Pneumatic membrane compression bar and manufacturing method thereof

An inflatable membrane and pressure rod technology, applied in the field of rods and airbag-type inflatable membrane pressure rods, can solve the problems of large bearing capacity, insufficient bearing capacity of air beams and air pillows, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiment:

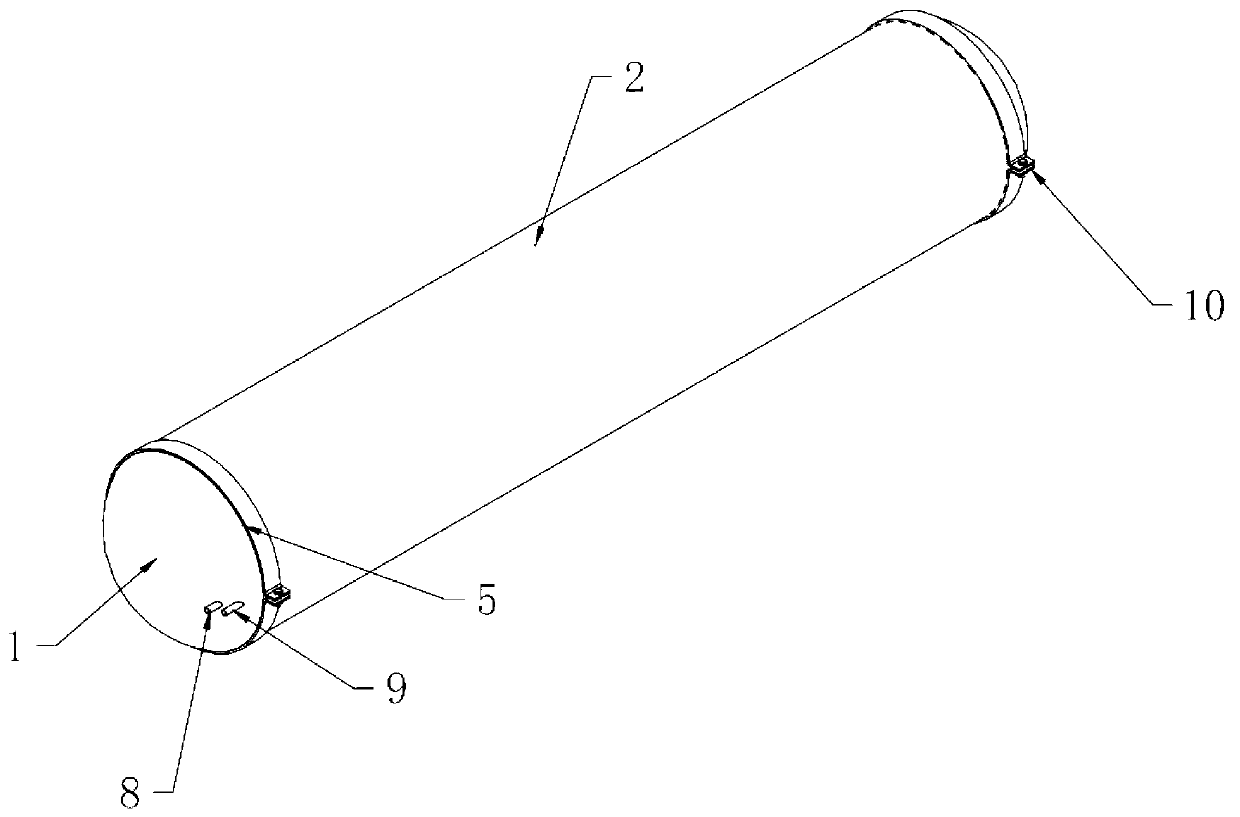

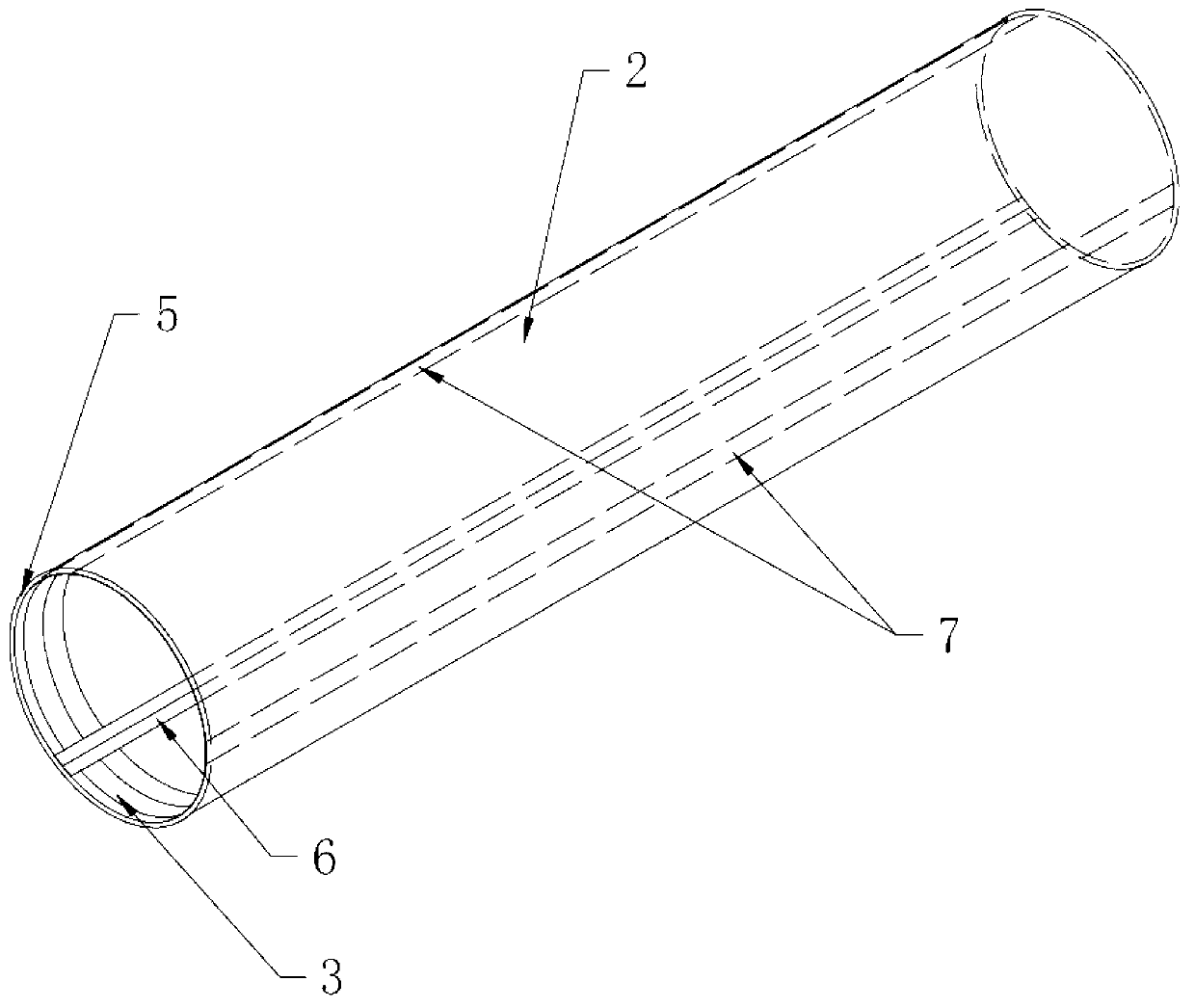

