Method for rapid prototyping by taking wire as raw material and rapid forming machine

A raw material and forming machine technology, applied in the field of methods and rapid prototyping machines, can solve the problems of limiting the application field of welding cladding rapid prototyping technology, slow 3D printing forming speed, affecting the precision of manufactured parts, etc., to achieve rapid, high-efficiency and precise forming , Guarantee the quality of metallurgical bonding, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

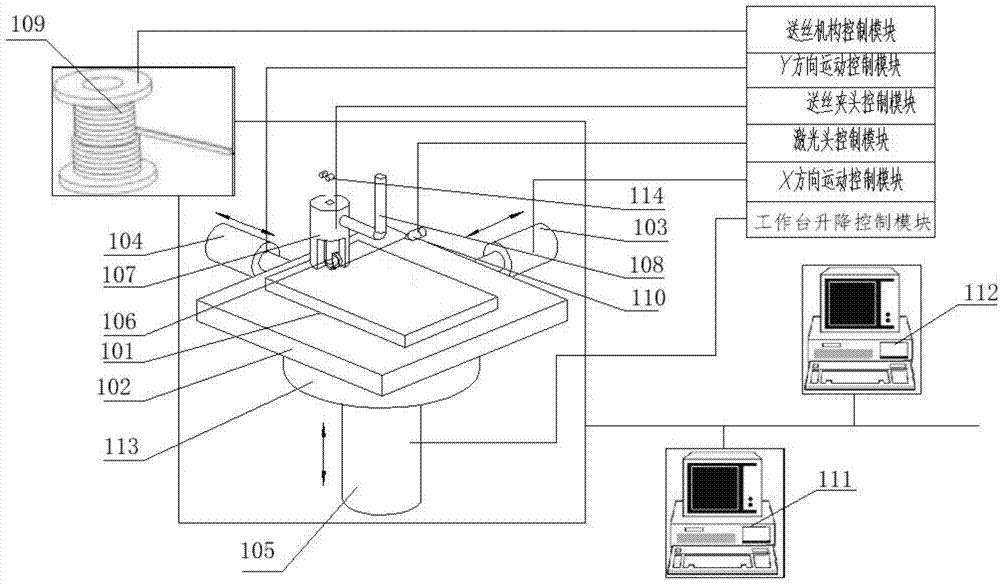

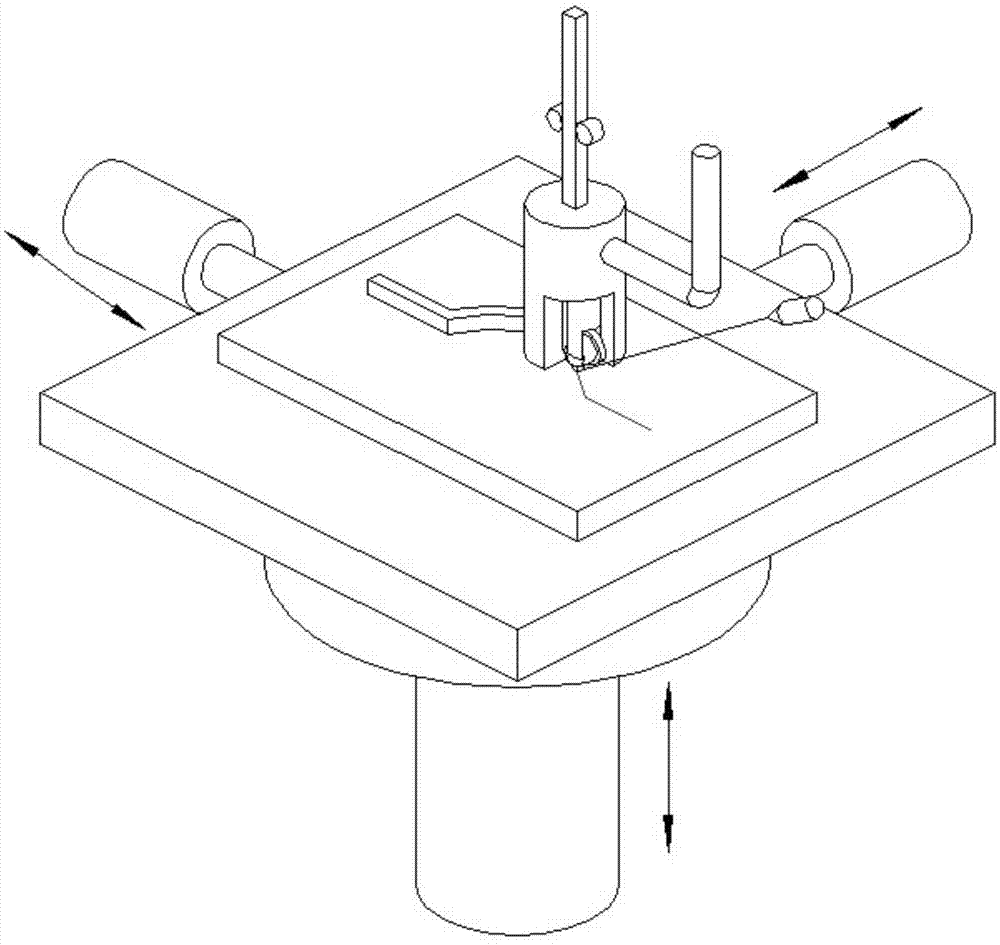

[0031] The method for rapidly manufacturing a prototype using wire as a raw material according to the present invention is firstly to draw a wire on a forming board to form a straight line or a curved plane trajectory shape, and at the same time, combine the wire on the forming board to maintain the corresponding shape ;Secondly, based on the wire material, the rapid prototyping layered superimposed material is carried out, including the following two situations:

