Method for antilocking for shuttle operation of three-dimensional textile machine

A three-dimensional knitting machine and knitting machine technology, which is applied in the directions of twisting lace looms, woven fabrics, textiles and paper making, etc. problems, to achieve the effect of smooth operation, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

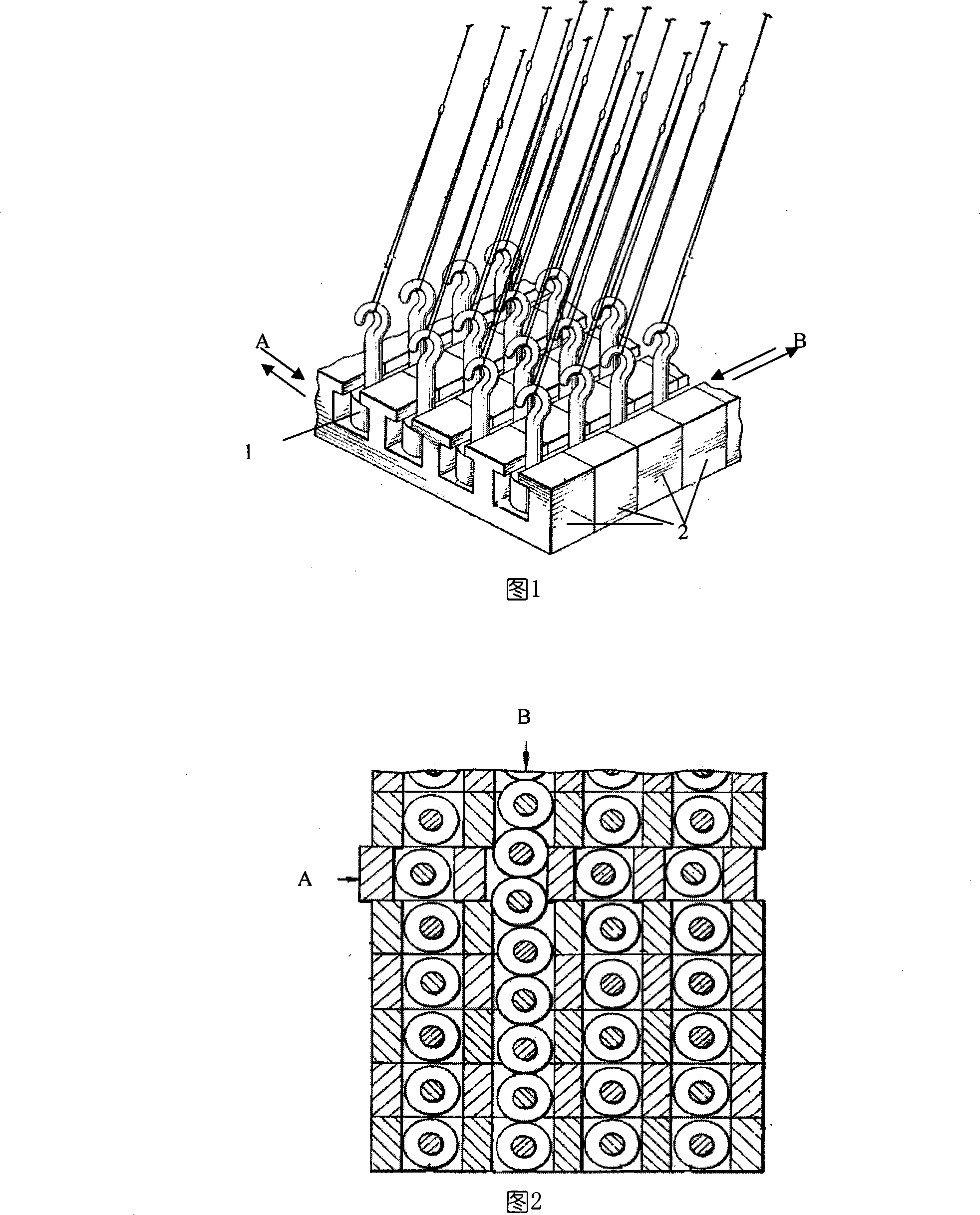

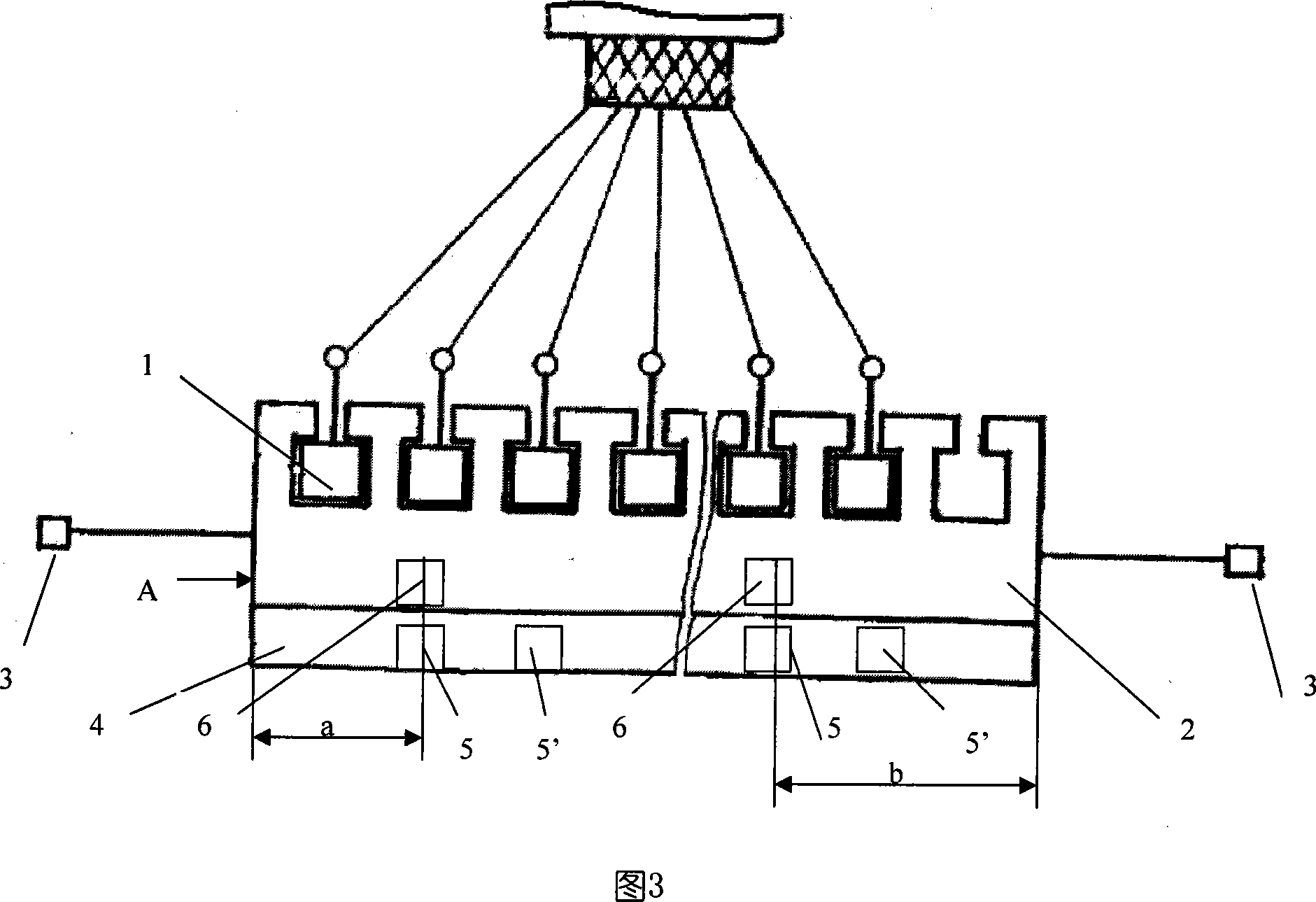

[0016] In the embodiment shown in Figure 3: the shuttle 1 is placed in the groove of each shuttle box 2, and can be controlled to slide back and forth in the direction B along the groove of the shuttle box 2, and each shuttle box 2 arranged side by side on the machine bracket It can slide back and forth in the direction A under the promotion of the respective shuttle box push rods 3, so that each shuttle 1 can move up, down, left, and right in the four-step knitting. Two cylindrical sintered NdFeB magnets are embedded in the lower plane of each shuttle box 2, which are called shuttle box magnets 6 in the present invention. The diameter of these two cylindrical magnets is 10 mm, the height is 10 mm, and the magnetic pole N faces downward, and they are respectively arranged at the left and right ends of the shuttle box. The specific position is that the distance a from the left end is 100 mm, The distance b from the right end is 115 mm. And in the upper plane position of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com