Knitted fabric straightening device for textile mill

A technology for textile mills and fabrics, applied in the field of knitted fabric straightening devices, can solve problems such as reducing the efficiency and quality of straightening, and achieve the effects of improving efficiency, high efficiency, and improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

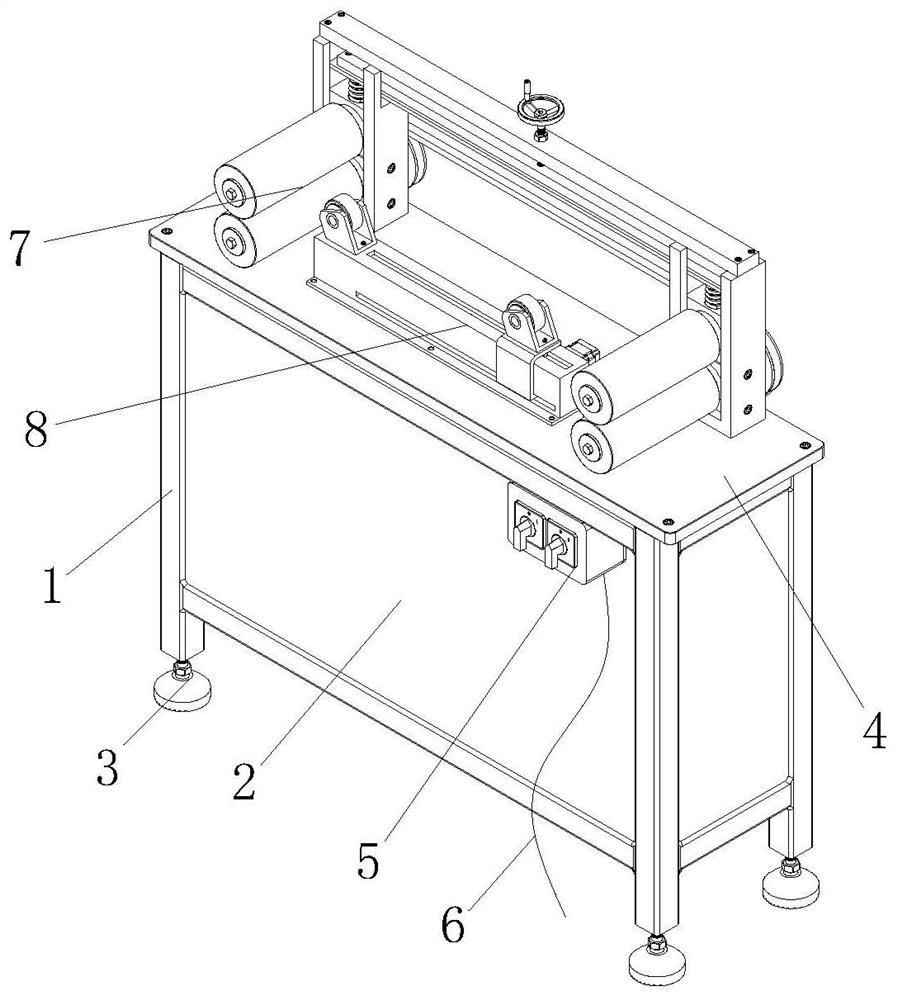

[0032] see figure 1As shown, the present invention provides a knitted fabric straightening device for textile mills through improvement, including support legs 1, cabinet 2, feet 3, workbench 4, controller 5, power cord 6, two-way straightening device 7 and an auxiliary pushing device 8, an organic case 2 is installed between the supporting legs 1, a foot 3 is installed at the bottom of the supporting leg 1 for supporting the ground, and a workbench 4 is installed on the upper end of the supporting leg 1 for straightening the working platform , a controller 5 is arranged on the right side of the front end of the chassis 2, which is used to control the opening and closing of the motor. The bottom of the controller 5 is connected to a power cord 6, which is used to connect with an external power supply to power the device. The two-way straightening device 7 is installed On both sides of the upper end of the workbench 4 and inside the cabinet 2 , an auxiliary pushing device 8 is ...

