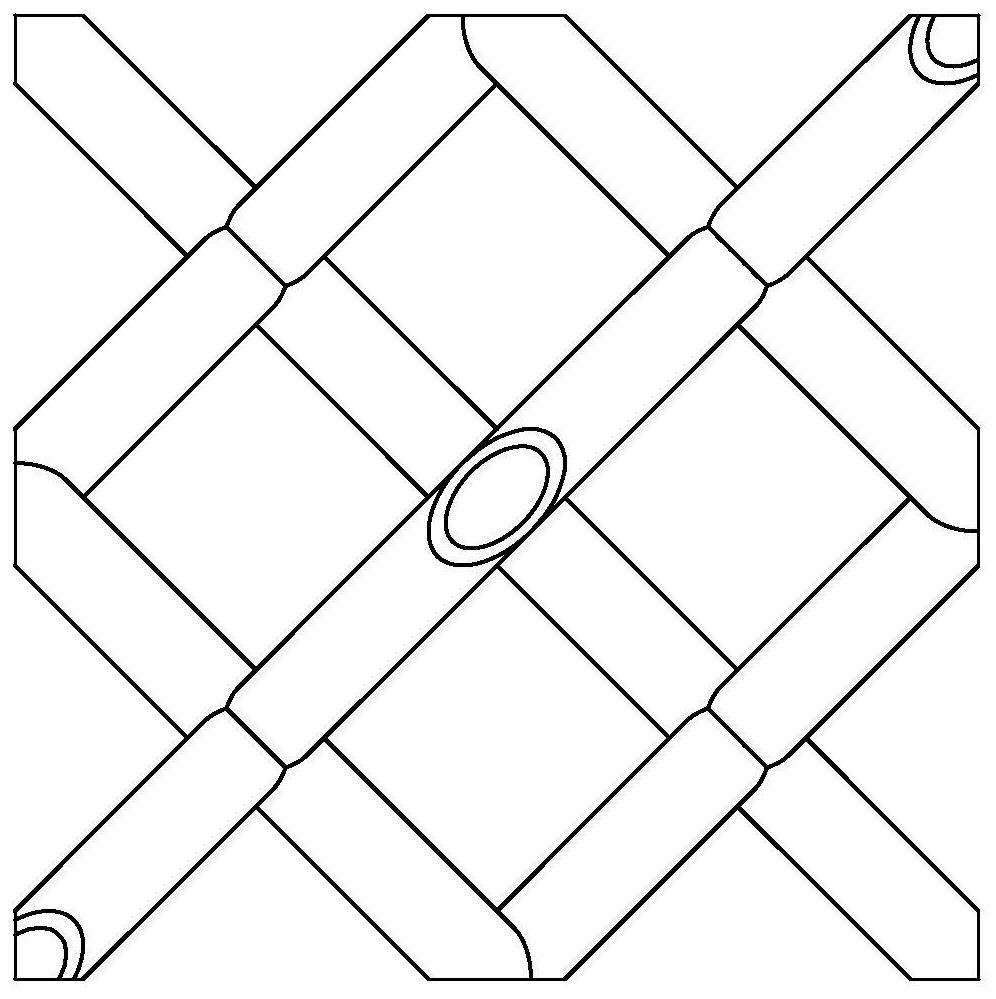

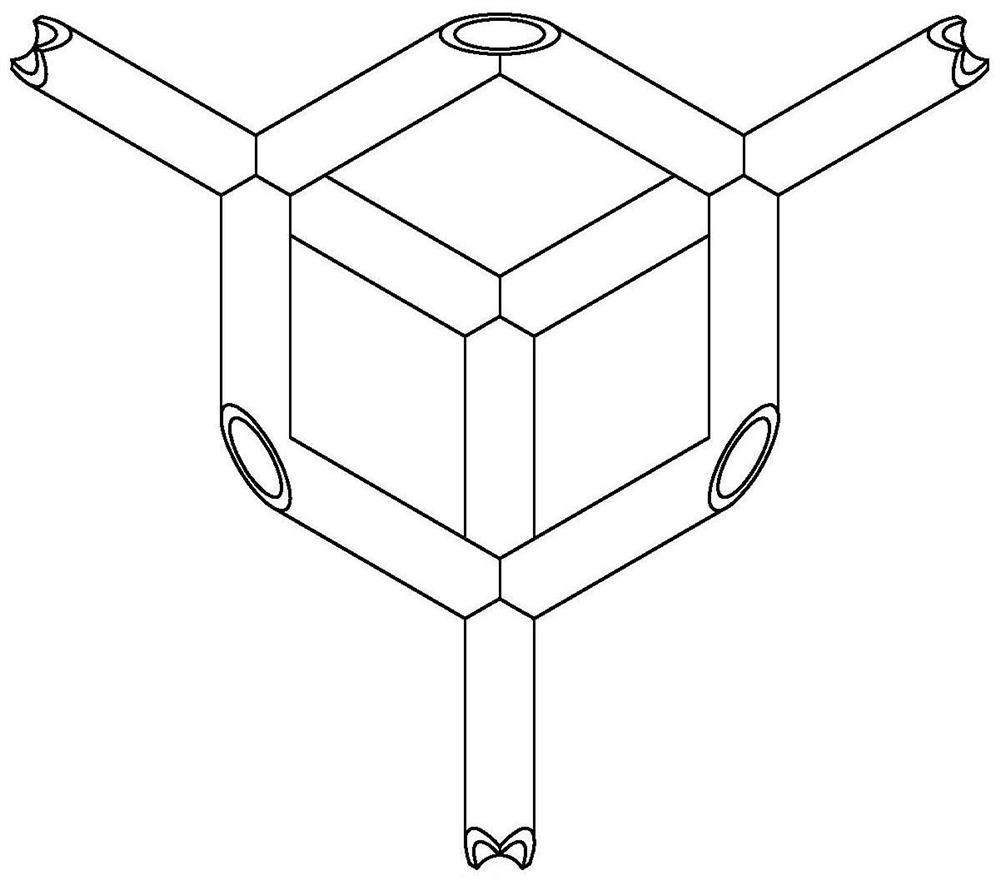

[0029] A lattice magneto-rheological intelligent damping structure of this embodiment includes several lattice unit cells that are periodically arranged in a three-dimensional space and connected to each other; the lattice unit cells include spatially distributed nodes and connections A hollow rod between the nodes; the hollow rod is filled with magnetorheological fluid; the lattice unit cell is a diamond cubic structure with a size of 4×4×4mm3; the outer diameter of the hollow rod is 0.4mm, inner diameter 0.3mm, rod wall thickness 0.05mm; figure 1 , figure 2 It is the front view and isometric view of the hollow diamond lattice unit cell structure. The lattice magnetorheological intelligent damping structure of this embodiment changes the solid rod of the traditional lattice structure into a hollow rod, and fills the magnetorheological fluid inside , which can change with the intensity of the environmental magnetic field, realize the real-time adjustment of adaptive stiffnes...

Embodiment 2

[0032] This embodiment is a manufacturing method of a lattice magneto-rheological intelligent damping structure, including the following steps:

[0033] s1. Construct a hollow three-dimensional lattice structure model using computer-aided software (CAD).

[0034] s2. Optimizing the resin plastic material as the base material, making a shell with a lattice structure, and using stereolithography (SLA) technology with fine resolution in additive manufacturing technology to prepare an investment pattern with a hollow diamond lattice structure.

[0035] s3. Coating the nickel-phosphorus (Ni-P) film on the polymer investment pattern through chemical deposition and electroplating technology, and immersing in the investment pattern, and controlling the thickness of the deposited film by controlling the reaction time.

[0036] s4. Fourth, thermal gravimetric analysis is performed on the resin, and the resin is continuously calcined at a high temperature (500°C) for 1 hour in an argon a...

