Automatic focusing method of laser cleaning machine

A laser cleaning and auto-focusing technology, which is applied in cleaning methods and utensils, chemical instruments and methods, optics, etc., can solve problems affecting the accuracy of focusing and focusing, affecting the accuracy of distance data, and damage to workpieces, so as to improve the convenience of focusing Sexuality, convenience, automation, rapid leveling, and the effect of improving focus accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

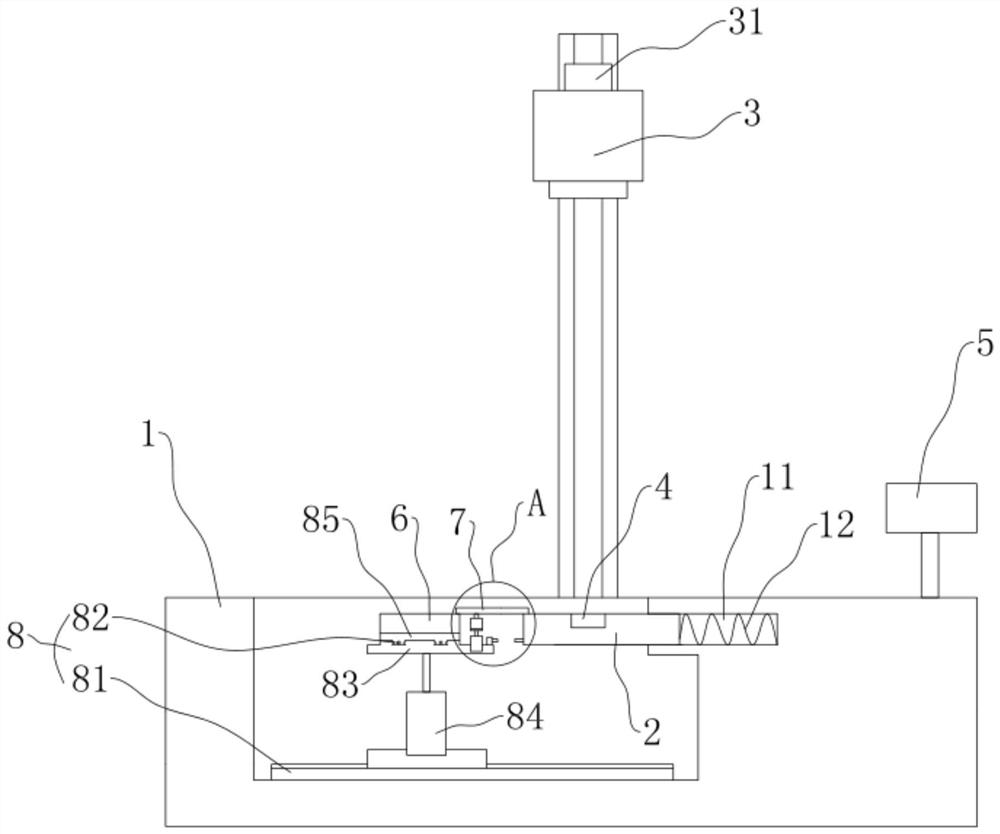

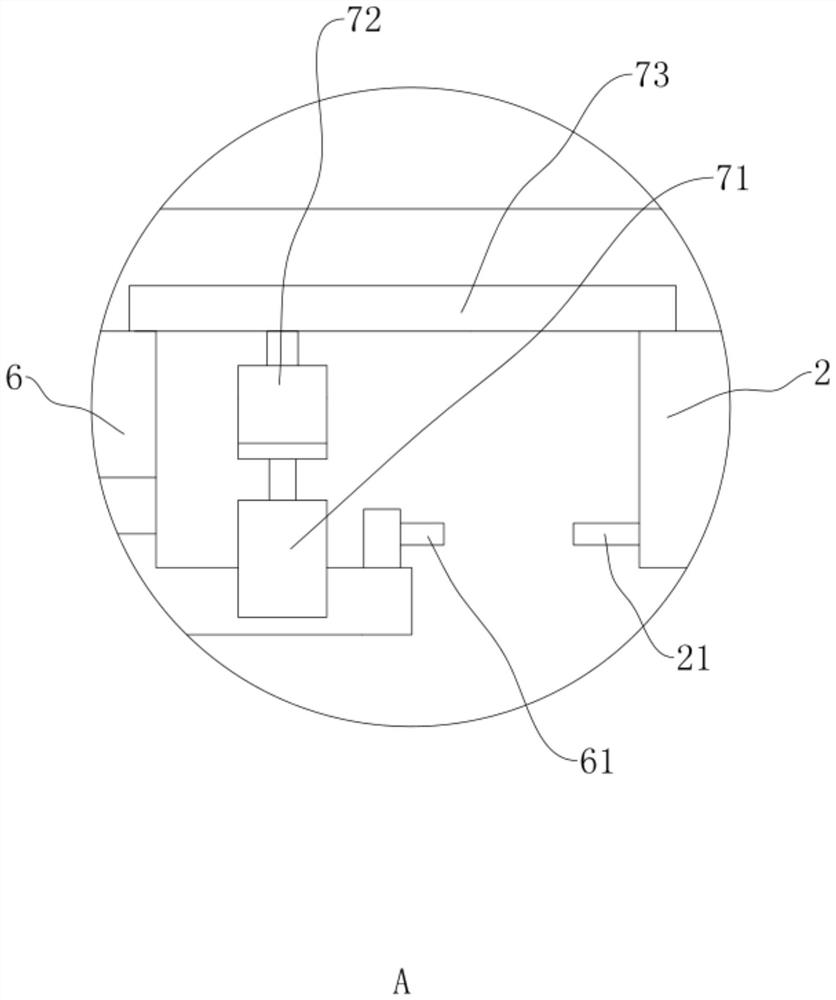

[0032] refer to Figure 1 to Figure 3 Further explain the autofocus method of the laser cleaning machine.

[0033] A laser cleaning machine automatic focus method, such as figure 1 As shown, the autofocus device is used for focusing, and