Direct-buried type high-voltage cable automatic laying device and laying method

A high-voltage cable, automatic laying technology, applied in cable laying equipment and other directions, can solve the problems of large labor and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

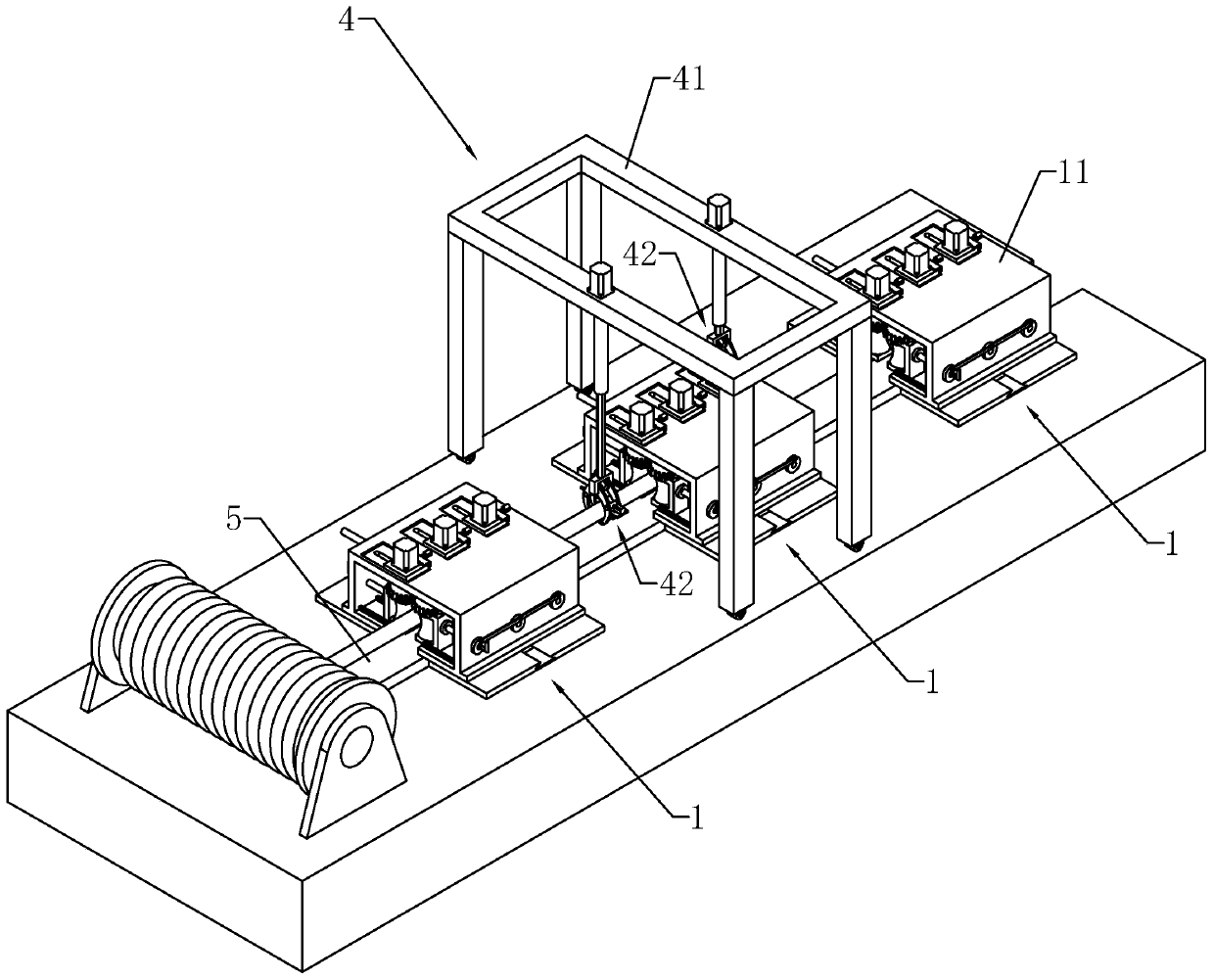

[0048] Example 1: Reference figure 1 , a direct buried high-voltage cable automatic laying device, including a traction device 4 and a conveying device 1, the conveying device 1 straddles the cable trench 5 and one conveying device 1 is set every 10 meters. The reel of the reeled cable is placed at one end of the cable trench 5, first the cable is fixed on the traction device 4, and then the traction device 4 is moved so that the cable passes through the conveying device 1, and each conveying device 1 plays a role in conveying the cable. The role of preventing cables from dragging on the ground. After a cable is transported to the designated position, the cable is unloaded from the conveying device 1 and the traction device 4, so that the cable falls in the cable trench 5. This method replaces the manual handling of the cable and reduces the amount of labor.

