Patents

Literature

38results about "Twist lace-making machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

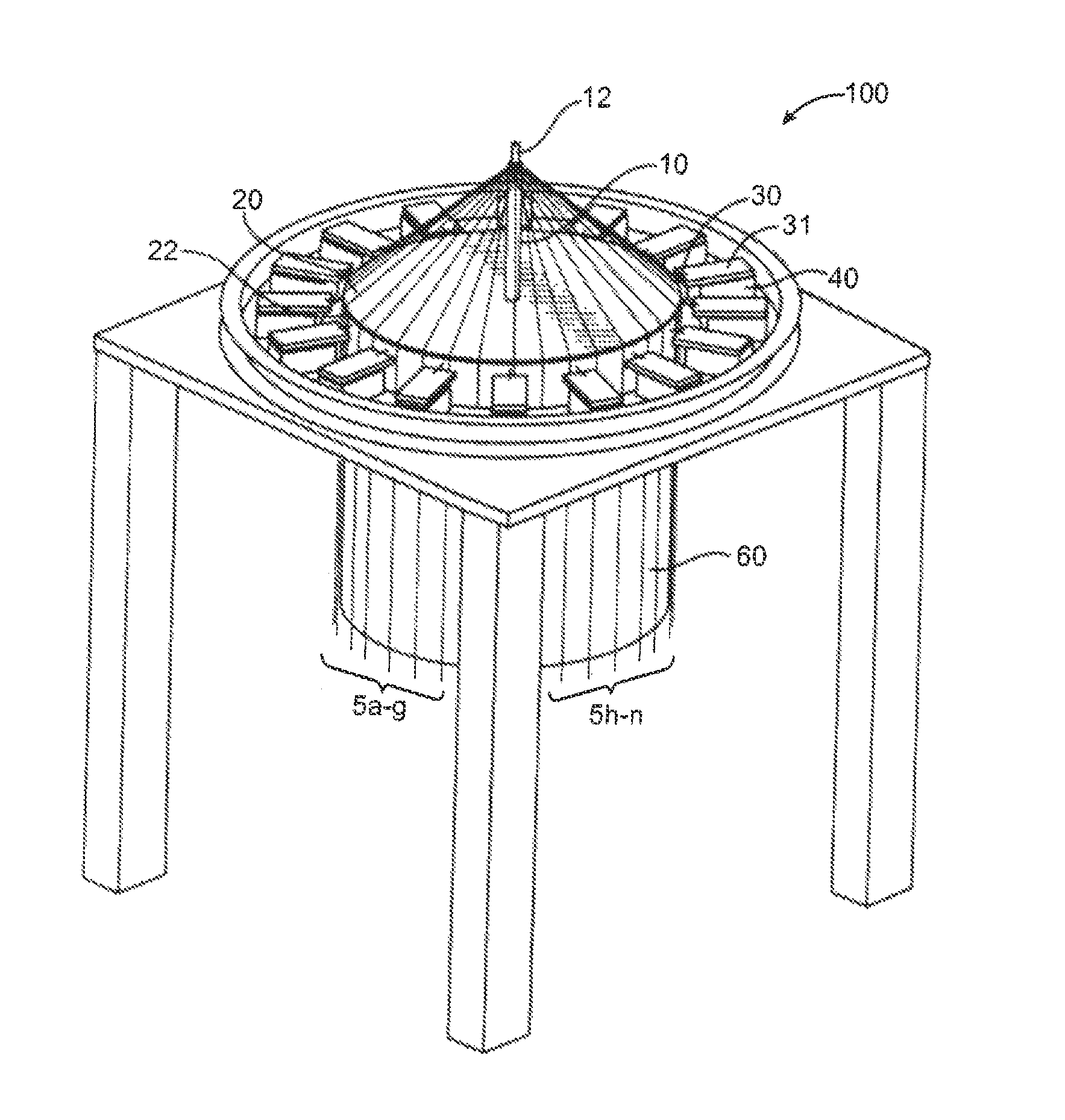

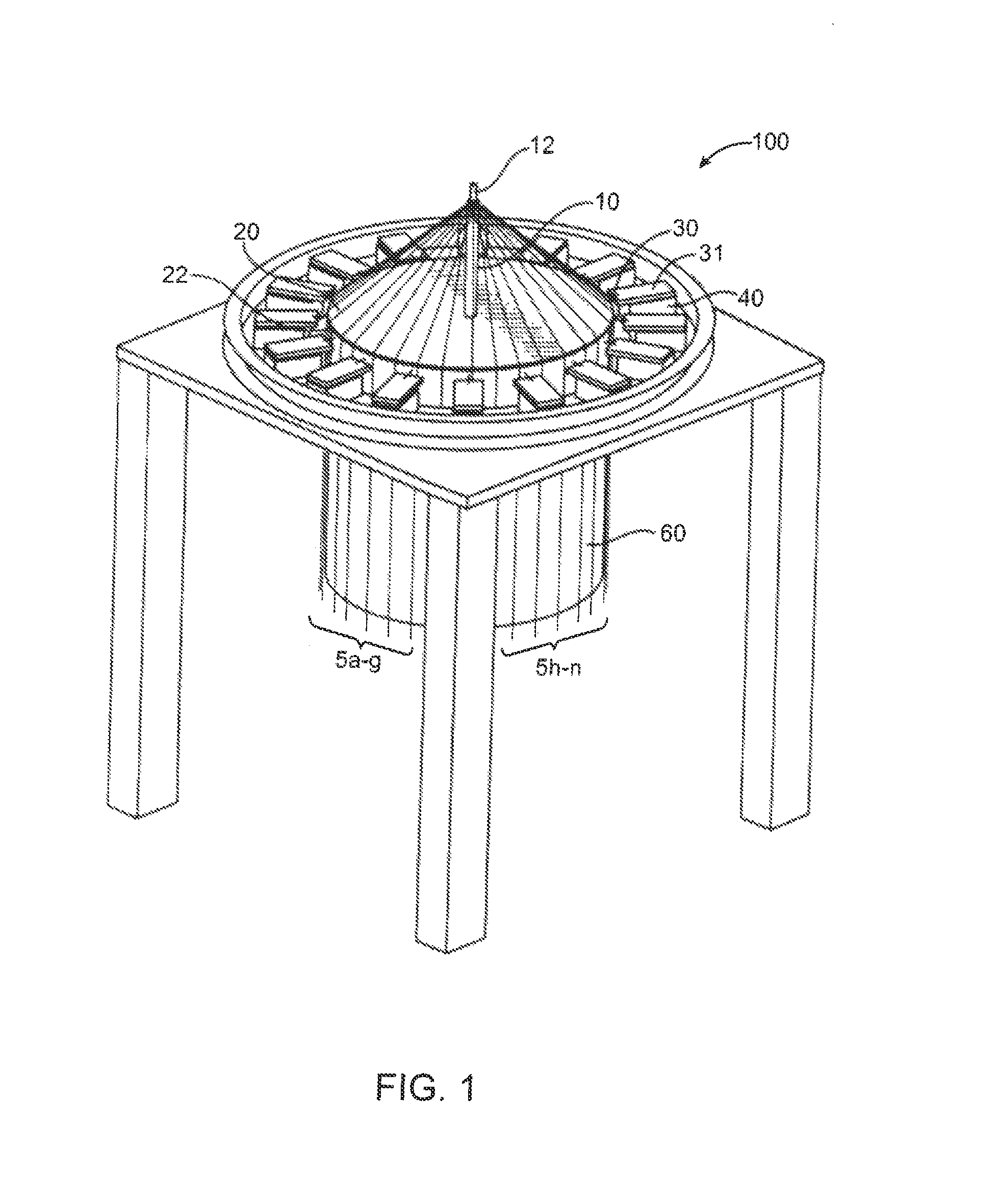

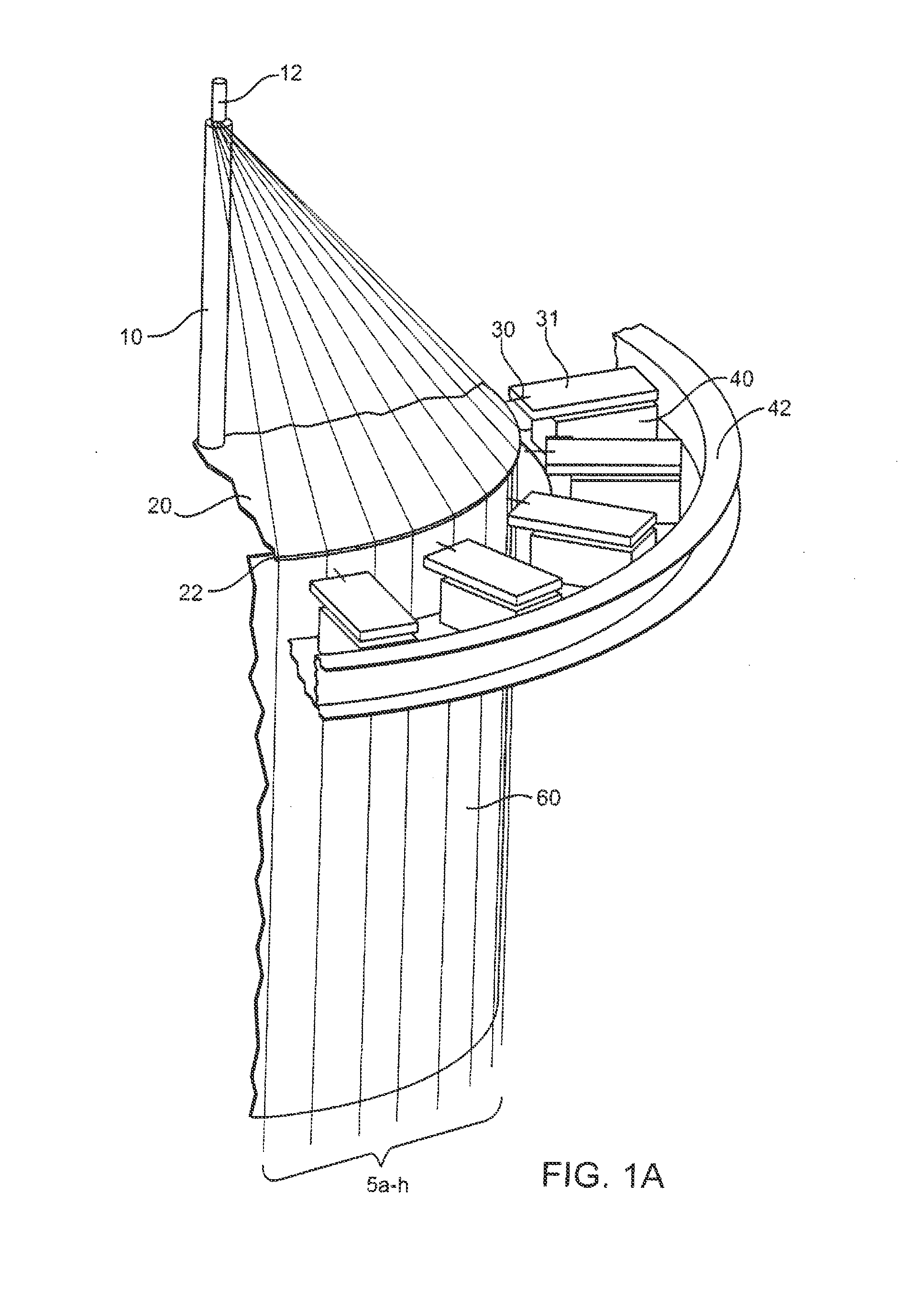

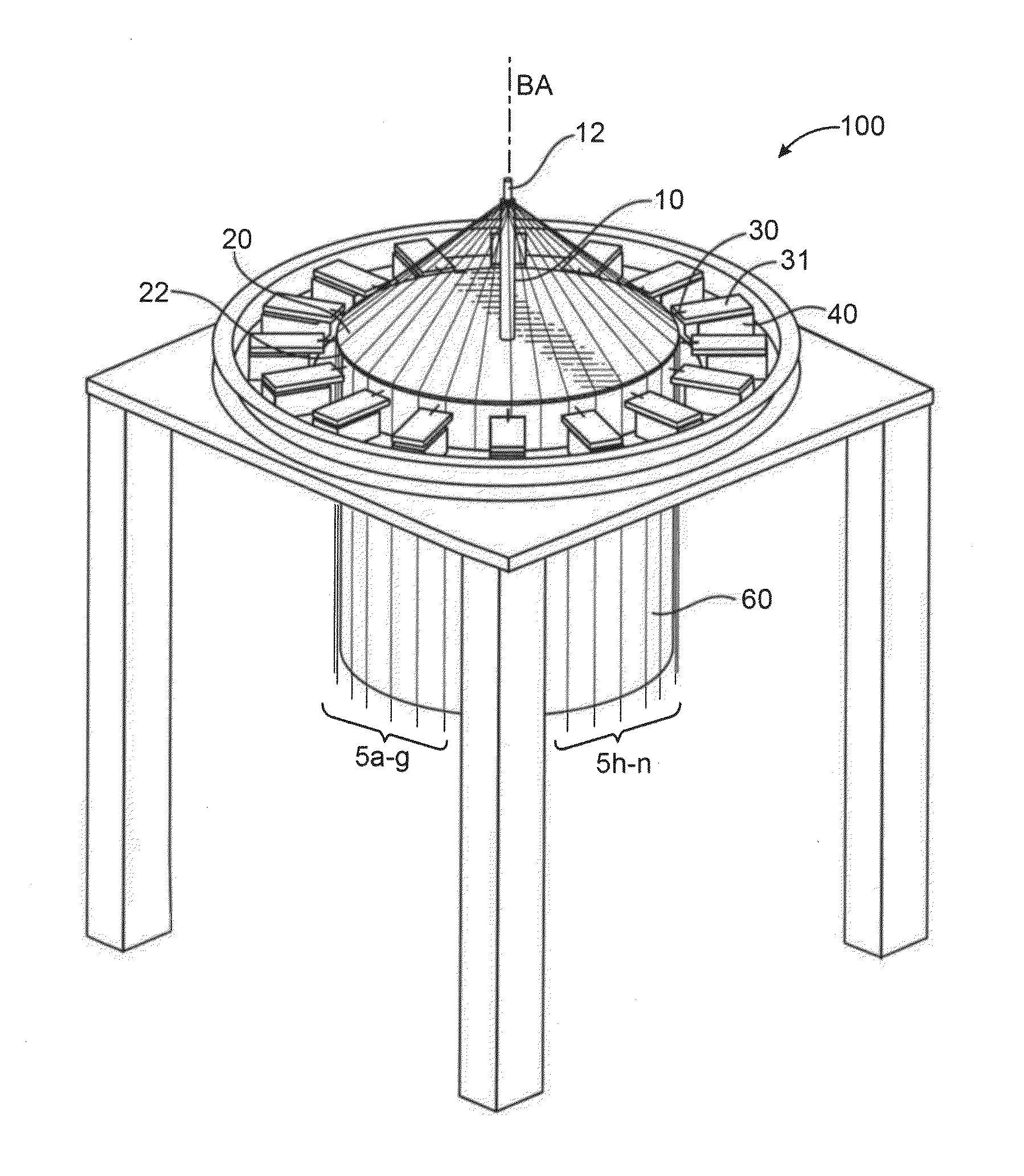

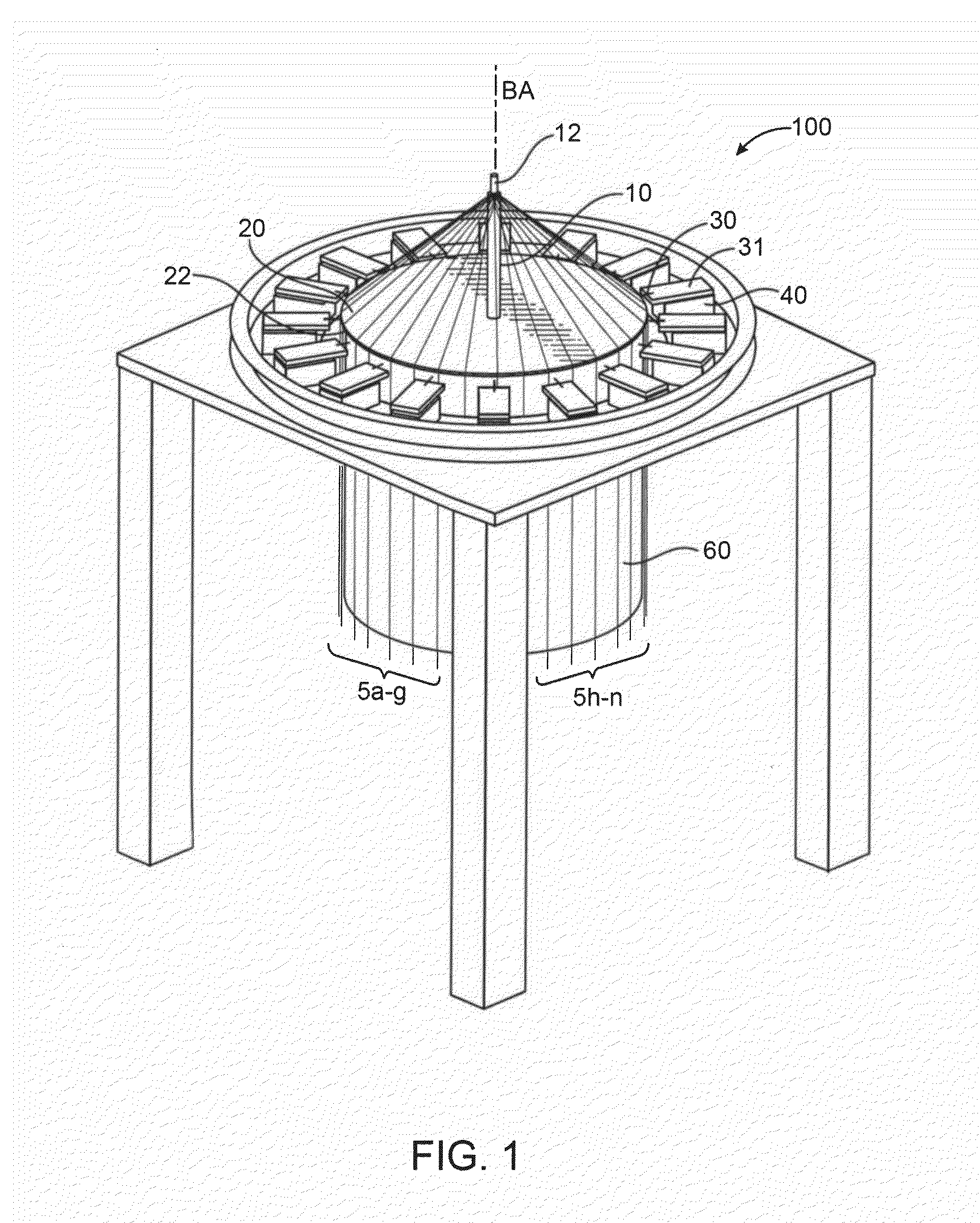

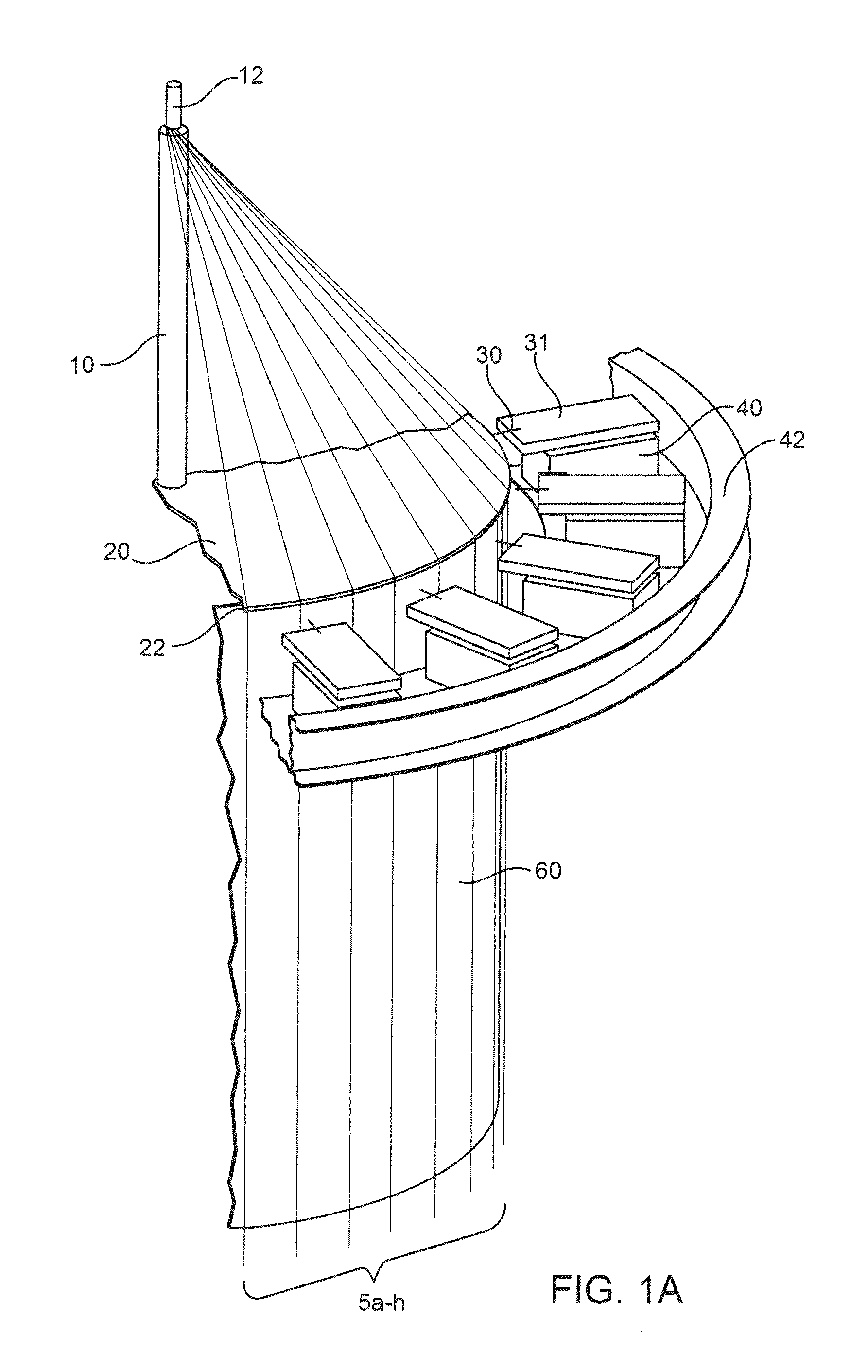

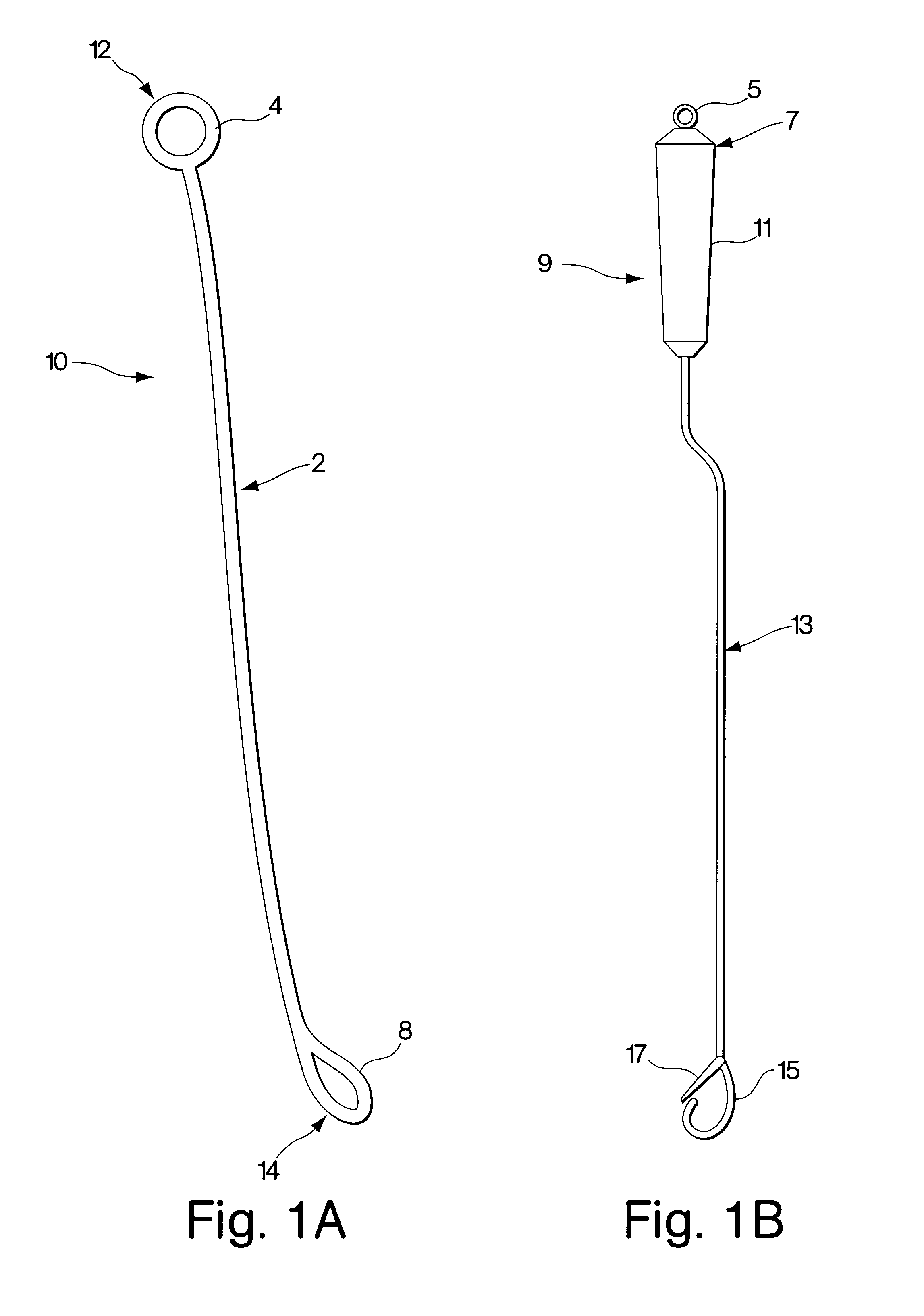

Braiding mechanism and methods of use

A device and method for forming a tubular braid comprising a plurality of filaments. The braiding machine comprises a disc with a mandrel extending from the center in a perpendicular direction and a plurality of catch mechanisms arranged circumferentially around the edge of the disc. A plurality of filaments are temporarily affixed to the mandrel, each filament extending from the mandrel toward the edge of the disc and engaging the edge of the disc at a discrete point of engagement The plurality of catch mechanisms are attached to actuators adapted to move the catch mechanisms in a generally radial direction relative to the edge of the disc to allow the catch mechanism to engage a subset of the filaments and move the engaged filaments beyond the circumferential edge of the disc.

