Automatic flattening process parameter optimization of metal plate band

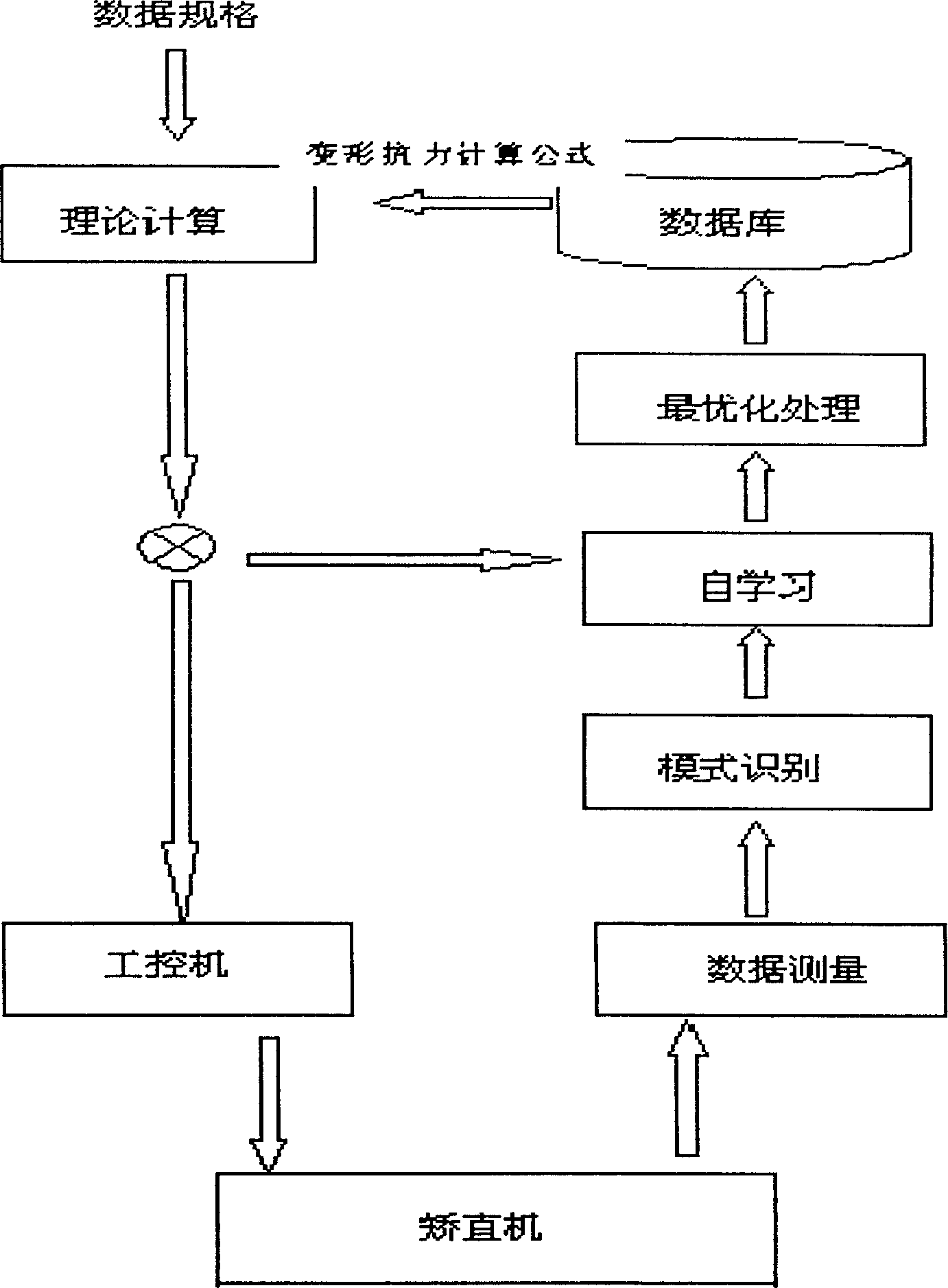

A technology of process parameters and metal strips, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of product flatness that cannot meet the requirements, deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

