Construction method for embedding wall pipeline

A construction method and wall technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of pipeline displacement, difficulty in ensuring the accuracy of pipeline pre-embedded positions, and inability to ensure accurate pre-embedded pipelines, etc. problem, to achieve the effect that is conducive to position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is further described in detail through specific implementation methods:

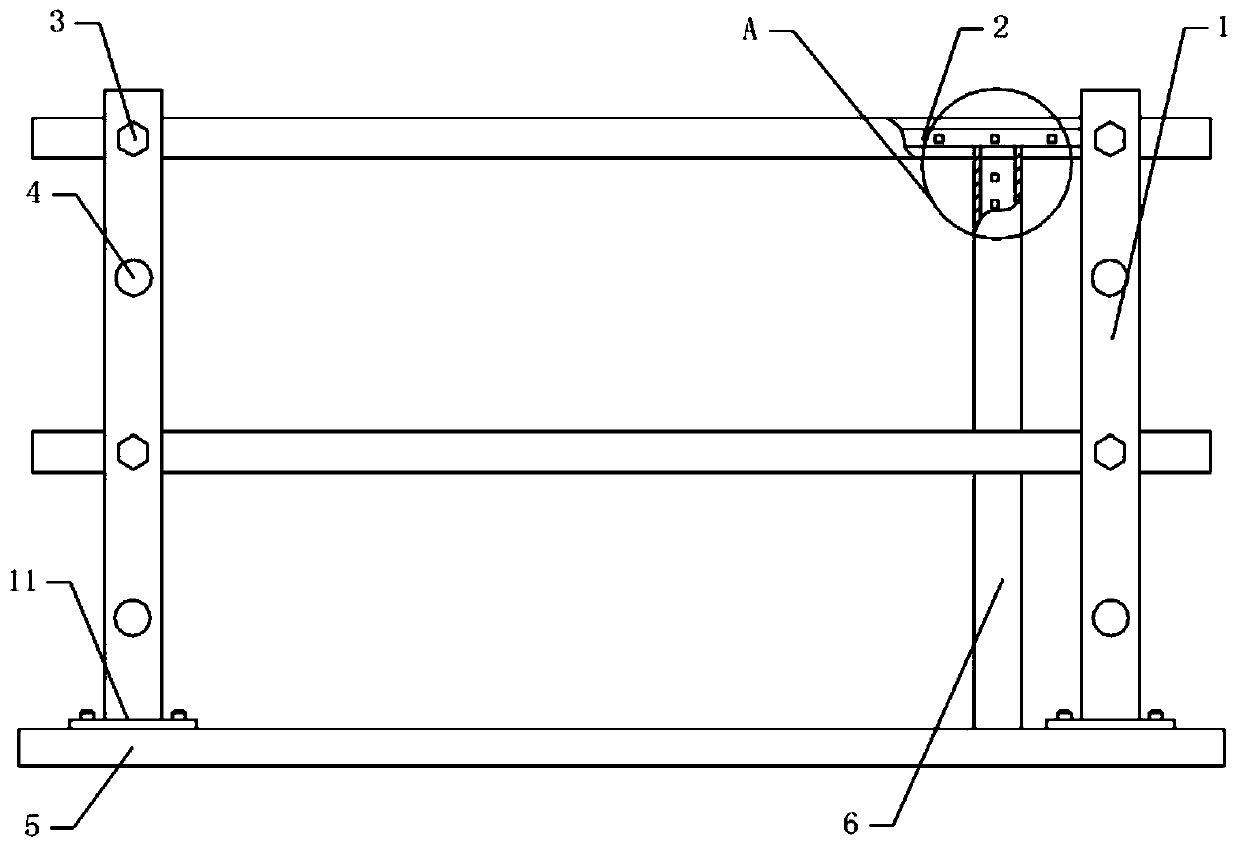