Owner:MICROVENTION INC

Braiding mechanism and methods of use

A device and method for forming a tubular braid comprising a plurality of filaments. The braiding machine comprises a disc with a mandrel extending from the center in a perpendicular direction and a plurality of catch mechanisms arranged circumferentially around the edge of the disc. A plurality of filaments are temporarily affixed to the mandrel, each filament extending from the mandrel toward the edge of the disc and engaging the edge of the disc at a discrete point of engagement. The plurality of catch mechanisms are attached to actuators adapted to move the catch mechanisms in a generally radial direction relative to the edge of the disc to allow the catch mechanism to engage a subset of the filaments and move the engaged filaments beyond the circumferential edge of the disc.

Owner:MICROVENTION INC

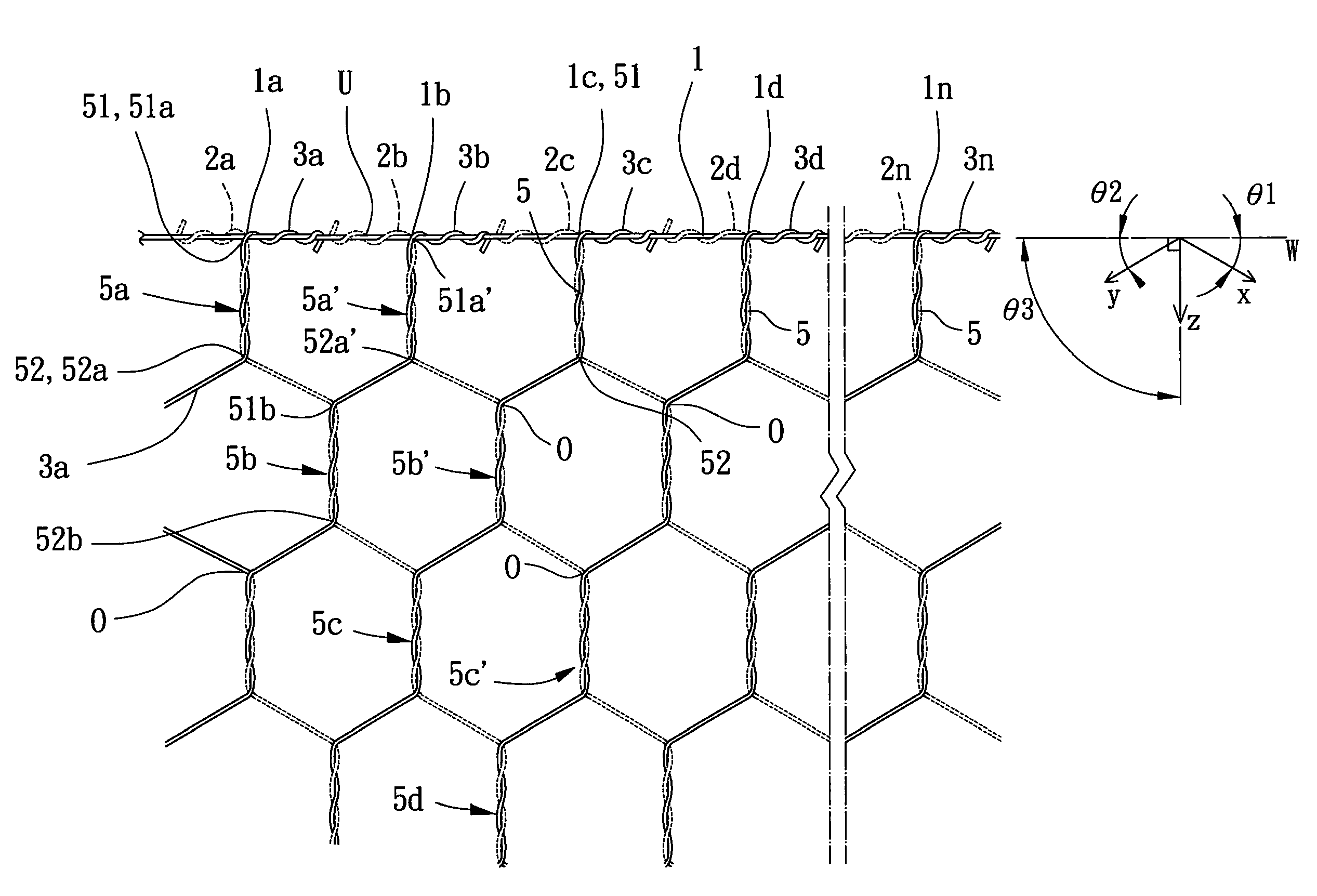

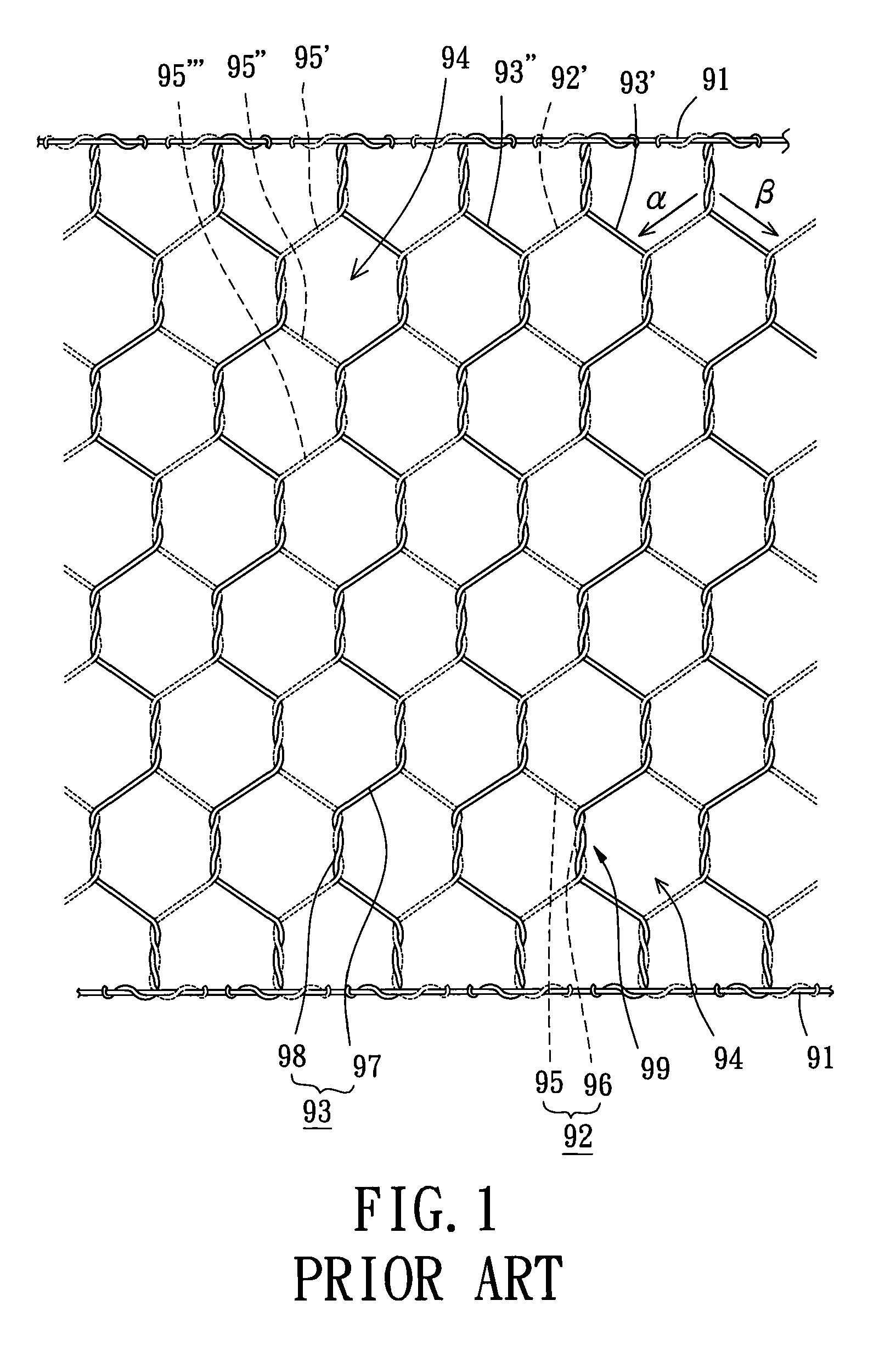

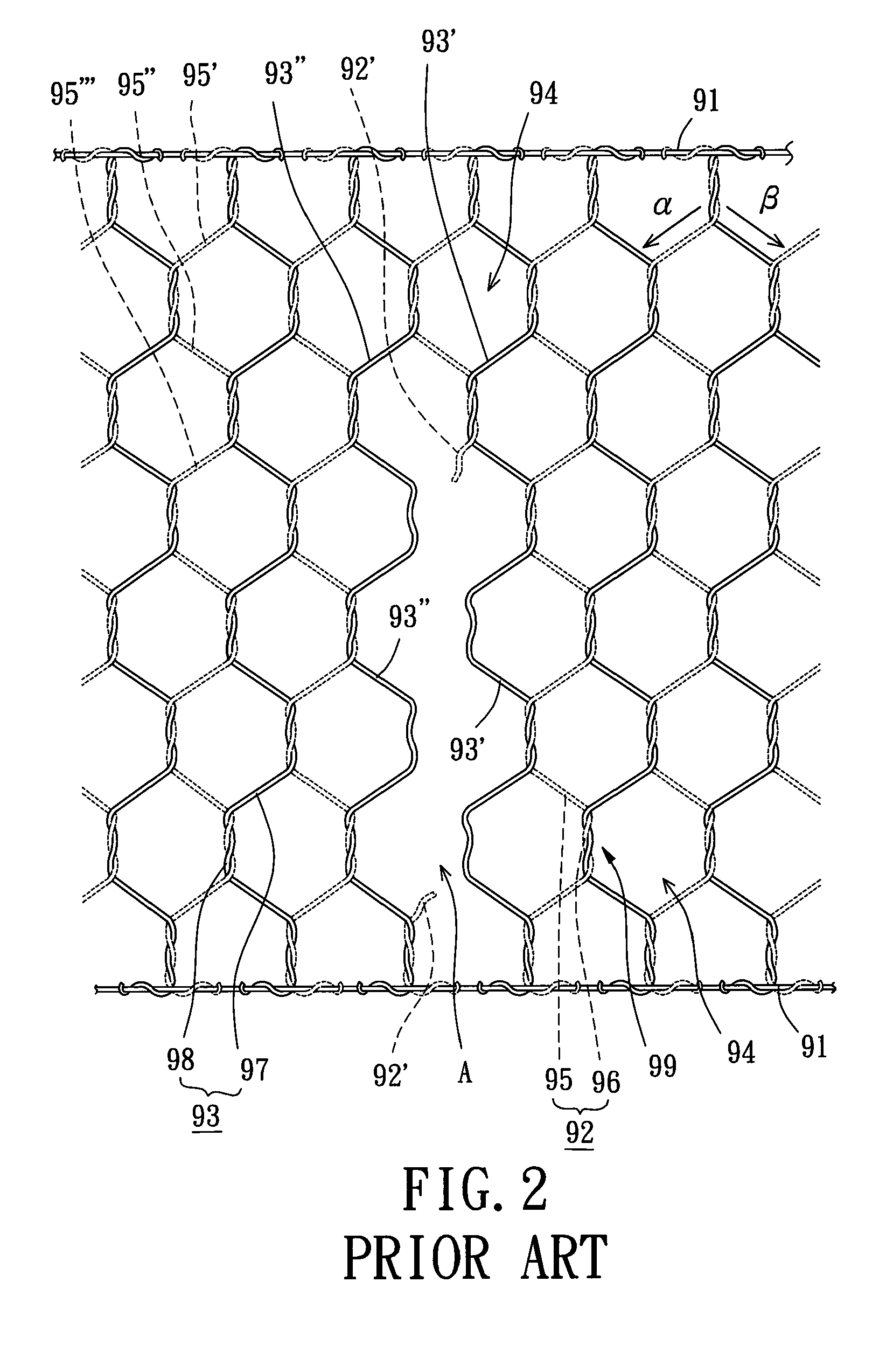

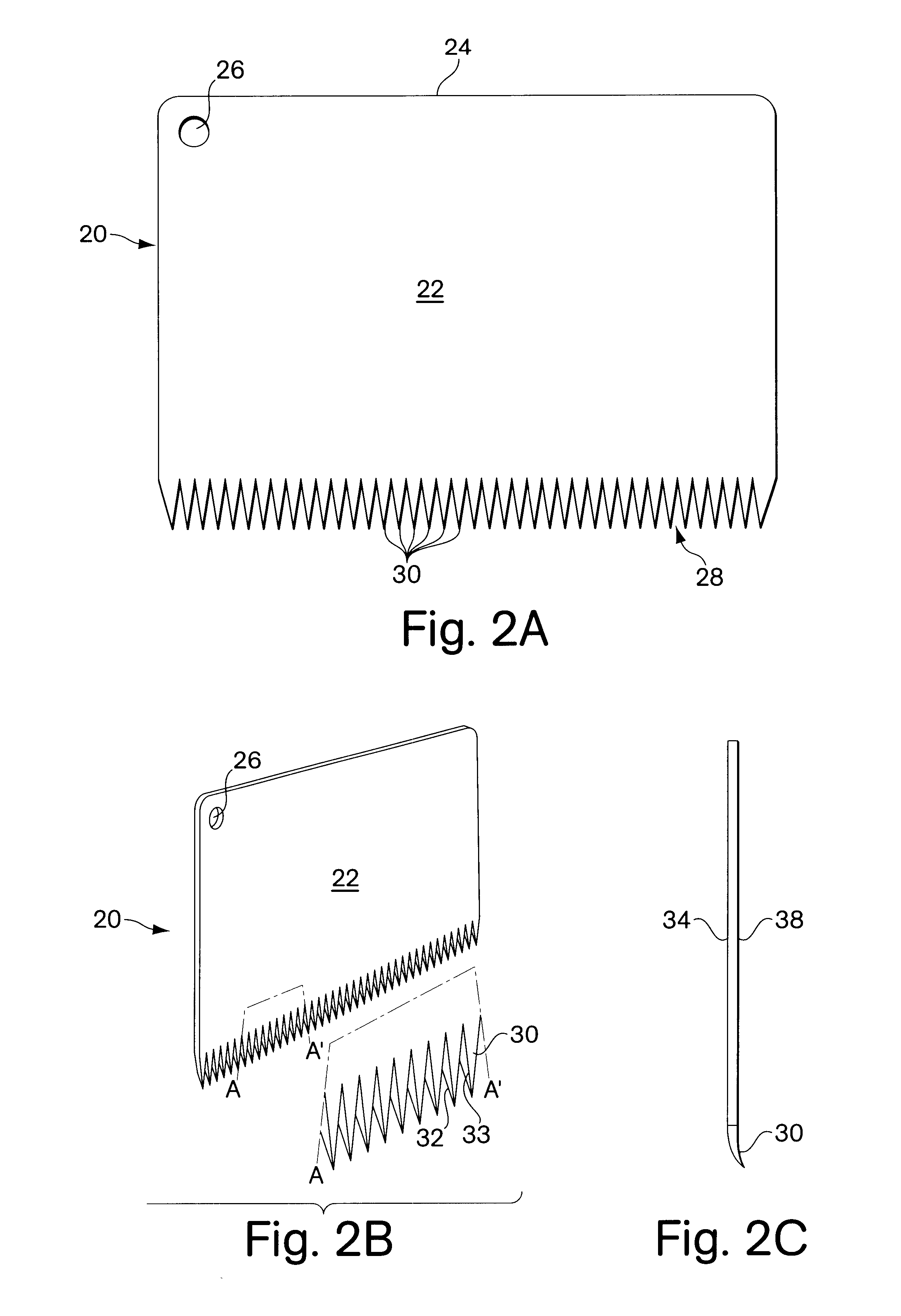

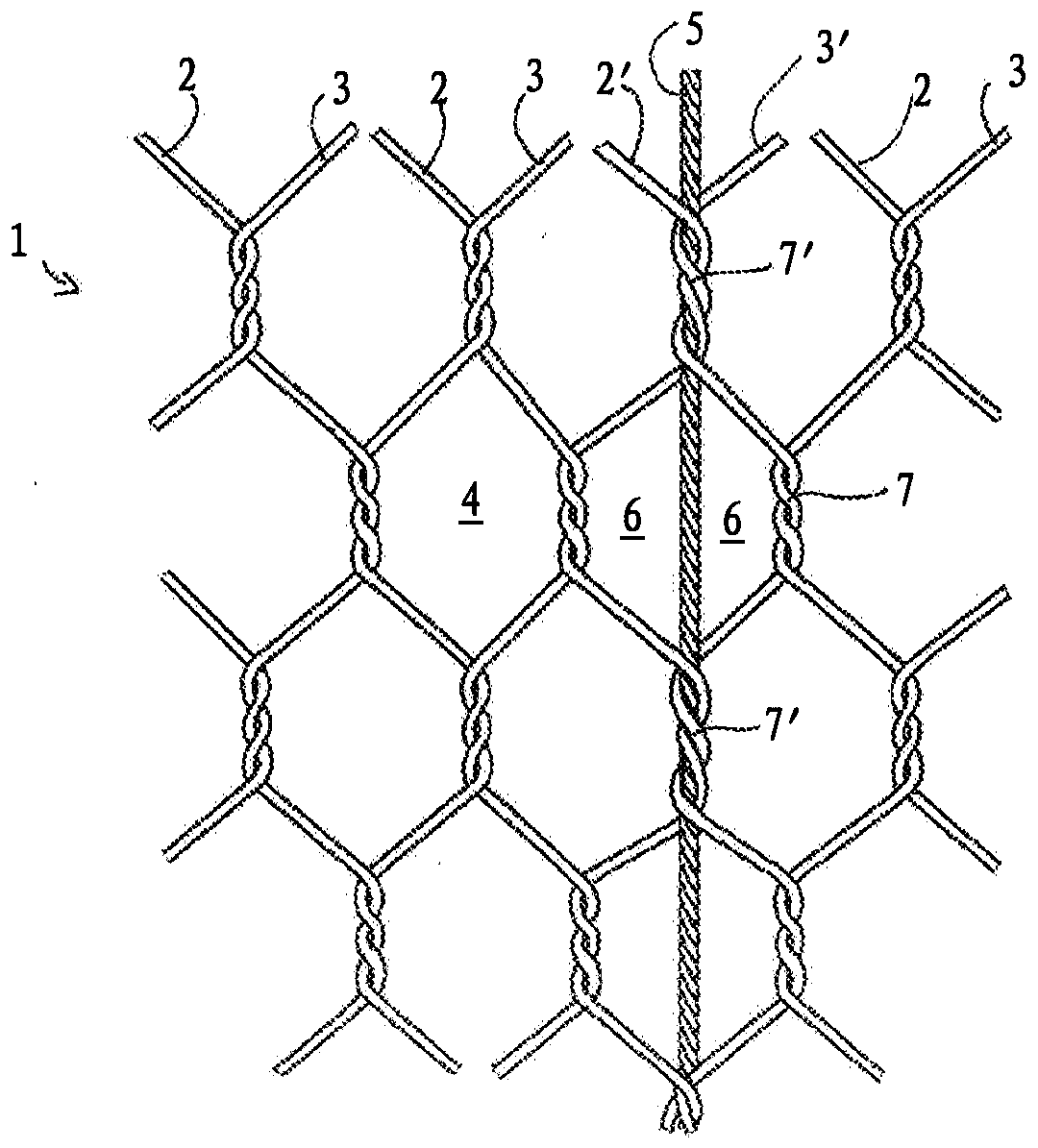

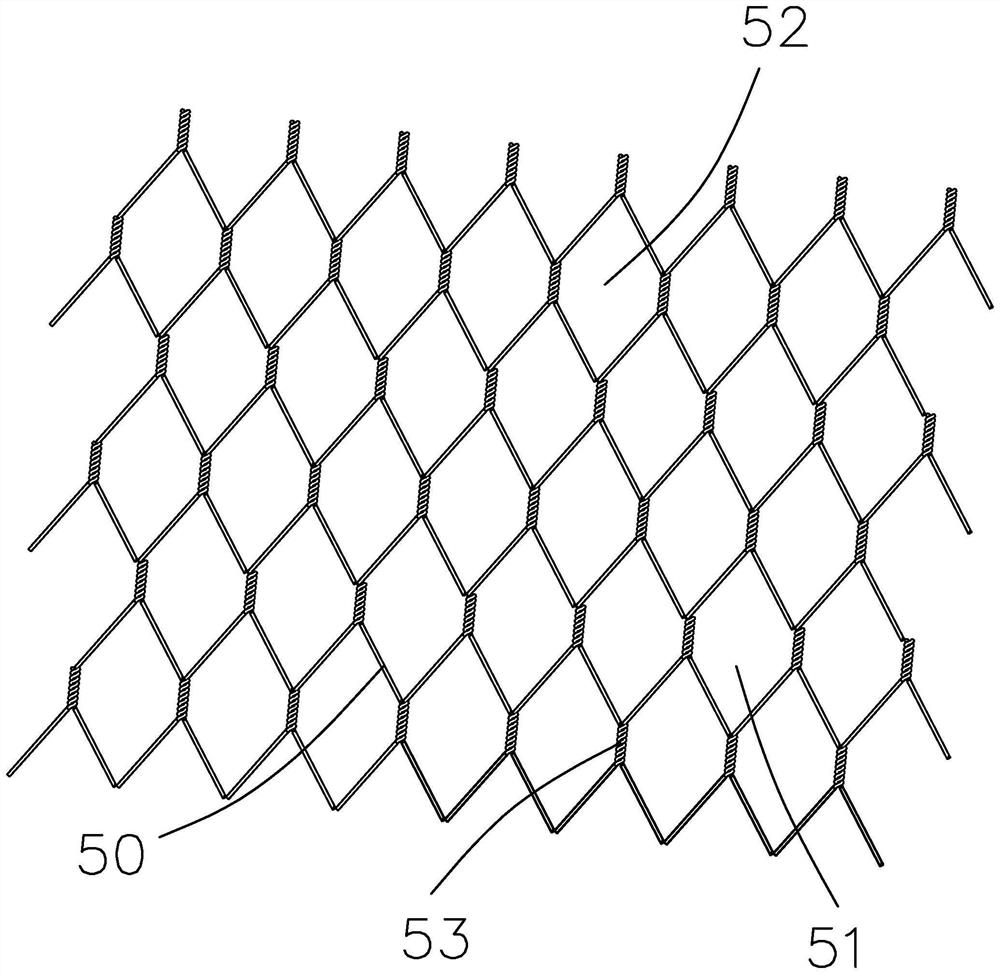

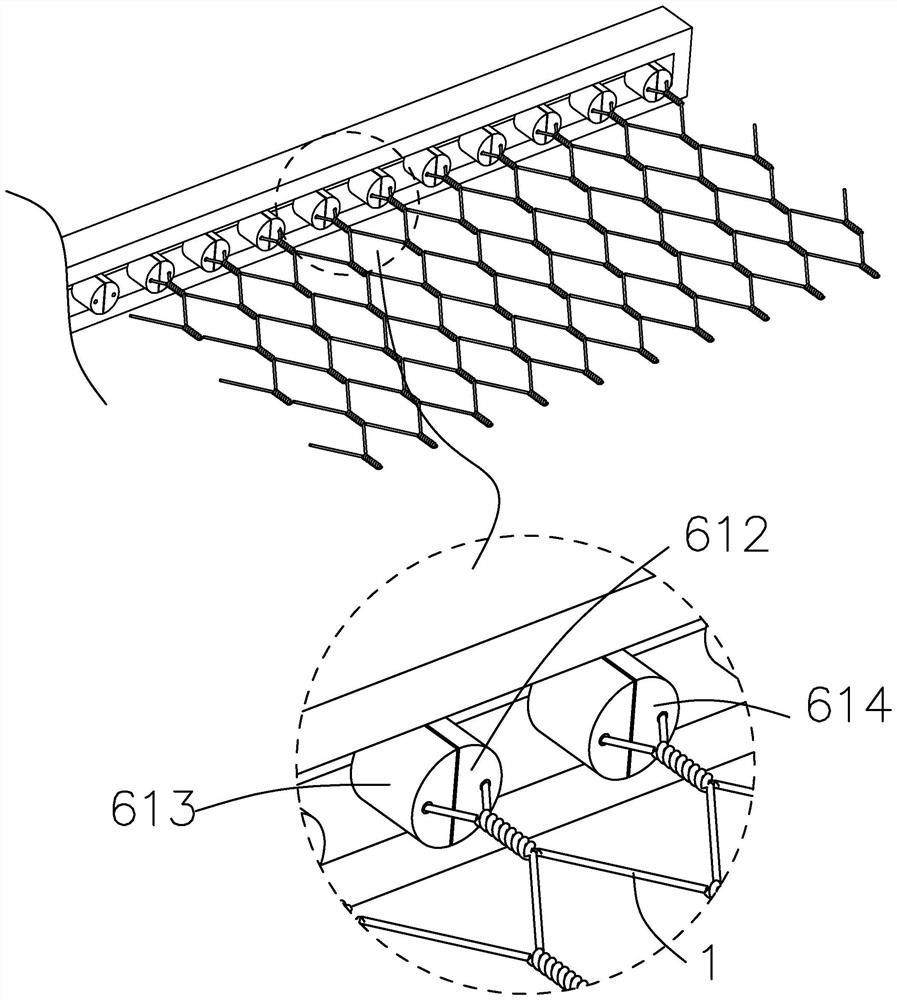

Net structure and methods of making the same

A net structure includes a plurality of metal rightwards inclined wires including, in sequence, a first rightwards inclined wire, a second rightwards inclined wire, and an N-th rightwards inclined wire. The net structure further includes a plurality of metal leftwards inclined wires including, in sequence, a first leftwards inclined wire, a second leftwards inclined wire, and an N-th leftwards inclined wire. The first rightwards inclined wires intersects, in sequence, from the first rightwards inclined wire through the N-th rightwards inclined wire at an intersection at which a twine portion is formed. The second rightwards inclined wires intersects, in sequence, from the second rightwards inclined wire through the N-th rightwards inclined wire at an intersection at which a twine portion is formed. The N-th leftwards inclined wire intersects the N-th rightwards inclined wire at an intersection at which a twine portion is formed, thereby forming a net structure with a plurality of hexagonal meshes. The net structure is made by slant weaving.

Owner:GANGZHAN ENTERPRISE

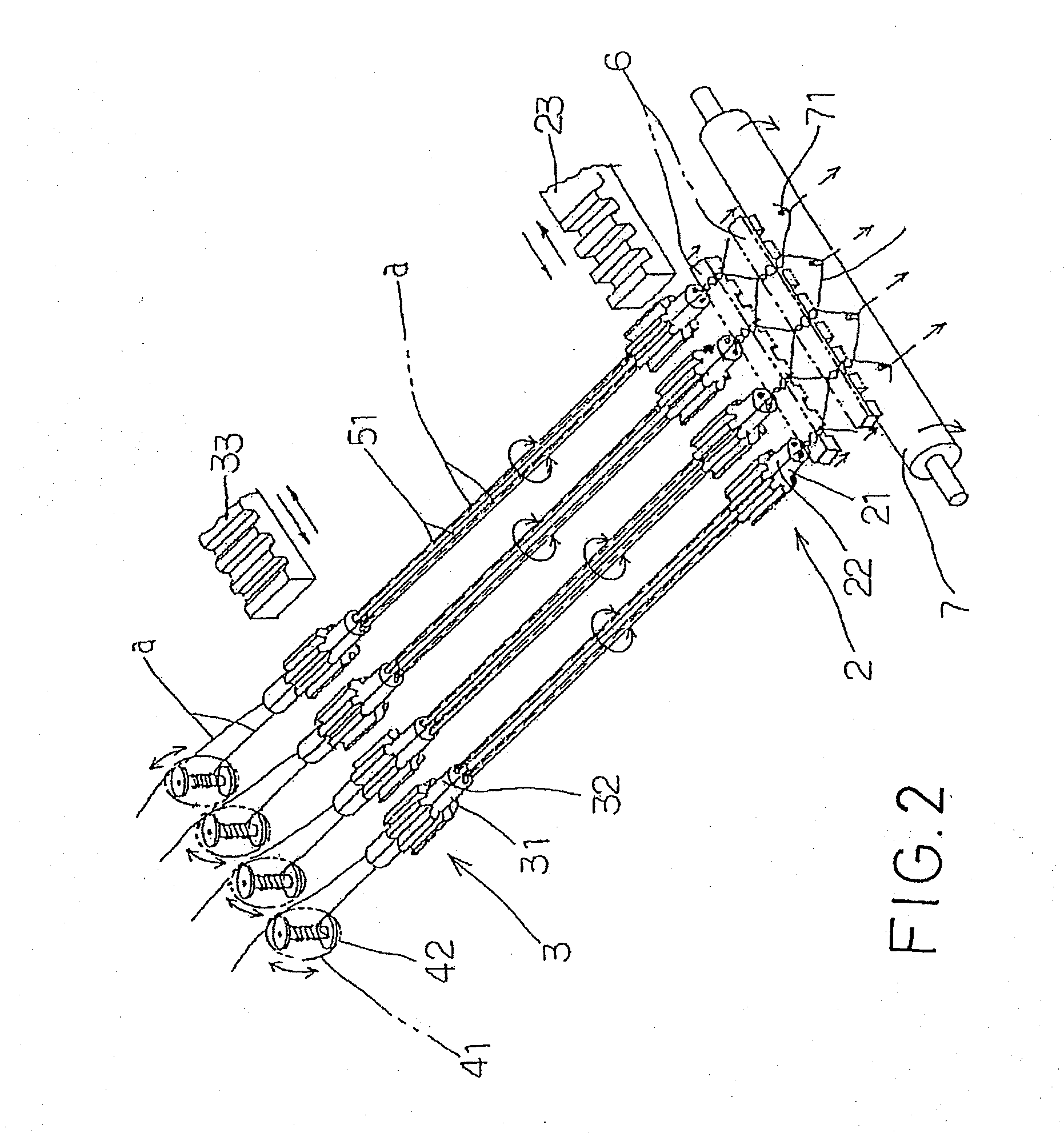

Plastic open mesh net manufacturing device and machine

