Material transfer box for sealing device and transfer method

A technology of closing device and transfer box, applied in the directions of capping, closing, packaging, etc., can solve the problem of time-consuming and labor-intensive, and achieve the effect of ensuring safety, wide application range, and convenient operation of the robotic arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

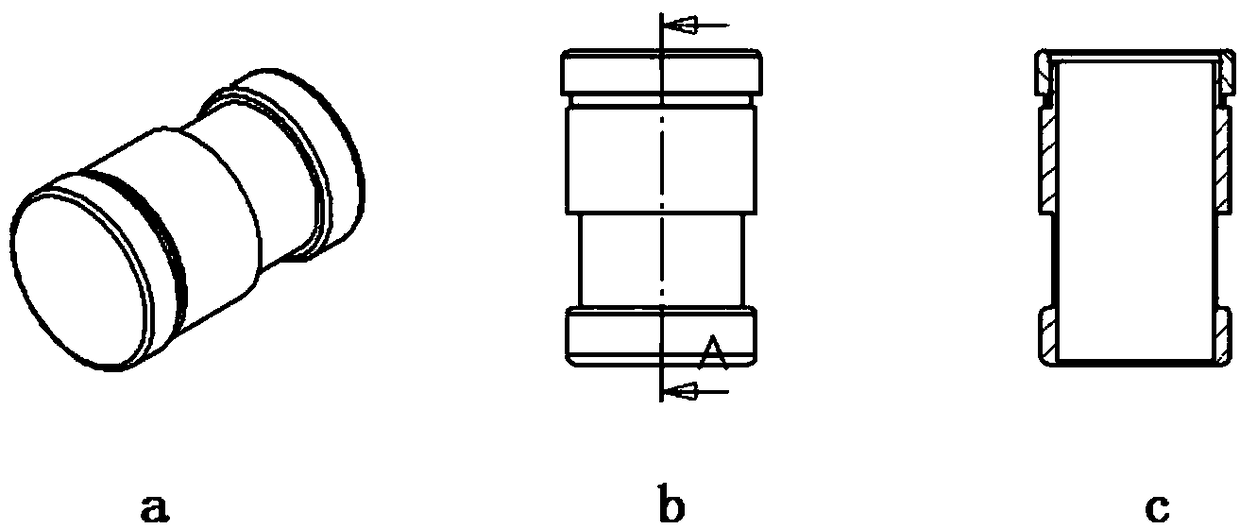

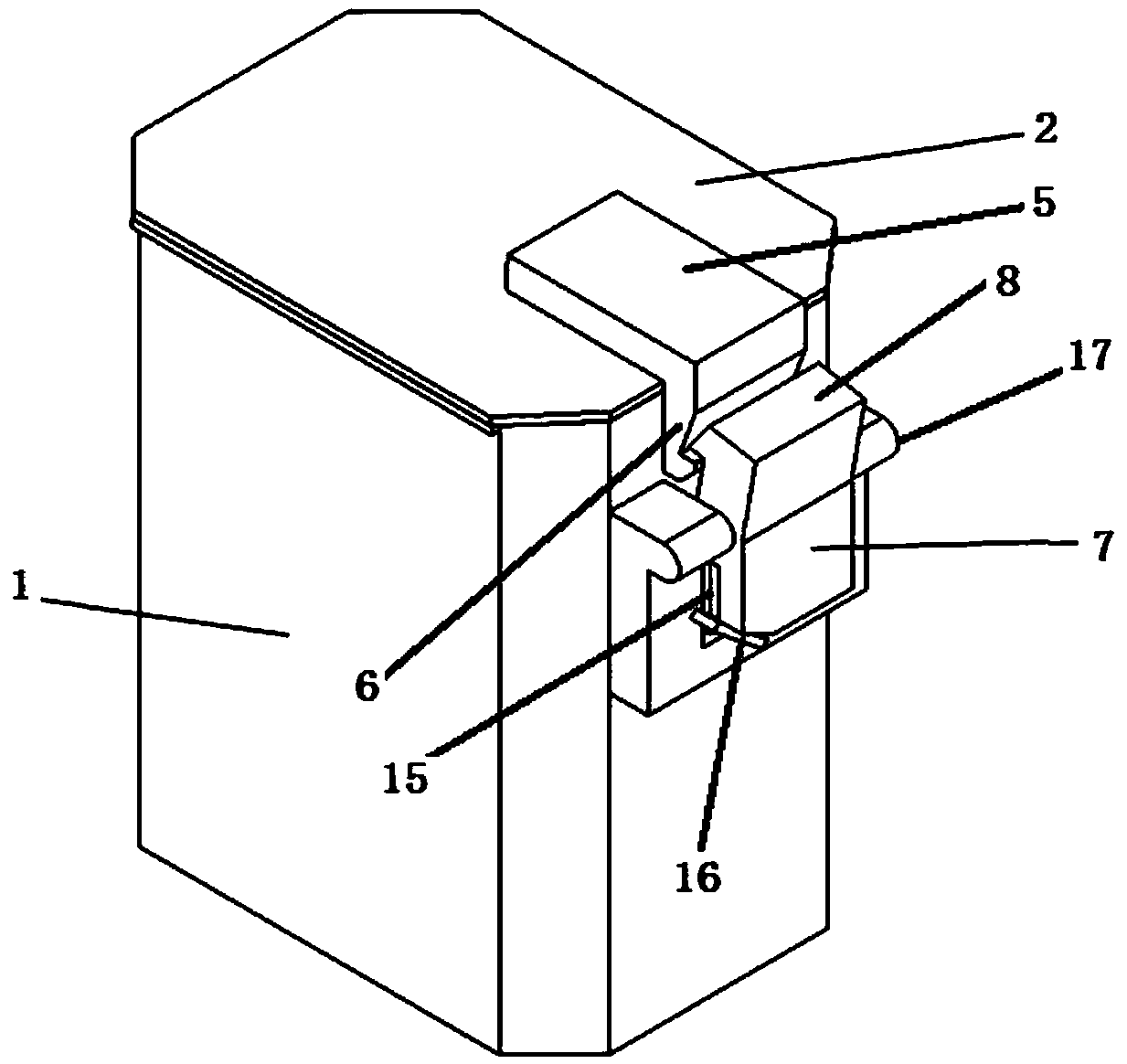

[0033] A material transfer box used in a closing device, comprising a box body 1 and a box cover 2 whose inner side is rotatably connected to the top of the box body 1 through a torsion shaft, and the outer side of the box cover 2 is fixed with an upper fixing part 5 and upper hook 6 constitute the upper lock, the outer side of the box body 1 is provided with a lower lock composed of the lower rotating part 7 and the lower hook 8 matching with the upper hook 6, the lower The rotating part 7 is rotationally connected with the box body 1 through a rotating shaft 9 , and a compression spring 10 is provided in the gap between the outer walls of the box body 1 of the lower rotating part 7 .

[0034] With the side close to the outer wall of the box body 1 as the inside and the side farther away from the outer wall of the box body 1 as the outside, the upper lock and the lower lock are arranged to facilitate the manipulator to open and close the box. When closing the box, the manipula...

Embodiment 2

[0040] In order to further optimize the shape and material of the transfer box, this embodiment is improved on the basis of embodiment 1.

