Automatic sorting and weighing machine and working process thereof

An automatic sorting and weighing machine technology, applied in sorting and other directions, can solve problems such as device interference and inaccurate weighing, and achieve the effect of improving accuracy, ensuring accuracy, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

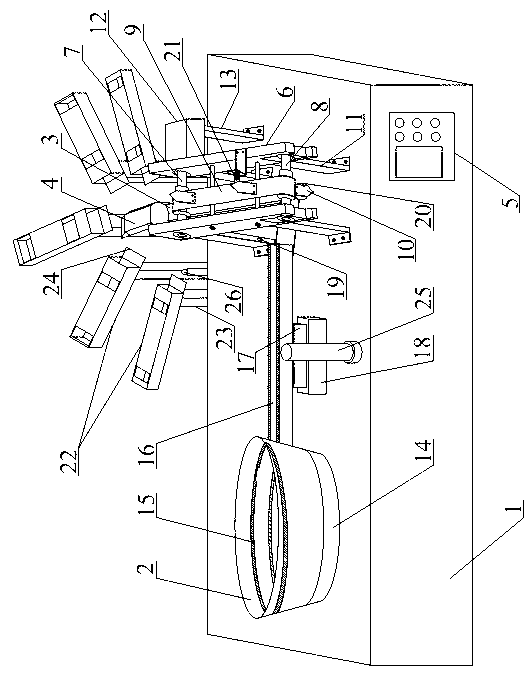

[0030] Such as figure 1 As shown, the automatic sorting weighing machine includes a base 1, a container 2 arranged above the base 1 and fixedly connected with it, a conveying device connected with the container 2 and arranged on the base, connected with the conveying device and set The weighing device on the base, the sorting device connected with the weighing device, and the material receiving device connected with the sorting device; the weighing device includes a weighing platform 3 connected with the conveying device, which is arranged on the weighing platform The weight sensor below, and the central processing unit connected with the weight sensor and arranged on the base; the weight sensor used in the present invention is more accurate than the existing weighing device, and the final result will not be caused by human factors An error occurred. The sorting device includes a transmission cylinder 4 connected to the weighing platform and the material receiving device, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com