ActiveCN102656304AConsistent shapeConsistent strengthTwist lace-making machinesWire networkEngineeringMechanical engineering

A device for twisting plastic wires to form a plastic open mesh net comprises a front twist mechanism and a back twist mechanism which have corresponding pairs of front and back thread-holes for receiving plastic wires to be twisted. Each couple of a front thread-hole and a back thread-hole is connected by a corresponding heat-conductive thread guide, preferably in the form of a pipe, which provides a uniform heating of the plastic wire which is guided therein. A machine for manufacturing a plastic open mesh net comprises a holding device downstream of the twisting device to maintain a uniform shape of the just formed open mesh net.

Owner:OFFICINE MACCAFERRI SPA

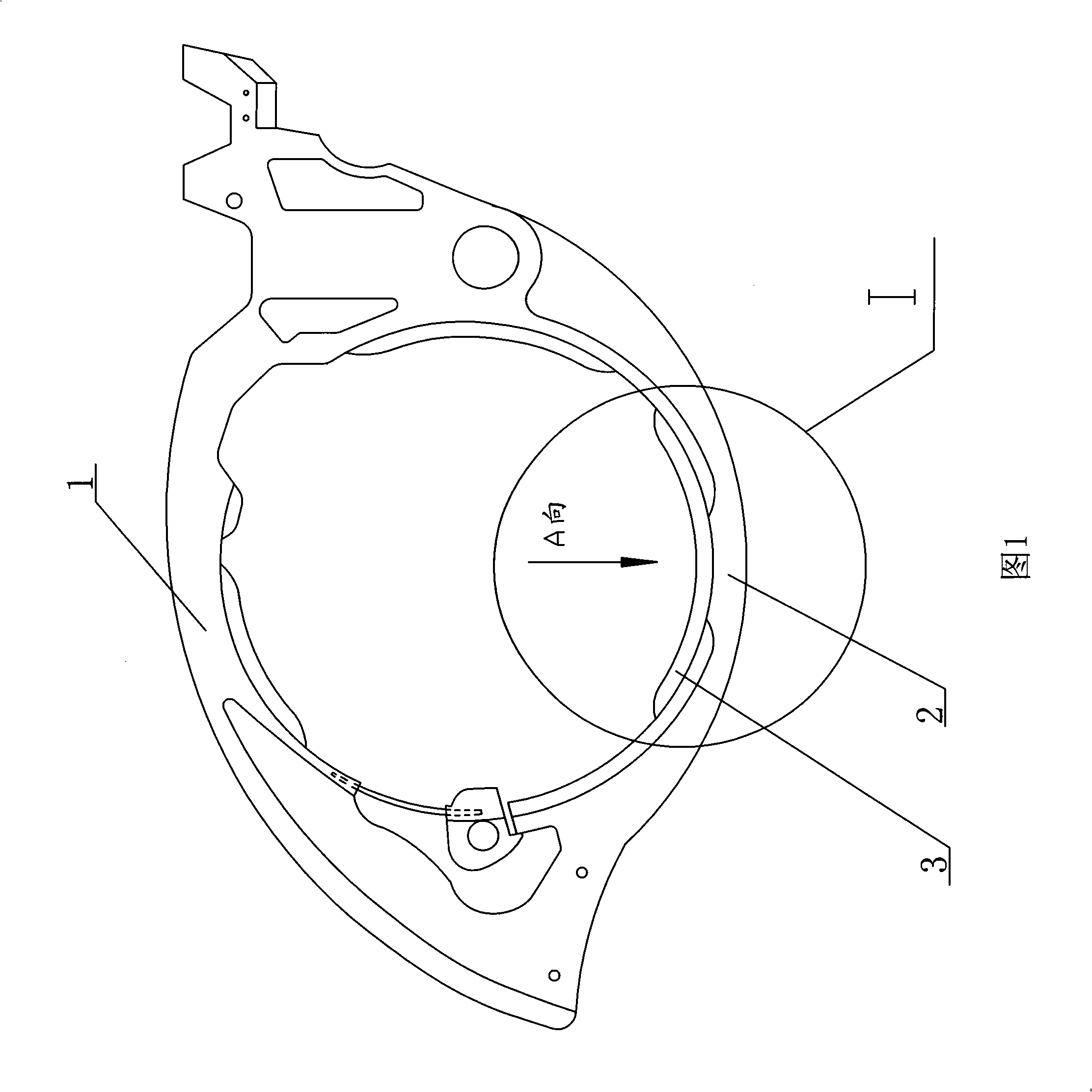

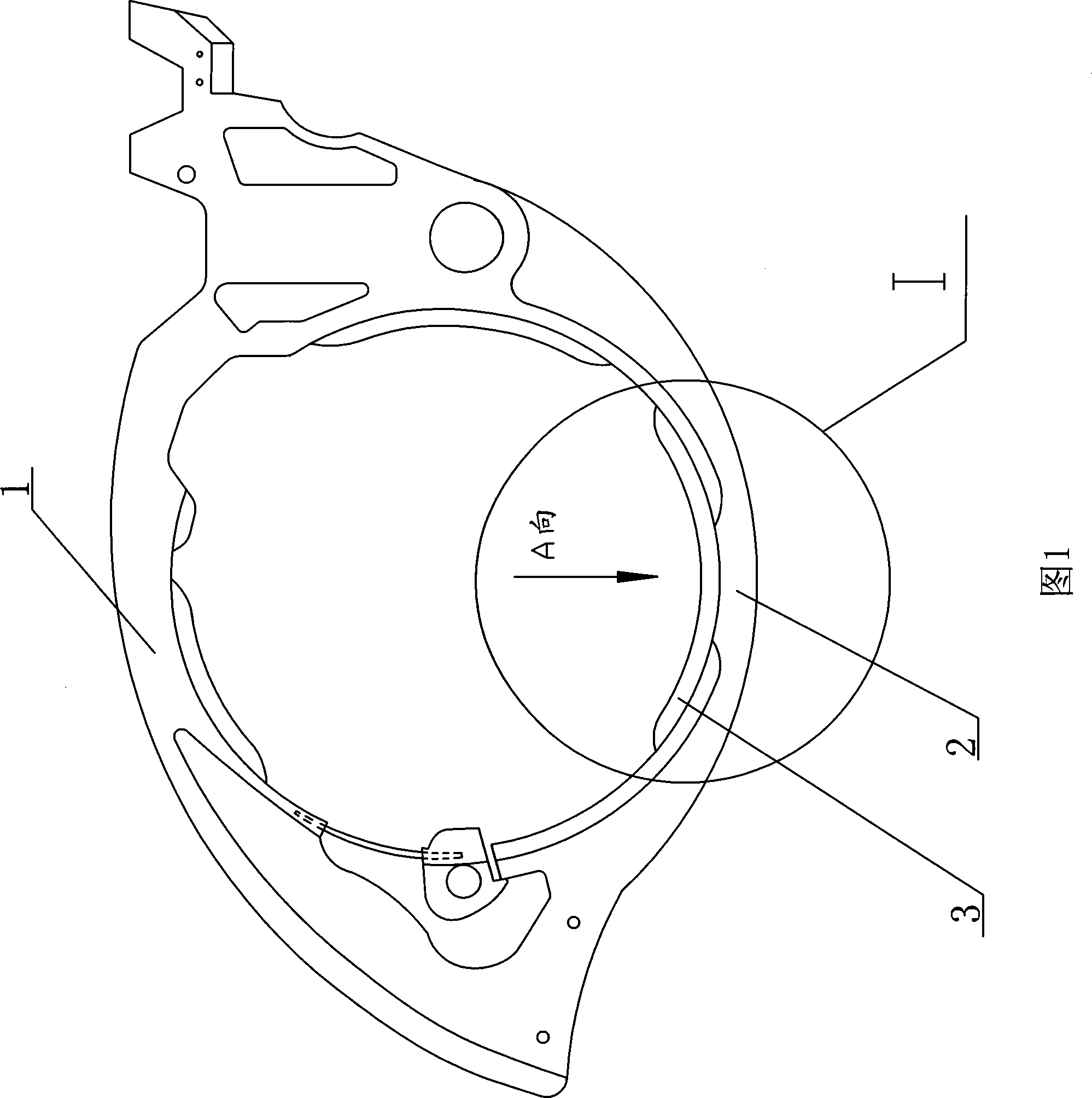

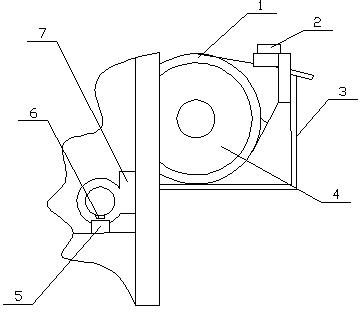

Plastic shuttle of netting machine

ActiveCN101333725AImprove wear resistanceExtended service lifeTwist lace-making machinesKnotting netsWear resistantMetallic materials

The invention discloses a plastic shuttle of the netting machine, which comprises a plastic shuttle body and an arc-shaped bottom supporting section that is arranged at the bottom of the plastic shuttle body and is used to support a line disk. One side of the arc-shaped bottom supporting section is provided with a shuttle retaining edge; and the inner surface of the arc-shaped bottom supporting section is buried with a layer of corresponding arc-shaped metal coupon which is made of wear resistant metal material. The plastic shuttle of the netting machine has the advantages that as a layer of arc-shaped metal coupon is arranged in the arc-shaped bottom supporting section, the wear resistant performance between the arc-shaped bottom supporting section and the line disk is improved, thereby prolonging the service life of the plastic shuttle; furthermore, the arc-shaped metal coupon and the plastic shuttle are lapped reasonably and ingeniously, so stronger binding force between the metal coupon and the plastic shuttle can be assured, and strength in the inner structure will not be affected due to the arrangement of the metal coupon.

Owner:张家港市新盈模具塑化有限公司

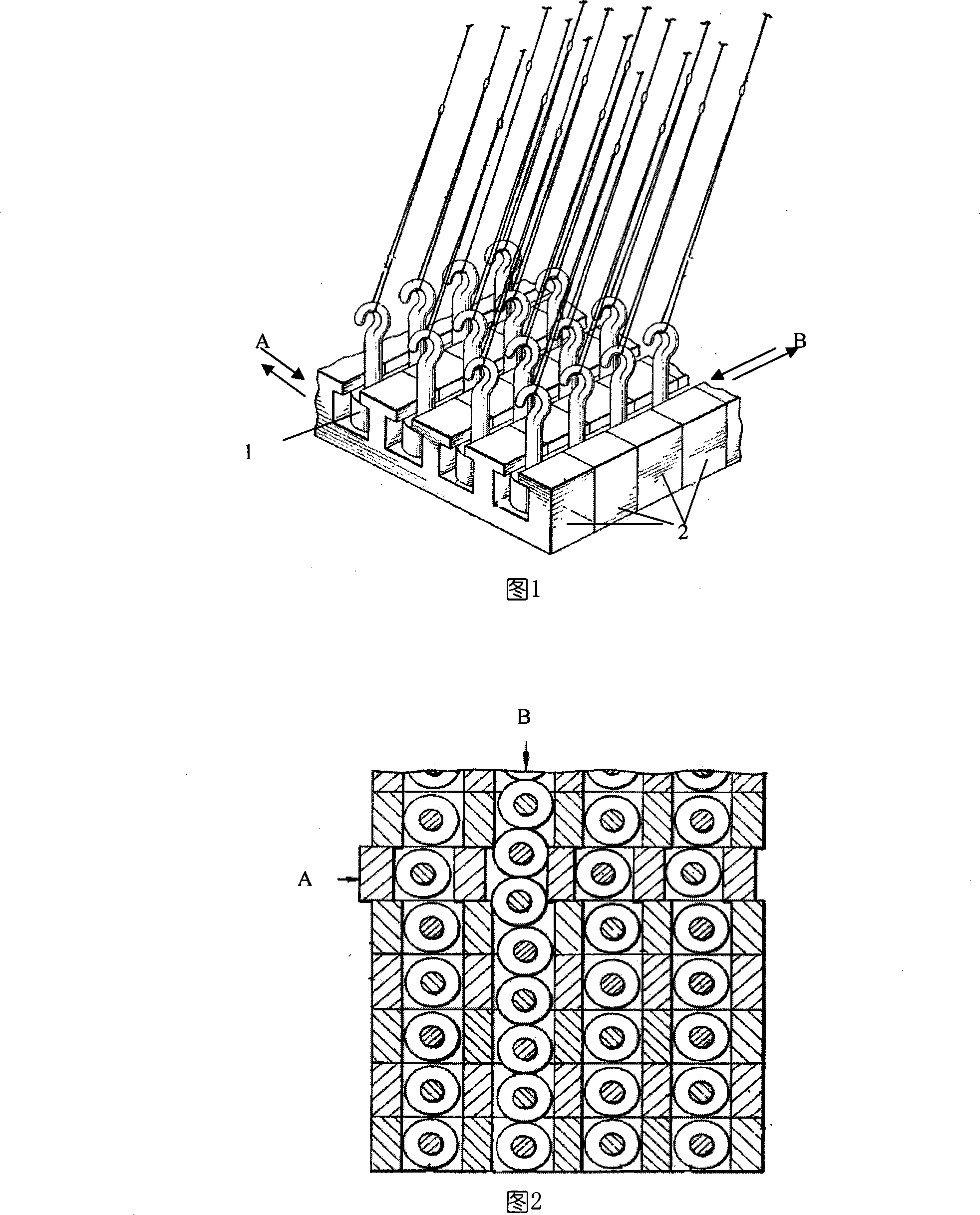

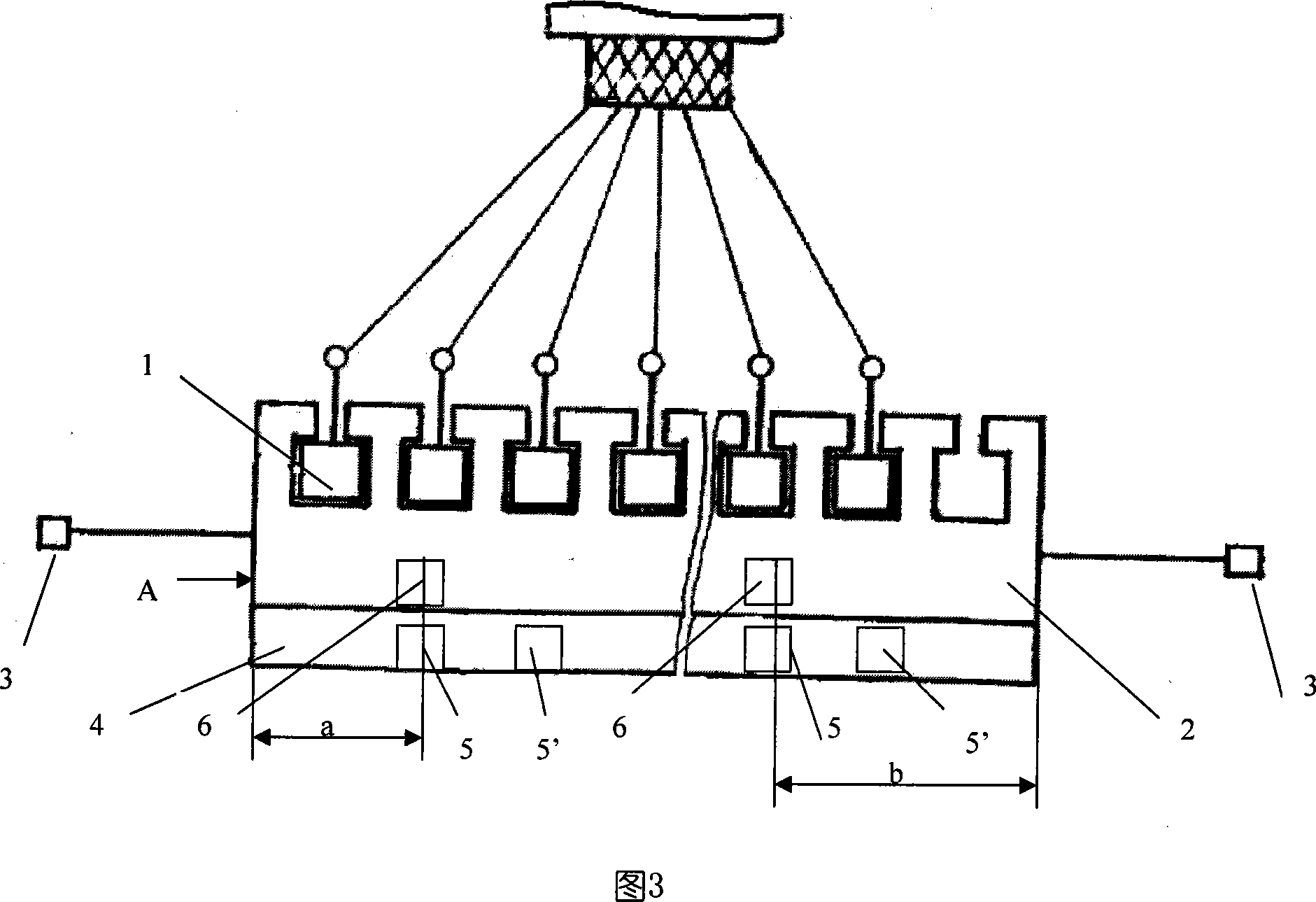

Method for antilocking for shuttle operation of three-dimensional textile machine

