Adjustable bent steel strip straightening machine

A straightening machine, adjustable technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve problems affecting production efficiency, troublesome operation, waste of manpower and material resources, etc., to improve the quality of straightening, product quality, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

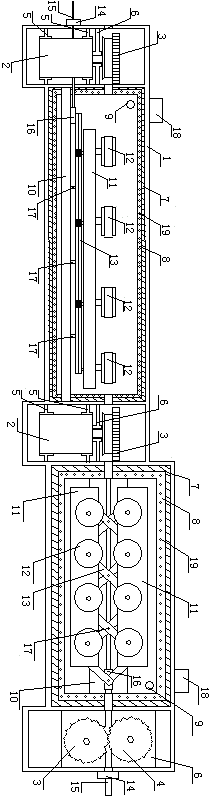

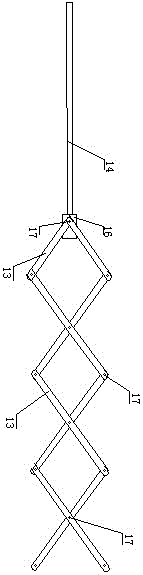

[0012] Such as figure 1 and figure 2 As shown, the adjustable curved steel bar straightening machine of the present invention includes a steel bar conveying system and a curved straightening system. The steel strip conveying system includes two horizontal conveying units and a longitudinal conveying unit, and the curved straightening system includes a transverse straightening unit and a longitudinal straightening unit. Straightening unit, unit connection sequence from left to right is horizontal conveying unit, horizontal straightening unit, horizontal conveying unit, longitudinal straightening unit and longitudinal conveying unit; horizontal conveying unit includes casing 1, motor 2, motor fixing plate 5, ratchet fixing plate 6. The active ratchet 3 and the driven ratchet 4, the lateral conveying unit is a cube wrapped by the casing 1, the motor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com