Dismounting and mounting special tool of outer barrel nut of undercarriage support

A technology for aircraft landing gear and special tools, which is applied in aircraft assembly, manufacturing tools, screwdrivers, etc. It can solve the problems of no adjustable space, difficult disassembly of open-end wrenches, uneven force application, etc., and achieve the effect of increasing the use of diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

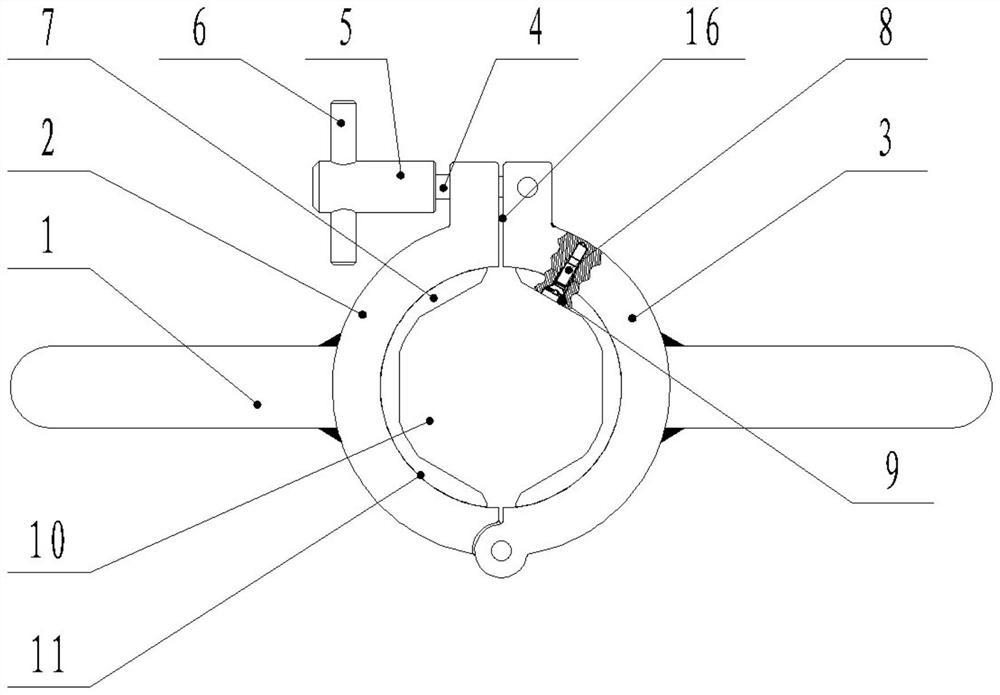

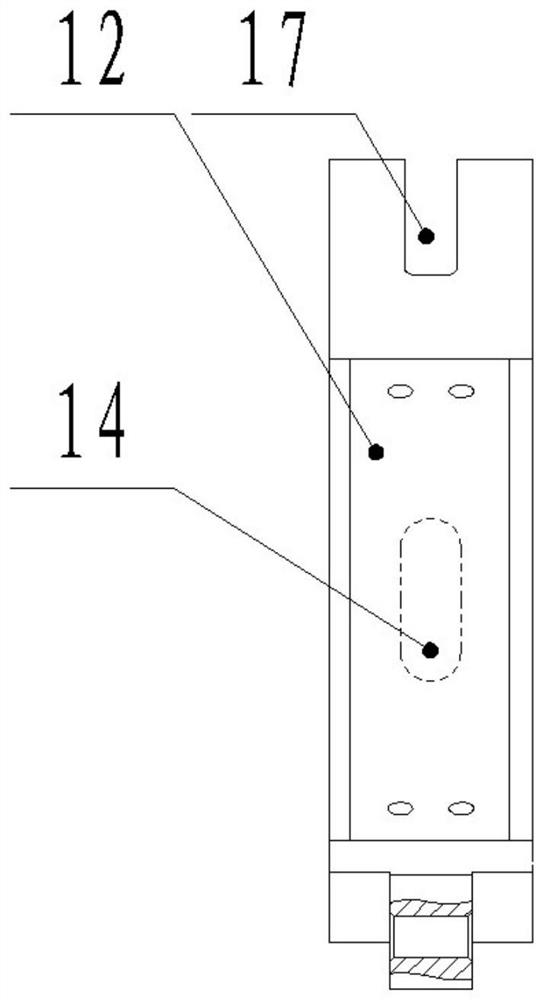

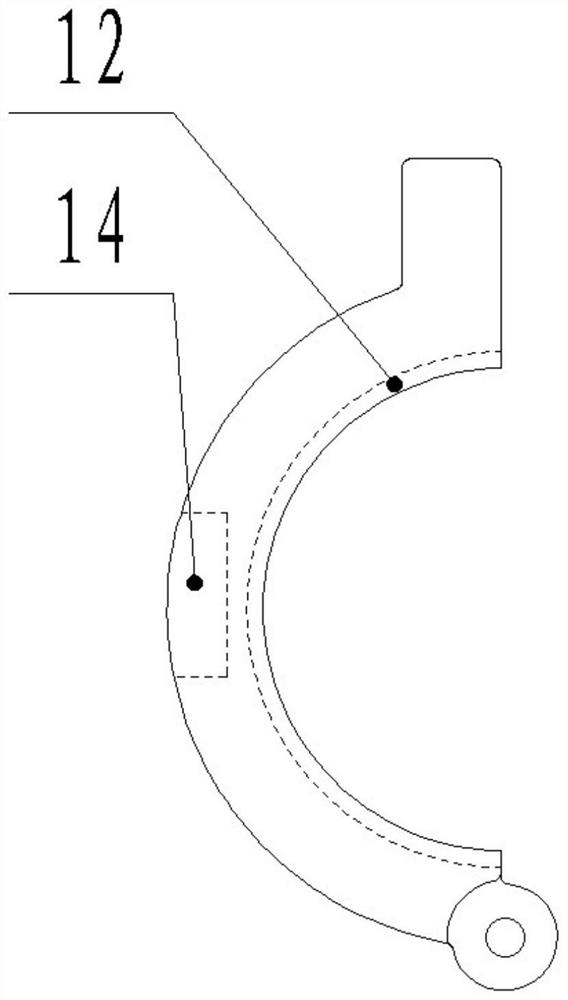

[0037] According to the size of the actual dismantled outer cylinder nut, select the appropriate size of the bushing 7, and install the bushing 7, such as Figure 8 As shown, unscrew the locking sleeve 5, lift the locking screw 4, open the left wrench base 2 and the right wrench base 3 to install the bushing 7, and insert the outer sides of the two bushings 7 into the left wrench base 2 respectively. In the groove one 12 and the groove two 13 of the right wrench base body 3, and tighten and fix with the screw 8, then the locking screw 4 is put down, and the locking sleeve 5 is tightened to form as figure 1 The status shown is ready for use.

[0038] When in use, align the inner hexagonal hole 10 formed by the bushing 7 with the outer cylinder nut, and after putting on the outer cylinder nut, adjust the locking sleeve wrench 6 according to the tightness state, and when there is a certain margin, tighten the locking sleeve wrench 6 , the right end surface of the locking sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com