Adjustable tower crane steel platform foundation

A technology of tower crane foundation and tower crane steel, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of unusable foundation cap, reduced vertical support rigidity of pile foundation, excessive vibration, etc., and achieves stress condition and anti-overturning ability The effect of improving and reducing labor intensity and project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

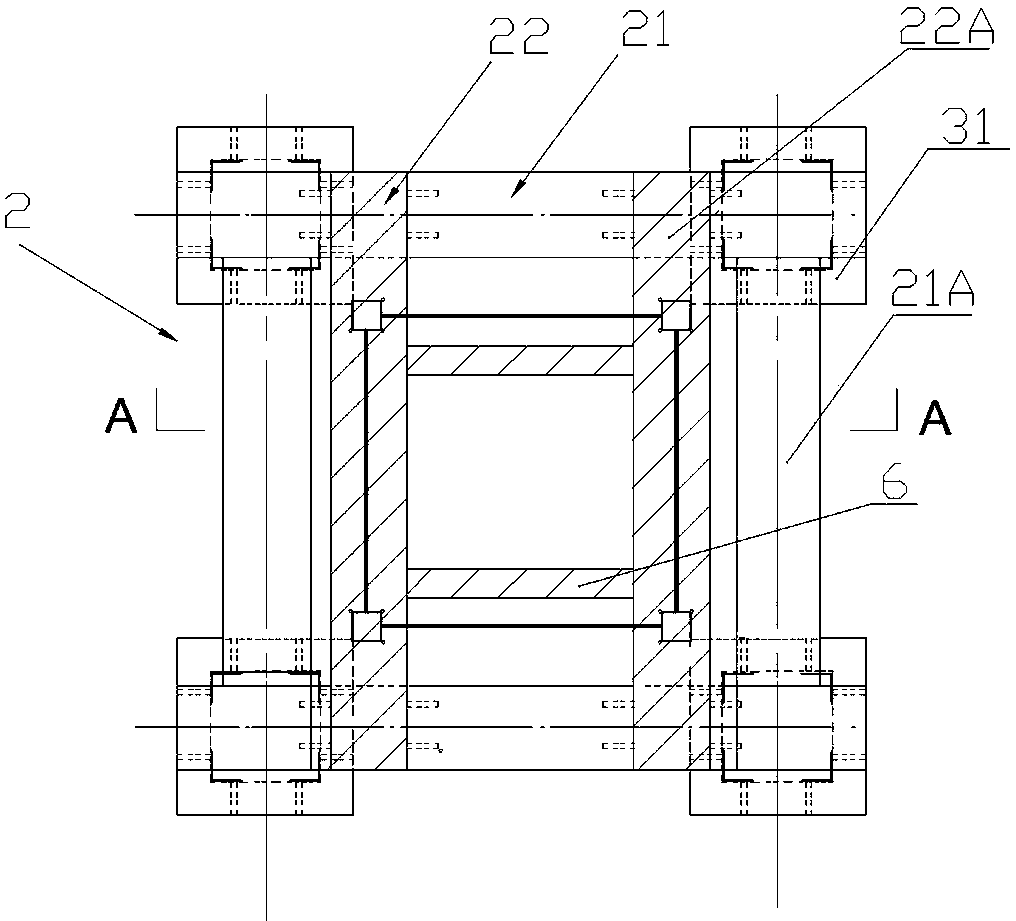

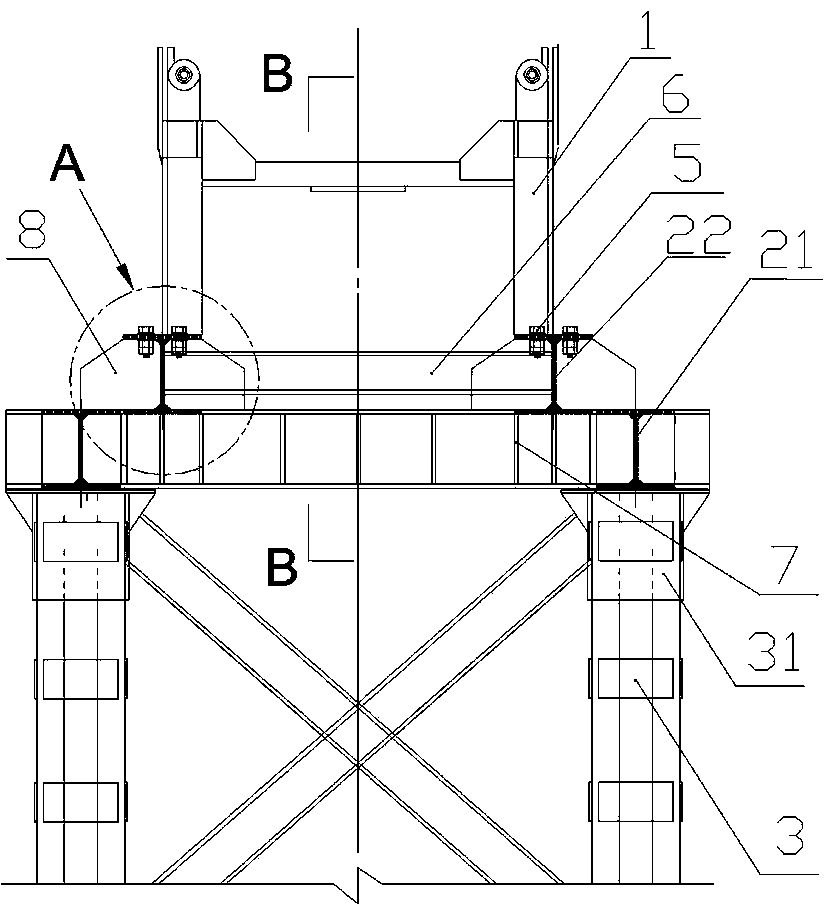

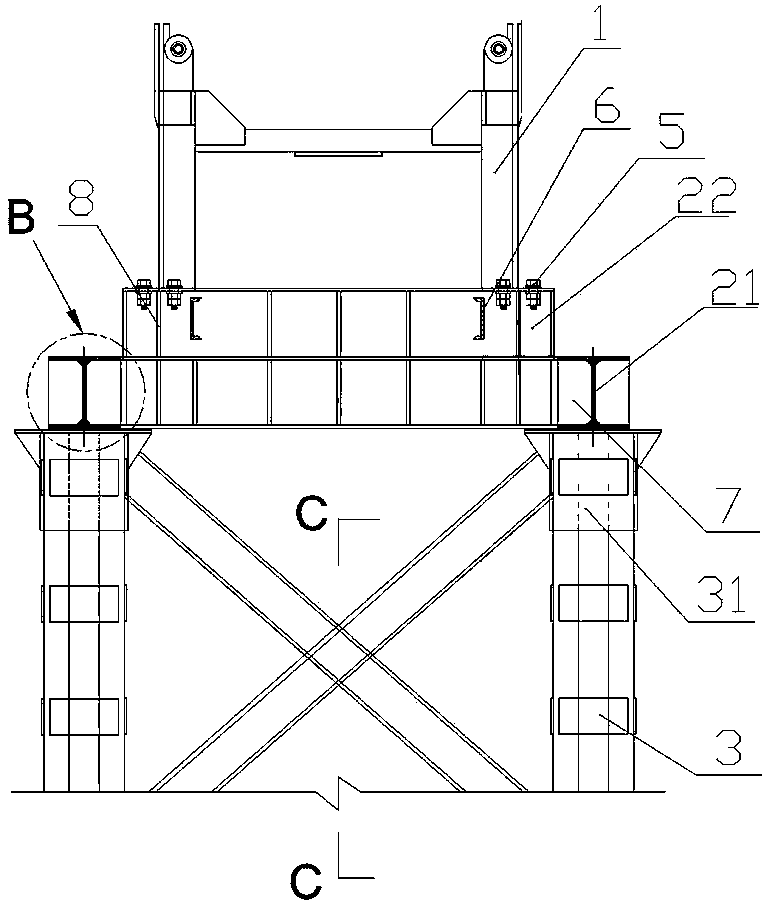

[0057] see figure 1 , 2 , with reference to Figure 3 ~ Figure 14 , shown in the figure is an adjustable tower crane steel platform foundation related to the present invention, which mainly includes a foundation cap fixedly connected with the tower crane foundation section 1, and a lattice column 3 fixedly connected with the bottom of the foundation cap; 3 is fixedly installed in the foundation pile 4 of the tower crane, and the foundation cap is a steel platform base 2 welded by H-shaped steel.

[0058] One of the key technical solutions:

[0059] Such as Figure 1~3 As shown, the steel platform base 2 involved in the present invention includes double-layer structural steel beams fixed up and down; wherein:

[0060] The lower structural steel girder is the auxiliary steel girder 21, which is composed of four H-shaped steel 21A fixedly distributed in the shape of a square;

[0061] The superstructure steel beam is the supporting steel beam 22, which is composed of two H-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com