Method and tool for straightening bending deformation of crankshaft

A bending deformation and crankshaft technology, which is applied in the field of crankshaft straightening method and straightening tooling, can solve the problems of easy cracking and difficult straightening of large crankshafts, and achieve the effect of simple straightening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

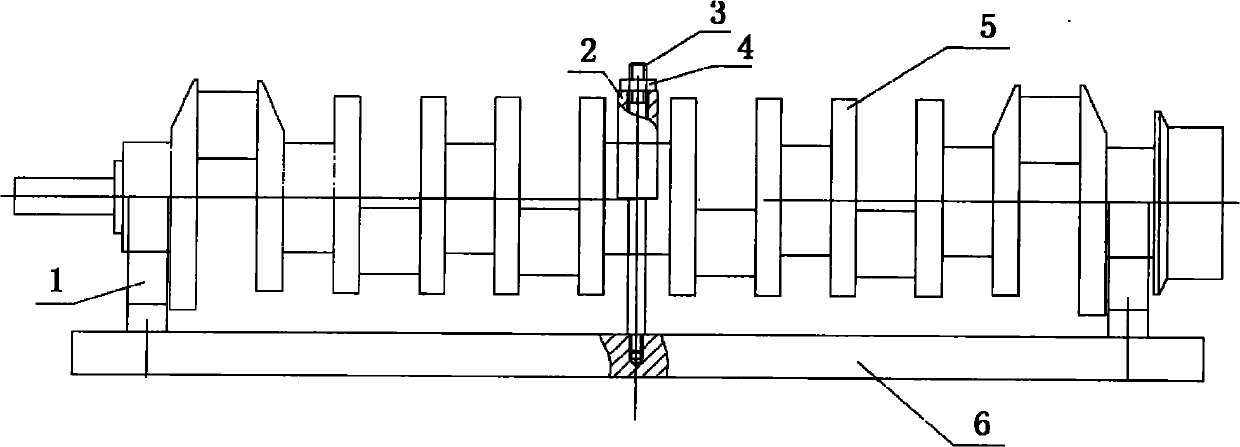

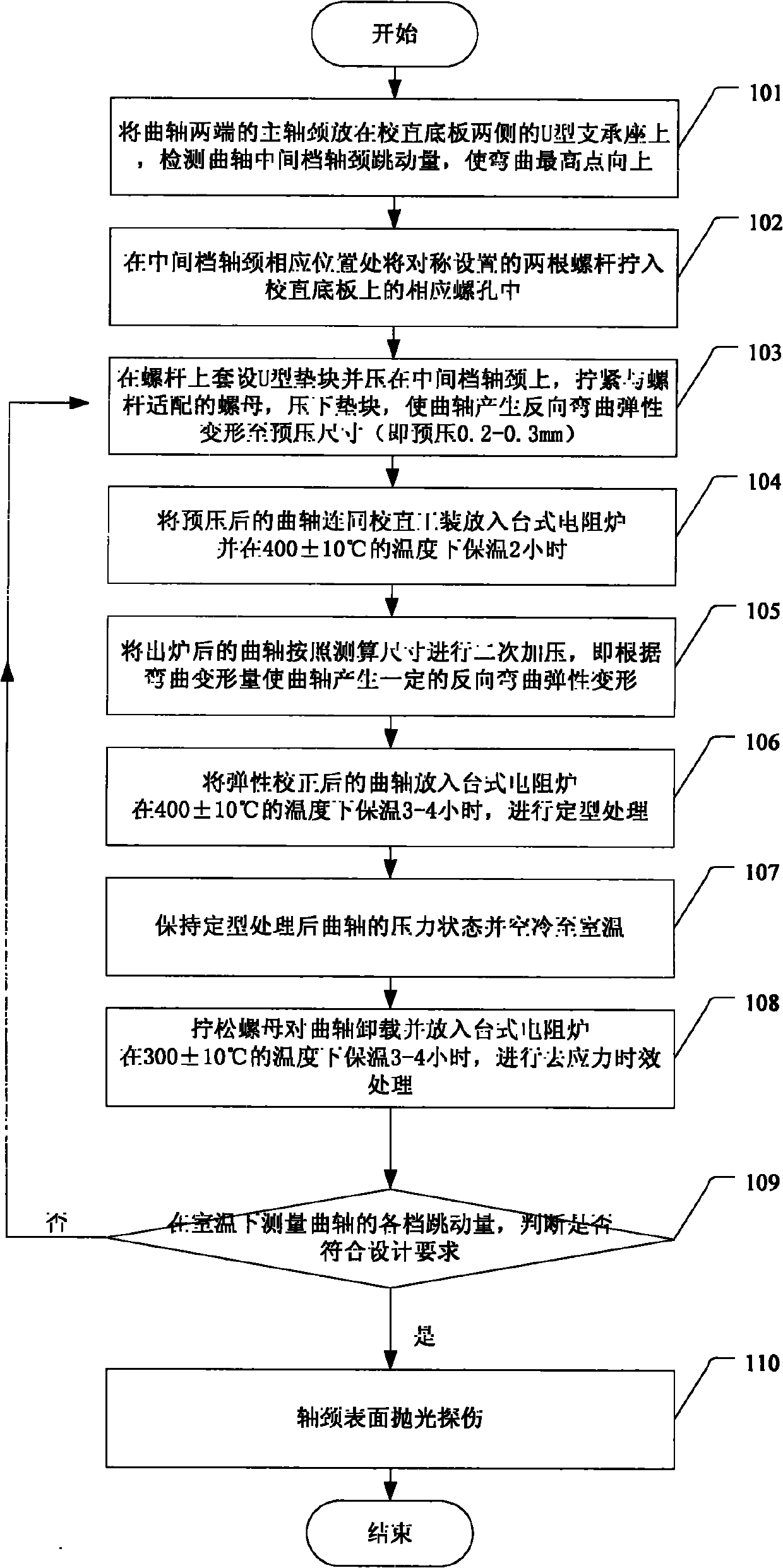

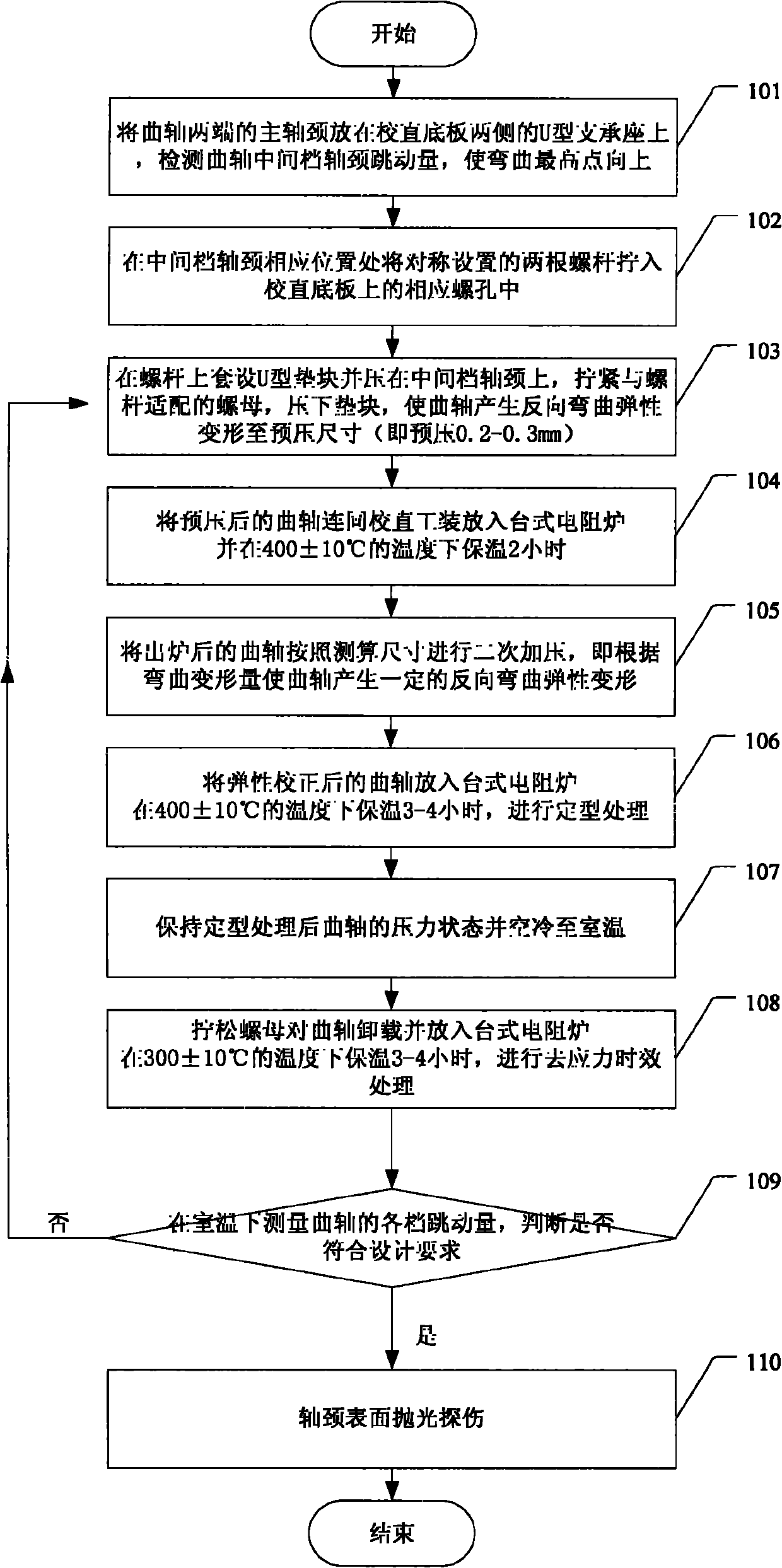

[0016] The straightening process of crankshaft bending deformation of the present invention mainly includes two steps of crankshaft straightening treatment and crankshaft heat setting treatment. The principle of slow and continuous plastic deformation. Since the creep effect of the metal is more obvious only when the temperature is higher than 0.3Tf (melting point temperature), we choose a temperature range of about 400°C for the nitrided crankshaft, and this temperature has no effect on the hardness of the nitrided layer. When straightening, use a special straightening platform (that is, the straightening base plate of the present invention). A screw rod for applying pressure is added to the middle position of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com