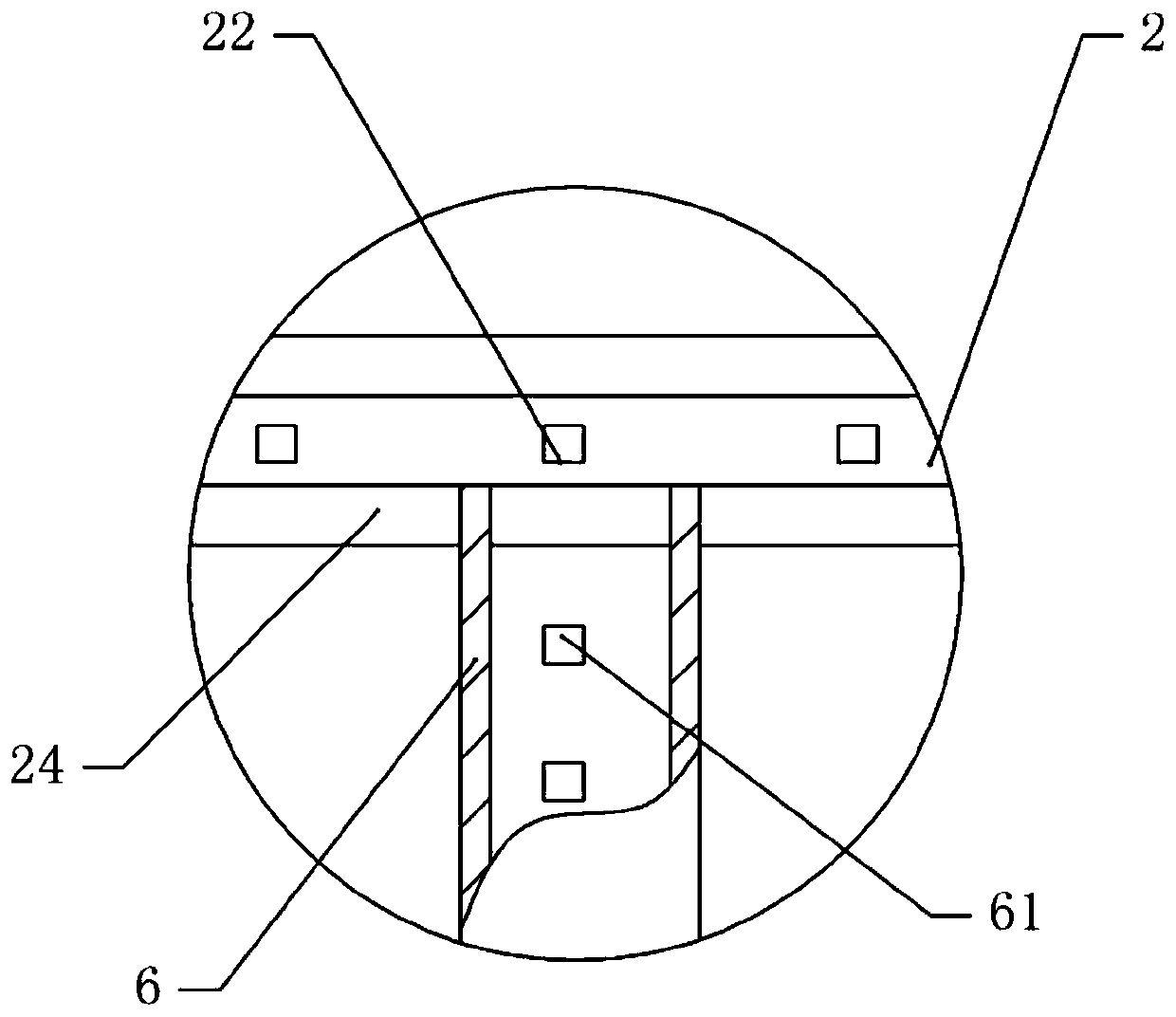

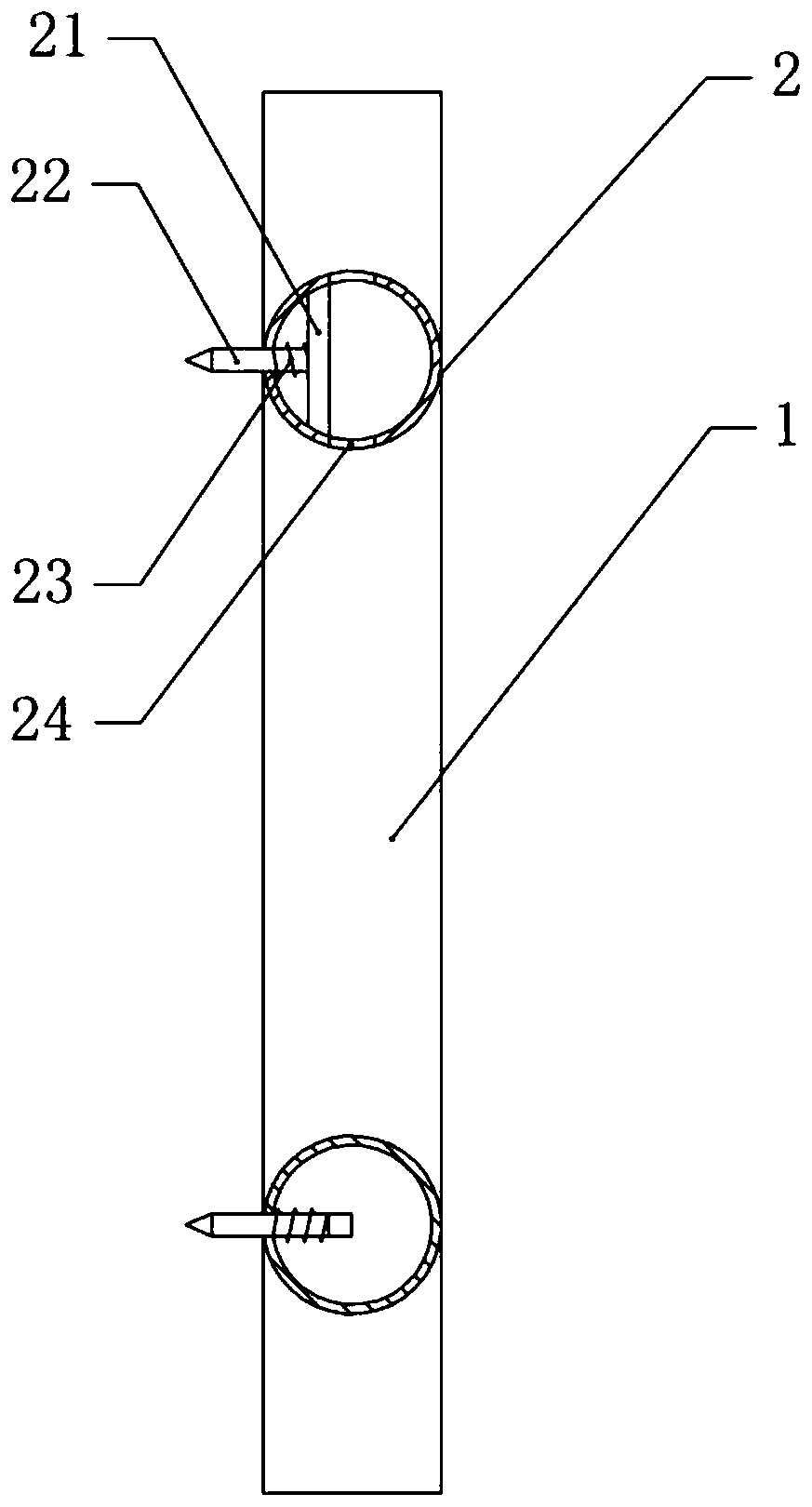

[0035] The reference signs in the drawings of the description include: support frame 1, sliding seat 11, horizontal tube 2, positioning plate 21, positioning nail 22, spring 23, sliding groove 24, fastening bolt 3, positioning hole 4, mounting seat 5, Standpipe 6, perforated nail 61, back-moving spring 62.

[0036] A construction method for pre-embedded wall pipes, comprising the following steps:

[0037] S1: Prepare as attached figure 1 And attached figure 2 As shown in the installation seat 5, the length of the installation seat 5 is equal to the length of the wall, and the installation seat 5 is against the wall.

[0038] S2: At least two support frames 1 are installed on the mounting base 5. Specifically, the bottom of the support frame 1 is welded with a sliding base 11. The bottom of the sliding base 11 is provided with a slider, and the mounting base 5 is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com