Embodiment 2

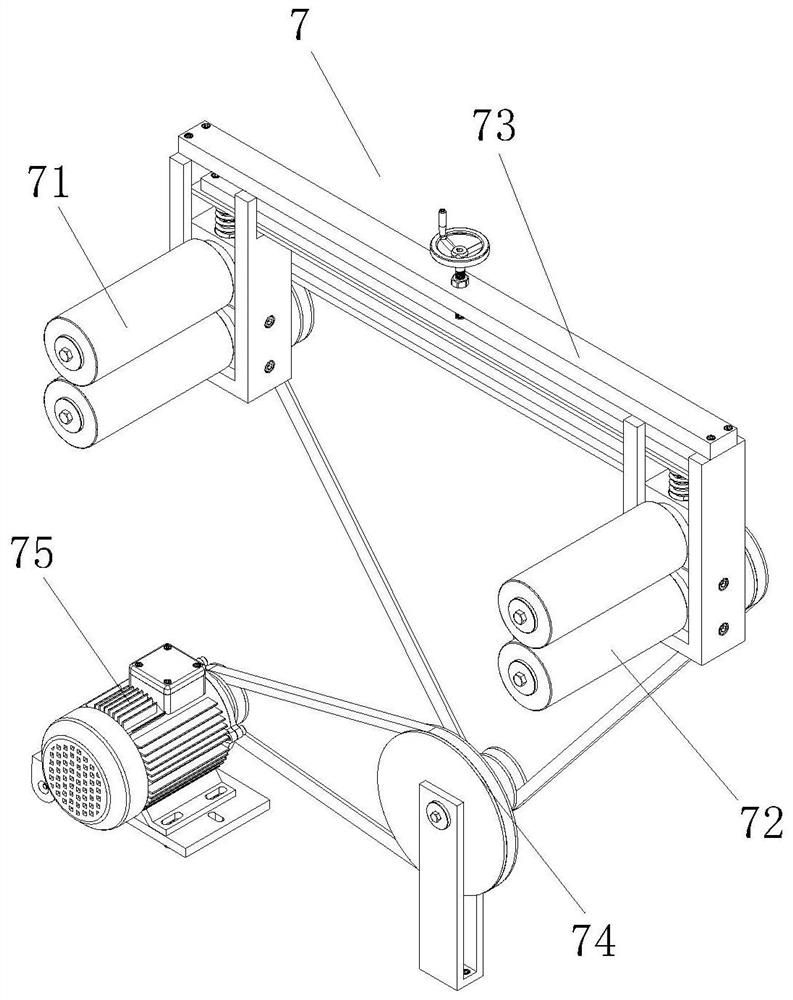

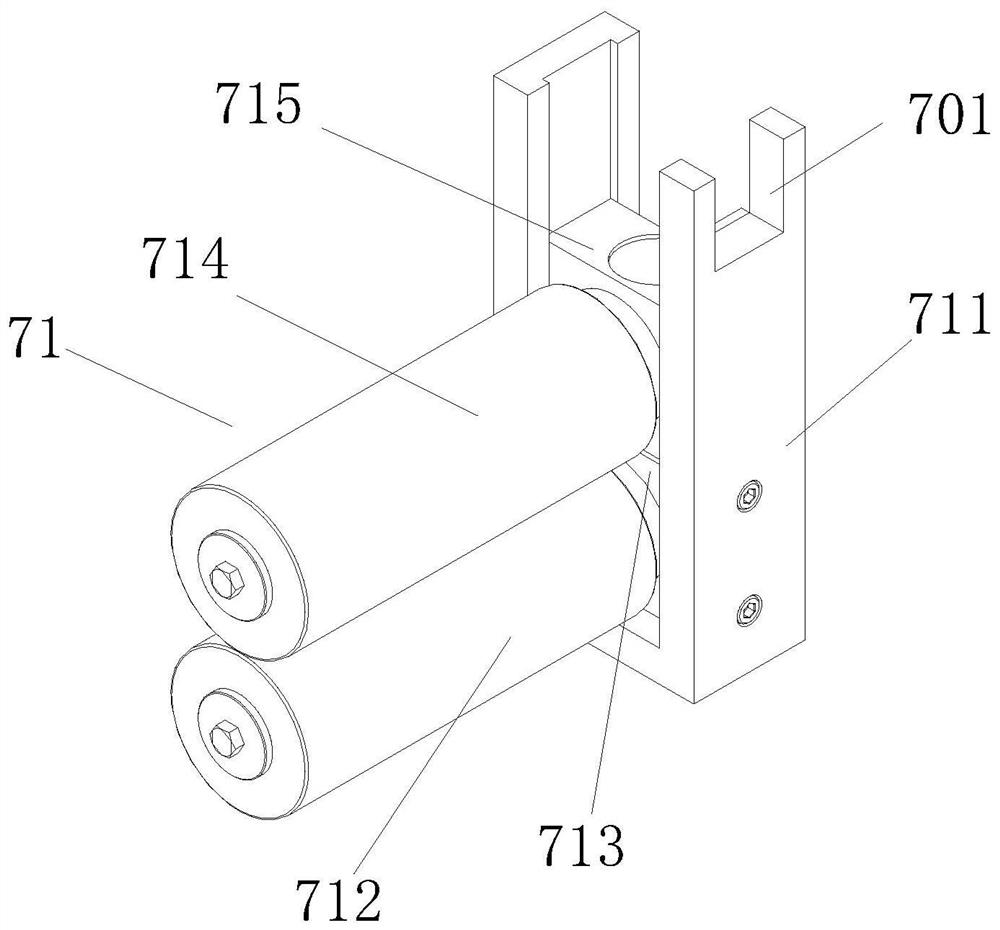

[0040] The present invention provides a kind of straightening device for knitted fabrics used in textile mills through improvement. The first push wheel 82 and the second push wheel 84 are arranged parallel to each other, so that the cloth is kept parallel when auxiliary pushing, and the lower straight roller 712 is aligned with the upper Straightening rollers 714 are arranged symmetrically up and down, which is convenient for straightening the cloth. The shaft bar at the rear end of the pull-down straight roller 712 passes through the fixed block 713 and connects with the synchronous transmission mechanism 74, so that the pull-down straight roller 712 can be driven after the synchronous transmission mechanism 74 is driven. Rotate, the first spring 736 joins with the middle part of the upper end of the movable block 715 in the left straightening mechanism 71, the second spring 737 joins with the middle part of the upper end of the movable block 715 in the right straightening mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com