[0032] 1) Closely stack other wires layer by layer on the wire to form the spatial shape of the required component, and realize metallurgical bonding between the wires, and finally the component with the desired shape can be manufactured;

[0033] 2) Put other wires and the wire strips side by side and combine them together to form a board structure, and realize metallurgical bonding between the wires to maintain the corresponding shape, and then place the wires on the board structure According to the required track...

Embodiment 2

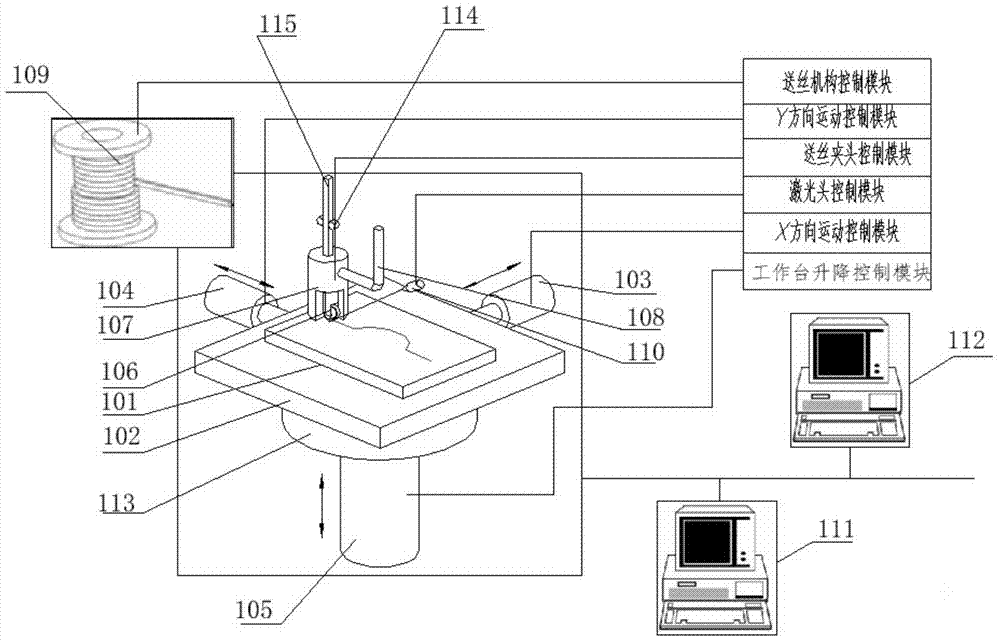

[0038] The difference from Example 1 is that this example manufactures a cube, using a stainless steel square wire 116 with a section width of 1 mm and a thickness of 1 mm. The X-axis servo drive mechanism 103 and the Y-axis servo drive mechanism 104 drive the workbench 102 so that the ends of the stainless steel square wire 116 are aligned at the initial forming position of the forming plate 101, and the pressure roller 106 is pressed on the end surface of the stainless steel square wire 116 to make It is attached to the initial forming position of the forming plate 101, the laser welding mechanism 110 emits laser light, and the end of the stainless steel square wire 116 is welded to the initial forming position of the forming plate 101, and then the lower computer 112 of the control system drives the X-axis servo drive mechanism 103 And the Y-axis servo drive mechanism 104 drives the workbench 102 to press against the end of the stainless steel square wire 116 Figure 3a Sca...

Embodiment 3

[0040] Different from Embodiment 1, the rapid prototyping machine described in this embodiment can manufacture bottle body hollow parts, such as Figure 4 As shown, it includes a forming plate 201, a worktable 202, a rotary drive mechanism 203 for driving the horizontal rotation of the worktable 202, a lift drive mechanism 204 for driving the rotary drive mechanism 203 up and down, and a pressure roller 205. Wire feeding collet 206 (such as Figure 6 As shown), chuck motion servo drive mechanism 207, wire feeding mechanism 208 with wire wheel, laser welding mechanism 209, computer graphics processing system upper computer 210, control system lower computer 211, wherein, the lifting drive mechanism 204 is set at The bottom of the rotary drive mechanism 203 and is connected with it; the worktable 202 is mounted on the rotary drive mechanism 203 and can be driven to rotate by the rotary drive mechanism 203; the forming plate 201 is fixedly mounted on the worktable 202, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com