Vibration reduction column composite foundation for subway station and vibration reduction method of vibration reduction column composite foundation

A composite foundation and subway station technology, which is applied to the composite foundation of the vibration damping column for the subway station and its vibration reduction field, can solve the problem of reducing the comfort of pedestrian subway traffic facilities, endangering the overall structural safety of the subway station, and increasing the overall cost of the subway station, etc. problems, to achieve the effect of preventing long-term vibration cracking, avoiding natural vibration, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

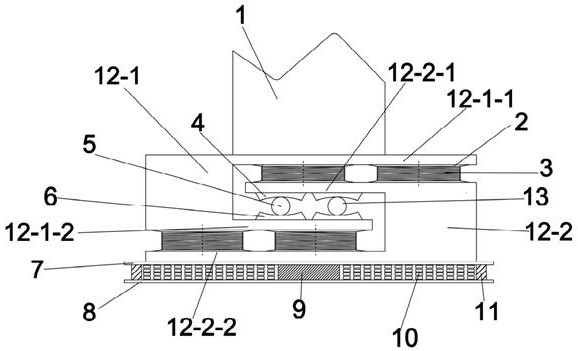

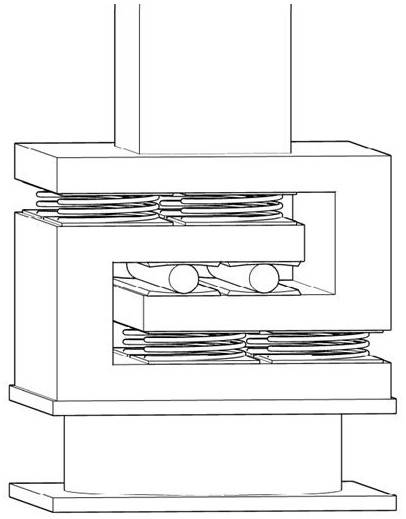

[0047] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The present invention includes cylinder 1, anti-slip and wear-resistant rubber sheet 2, low-frequency spray plastic spring 3, upper connecting concave plate 4, steel rod 5, lower connecting concave plate 6, upper connecting plate 7, lower connecting plate 8, lead rod 9, Viscoelastic composite steel plate structure 10, durable rubber 11, special-shaped U-shaped support and rolling wear structure 13;

[0049] The energy-dissipating composite structure at the bottom of the foundation is preset to connect the upper connecting plate 7 and the lower connecting plate 8; a lead rod 9 without pores and impurities inside, wear-resistant and compressive is inserted in the center of the energy-dissipating composite structure at the bottom of the foundation.

[0050] The viscoelastic composite steel plate structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com