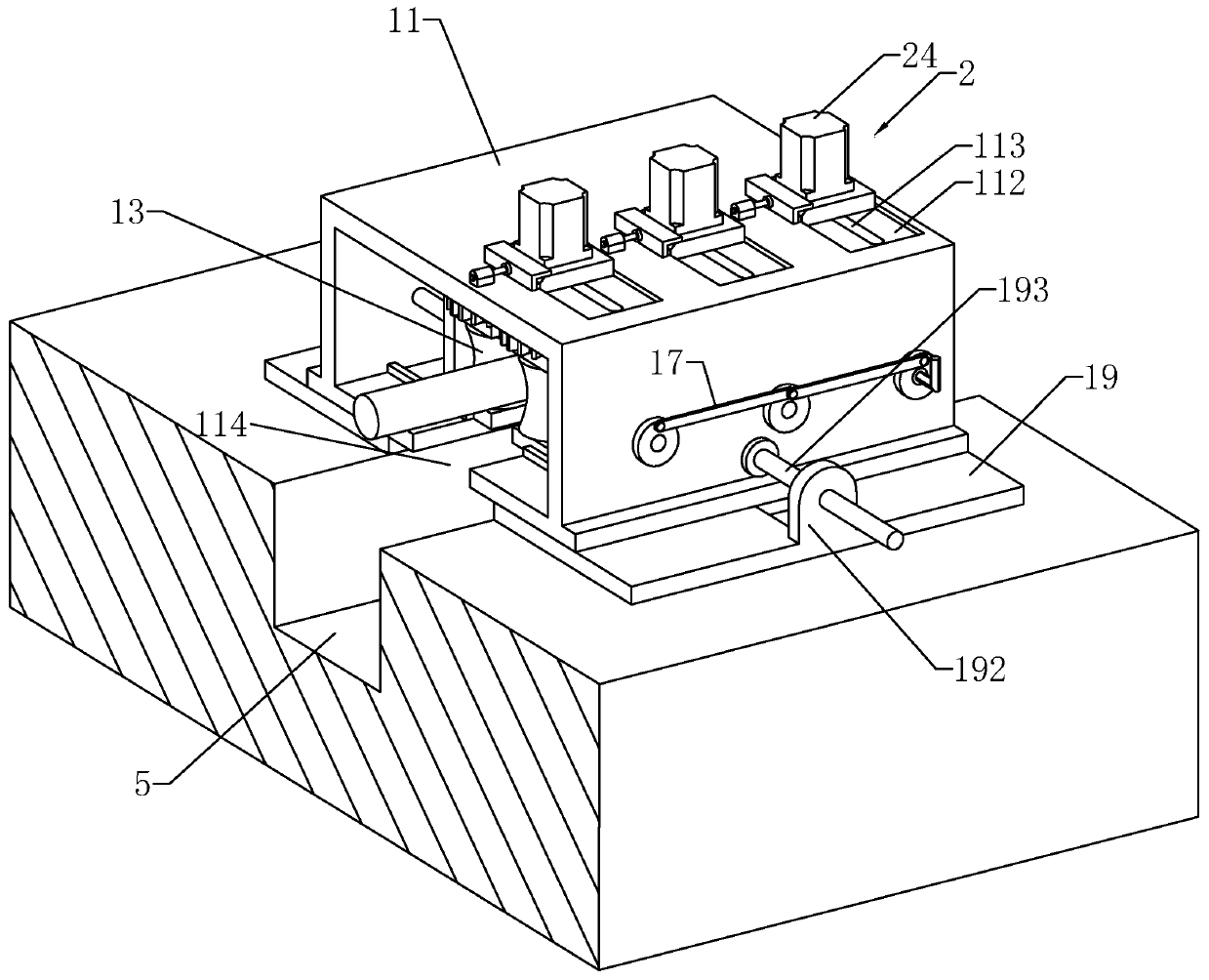

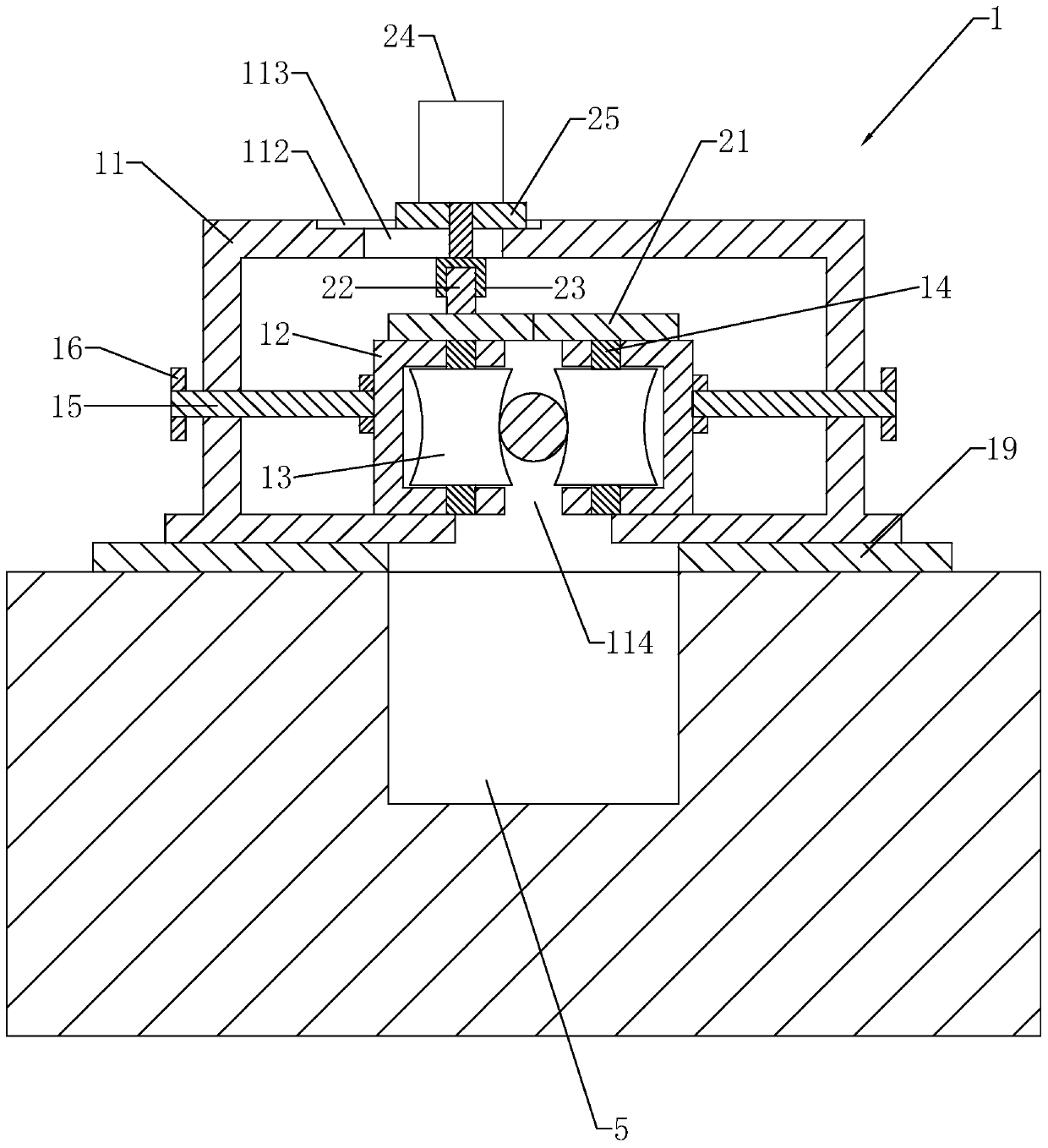

[0049] refer to figure 2 and image 3 , the conveying device 1 comprises a support frame 11 straddling the cable t...

Embodiment 2

[0061] Embodiment 2: Referring to the figure, a method for automatic laying of directly buried high-voltage cables includes the following steps:

[0062] 1. First, place the conveying device 1 on the cable trench 5 at equal intervals of 5-10 meters each;

[0063] 2. Fix one end of the cable on the traction device 4, and push the traction device 4 to move along the length direction of the cable trench 5;

[0064] 3. When the cable is close to the conveying device 1, the claws 42 close to the conveying device 1 open to send off the clamping of the cable, and at the same time the claws 42 move upwards driven by the servo motor 45;

[0065] 4. When the first claw 42 passes the conveying device 1 and the second claw 42 is close to the conveying device 1, the first claw 42 moves downward and gathers to clamp the cable, and then the second claw 42 Two jaws 42 open, send off the clamping of the cable and move upward;

[0066] 5. When the second claw 42 passes through the conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com