Method and system for accurately controlling position of liquid level pipe of filling head

A technology of precise control and control system, applied in liquid distribution, conveying or transfer devices, distribution devices, special distribution devices, etc., can solve the problems of incompressible liquid, inaccurate liquid level control, etc., to avoid failures, save costs, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

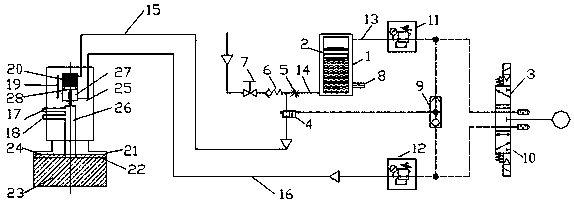

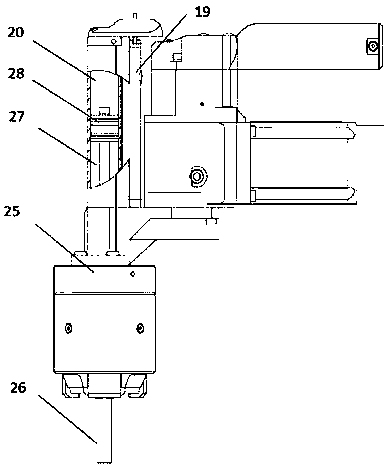

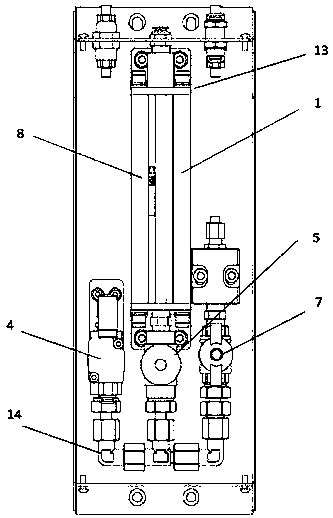

[0032]The precise control of the position of the liquid level tube of the filling head in the present invention is to adjust the hydraulic oil in the upper chamber 20 and the compressed air in the lower chamber 27 , and realize the control through the control cylinder 1 . Driven by the combined effect of liquid and gas dual media, the liquid level tube 26 of the filling head is extended by hydraulic control and retracted by air pressure control, and the position information of the liquid level tube 26 is fed back by the position sensor installed on the filling head. The locking of any position of the liquid level pipe 26 can be accurately realized. The hydraulic control extension is the air pressure generated by the compressed air to push the liquid in the control cylinder 1. The liquid is linked with the liquid in the upper chamber 20 of the filling head executive cylinder, and the liquid in the upper chamber 20 is adjusted to push the lower chamber 27 of the actuator cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com