InactiveCN101245528AGuaranteed uptimeImprove the "stuck" phenomenon of inflexible lateral movementTwist lace-making machinesEngineeringMagnet

A method of the anti-blocking of the operation of the shuttle of a three dimensional fabric knitting machine arranges the shuttle in the slot of a shuttle box and the shuttle can be controlled to slide to and fro along the slot of the shuttle box; while the shuttle box can slide to and fro under the pushing of a shuttle box push bar; at the moment, a tiny transmission intermission exists between the shuttle box push bar and the shuttle box during design and mounting; besides, the lower plane part of each shuttle box is internally embedded with a plurality of shuttle box magnets arrayed in certain distance; while the upper plane parts of the bases of the shuttle boxes corresponding to the position of each shuttle box magnet is internally embedded with A-position magnets of the bases of the shuttle boxes with the same quantity; B-position magnets of the bases of the shuttle boxes with the same quantity are also embedded at the position which is one traverse step length to the A-position magnets of the bases of the shuttle boxes. The poles of the A-position magnets of the bases of the shuttle boxes and the B-position magnets of the bases of the shuttle boxes are collocated with the magnets of the shuttle boxes to form an 'opposite attraction' state to finish the automatic accurate contraposition of the shuttle boxes in A-position and B-position by the mutual attraction. Consequently, during the operation of the knitting machine, each push bar of the shuttle box pushes corresponding shuttle box in a not very accurate and in place mode; while the accurate position is automatically adjusted and reached by the opposite attraction of the shuttle box magnets to the magnets of the bases of the shuttle boxes, thus improving the operation state of the knitting machine to lead the knitting machine to be well-off and accurate.

Owner:CHANGZHOU BOLONG THREE DIMENSIONAL COMPOSITES

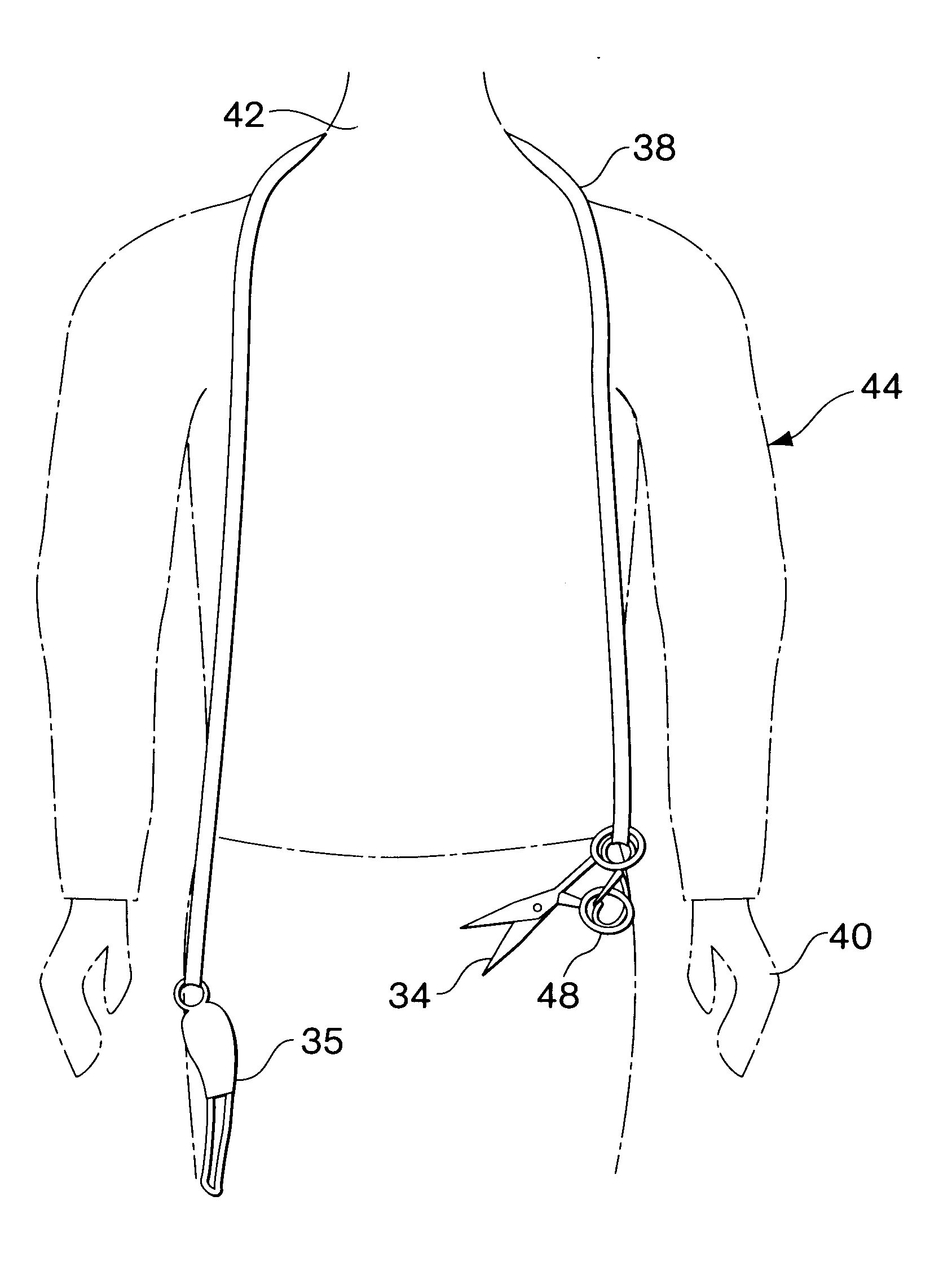

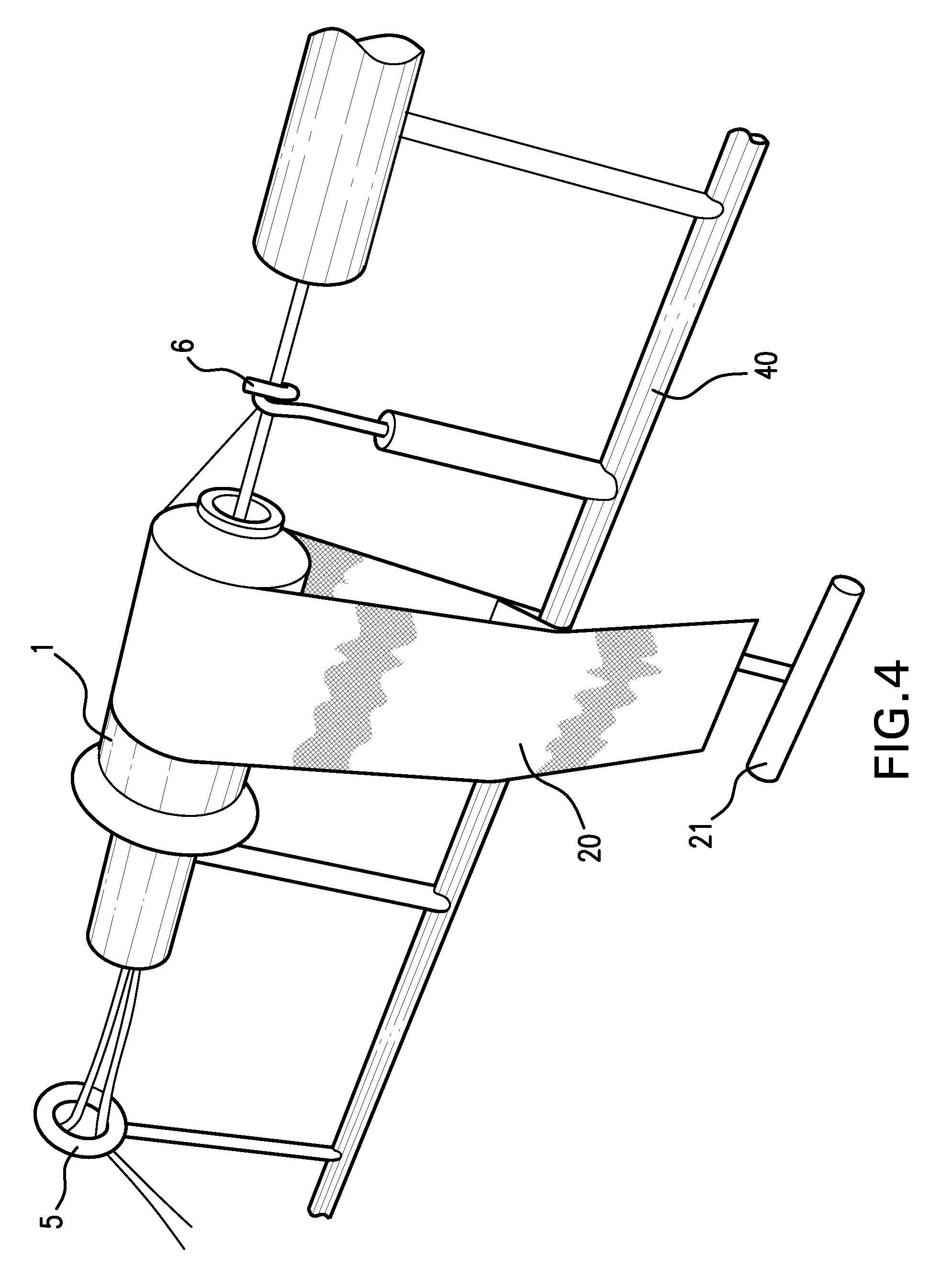

Horse hair braiding tools and methods for their use

The present invention provides tools, kits and methods for braiding animal hair, in particular hair of the horse's mane. Tools include a pulling tool, a cutting tool and a cutting comb. The pulling tool and the cutting tool are attachable to ends of a cord that retains them in a convenient position for the groomer to use. The tools may be assembled in a kit for easy use. Methods are disclosed for the use of these tools to braid the animal's mane in an aesthetically desirable manner.

Owner:SMITH RUTHANN

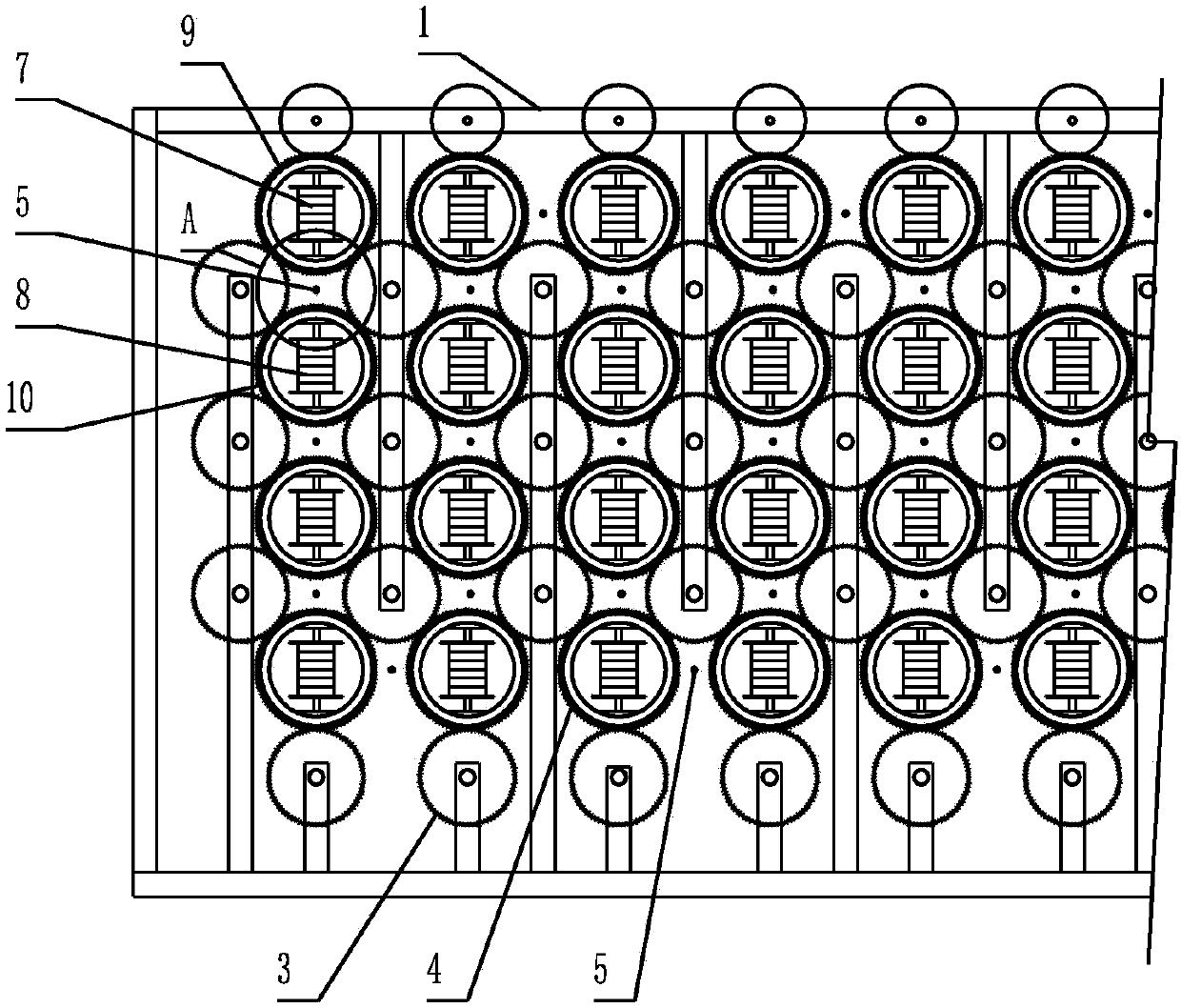

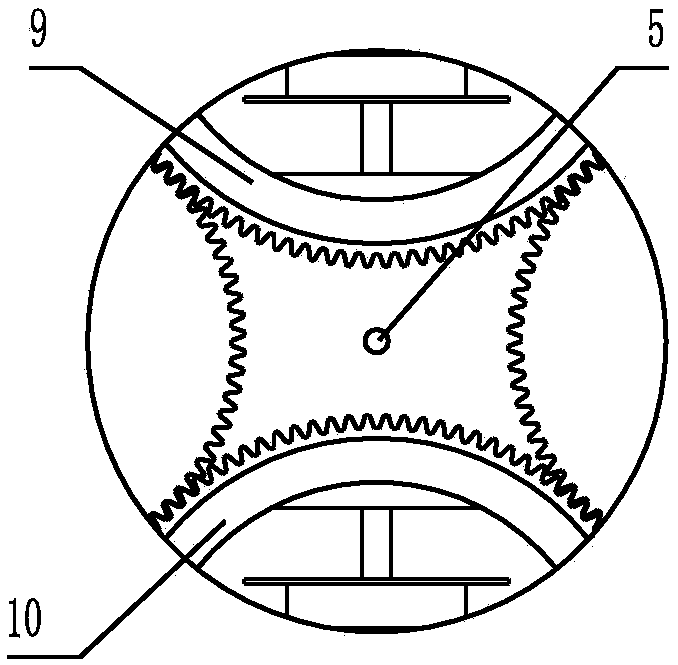

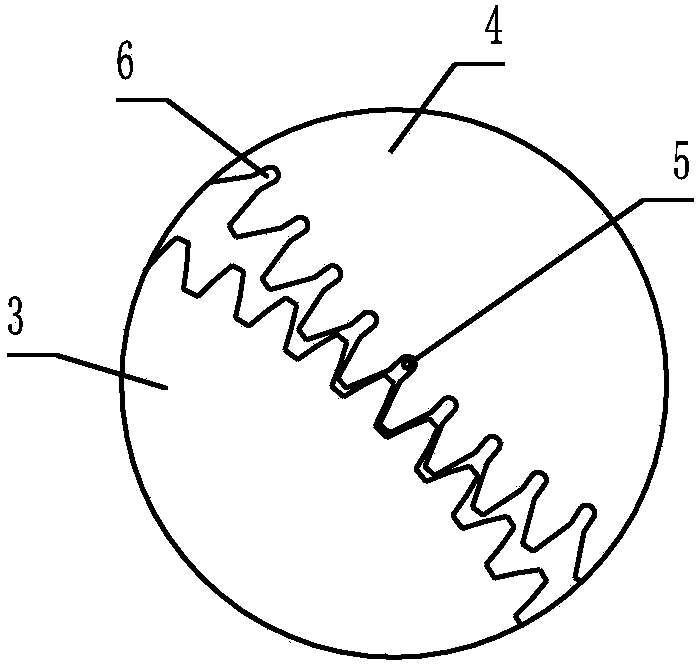

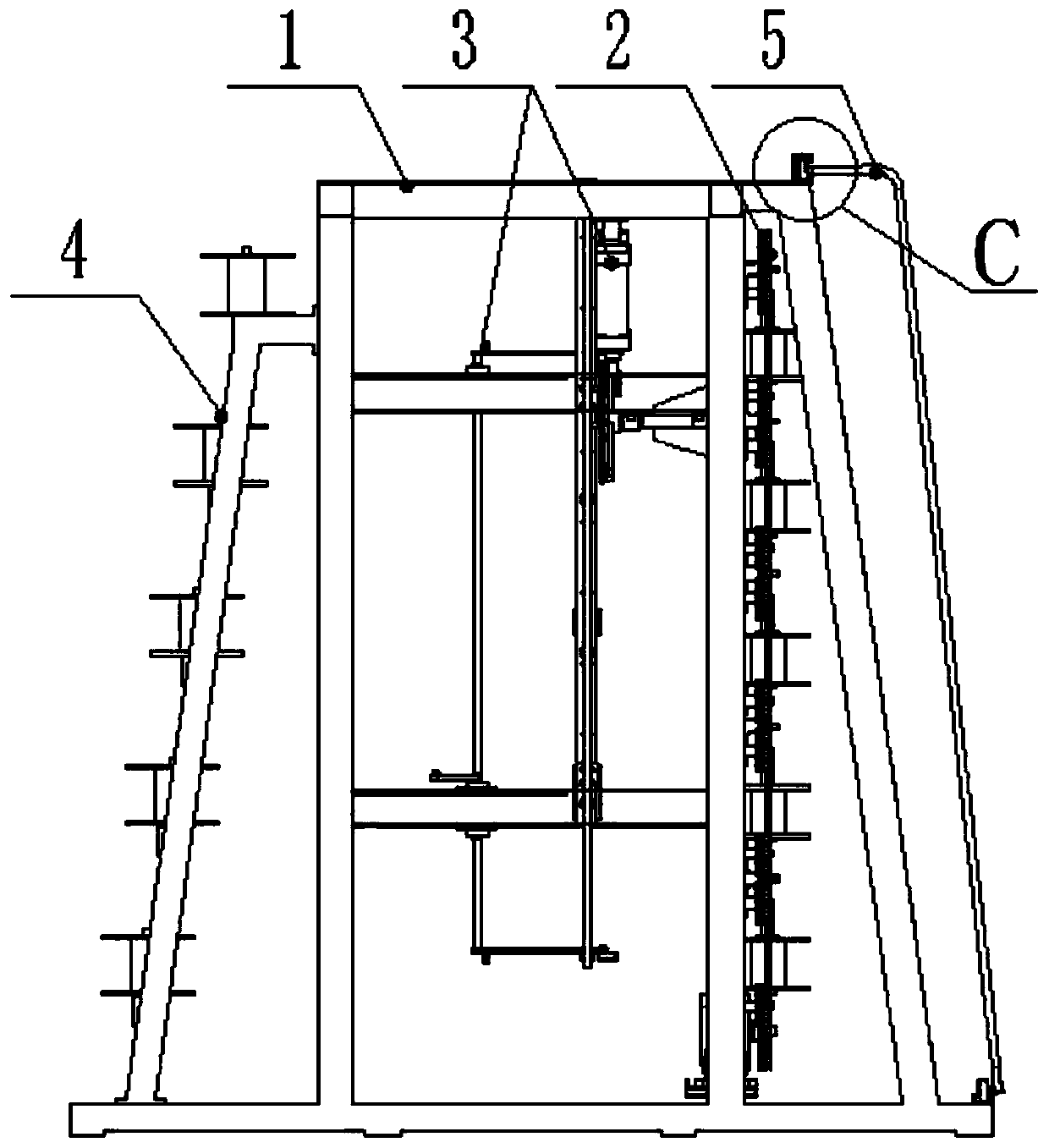

Hexagonal net automatic control efficient weaving system and use method thereof

PendingCN107805884AGuarantee quality and safetyGuaranteed operational safetyTwist lace-making machinesAutomatic controlDrive wheel

The invention discloses a hexagonal net automatic control efficient weaving system and a use method thereof. The system is provided with a mesh forming device of a hexagonal net weaving machine and ischaracterized in that a net wire winding module and a net wire displacement module are arranged in front of the mesh forming device; the net wire winding module is provided with a wire winding wheelgroup and a transmission wheel group; each wire winding wheel in the wire winding wheel group is driven by a driving wheel in an engaged way; a net wire groove is formed in the bottom of wheel teeth of the wire winding wheel; the net wire displacement module controls the displacement of a net wire arranged between two adjacent wire winding wheels; the net wire displacement module is provided witha general driving wheel; the general driving wheel is in driving connection with the net wire between the two adjacent wire winding wheels through a transmission component; the net wire winding moduleand the net wire displacement module simultaneously complete the wire winding action of the net wire in the wire twisting process; the system is additionally provided with a PLC (Programmable Logic Controller). The hexagonal net weaving system omits a conventional net machine spring beating and mounting structure; metal wire and plastic wire nets can be woven; the characteristics of cost saving,high efficiency, high quality, high adaptability and high automation degree are achieved.

