Integral ballastless track

A ballastless track, integral technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problem that the longitudinal end of the track slab is prone to warping, the stability of train running, the comfort of the track structure, the impact of the life of the track structure, and the filling layer. Cracking and other problems, to achieve the effect of reducing maintenance, uniform track stiffness, and increasing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

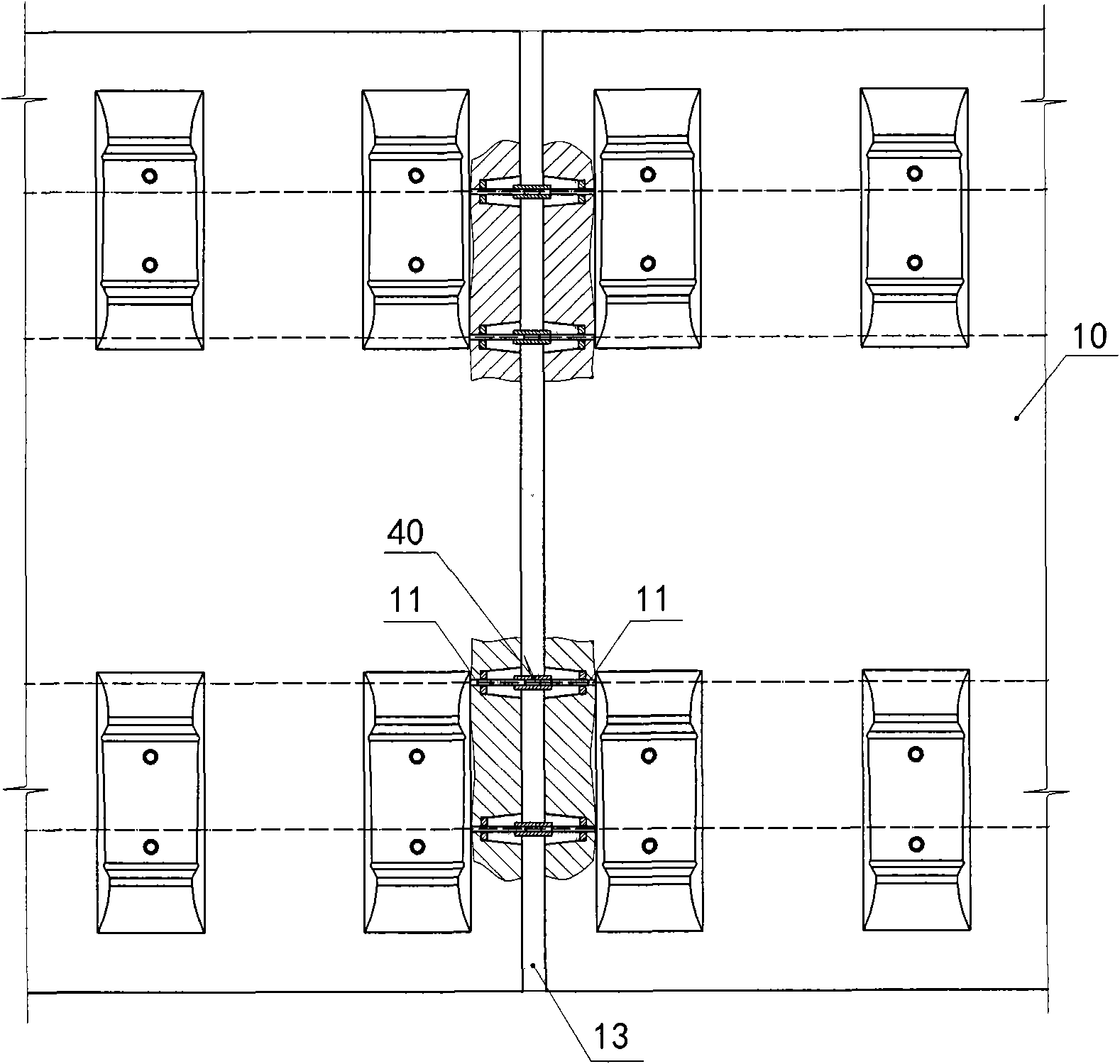

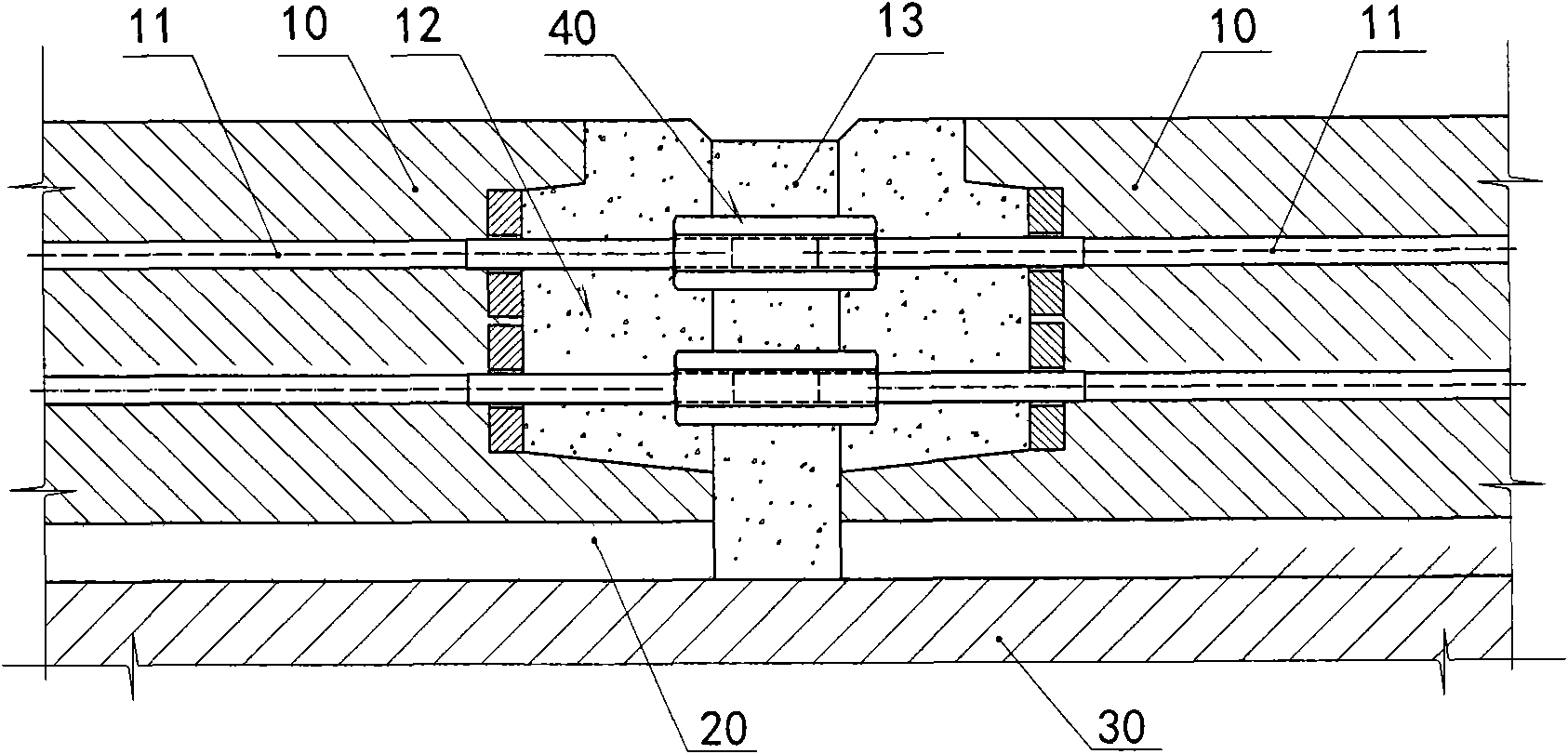

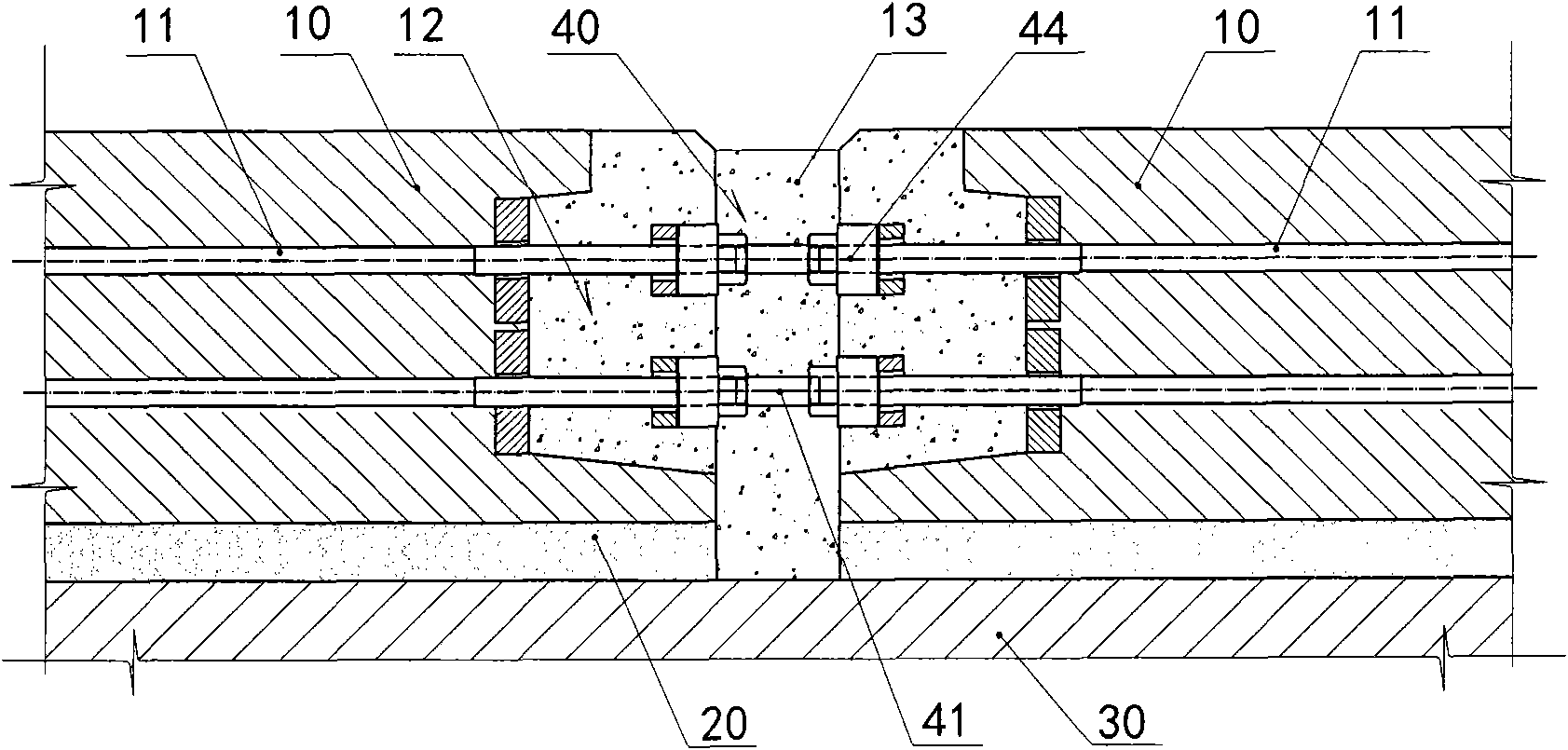

[0016] refer to figure 1 , figure 2 and image 3 The integrated ballastless track of the present invention includes a track plate 10, an adjustment layer 20 and a support layer 30. The track plate 10 is laid on the adjustment layer 20 along the line extension direction, and each track plate 10 is arranged with multiple groups of prestressed steel plates at intervals in the horizontal direction. The rod 11 is provided with a filling layer 13 between the gaps between two adjacent track plates 10 . Different from the existing ballastless track, the prestressed steel rods 11 corresponding to the track slab 10 are longitudinally connected and prestressed in sections to form an integral track slab. The integrated track slab improves the integrity of the track, and the track rigidity is uniform, which can effectively meet the requirements of the ballastles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com