Feeding and discharging device of pipe straightener

A technology for straightening machines and steel pipes, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as failure to meet normal production requirements, high labor intensity of manual stacking, and failure of straightening output by straightening machines. Avoid damage such as friction and collision, improve production efficiency, and improve the effect of straightening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

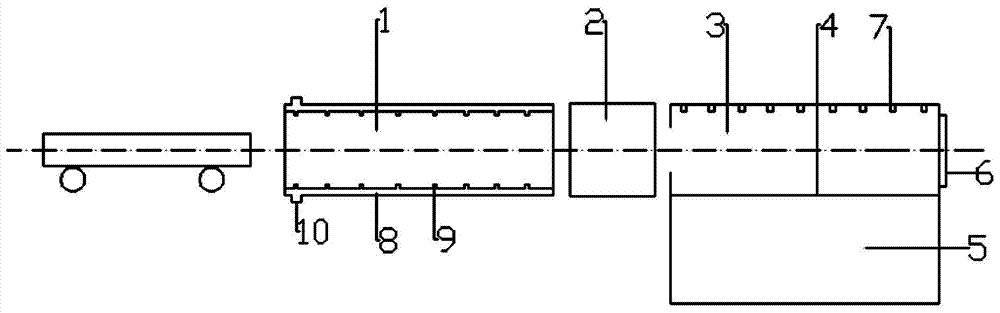

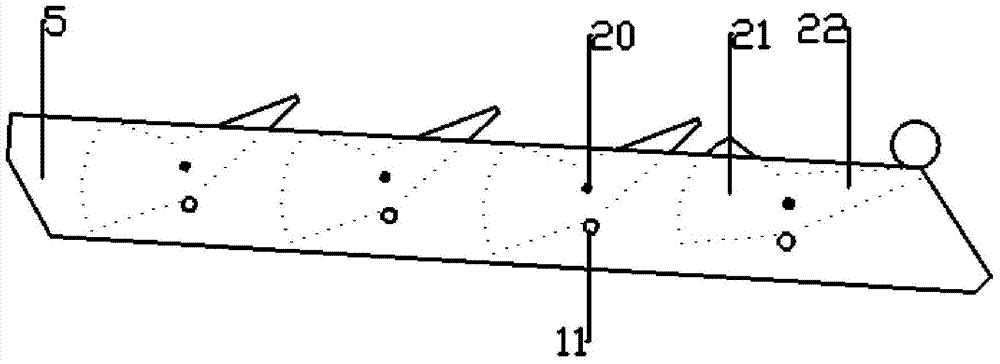

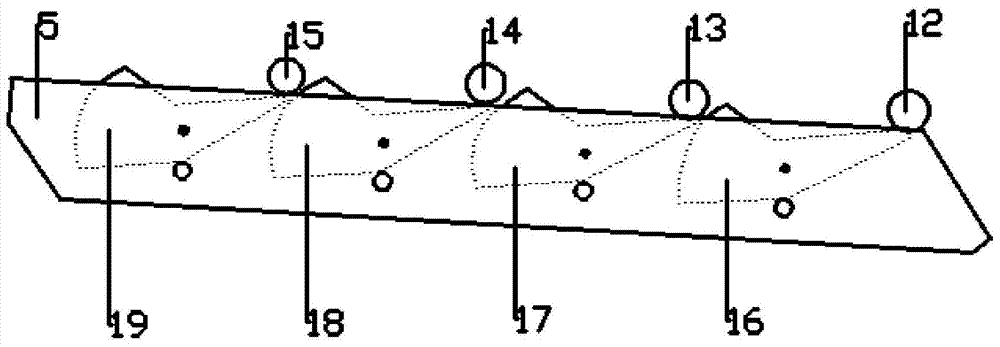

[0020] Such as figure 1 As shown, a loading and unloading device for a steel pipe straightening machine includes an inlet guide cylinder 1, a straightener 2, an upper outlet guide cylinder 3, an output roller table 4, and a stand 5, and the inlet guide cylinder 1 is located at the The front end of the straightening machine 2, the upper and lower inner walls are connected with spray water drains; the upper outlet guide cylinder 3 and the output roller table 4 are located at the rear end of the straightening machine 2, and the upper The rear end of the outlet guide cylinder 3 and the output roller table 4 is provided with a baffle plate 6; the described stand 5 is located at the lower end of the output roller table 4; the upper outlet guide cylinder 3 is located at the The upper end of output roller table 4, its inner wall is provided with more than one air blower 7.

[0021] Further, the spray water row includes a guide tube 8, a spray port 9, and a return port 10, and the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com