At-sea wind generation unit foundation formed by barrel type foundation and mooring rope anchor

A cylindrical foundation and offshore wind power technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of large impact, high requirements for load-bearing foundation, and high price, so as to reduce horizontal force and bending moment and improve anti-overturning ability , the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

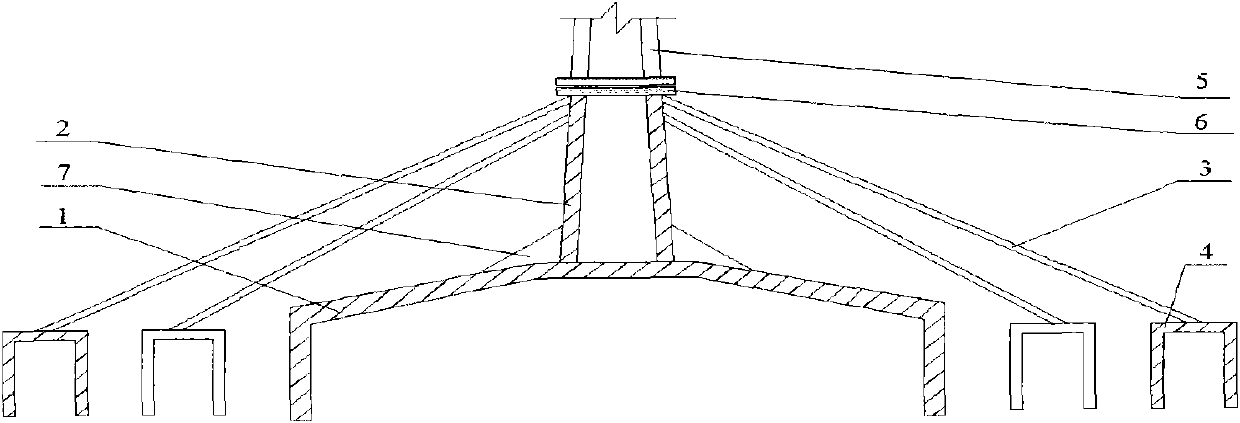

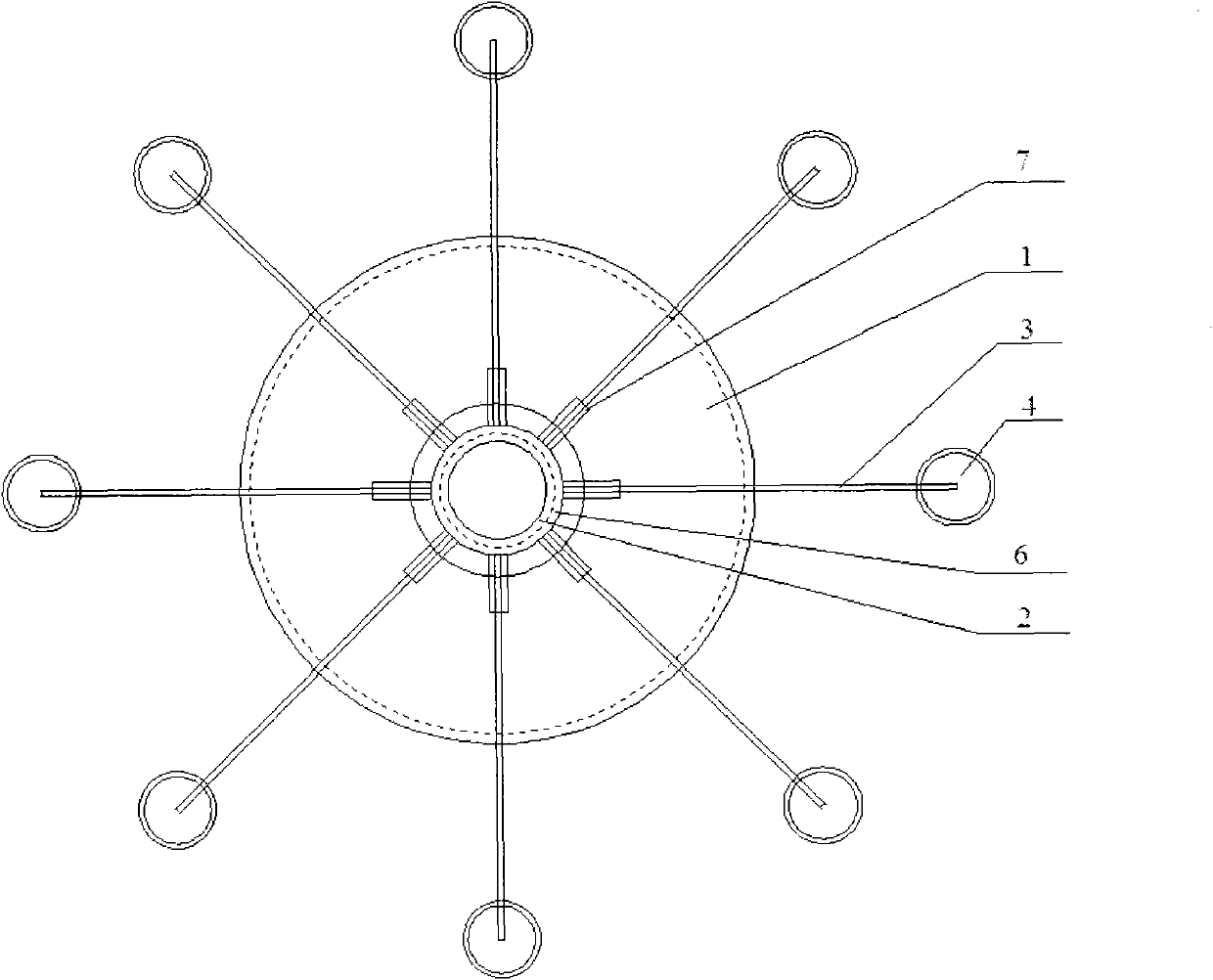

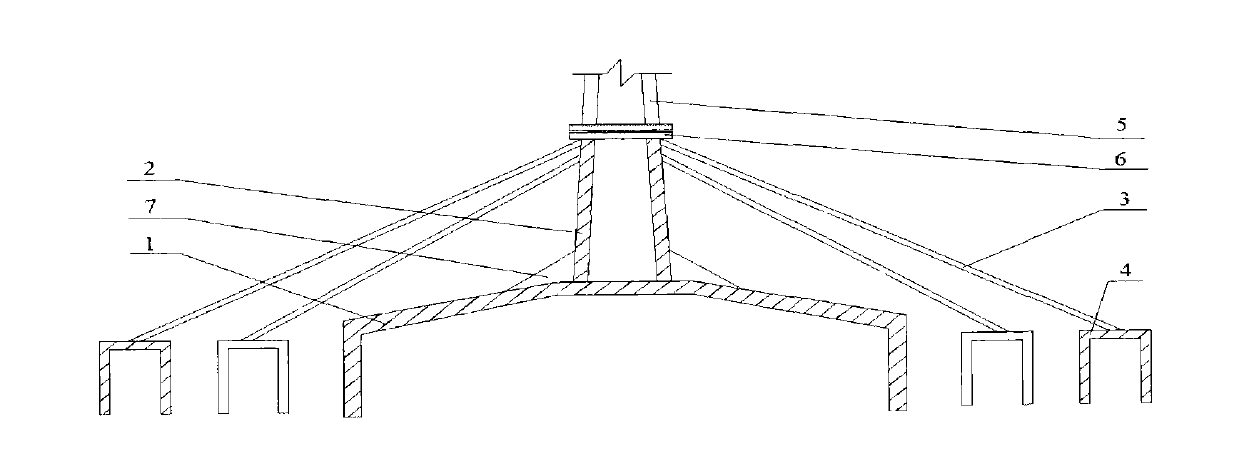

[0014] An offshore wind turbine foundation composed of a cylindrical foundation and mooring cable anchors. It is composed of a cylindrical foundation 1, a connecting tower 2, a steel cable 3 and a suction anchor 4. The cylindrical foundation 1 is equipped with a sealed top cover. Steel cylinder structure; the connecting tower 2 is a steel conical cylindrical structure; the connecting tower 2 and the cylindrical foundation 1 are fixed by welding and reinforced by eight ribs 7, and the connecting tower 2 and the wind turbine tower 5 are connected by the method The blue 6 is connected and fixed; one section of the steel cable 3 is welded and fixed to the top of the connecting tower 2, and the other end is welded and fixed to the suction anchor 4; the number of the steel cable and the suction anchor is the same as eight.

[0015] In this embodiment: the diameter of the steel cylindrical foundation is 10m, the wall thickness is 50mm, and the height is 8m; the diameter of the steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com