Alignment device of out shaft of rotor axis of electric engine

A motor rotor shaft and straightening device technology, applied in the field of measurement, can solve the problems of instruments and control systems without automatic measurement, lack of adjustment of the position of the workpiece to be measured, and affect the stability of straightening accuracy, etc., to achieve simple structure and fast speed , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

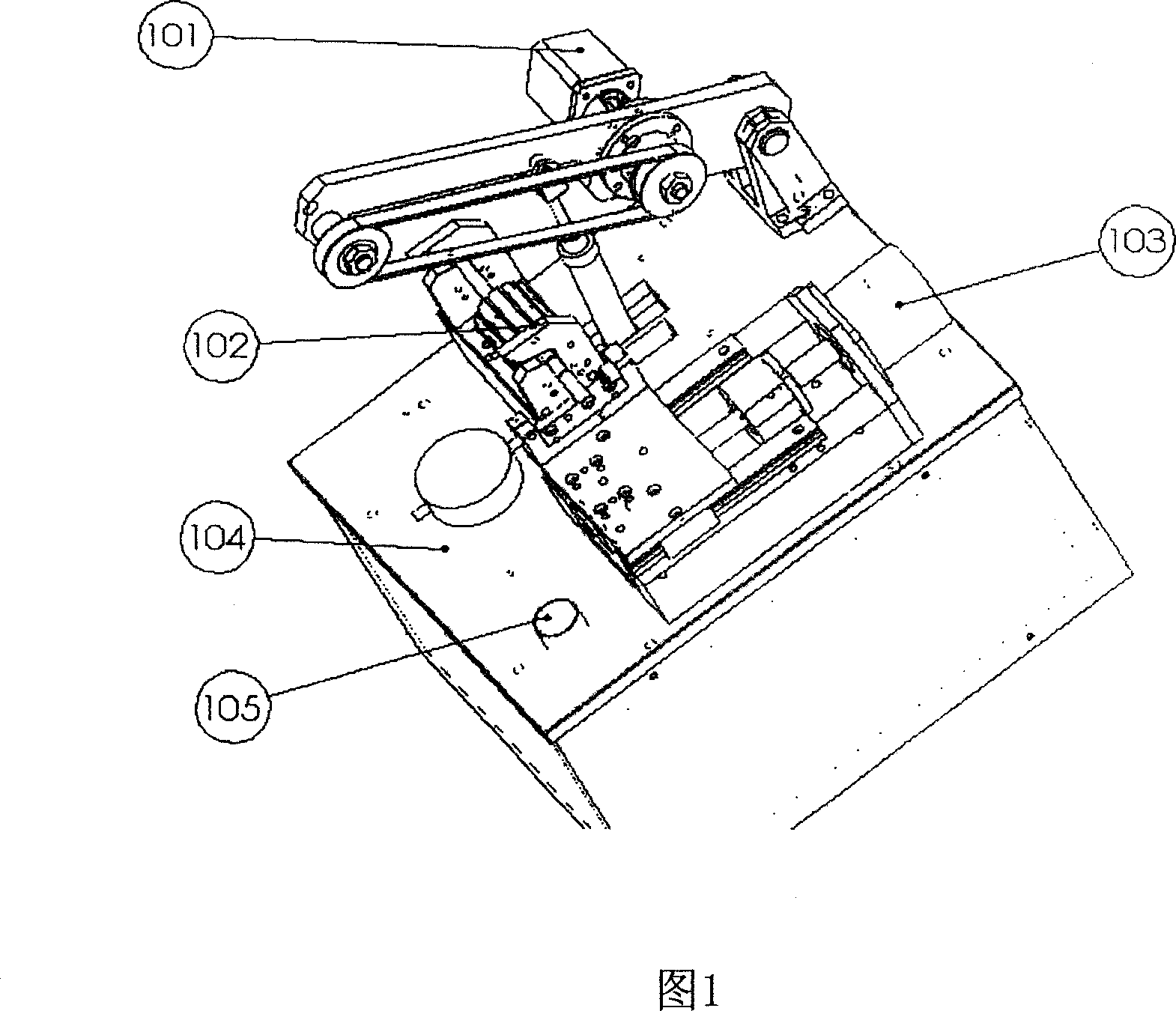

[0011] Fig. 1 is the structural diagram of the motor rotor shaft output shaft end straightening device of the present invention, comprising: a base plate 104, on which a roller driving device 101 is arranged for driving the motor rotor to be tested; the lower left side of the roller driving device 101 A finale detection fixture device 102 is provided for positioning and detecting the rotor of the motor to be tested; a straightening platform device 103 is provided on the front of the bottom plate 104 for realizing straightening and correction of workpieces; in the box under the bottom plate 104, install There are drivers and data communication devices for each motor, these drivers and data communication devices are connected with a computer and controlled by it; and process the data from the finale detection fixture device 102 to control the alignment of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com