Owner:翟魁元

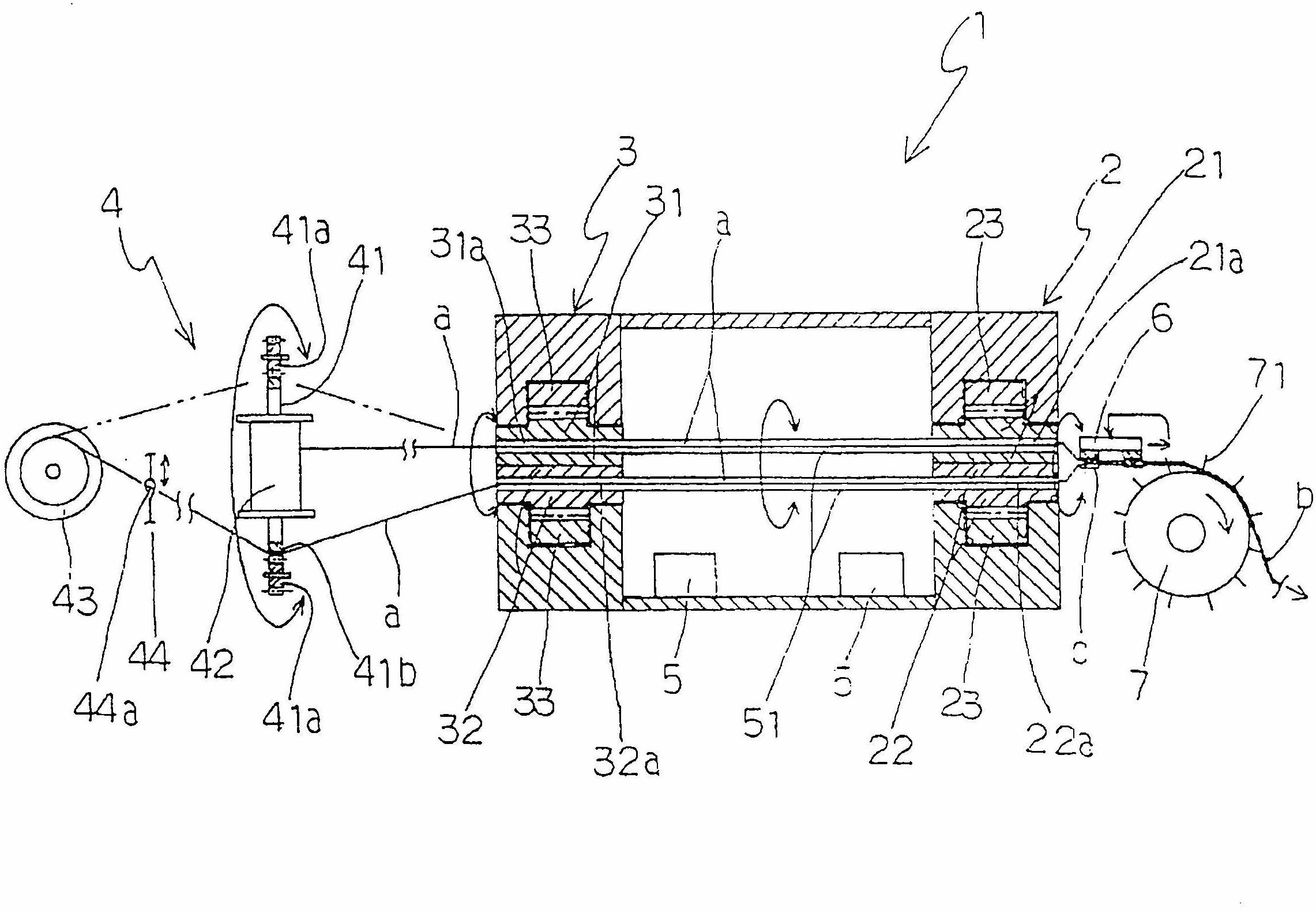

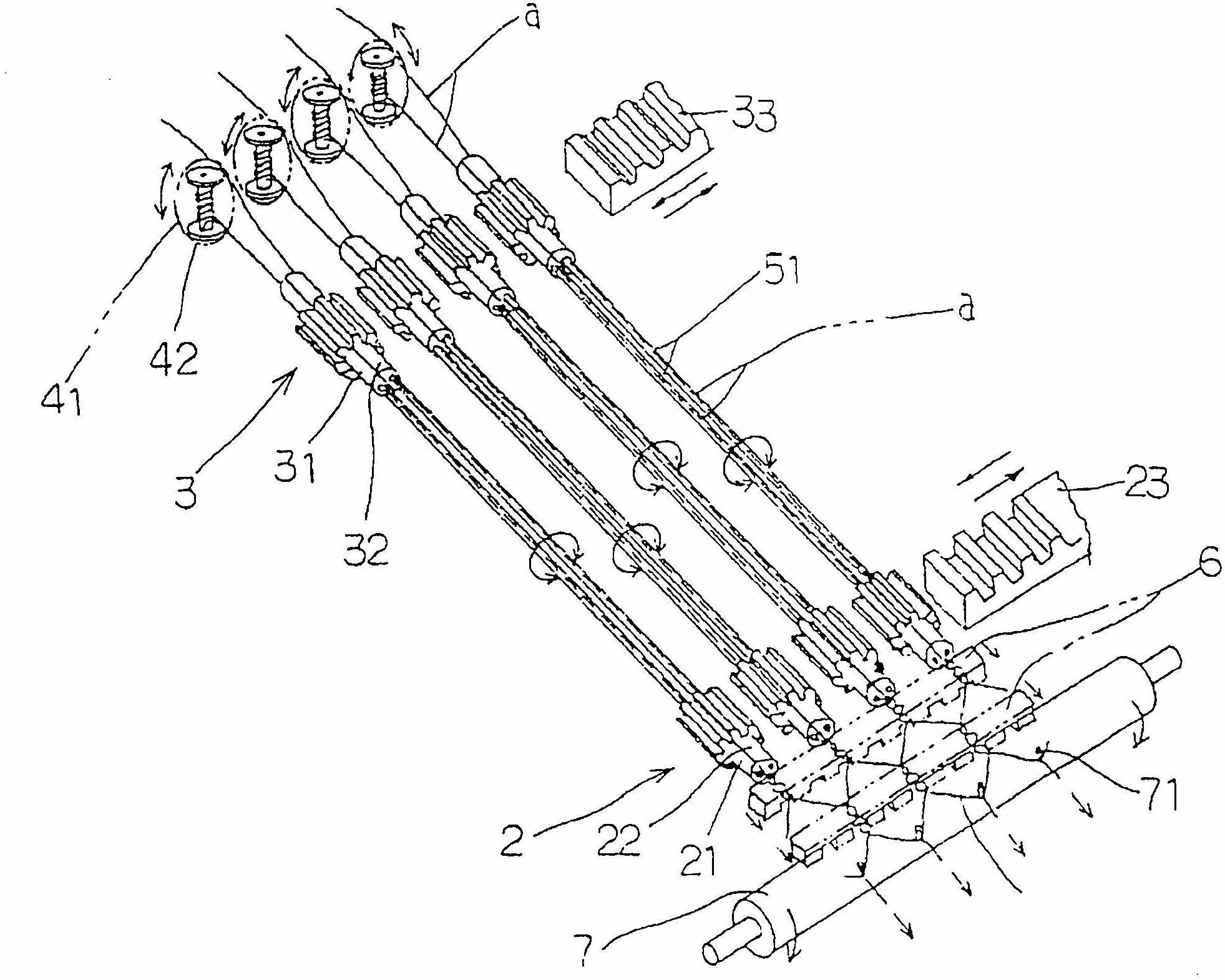

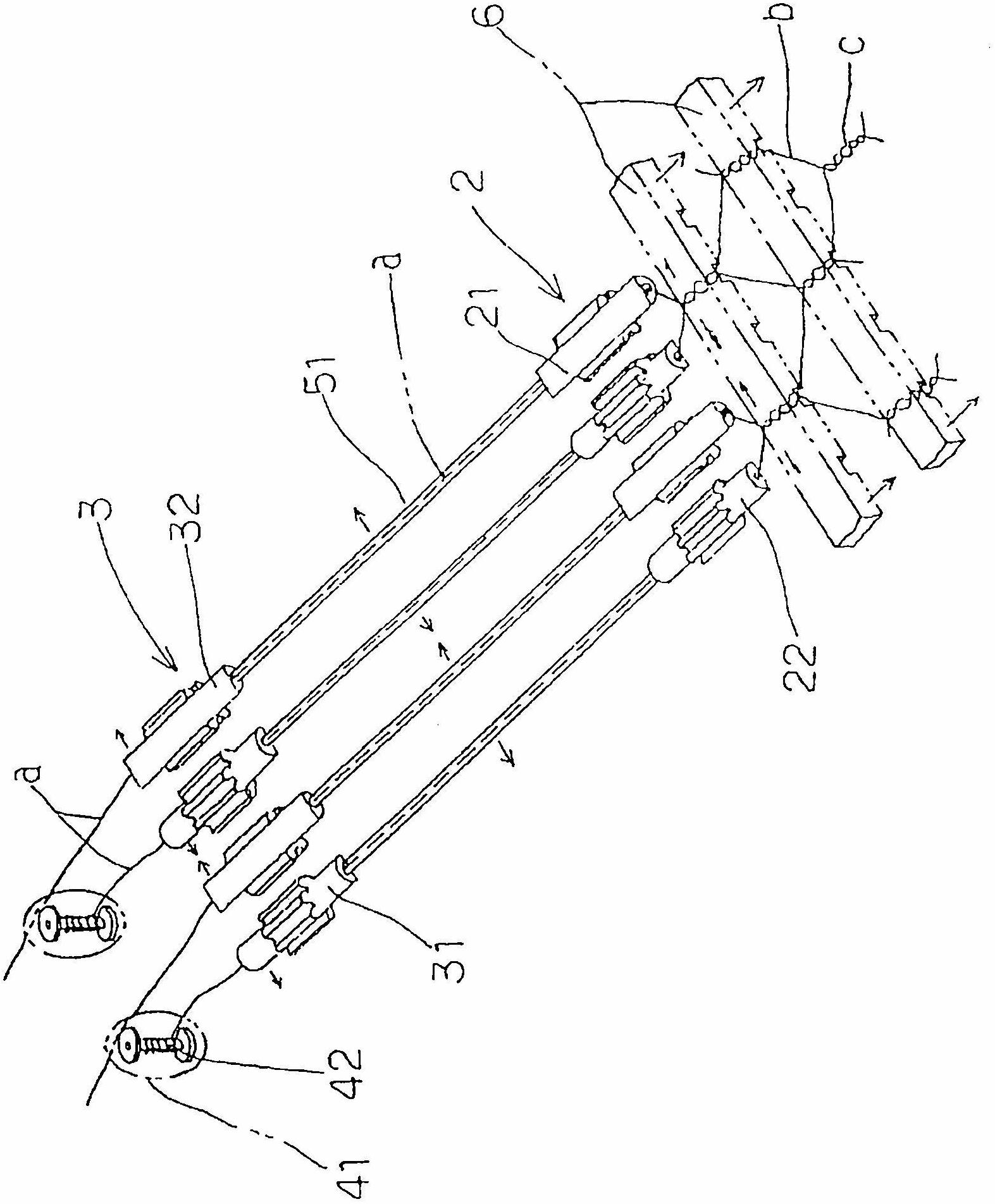

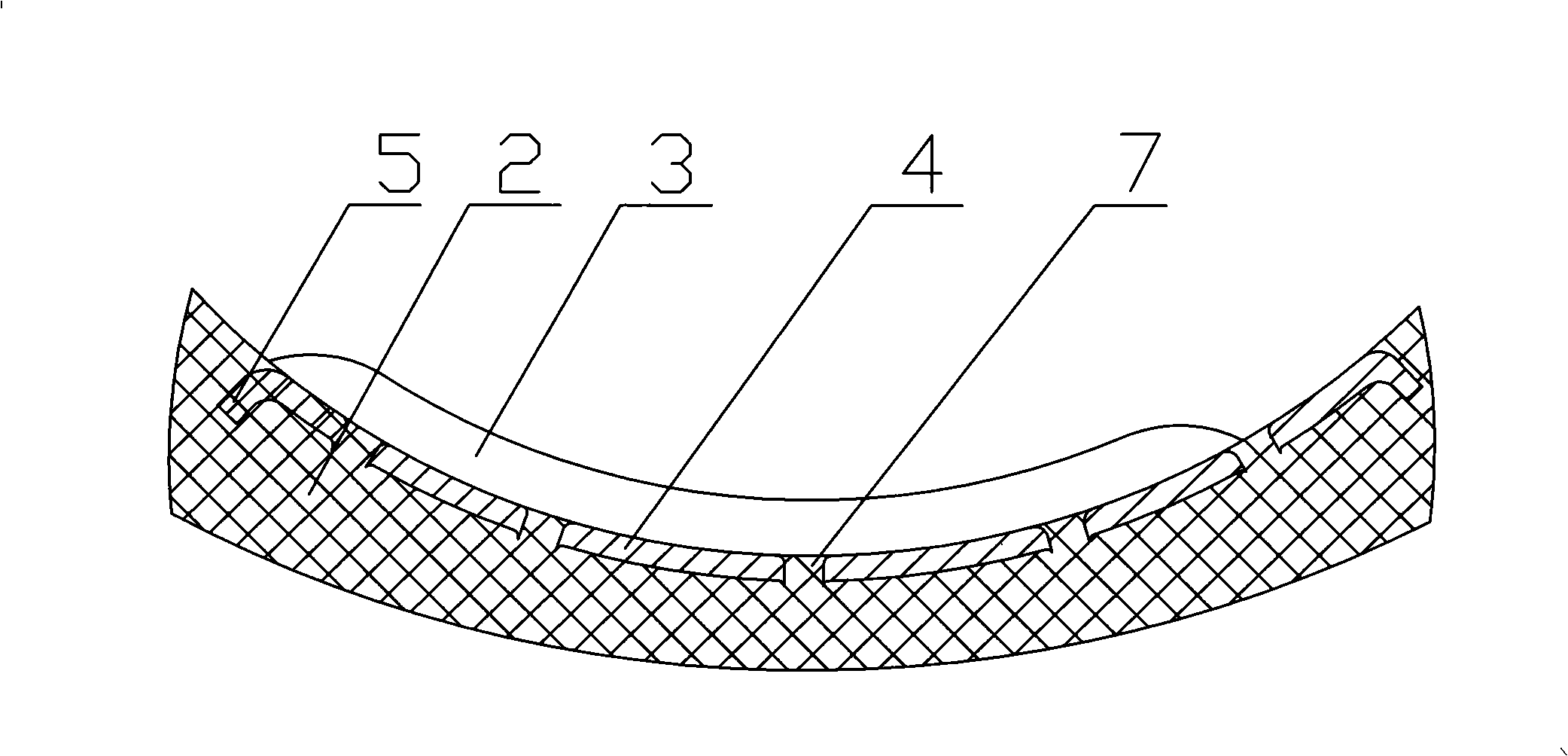

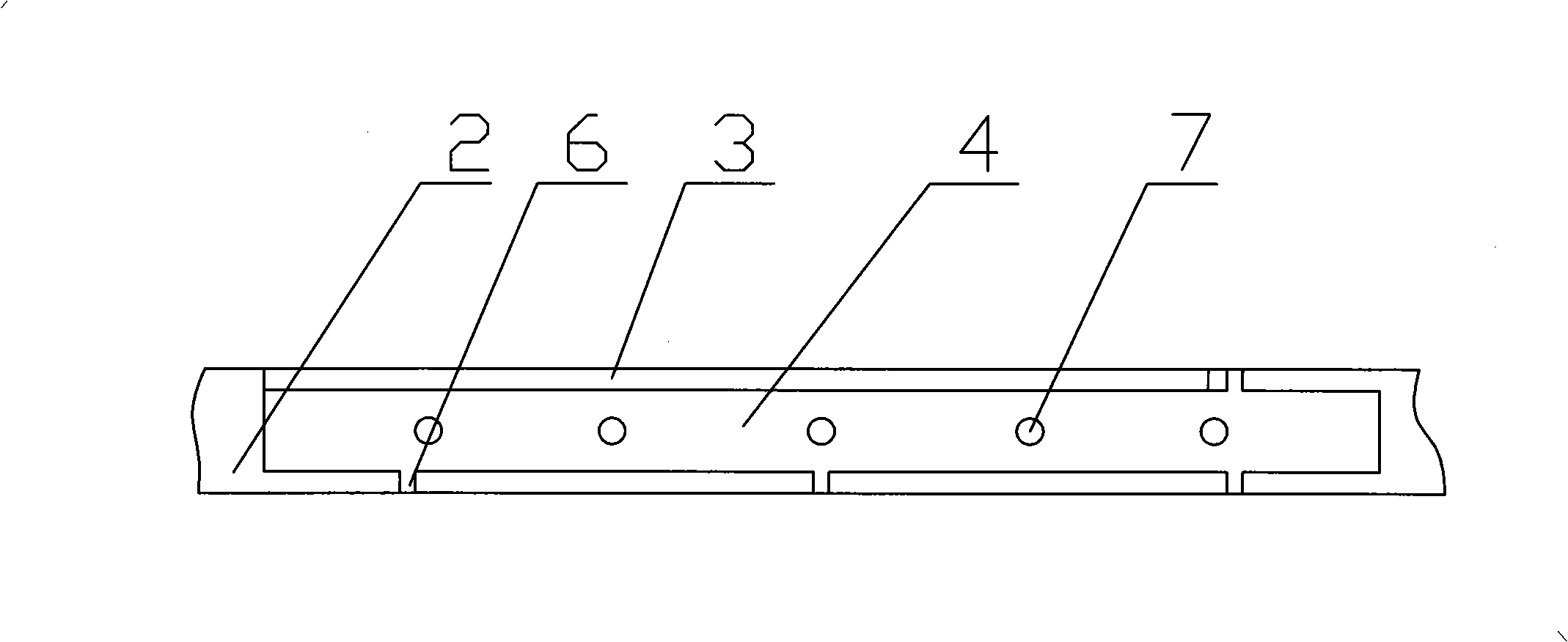

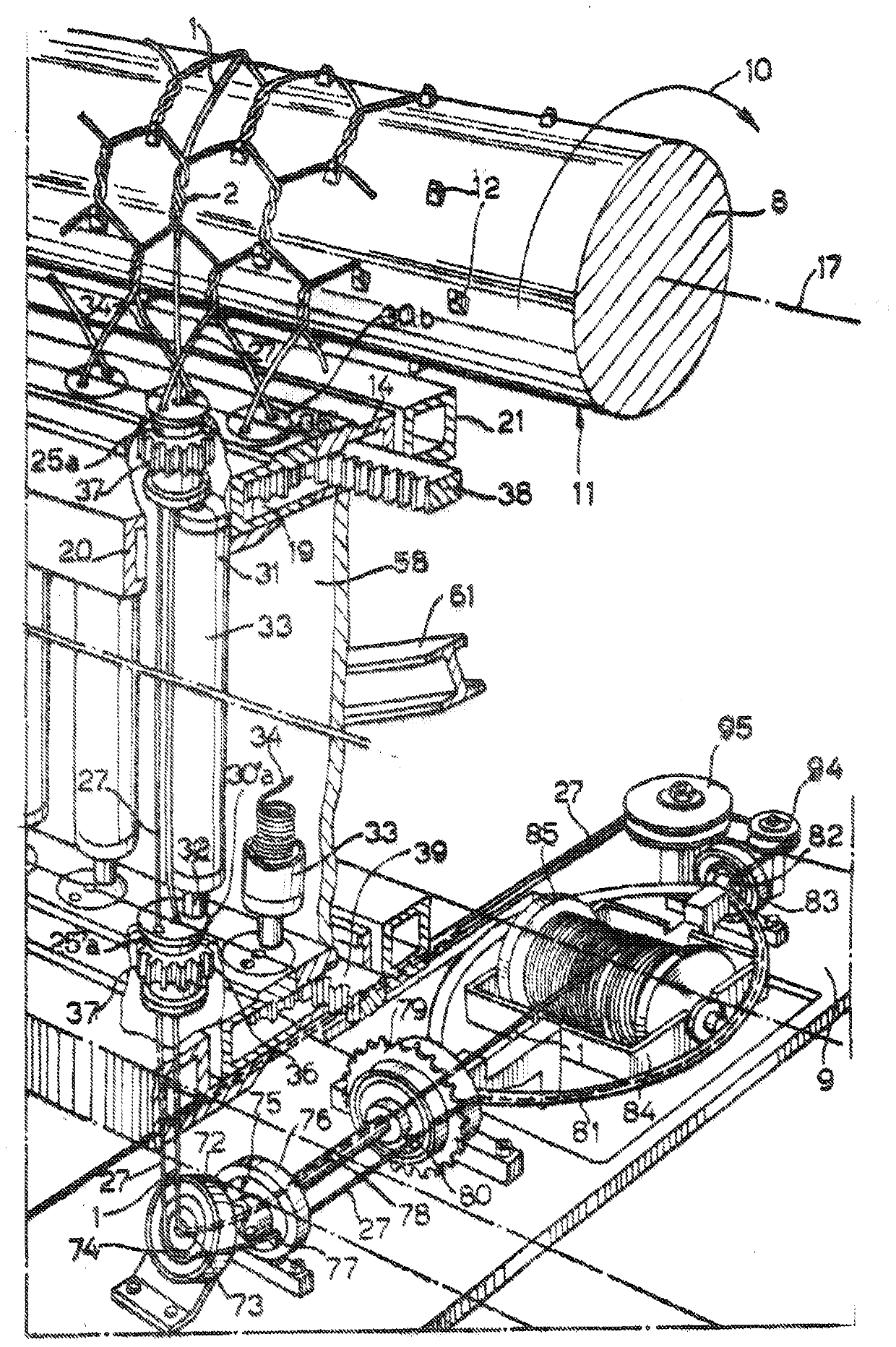

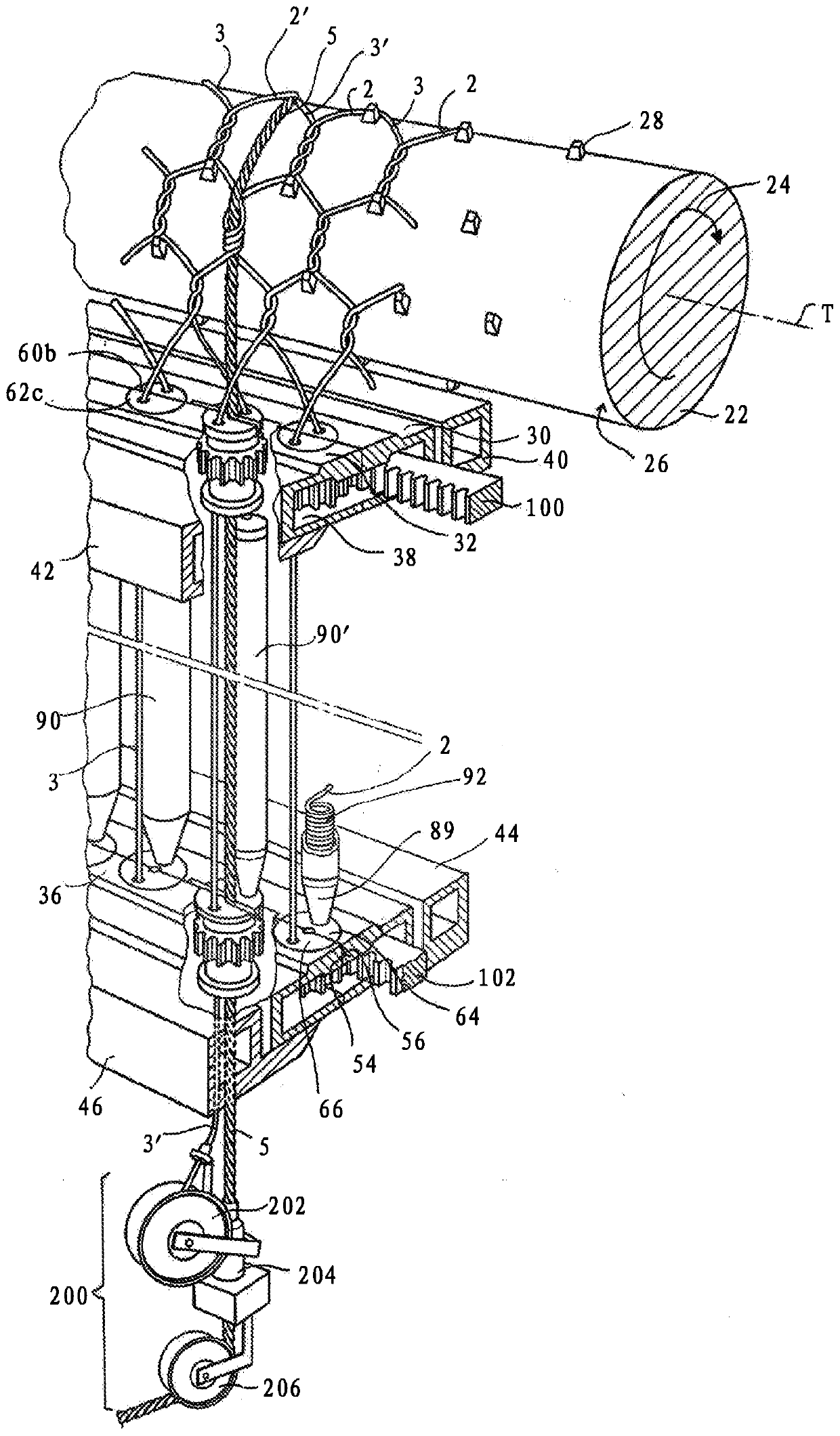

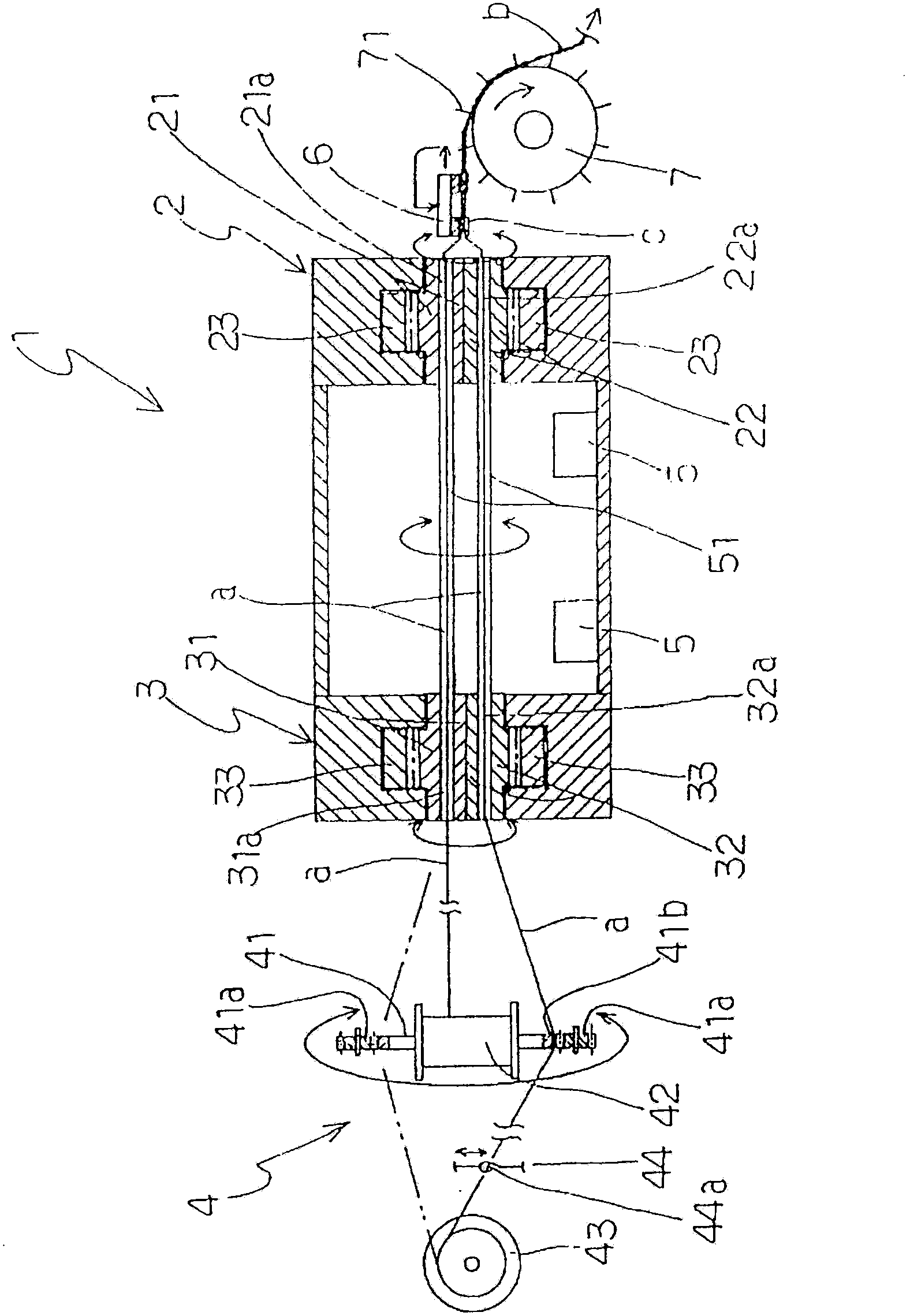

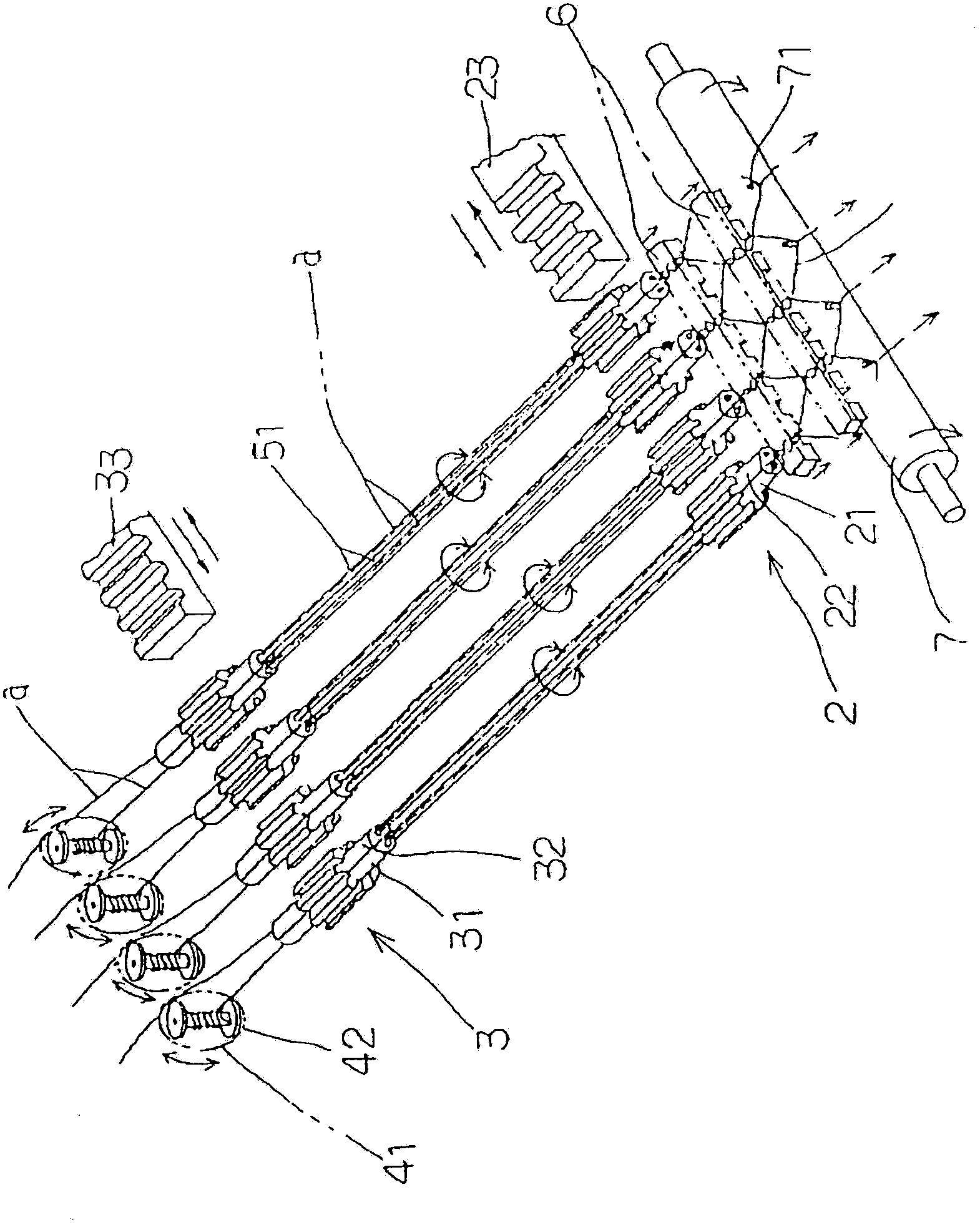

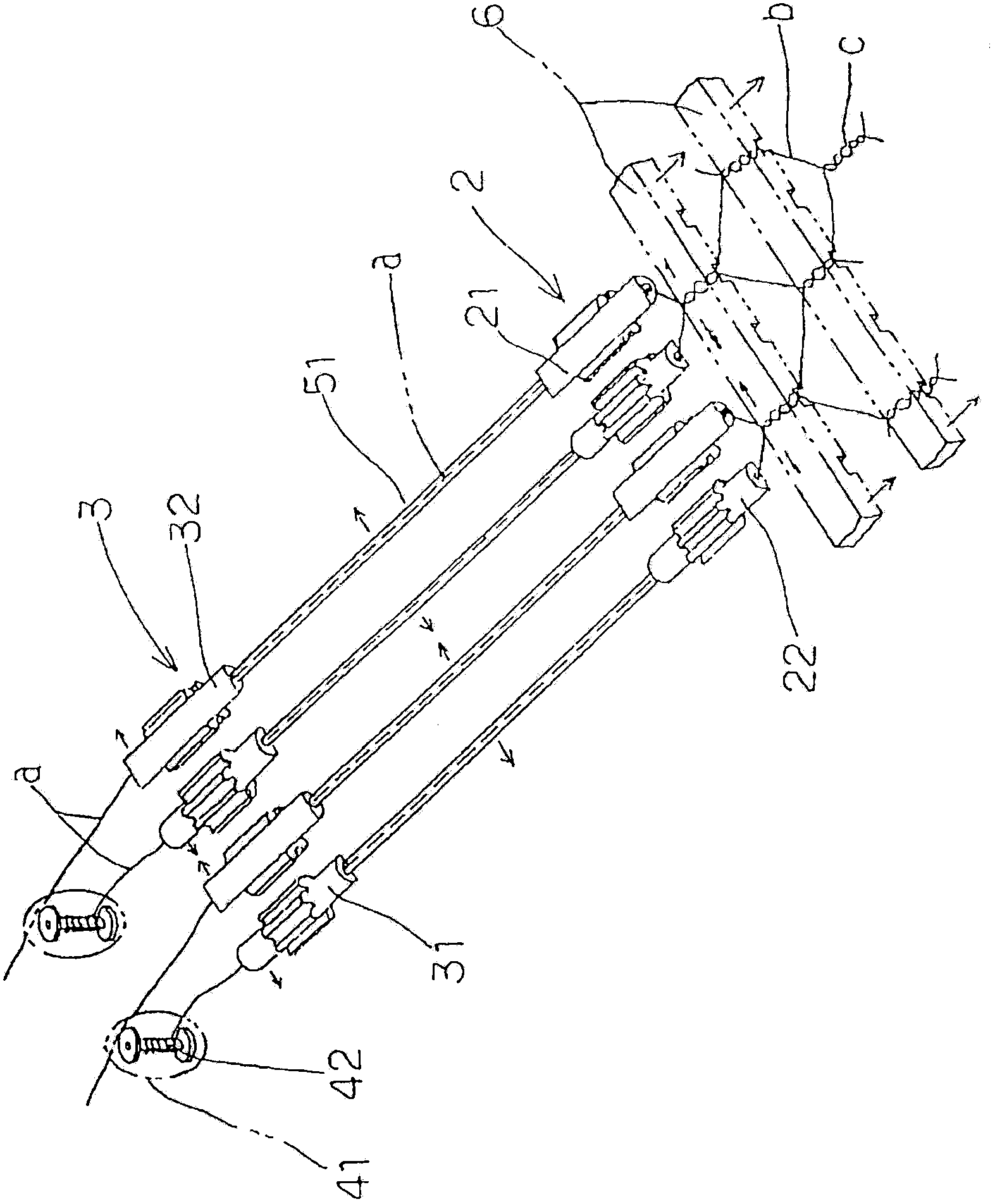

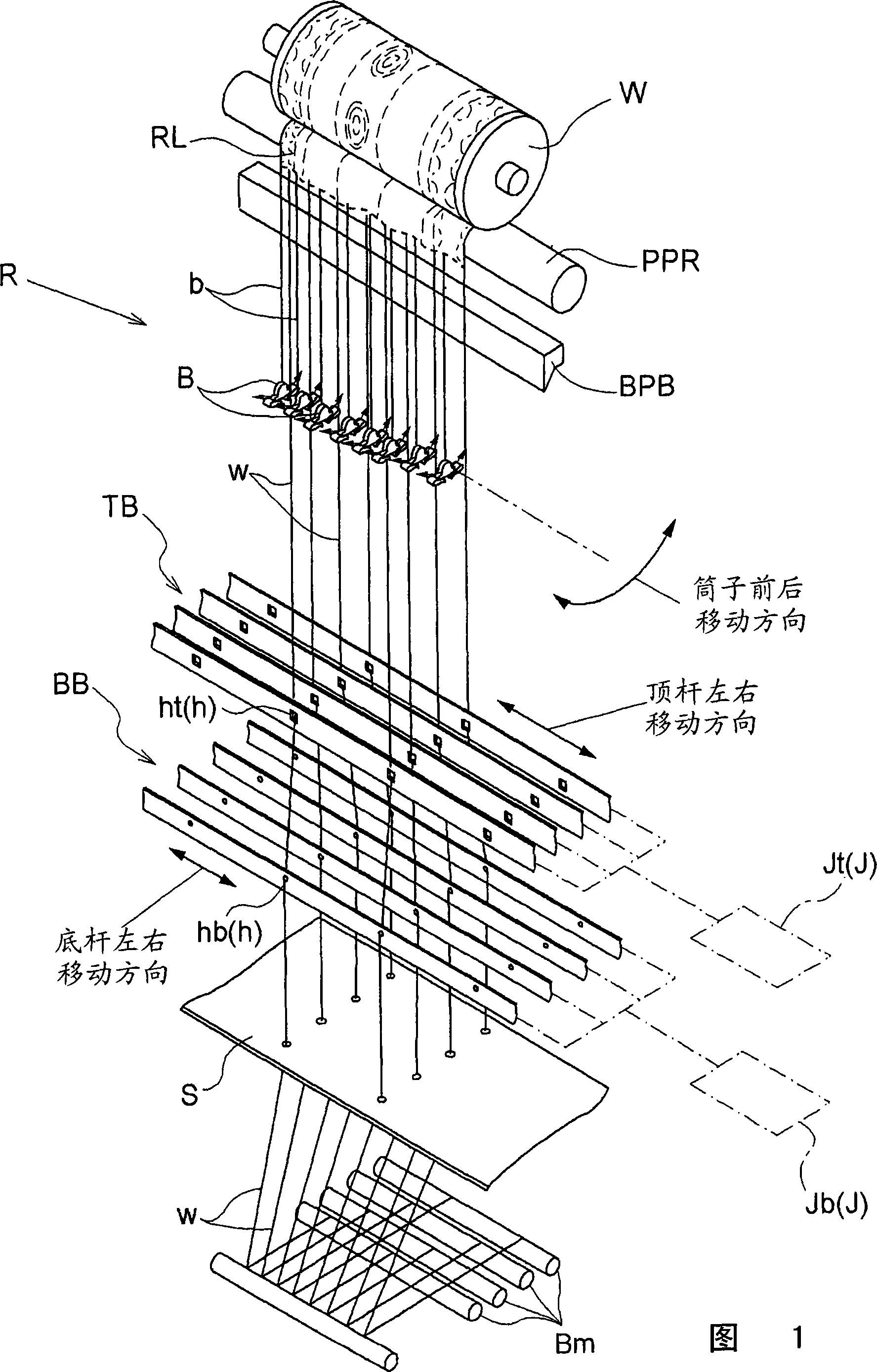

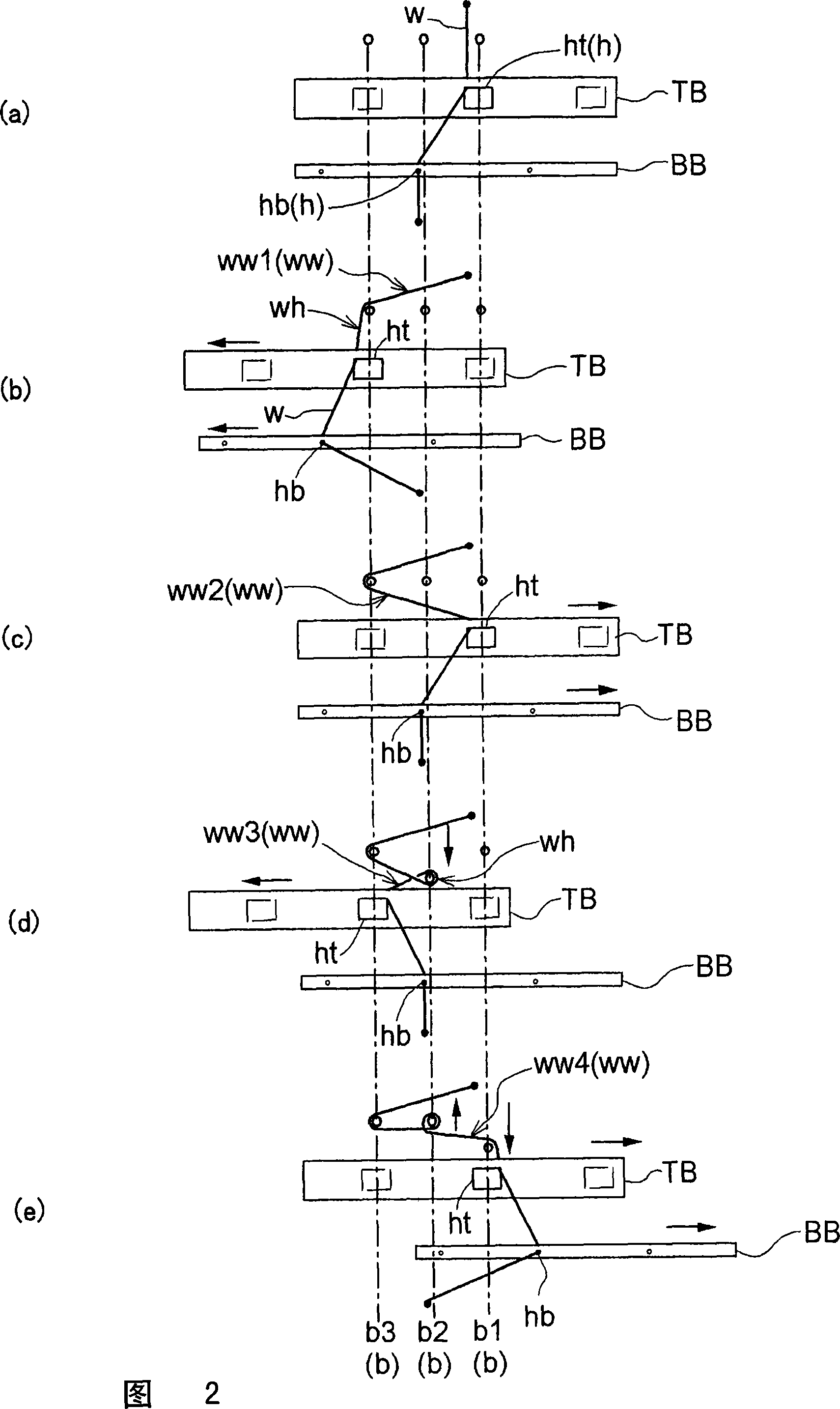

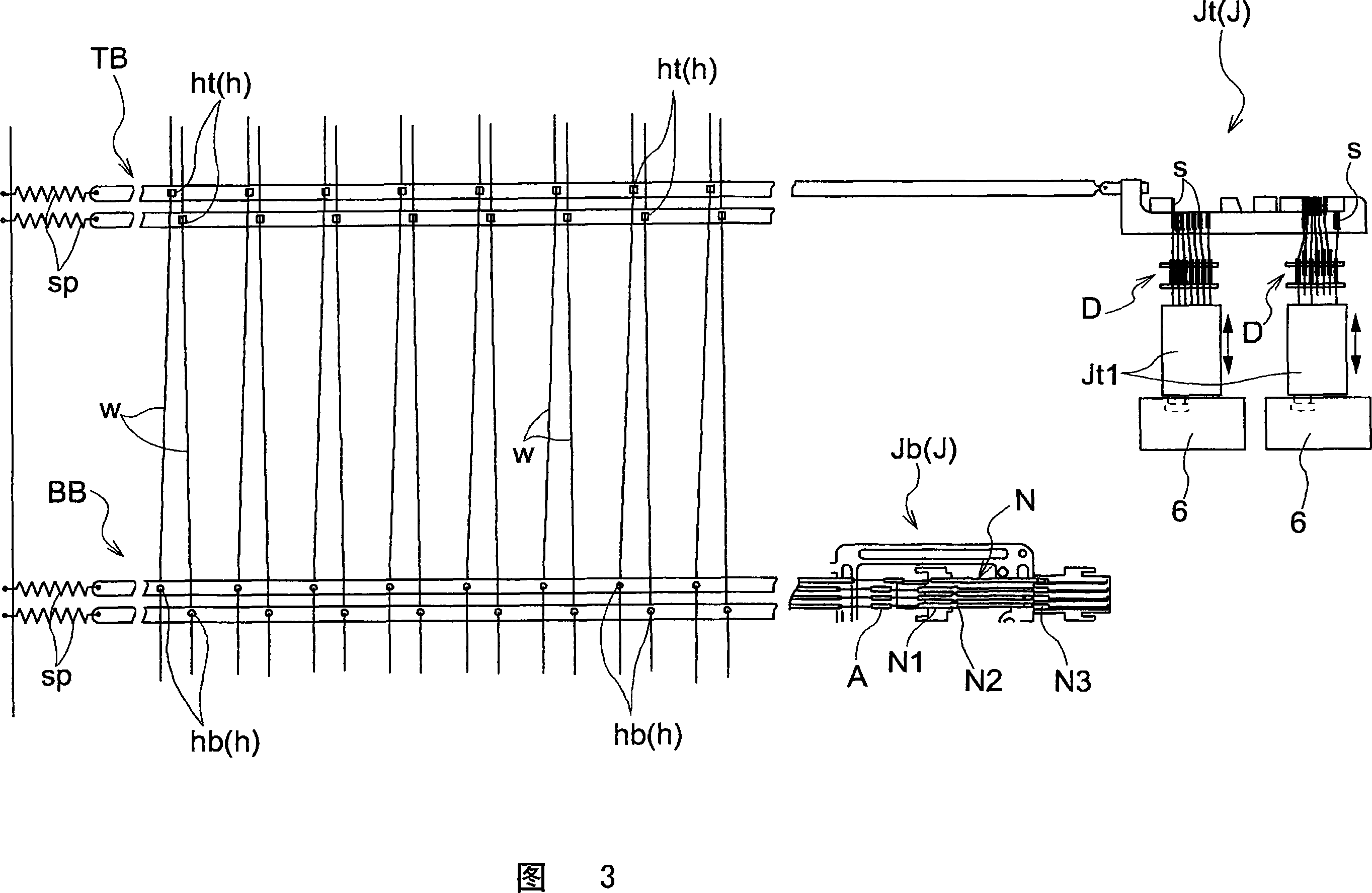

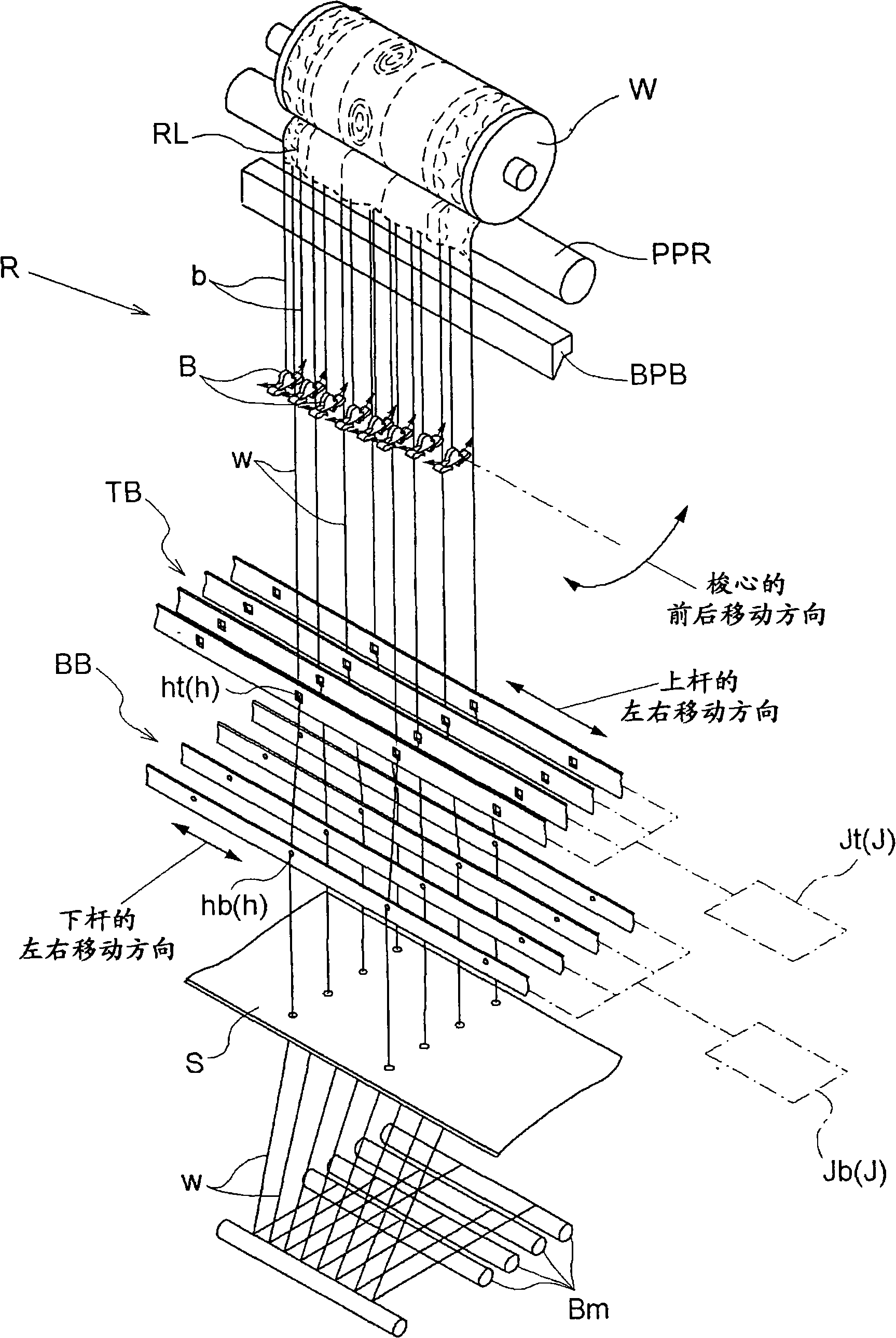

