Planetary web roll rotating hub type flattening machine

A planetary inclined roller and straightening machine technology, which is applied in the field of straightening machines for ultra-long thin-walled metal pipes, can solve problems such as danger, flattening of pipes, and difficulty in eliminating torque with rotation, and achieve improved contact and bending conditions, Improve straightness and facilitate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

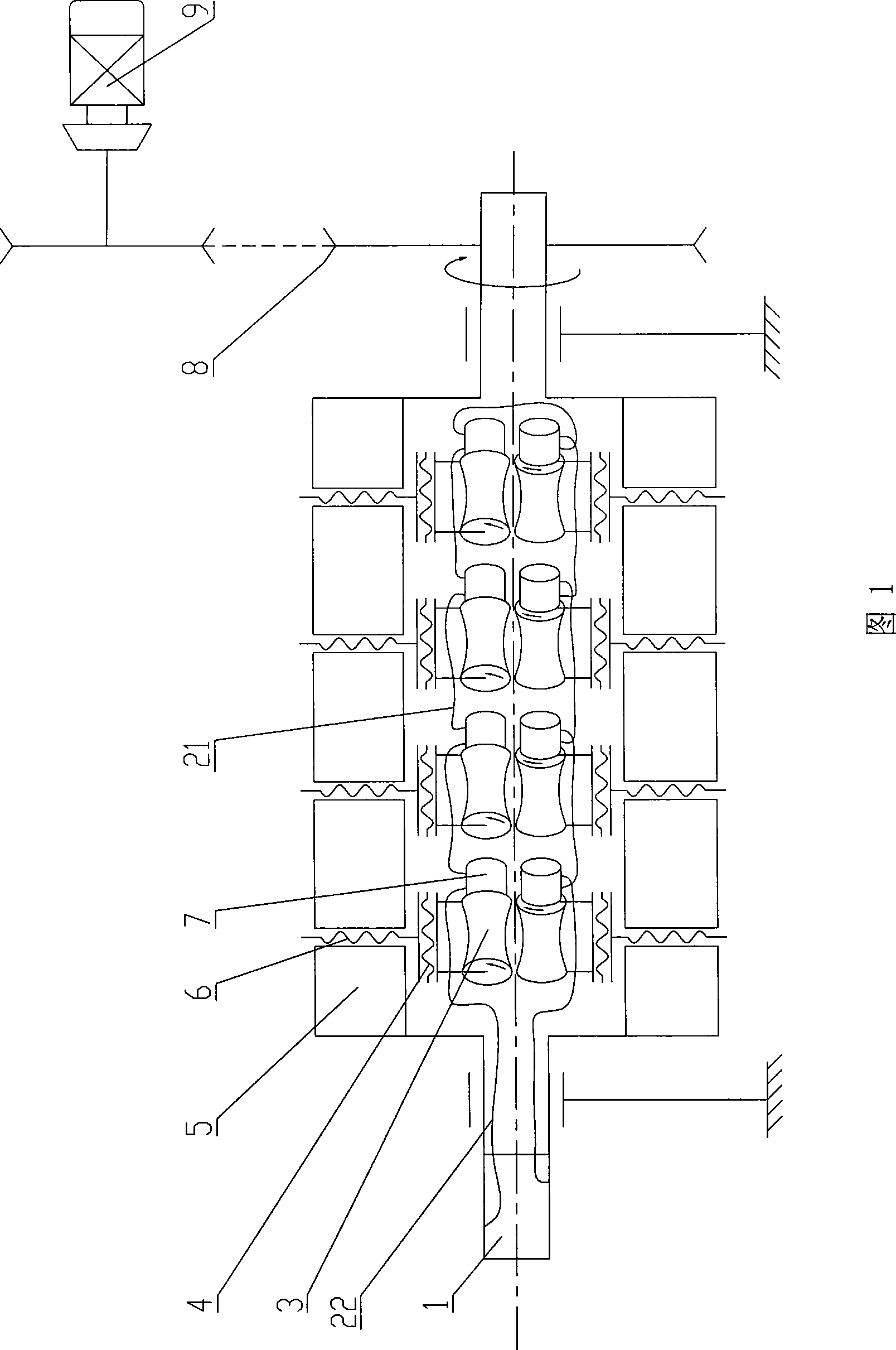

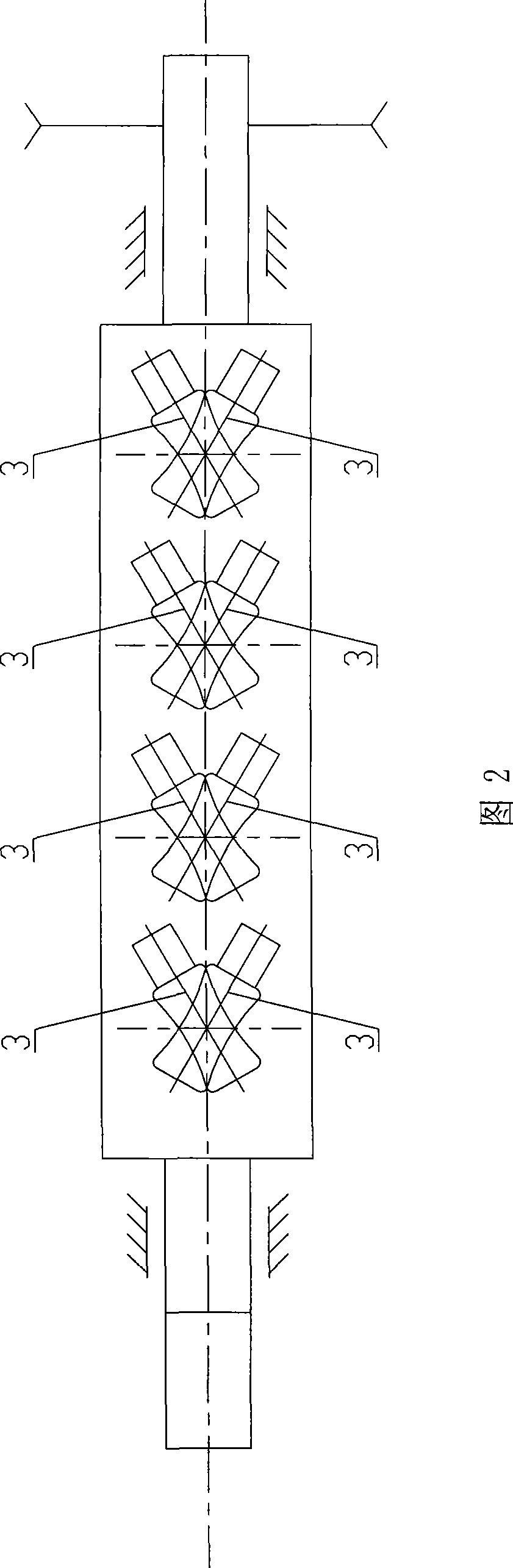

[0011] As shown in Figures 1 to 2, the planetary skewed roller hub-type round material straightening machine of the present invention adopts a straightening method in which the rotating hub 5 rotates and the straightening roller 3 rotates while the round material to be straightened does not rotate, including the rotating hub 5 and the first power drive device that drives the rotating hub 5 to rotate, at least two groups of straightening rollers 3 installed in the rotating hub 5 and the second power driving device that drives each straightening roller 3 to rotate, wherein each group of straightening rollers 3 The upper and lower straightening rollers are symmetrically arranged on both sides of the rotation axis, and each straightening roller 3 is inclined at a certain angle relative to the rotation axis. Wherein, the above-mentioned first power drive device is composed of a motor 9 and a pulley 8 . The above-mentioned second power drive device includes a plurality of hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com