Hydraulic straightening platform

A technology of hydraulic pressure and section steel, which is applied in the field of devices for stacking and aligning multi-layer workpieces. It can solve the problems of low alignment accuracy, high labor intensity, and impracticability, and achieve high alignment efficiency, high alignment accuracy, and Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

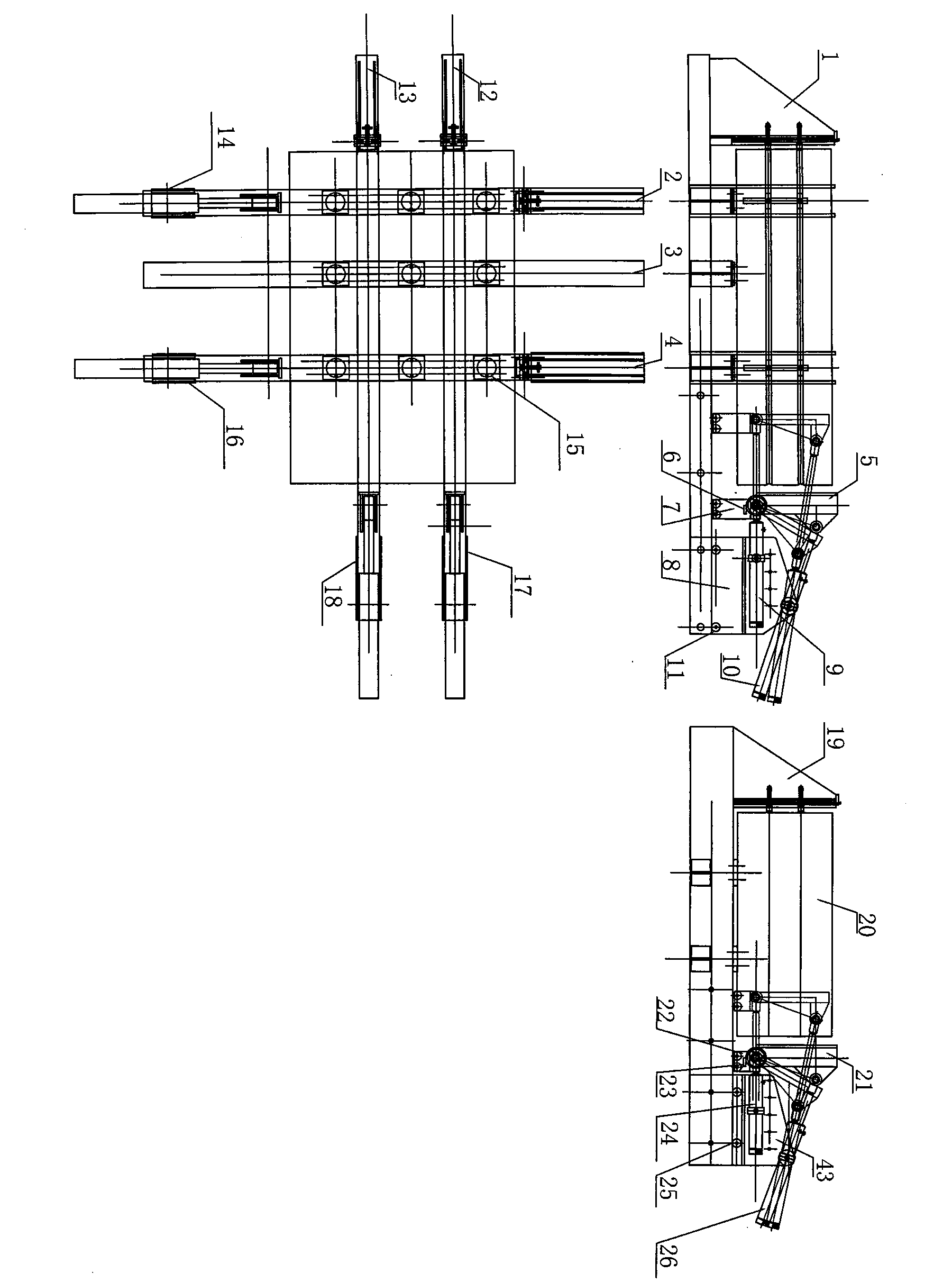

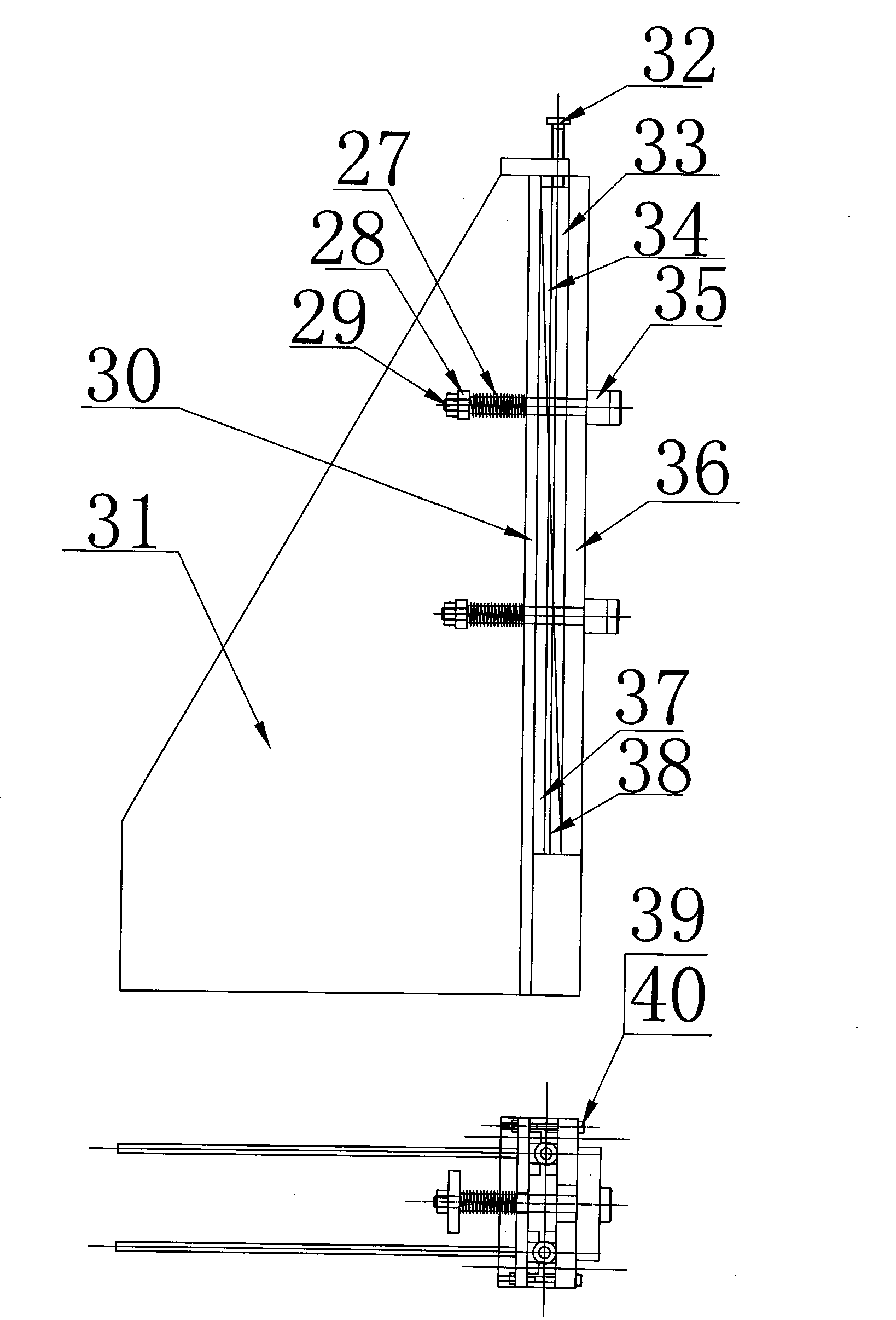

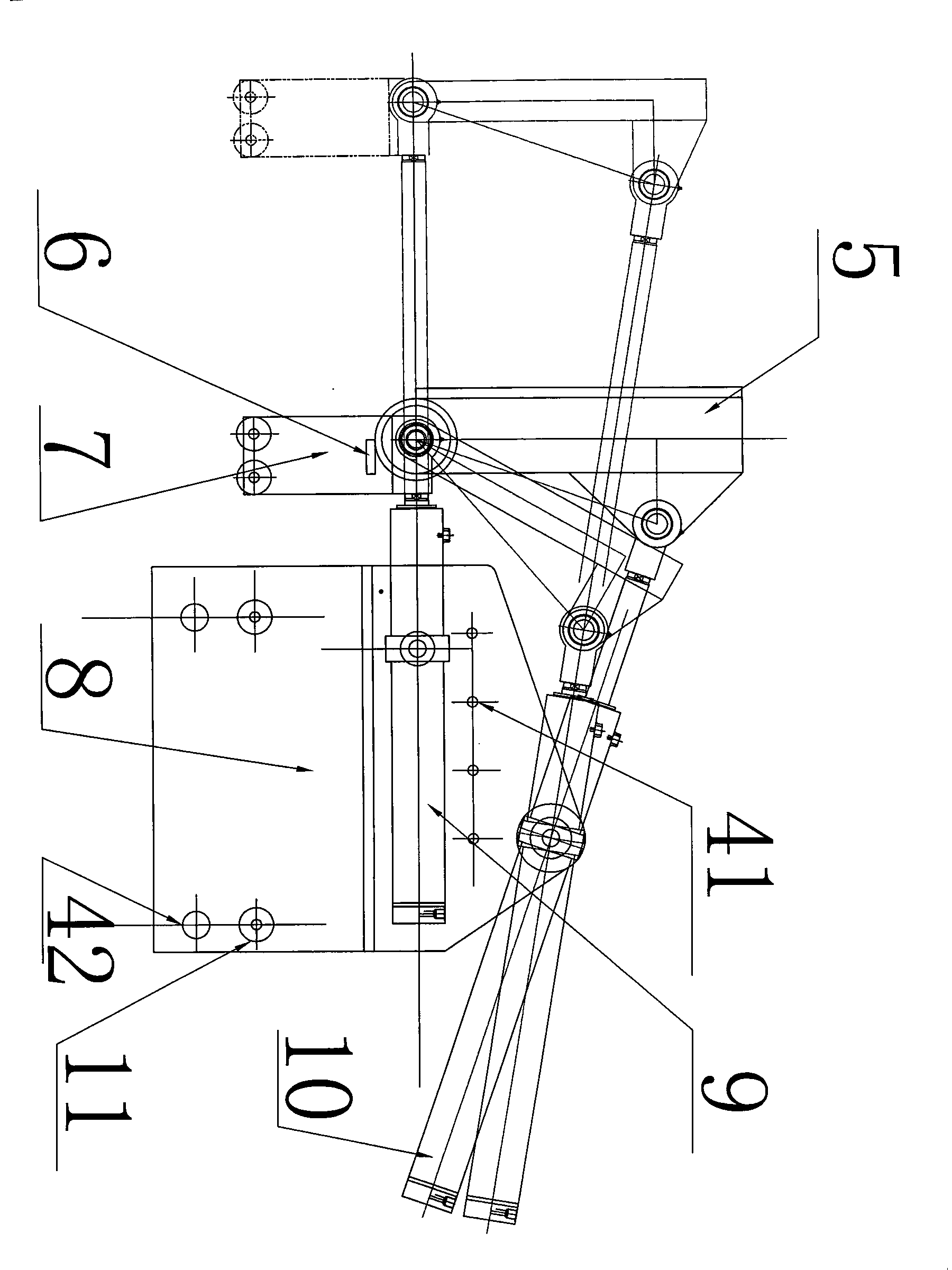

[0011] exist figure 1 According to the size of the workpiece and the stroke of the oil cylinder, adjust the positions of the vertically movable straightening end seat 8 and the horizontally movable straightening end seat 43; The movable top 35 is pushed out from the T-shaped slot, and after being rotated 90°, the upper and lower positions are adjusted, and then the workpiece is placed on the adjusted wear-resistant plate 15. position, and then push out the horizontal oblique cylinder 26, and straighten the upper workpiece 20 to the design position. At this time, the horizontal straight cylinder 24 and the horizontal oblique cylinder 26 will automatically abdicate by 3-8 mm, and can also be manually abdicated; the vertical straight cylinder 9 Push out, straighten the bottom workpiece 20 to the design position, then push out the longitudinal oblique cylinder 10, and straighten the upper workpiece 20, at this time, push out the longitudinal, horizontal straight cylinder and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com