A locking mechanism for transmission

A technology of locking mechanism and transmission device, applied in the direction of transmission device control, mechanical equipment, components with teeth, etc., can solve the problems of inaccurate locking position, insufficient fast locking, unstable locking, etc., and achieve the goal of locking Increased tightening speed, fast locking and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

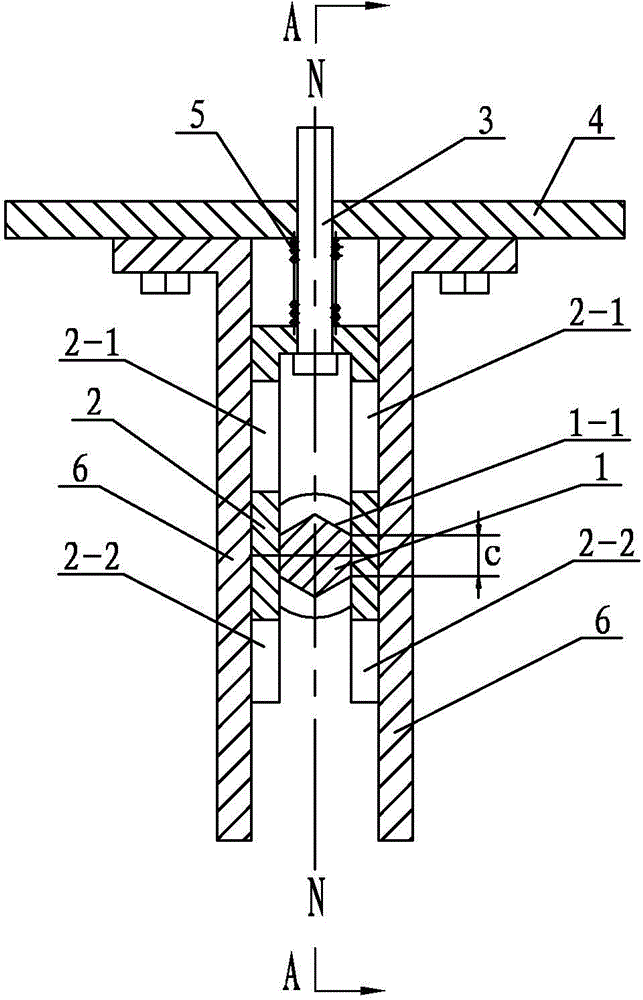

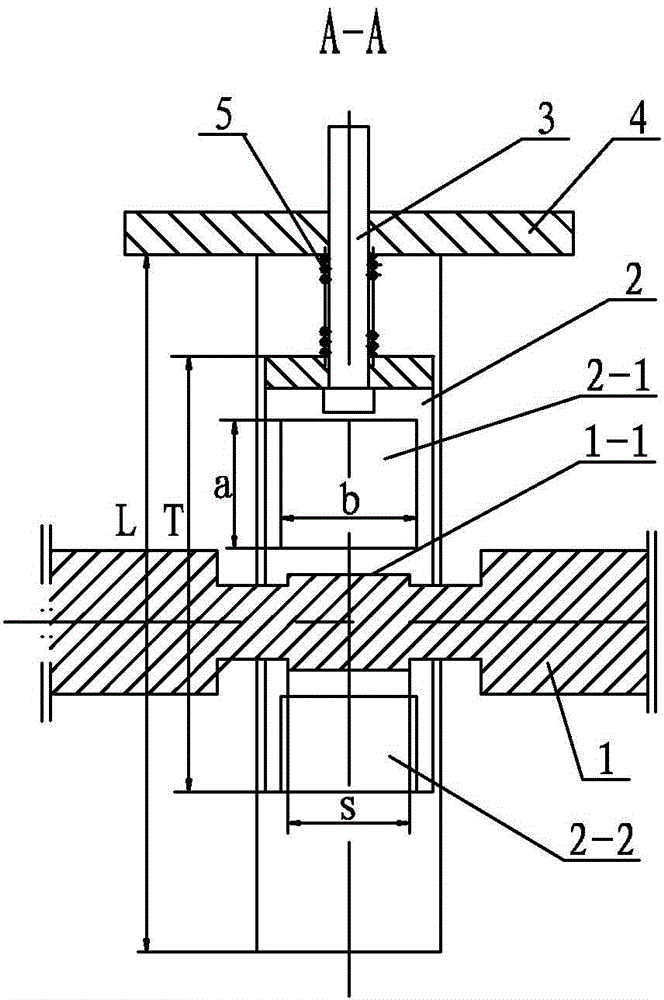

[0010] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment. In this embodiment, the locking mechanism of the transmission device includes a transmission shaft 1, an inverted U-shaped steel 2, a pull rod 3, an upper fixing plate 4, a spring 5, and two inverted L-shaped guide plates 6. The inverted U-shaped steel 2 Each side wall is provided with a through hole 2-1 and a groove 2-2 from the bottom end to the open end, one end of the pull rod 3 is set in the U-shaped groove of the inverted U-shaped steel 2, and the other end of the pull rod 3 passes through The bottom plate of the inverted U-shaped steel 2, the spring 5 and the upper fixing plate 4 are exposed outside the upper fixing plate 4, the middle part of the transmission shaft 1 is a hexagonal locking section 1-1, the transmission shaft 1 is horizontally arranged, and the hexagonal lock The tight section 1-1 is located in the U-shaped groove, the length s of the hexagonal locking se...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To describe this embodiment, the cross section of the hexagonal locking section 1-1 in this embodiment is a regular hexagon. This design can improve the stability of the hexagonal locking section 1-1 when it contacts the inner wall of the inverted U-shaped steel 2. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 This embodiment is described. In this embodiment, the length c of each side of the regular hexagon of the hexagonal locking section 1-1 is smaller than the distance from the lower edge of the through hole 2-1 to the upper edge of the groove 2-2. This design makes the contact area between the hexagonal locking section 1-1 of the transmission shaft 1 and the side wall of the inverted U-shaped steel 2 large and stable. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com