Prefabricated precast concrete tower crane foundation in the shape of bolt connecting box

A tower crane foundation and prefabricated assembly technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult control of base pressure, waste of prestressed steel bars, weakened anti-overturning ability, etc., to achieve easy filling quality assurance, increased shear resistance, Good anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

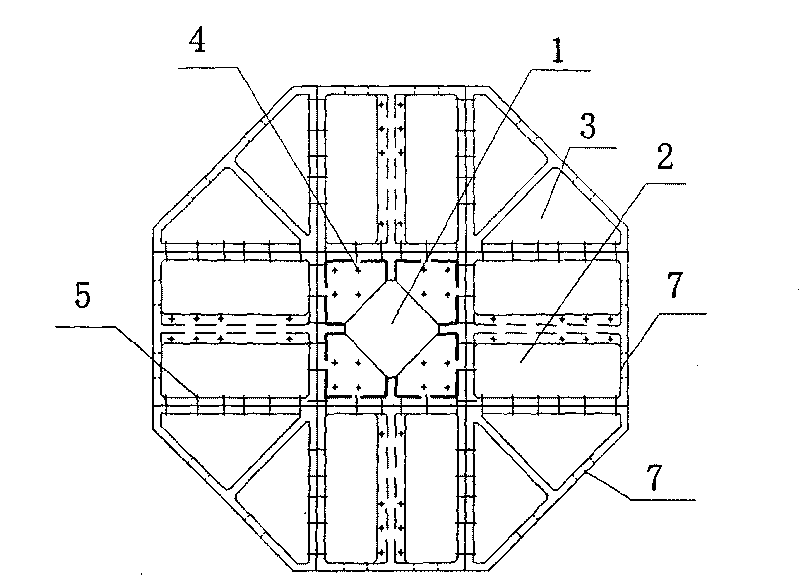

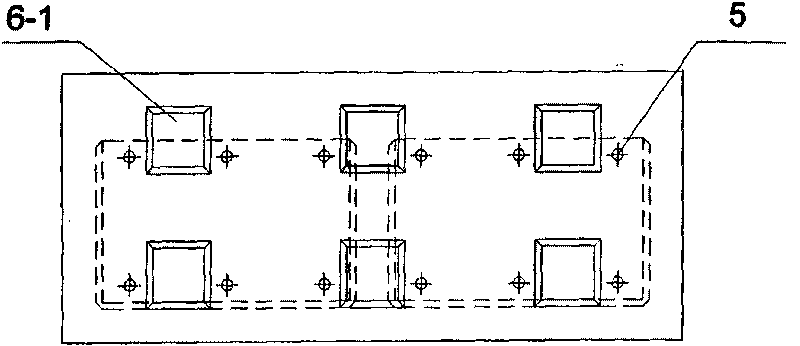

[0024] As shown in the figure: a bolt-connected box-shaped prefabricated concrete tower crane foundation, the tower crane foundation includes a plurality of box-shaped components composed of three structural forms, the middle position of the foundation has a central box-shaped component 1, and the center box A box-shaped member 2 is arranged on the front, rear, left, and right sides of the shaped member 1, and a box-shaped member 3 is arranged on one side of the box-shaped member 2. There are bolt holes 5 on the side walls of each box-shaped member, and each box-shaped member passes through its side wall. Insert the bolt welding body 8 into the bolt hole 5 for connection after the groove 6-1 and the protrusion 6-2 fit together.

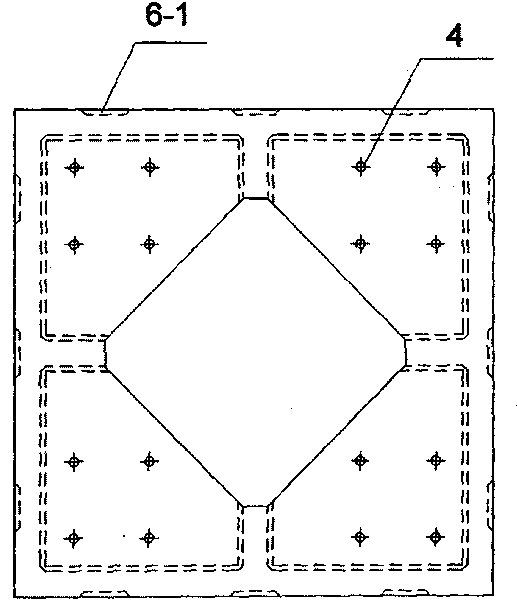

[0025] The central box-shaped member 1 is a hollow box-shaped structure, the concrete plate on the top of the box has bolt holes 4, and each surface around the central box-shaped member 1 has grooves 6-1 respectively.

[0026] The box-shaped member 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com