the autofocus device includes a cleaning platform 1, a focus measuring seat 2 arranged on the cleaning platform 1, and a vertical displacement for driving the laser cleaning head 3 to move closer to or away from the focus measuring seat 2 The mechanism 31 is equipped with a laser receiver 4 on the focus measuring seat 2 , and the laser receiver 4 is arranged opposite to the laser cleaning head 3 . Wherein, the laser receiver 4 is connected with a controller 5 , and the vertical displacement mechanism 31 is connected with and controlled by the controller 5 .

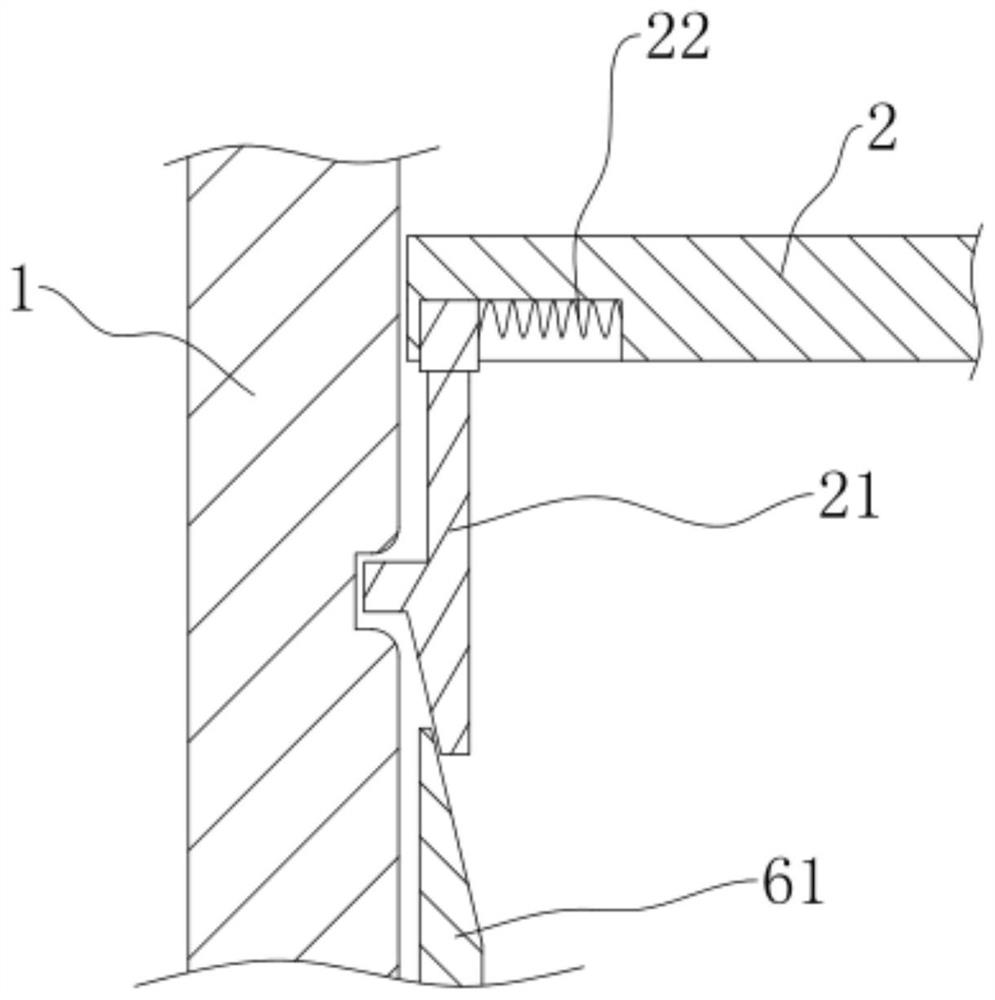

[0034] Such as figure 1 with image 3 As shown, further, a storage tank 11 is provided on the cleaning platform 1, and the focus measuring base 2 is slidably arranged on the storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com