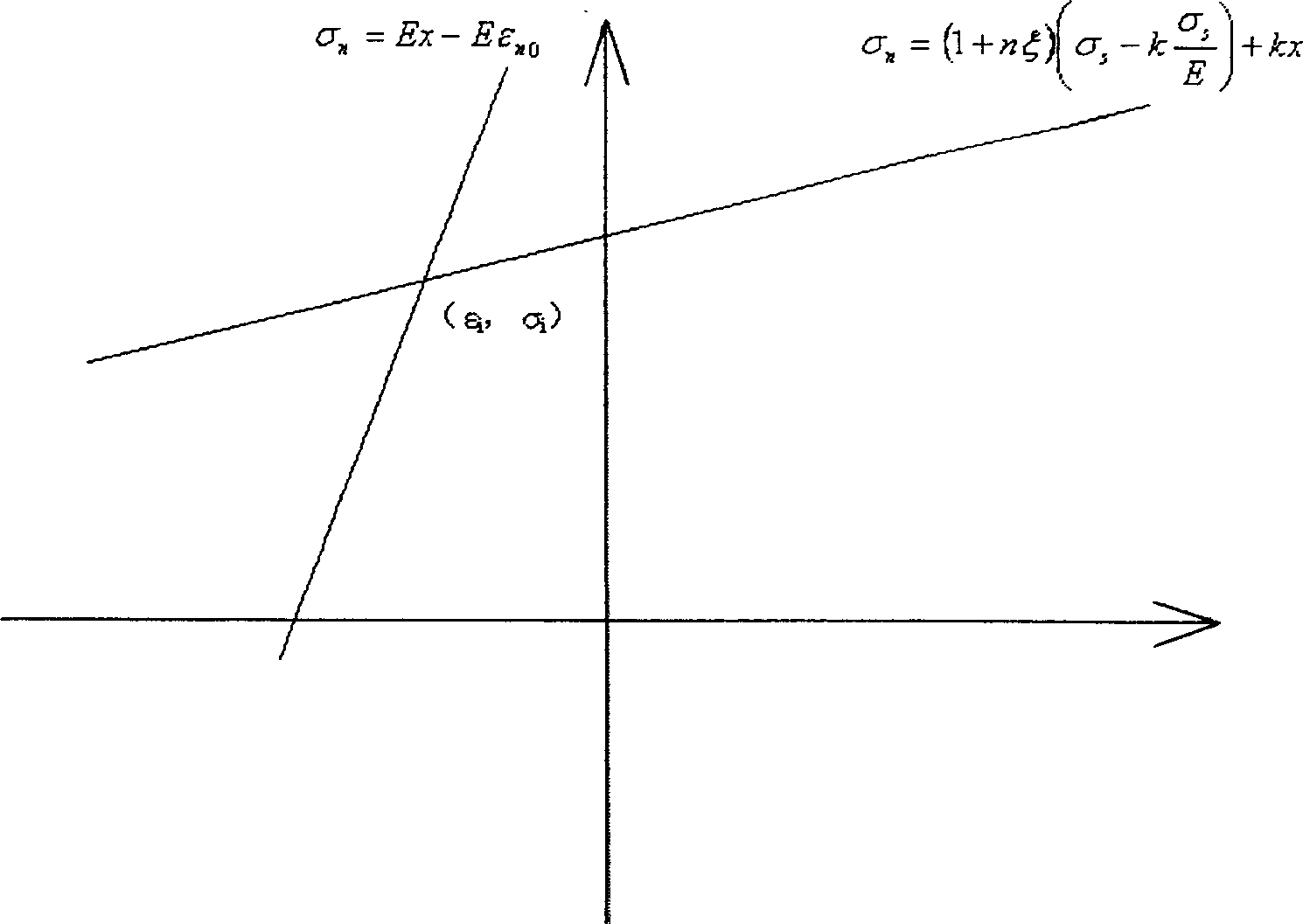

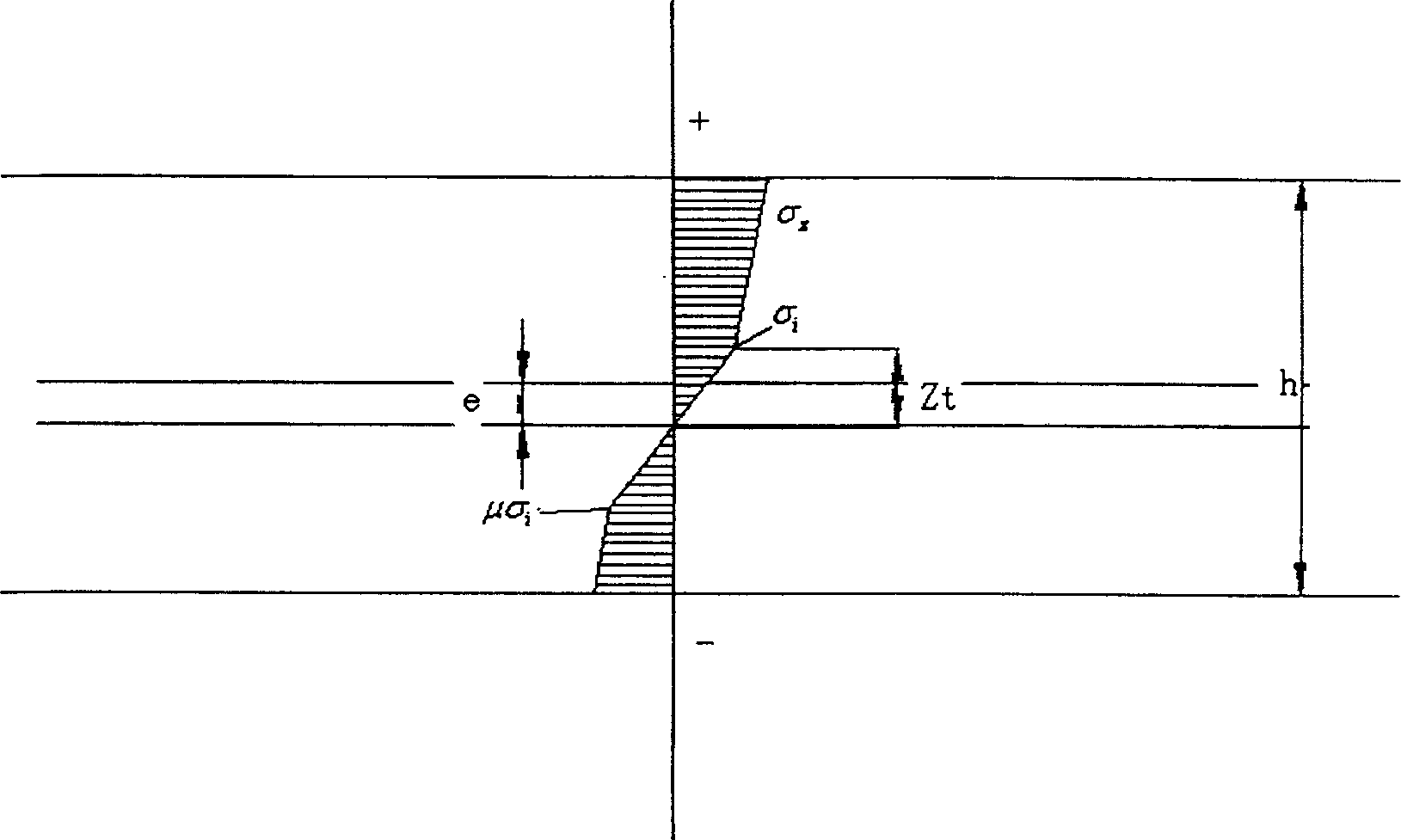

Method used

Image

Examples

Embodiment Construction

[0130] This embodiment is used to illustrate the present invention, but not to limit the present invention.

[0131] The method described in the present invention has been successfully applied to the 3500mm medium plate straightening machine of Shougang Medium Plate Plant. The difference between the average value of the measured straightening force and the calculated value is less than ±5%, and the residual curvature of the product is less than the specified requirement.

[0132] Take steel type 345D as an example, with a thickness of 60mm, a width of 2350mm, and a processing temperature of 681°C. Theoretical setting value of the straightening machine: the entrance roll gap is 59.01mm (the thickness of the sheet minus the reduction of the second straightening roller), the exit roll gap is 59.21mm (the thickness of the sheet minus the penultimate straightening roller), and the theoretical straightening The force calculation P=7336KN, the straightening force measured by the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com