Straightening machine with a modular interchangeable casette system

A straightening machine and replacement box technology, which is applied in the field of straightening machines, can solve problems such as lack of flexibility in production conditions, and achieve the effects of improving straightening quality, better matching possibilities, and expanding the straightening range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

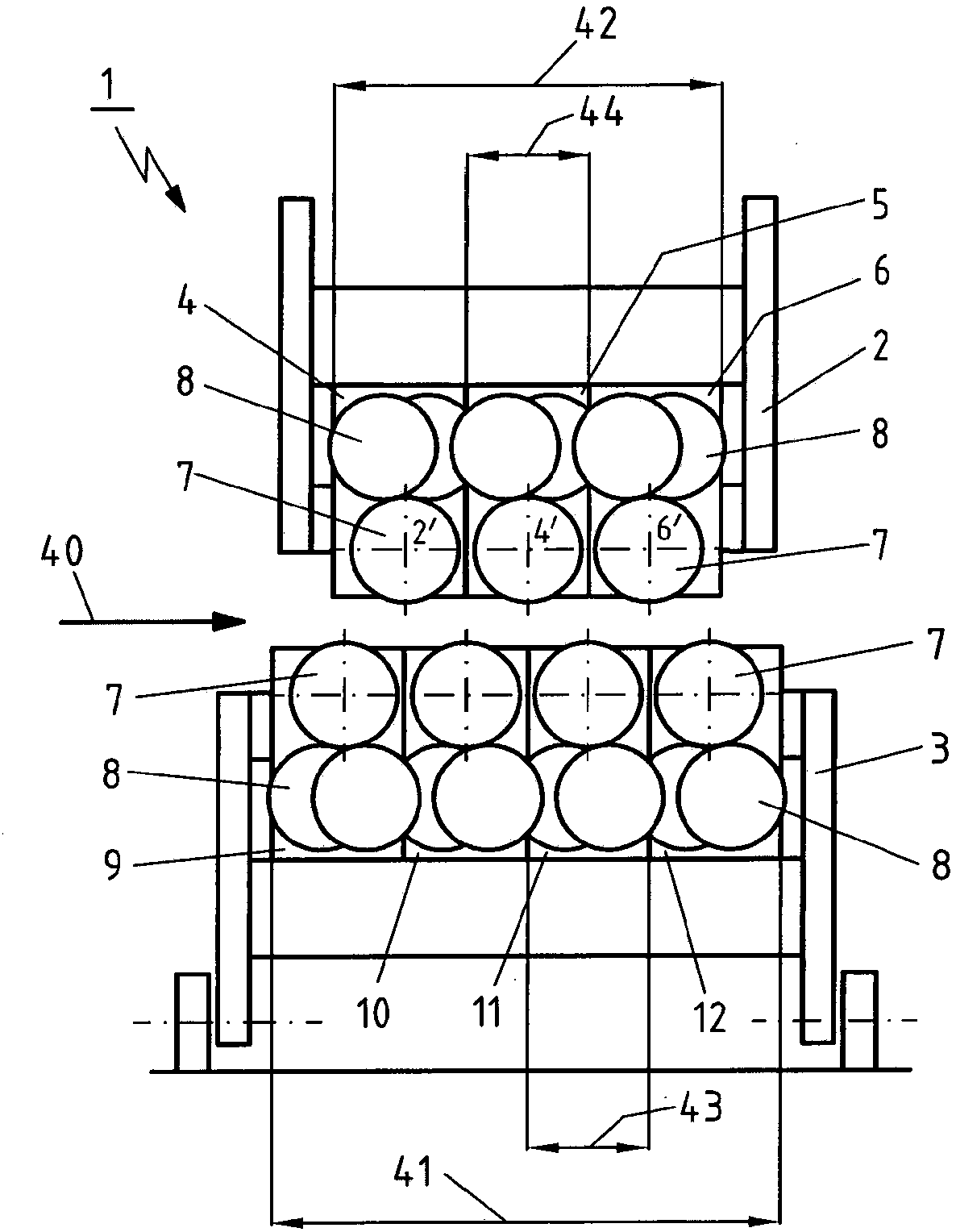

[0038] figure 1 Shown is a straightening machine denoted overall at 1 , comprising an upper support frame 2 and a lower support frame 3 . Arranged in the upper support frame 2 are three straightening roller sections 4 , 5 and 6 which are modularly coordinated with each other and are each configured in the form of exchangeable replacement cassettes. The ensemble of 7 and support rollers 8 is divided into straightening roller segments 4 , 5 and 6 . The three modular straightening roller segments 4 , 5 , 6 are designed uniformly in this exemplary embodiment and each have not only the same number of straightening rollers 7 and support rollers 8 but also the same diameter of straightening rollers 7 and support rollers 8 . Straightening rollers 2 ′ are arranged in the modular straightening roller section 4 , straightening rollers 4 ′ are arranged in the straightening roller section 5 and straightening rollers 6 ′ are arranged in the straightening roller section 6 .

[0039] Arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com