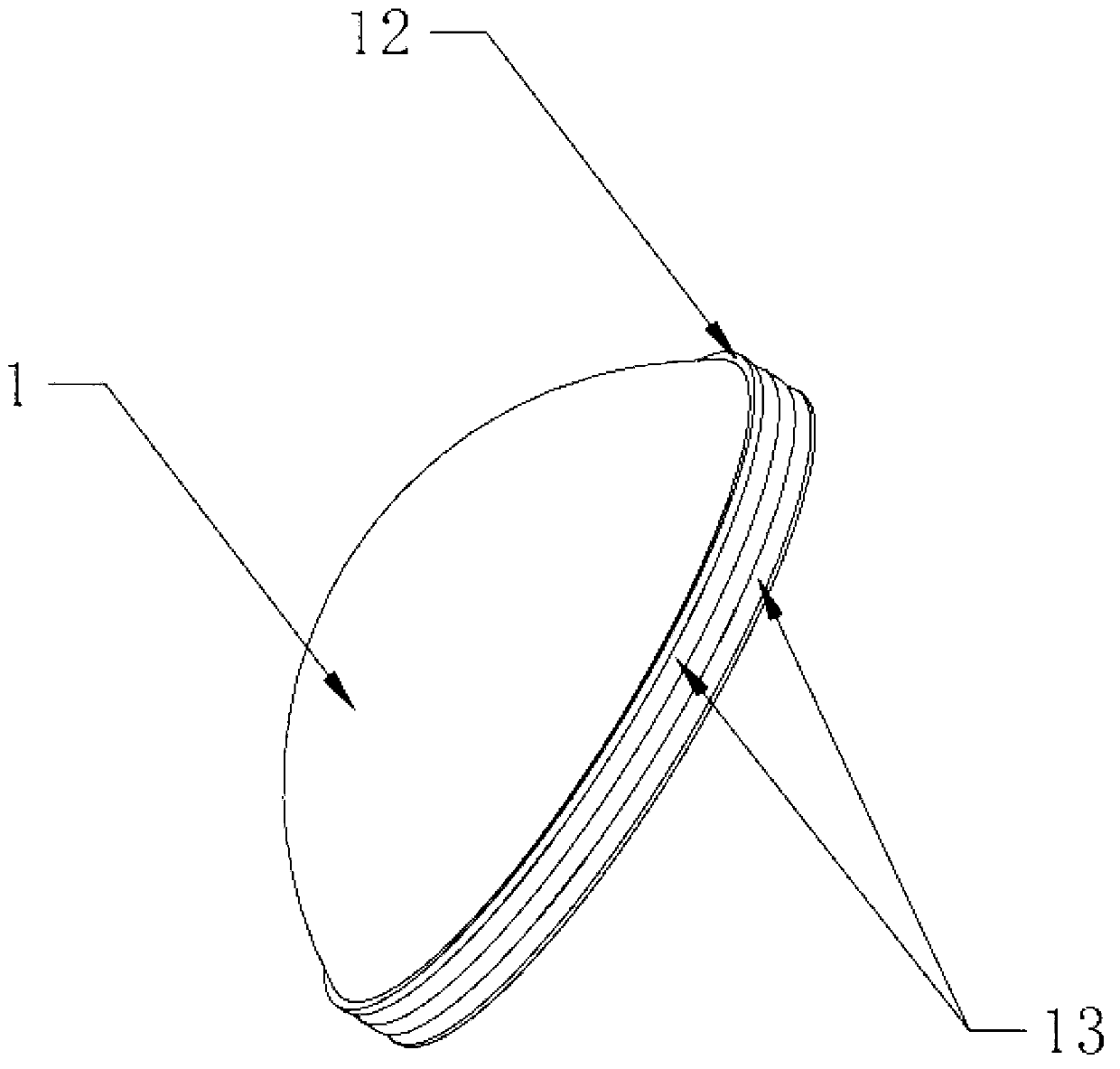

[0029] The structure and construction of inflatable membrane struts, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the production sequence is as follows:

[0030] 1) Cut the membrane material into a rectangle to make the tubular airbag 2, one side of the rectangle is parallel to the meridian direction of the membrane material and used in the circumferential direction of the tubular airbag 2, and the other side is parallel to the weft direction of the membrane material and used in the axial direction of the tubular airbag 2.

[0031] 2) On both sides of the rectangular membrane material, two 150-200mm wide reinforcing membrane materials 3 are arranged along the warp direction by high-frequency welding.

[0032] 3) Two balance ribs 7 are arranged on the inner wall of the membrane material by high-frequency welding.

[0033] 4) The membrane m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com