Embodiment 3

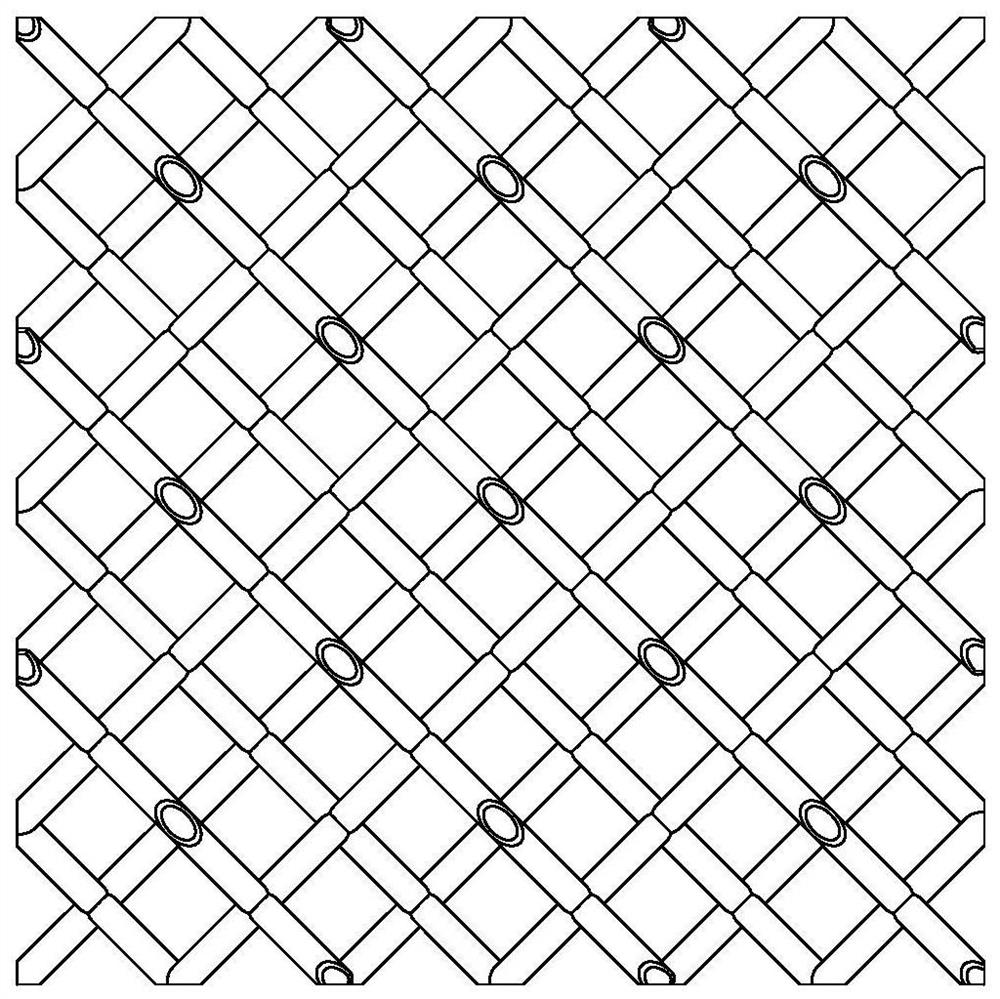

[0039] The hollow diamond unit cells are periodically arranged and combined, and the unit cells are closely combined. Through the combination of Boolean operations, the process flow in Example 2 can be used to form a lattice magnetorheological Compared with the original rheological block, the vibration isolator has the advantages of light weight and controllable structural stiffness design. Figure 7 is the isometric view of the upper and lower sides of the vibration isolator, Figure 8 In its top view, the vibration isolator has a diameter φ of 40mm and a thickness of 20mm. Figure 9 It is the extrusion working mode of the lattice magnetorheological vibration isolator (the moving direction of the magnetic pole is consistent with the direction of the magnetic field). When there is no magnetic field, the filling material is Newtonian fluid, which instantly transforms into a viscoplastic body under a strong magnetic field. After the magnetic field is removed, the fluidity is qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com