A method for improving the mechanical performance of steel-concrete composite multi-box continuous girder bridges in the negative moment zone

A technology of negative bending moment area and steel box girder, which is applied in bridges, special data processing applications, instruments, etc., can solve problems such as complex construction technology, increased workload, and extended construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

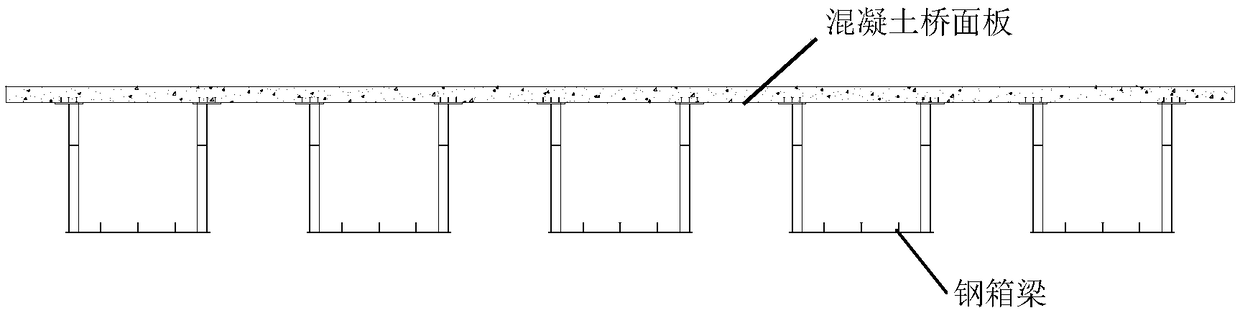

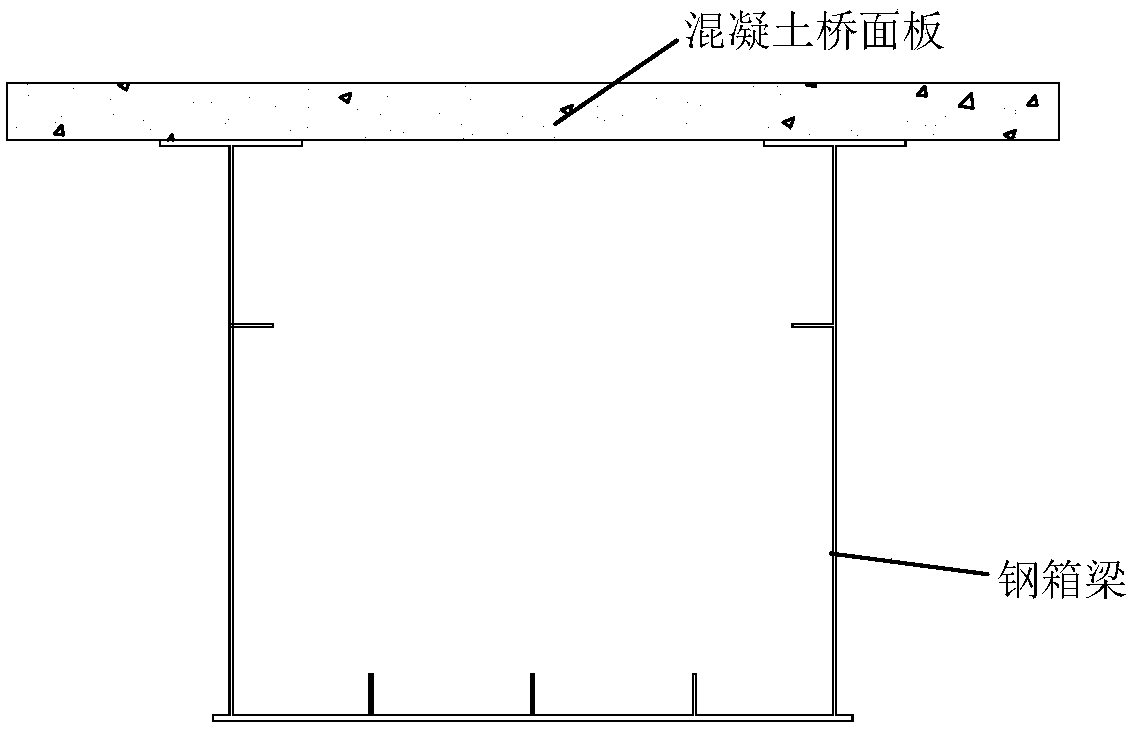

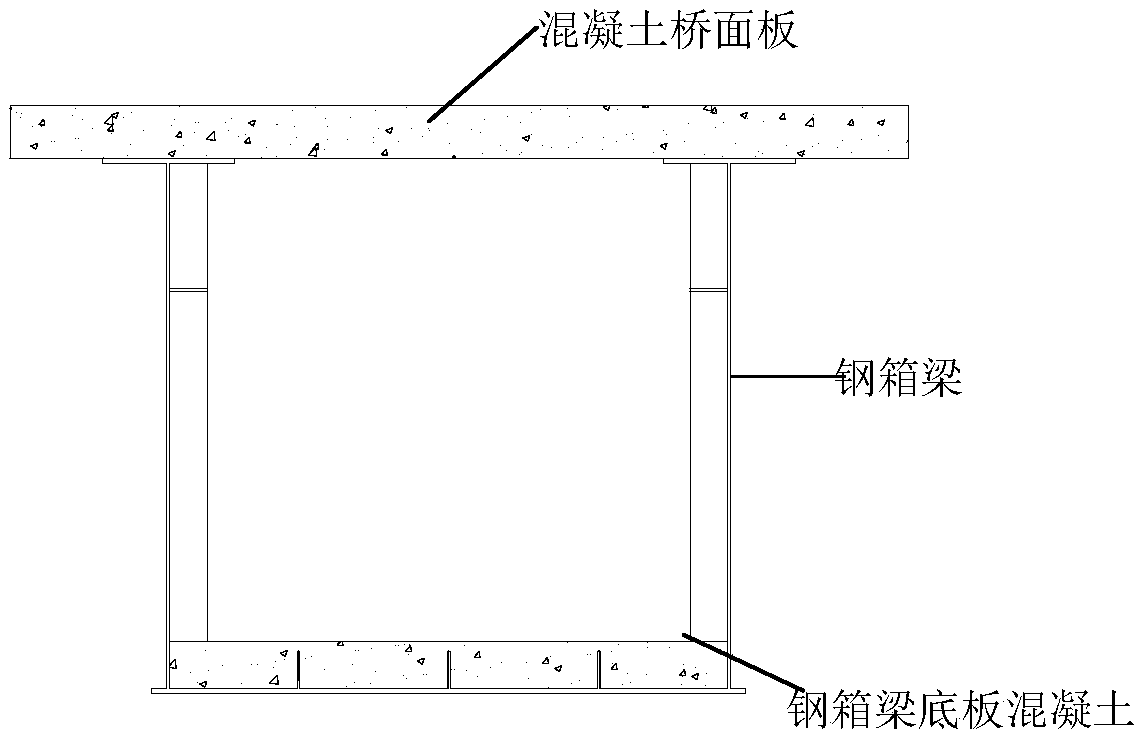

[0015] like figure 1 , figure 2 , image 3 As shown, a method for improving the mechanical performance of the steel-concrete composite multi-box continuous girder bridge in the negative bending moment area; the method is as follows:

[0016] The composite continuous girder bridge is composed of a plurality of horizontally connected separate small box girders, the upper part of each small box girder is a concrete bridge deck, and the lower part is a steel box girder, and the two are connected as a whole by the shear connector of the upper flange of the steel box girder; The whole bridge is equipped with common stress steel and structural steel bars in the concrete deck, and common transverse and longitudinal stiffeners in the steel box girders; the longitudinal stress steel bars of the concrete deck in the negative bending moment area are densified. After pouring the bridge deck and reserving holes, pour concrete on the bottom plate of the steel box girder in the negative mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com