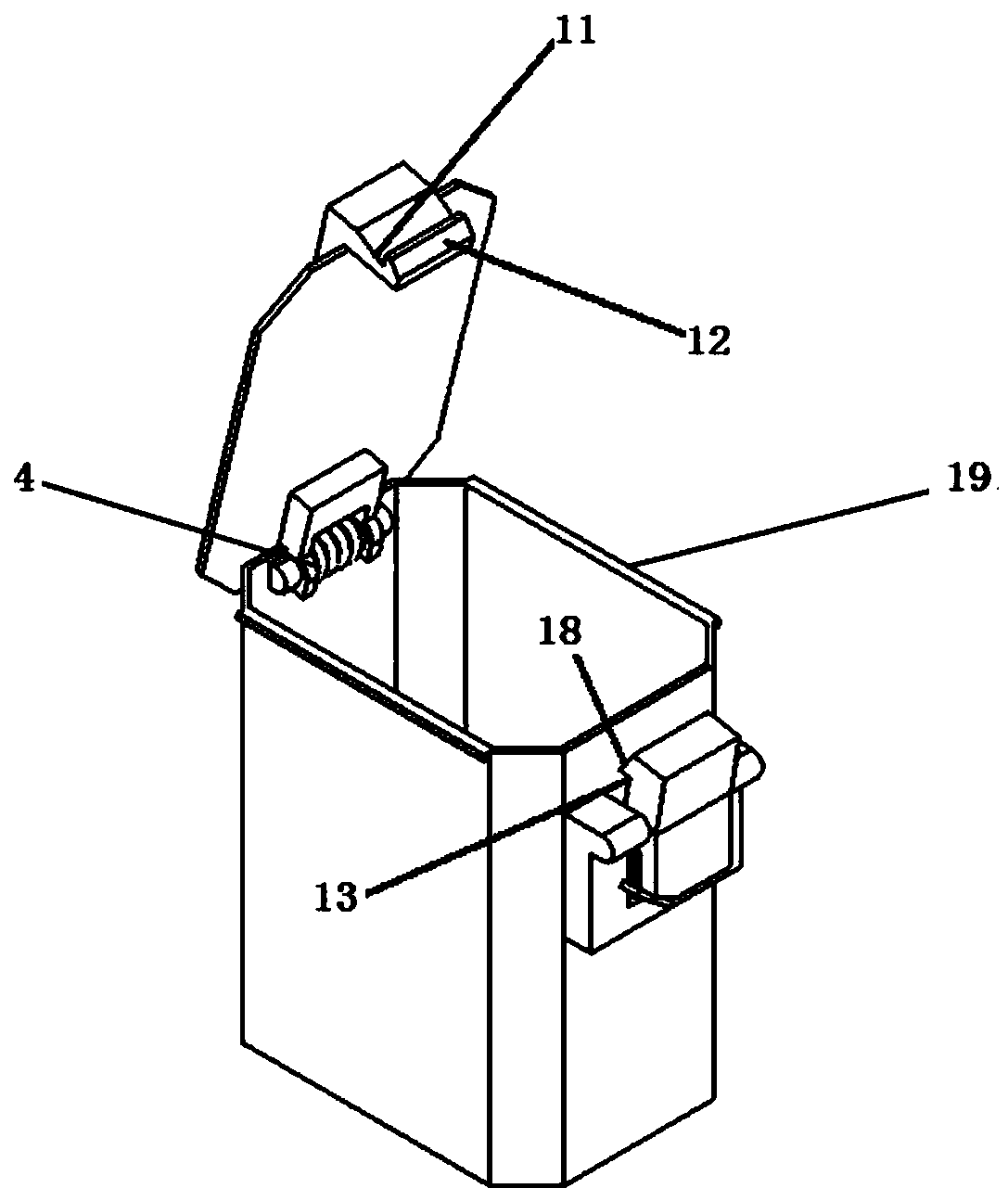

[0041] As a preferred manner, the box cover 2 is rectangular or octagonal, and the transverse section of the box body 1 is rectangular or octagonal, which is convenient for the manipulator to grab and can accommodate materials of different sizes.

[0042] As a preferred manner, the bottom side wall of the box body 1 protrudes from the bottom of the box body 1 to form a grabbing edge 14, which is convenient for the manipulator to grab the material box after dumping the material.

[0043] As a preferred manner, the top edge of the box body 1 is provided with a grasping flange 19 to facilitate the grasping and transportation of the robot.

[0044] As a preferred manner, the box body 1 and the box cover 2 are made of metal materials.

Embodiment 3

[0046] In order to further optimize the structure of the lower locking member, this embodiment is improved on the basis of embodiment 1 or embodiment 2.

[0047] As a preferred mode, the bottom end of the lower rotating part 7 is provided with a draw-in groove 15 for engaging the free edge of the compression spring 10, and the outside of the draw-in groove 15 is welded with a limit piece 16 arranged obliquely to prevent the compression spring 10 from coming out. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com