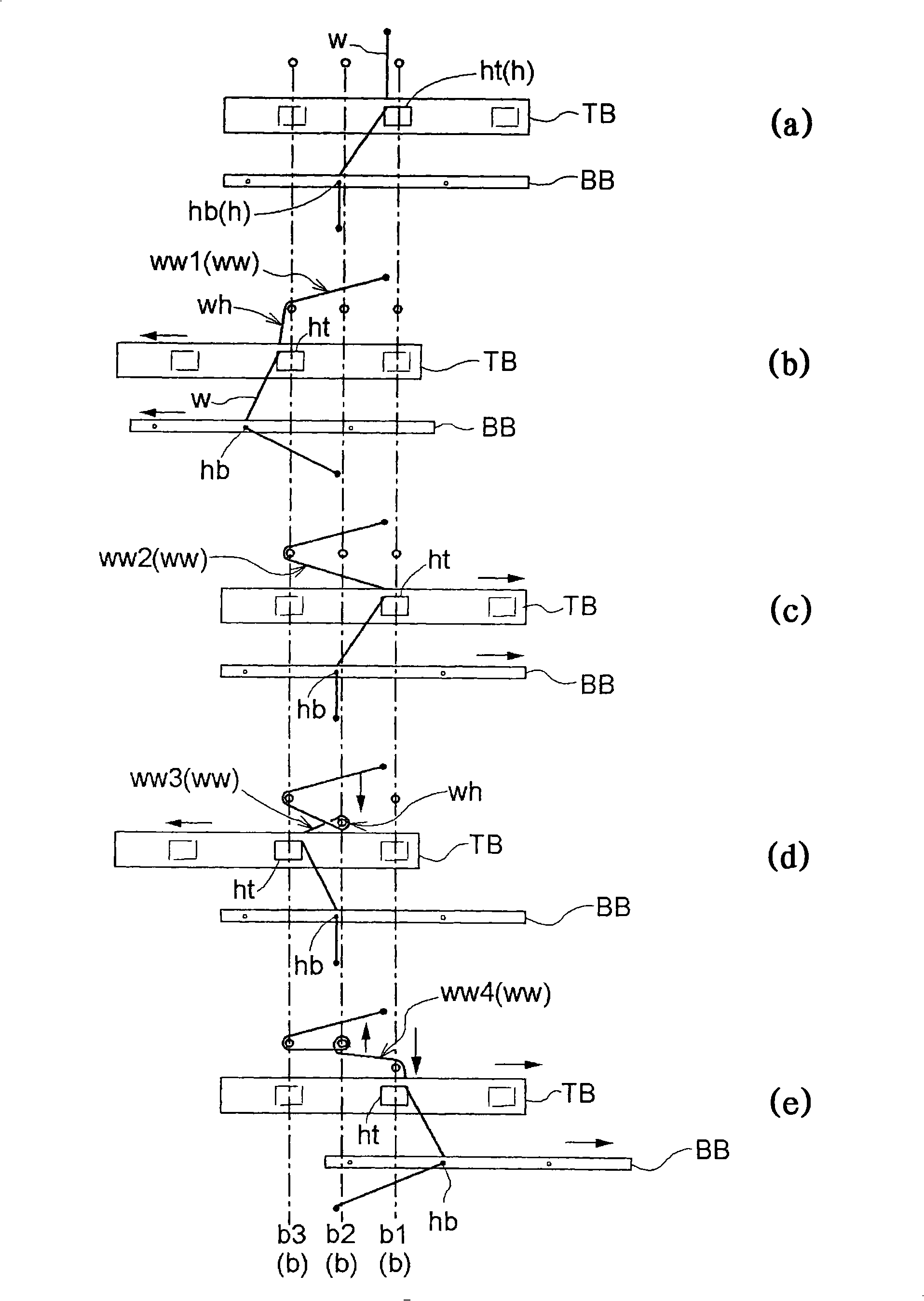

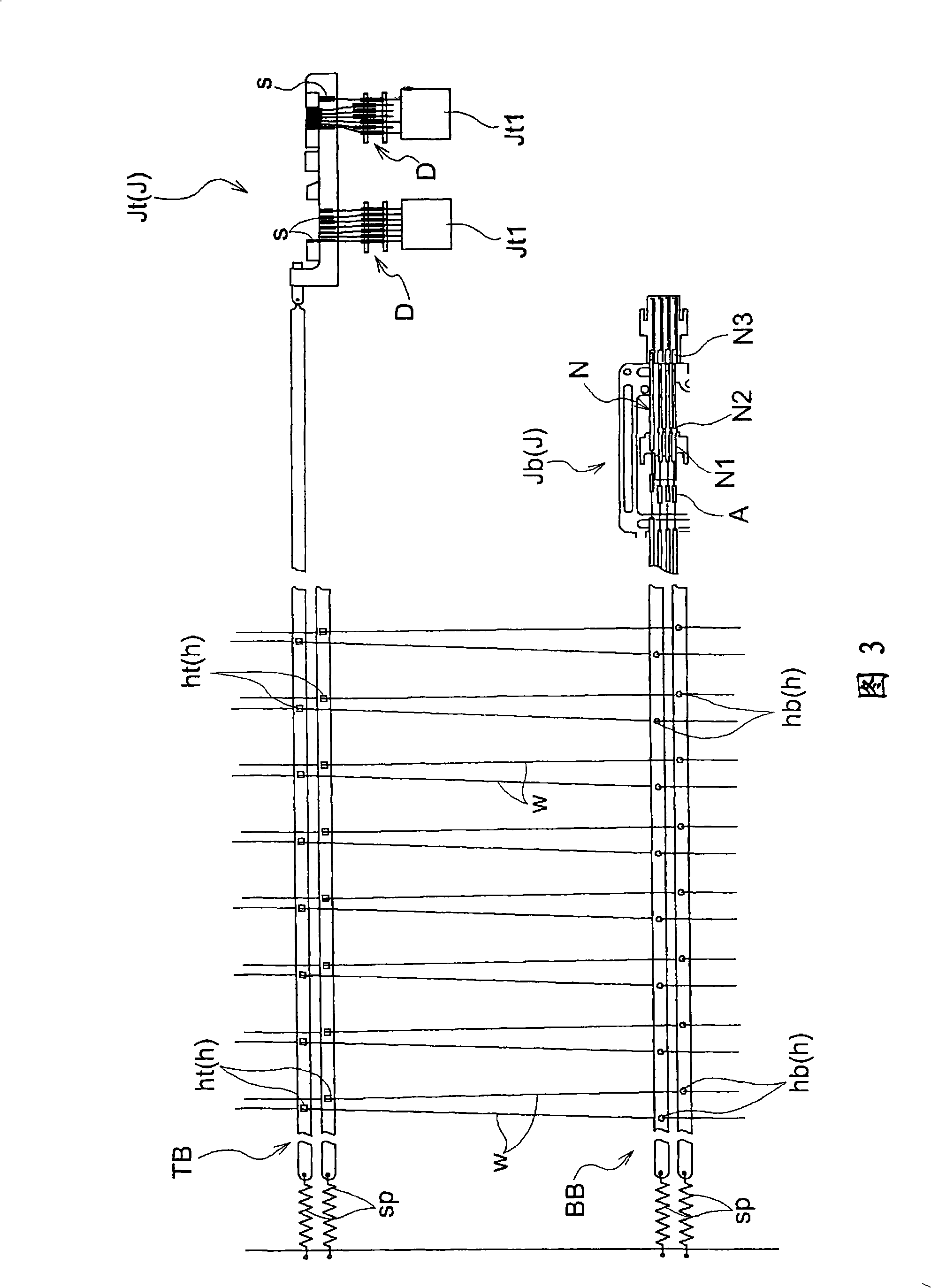

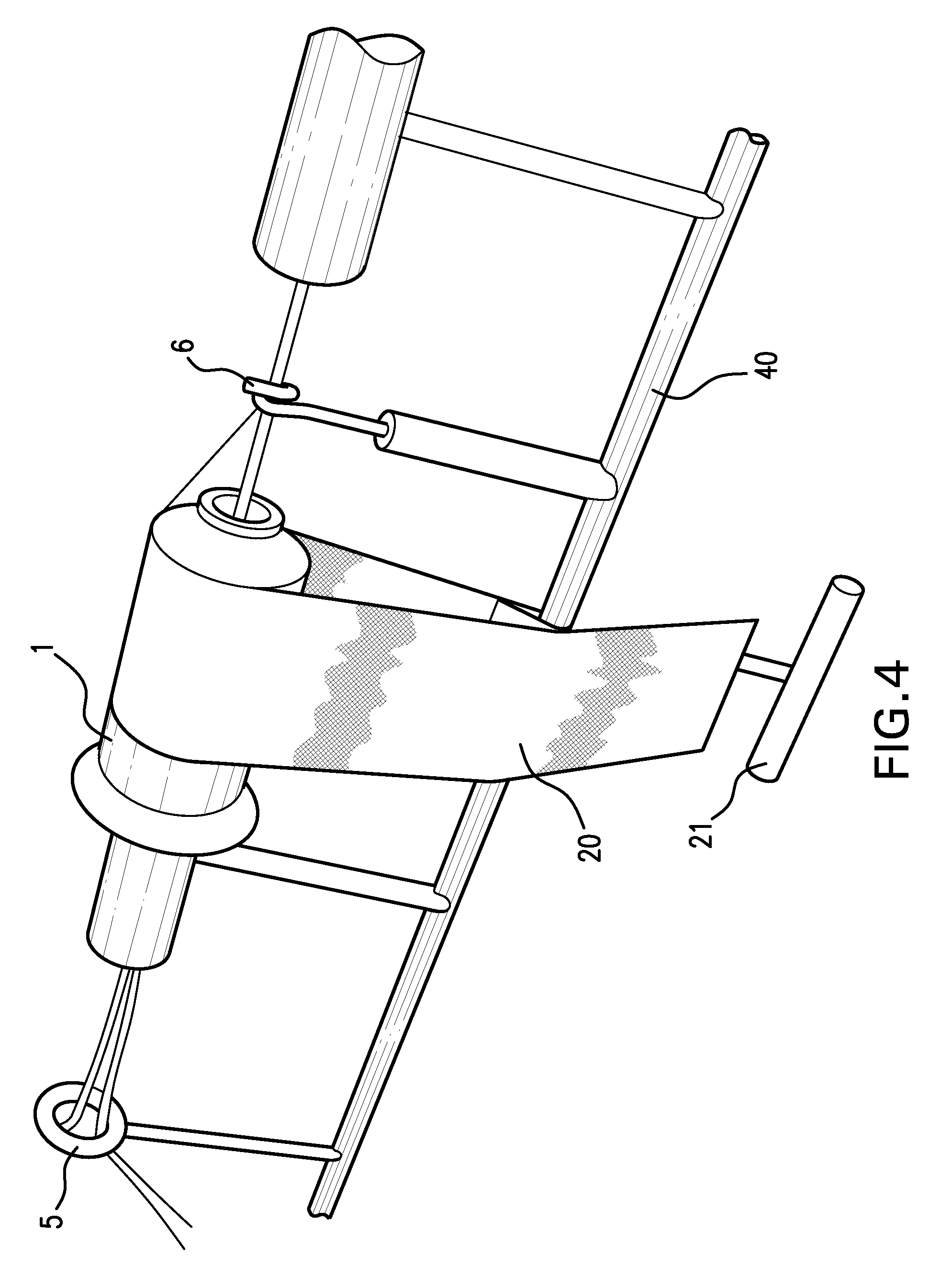

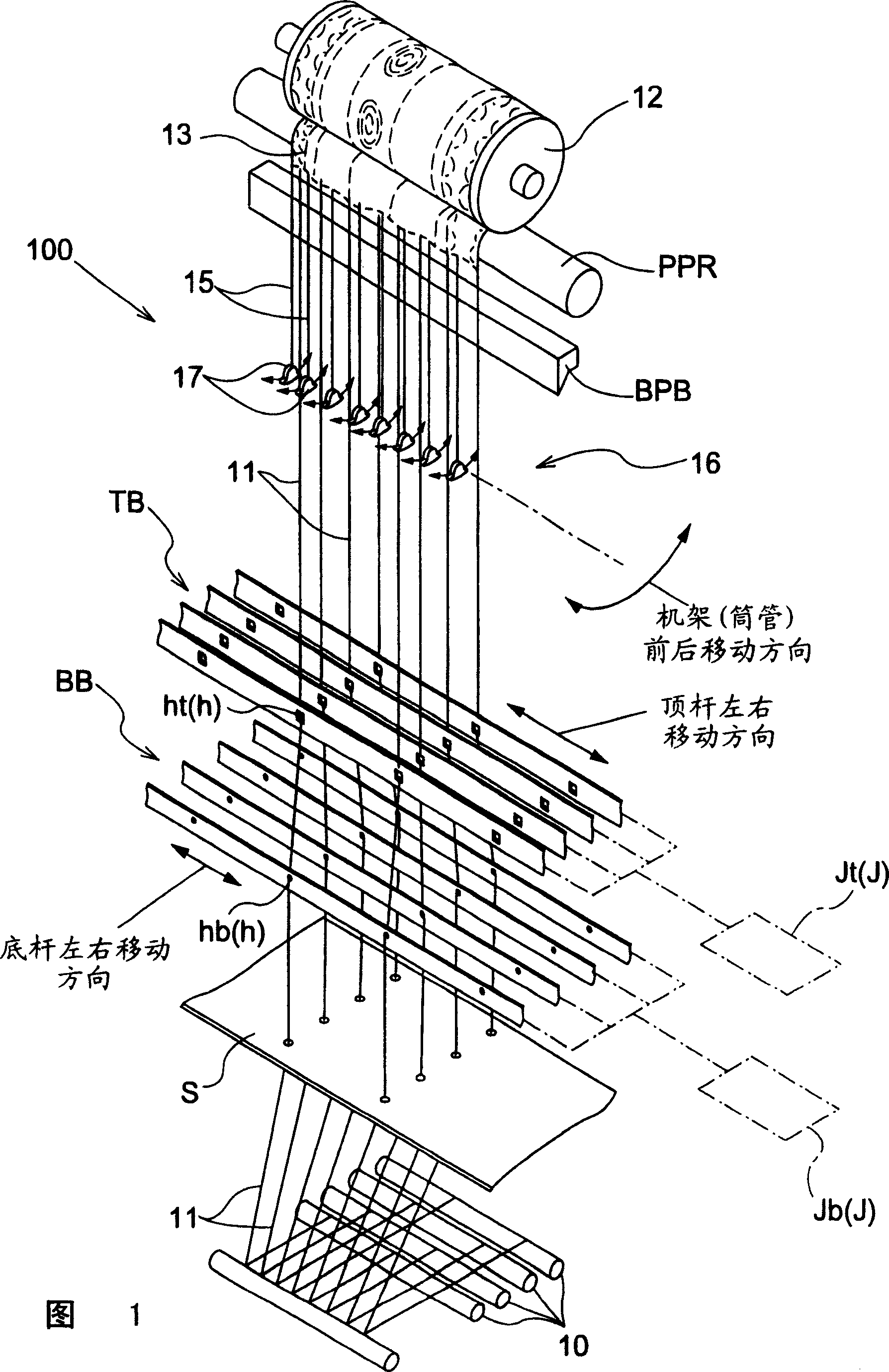

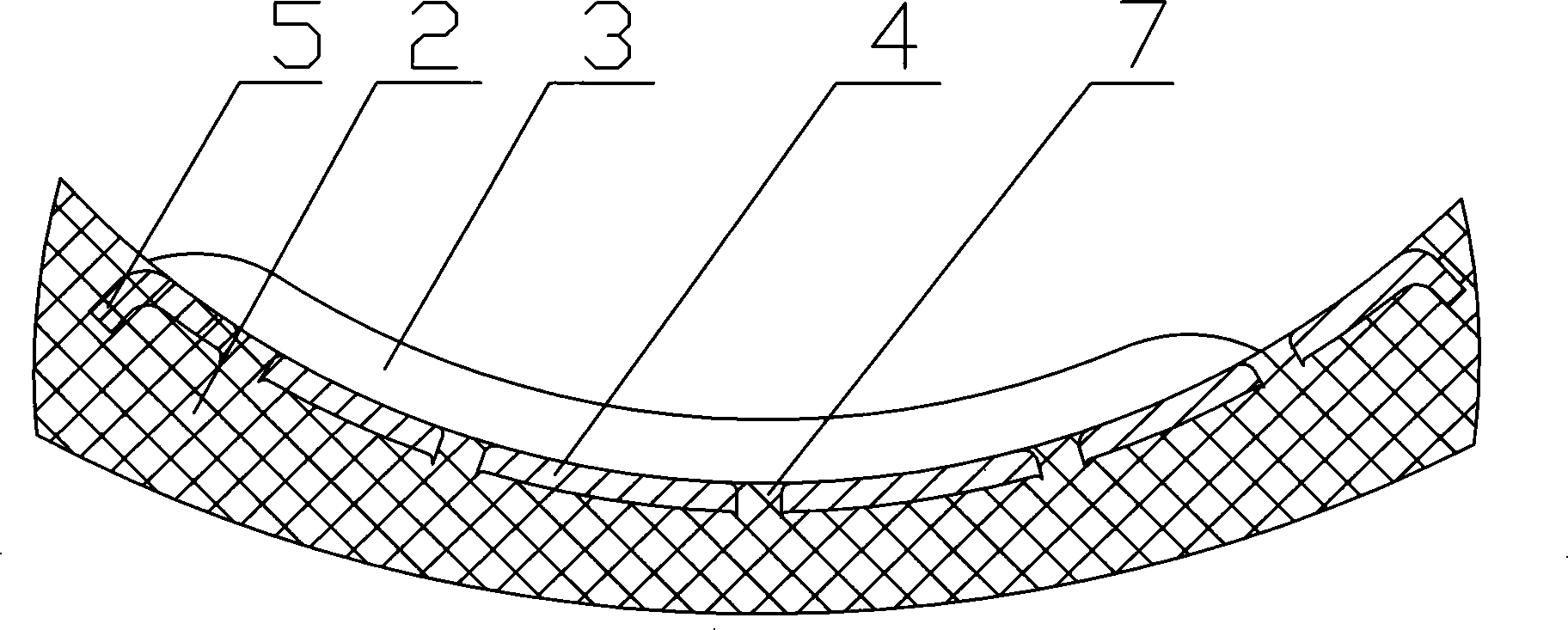

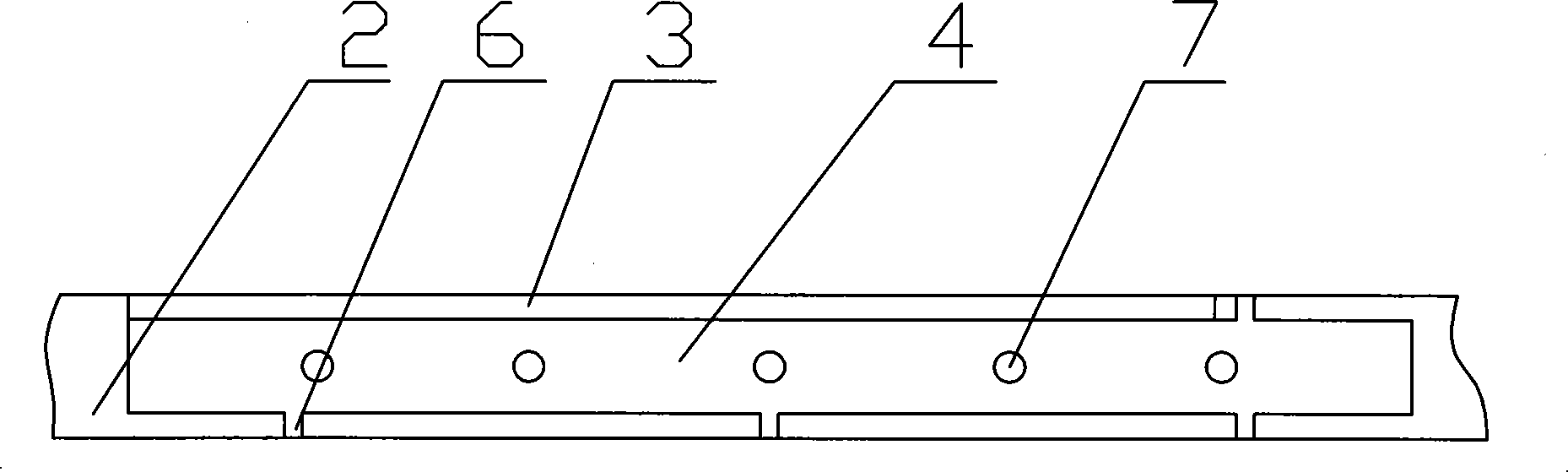

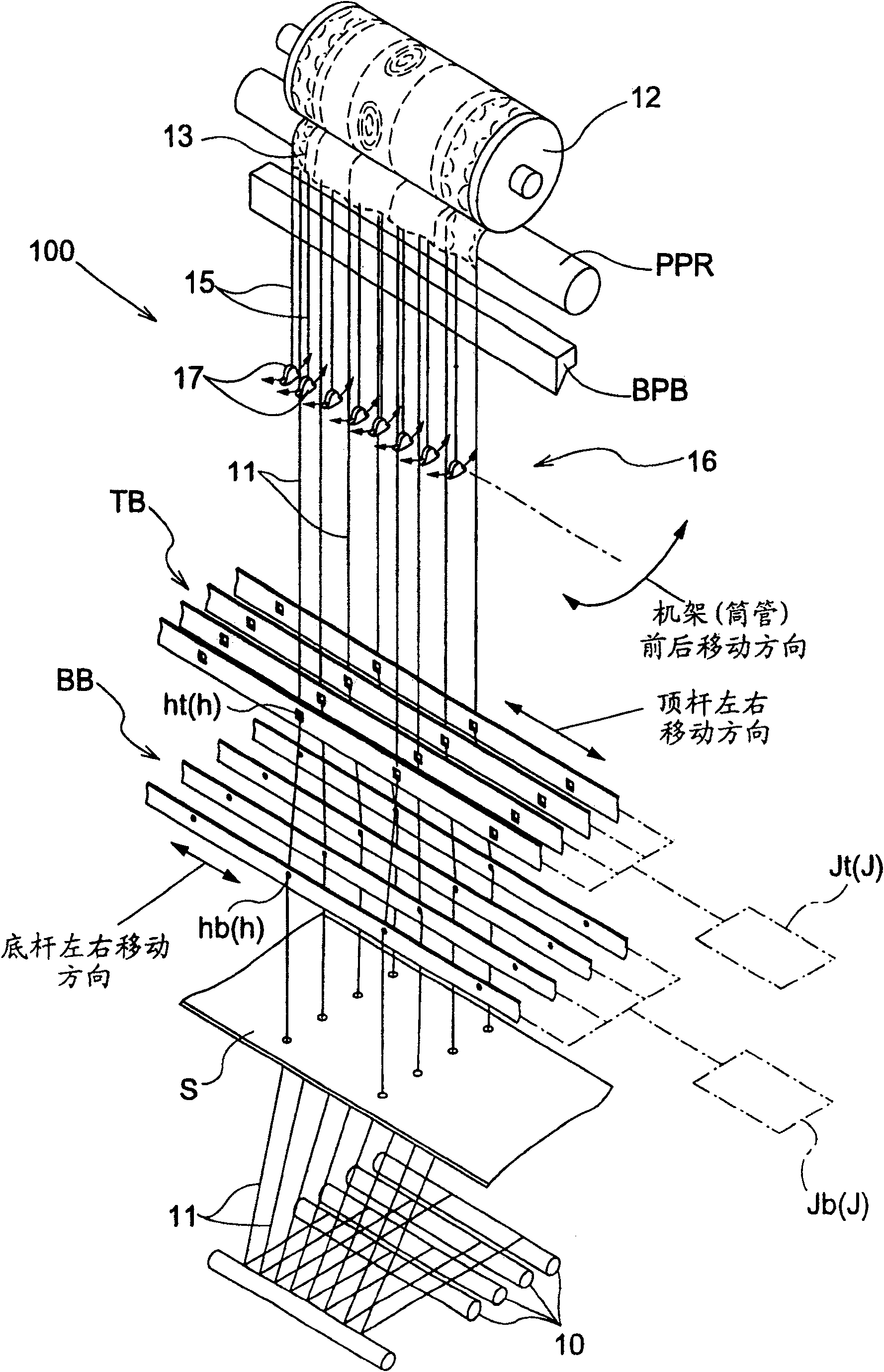

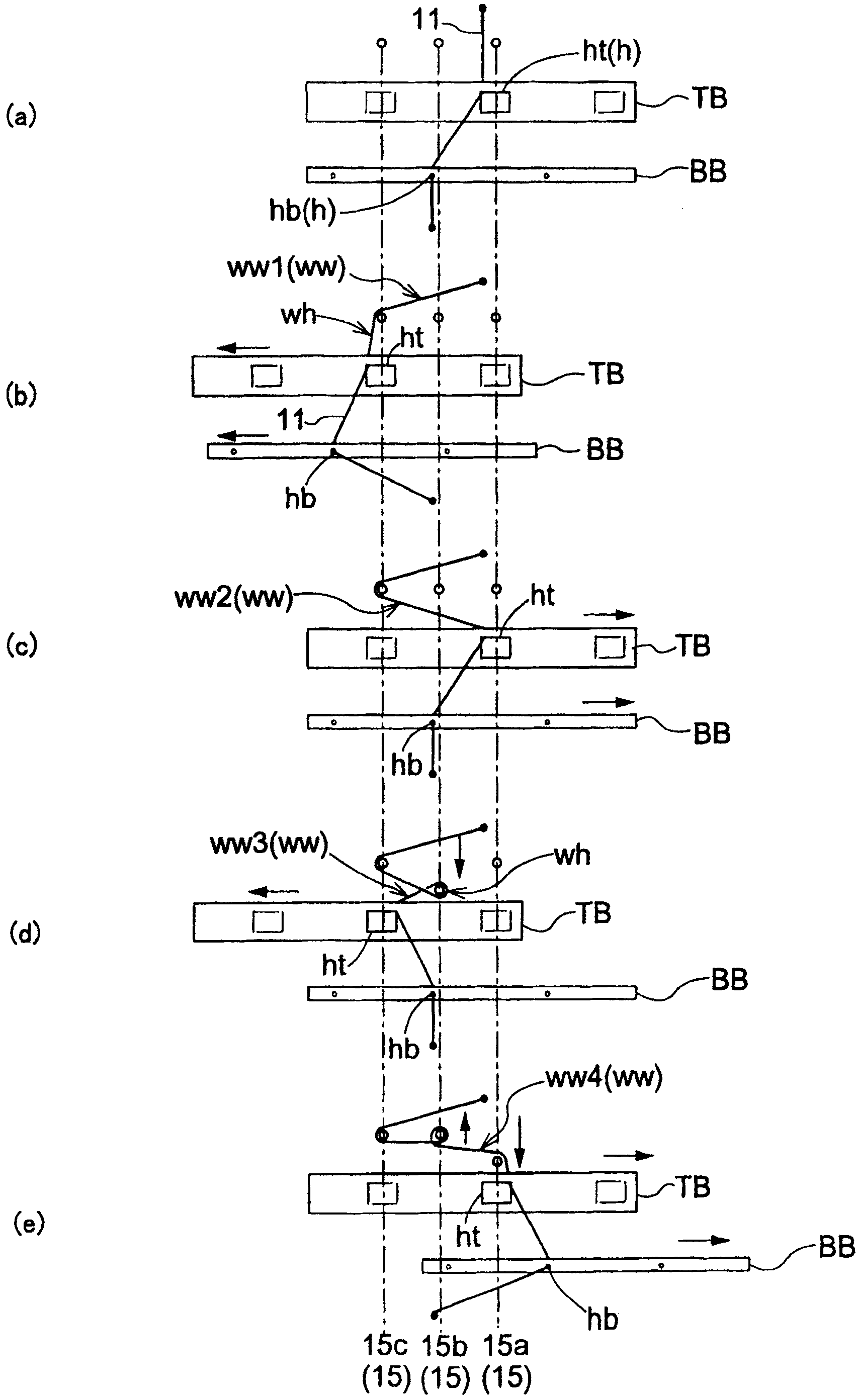

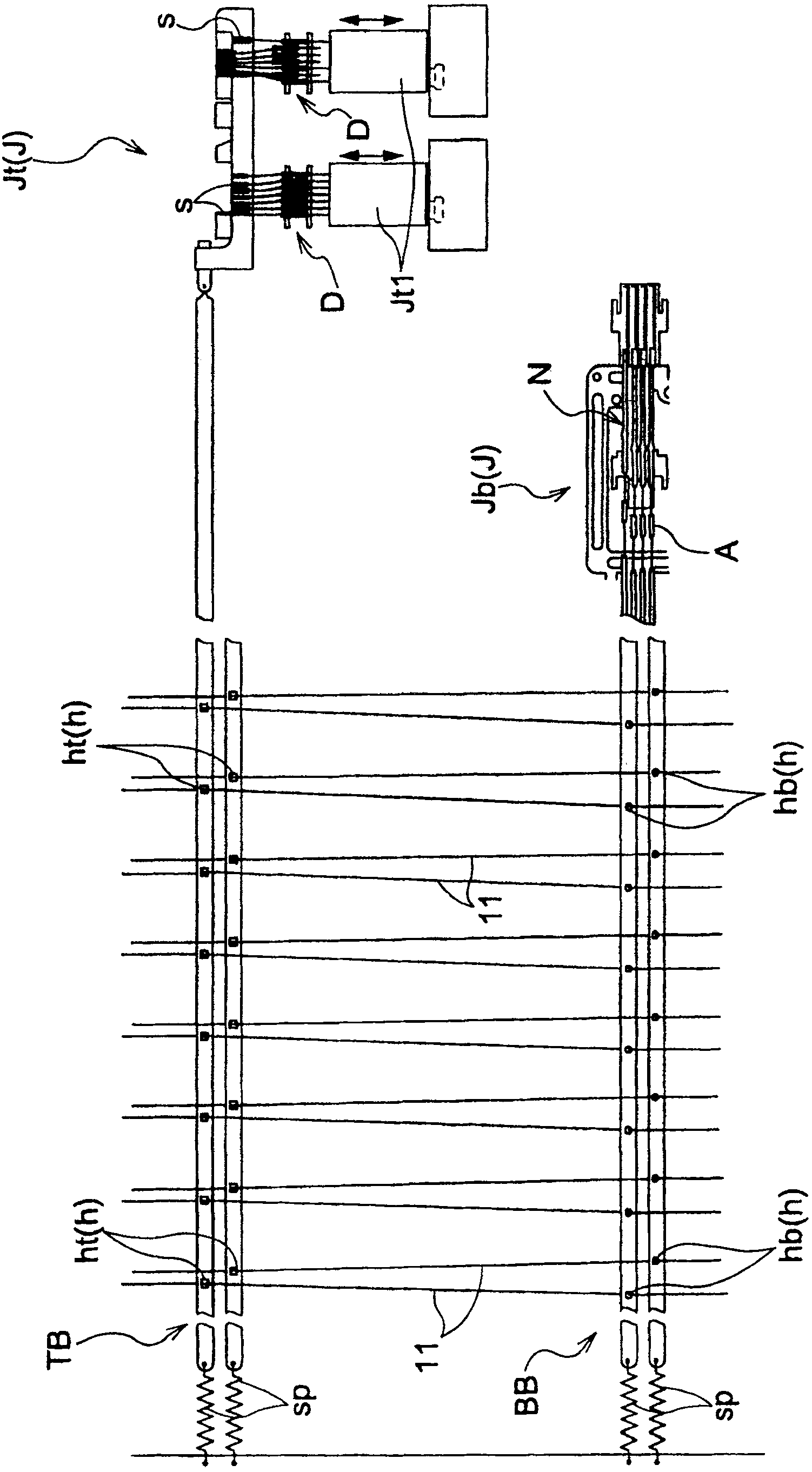

Machine and method for manufacturing reinforced net and reinforced net

A machine for manufacturing a reinforced net (1, 10), which has hexagonal meshes comprising a plurality of permanently deformable wires (2, 2', 3, 3') and at least one reinforcing element (5), comprises a mechanism for the reciprocal coiling of first wires (2, 2') and second wires (3, 3') in twos, which mechanism is provided with passages for the reinforcing elements (5), and a feed system for thefirst wires (2, 2'), fed in from a plurality of containers (90, 90') that are mounted on board the machine and provided internally with a predetermined length of said first wires (2, 2'), for part ofthe second wires (3), fed in alternately with the first wires, so as to be interwoven therewith in twos in the coiling mechanism, and for the reinforcing elements (5), fed into the machine, wherein,for all the reinforcing elements (5), a wire receptacle (202) is provided for one of said second wires (3'), the wire receptacle being rotatable around the reinforcing element. The invention also relates to a multiple-twist net with hexagonal meshes and a method for producing such a net.

Owner:OFFICINE MACCAFERRI SPA

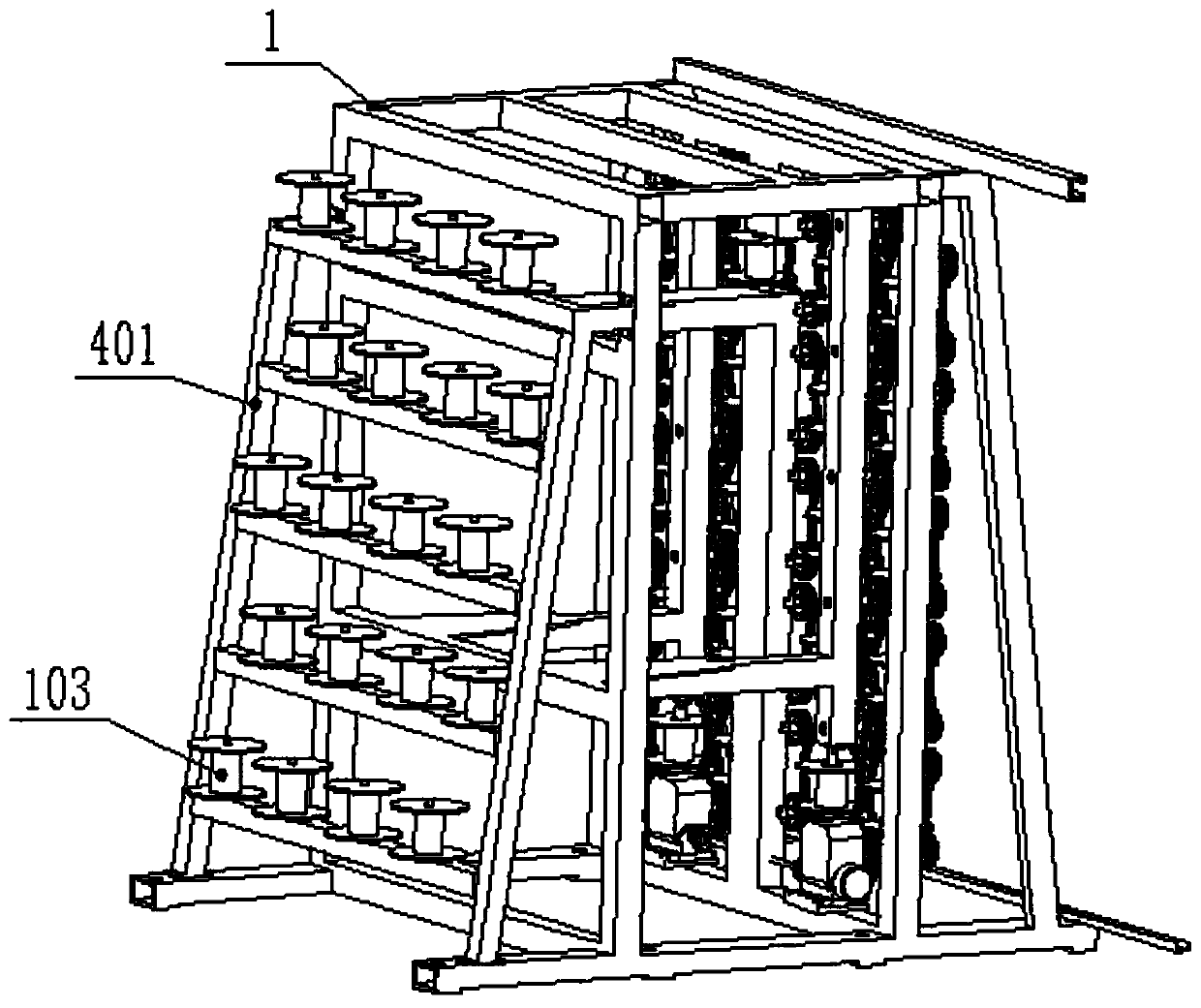

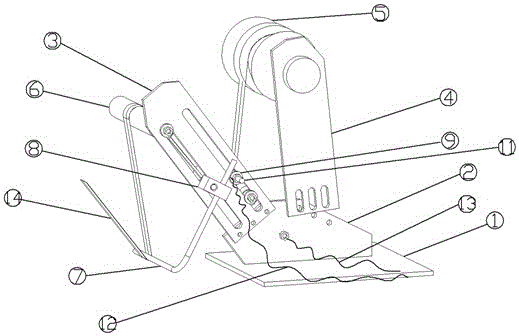

Twisting-free wire conveying system used for hexagonal net knitting

PendingCN110938938ASmooth rotationPlay a limiting roleTwist lace-making machinesEngineeringMechanical engineering

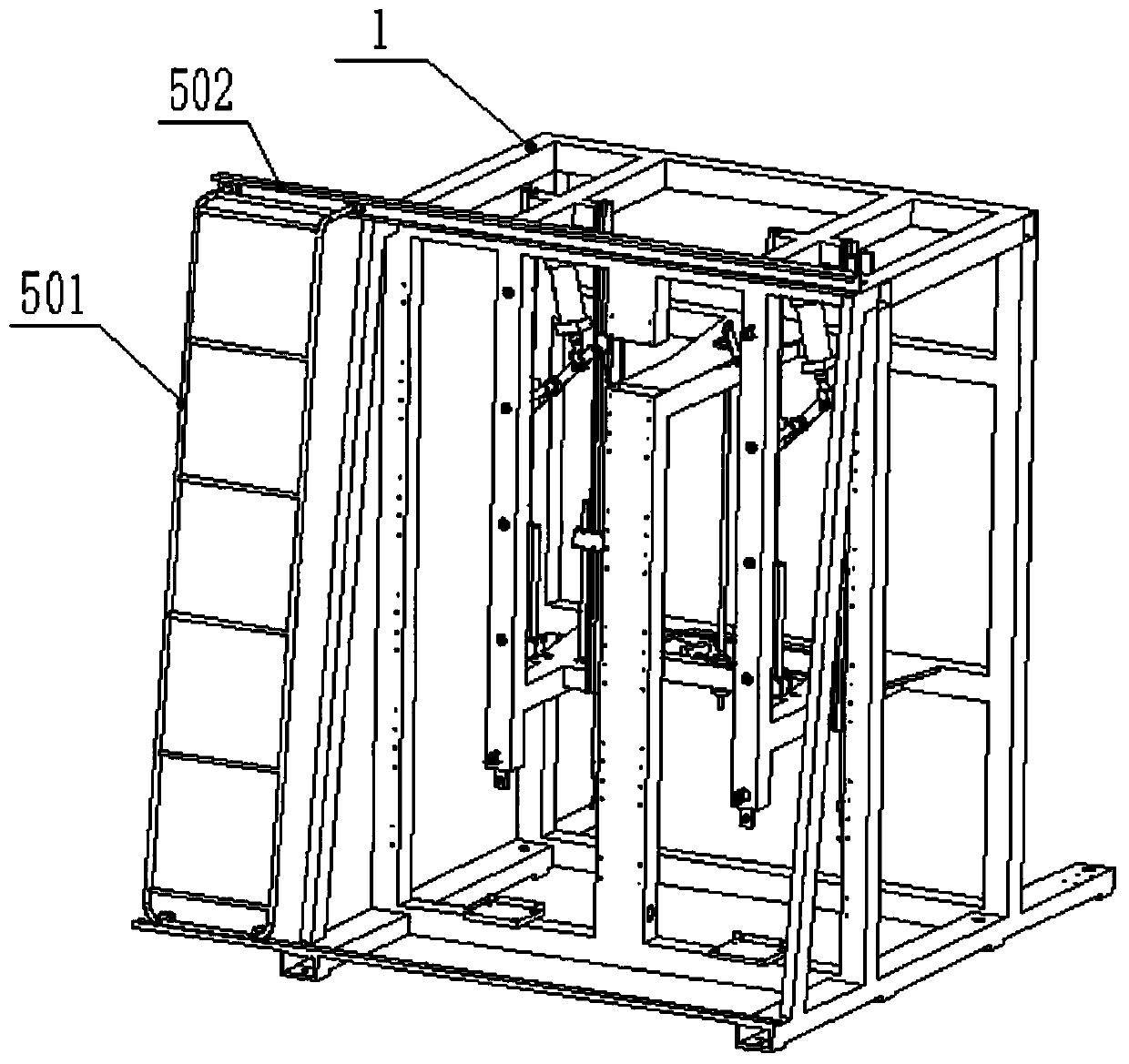

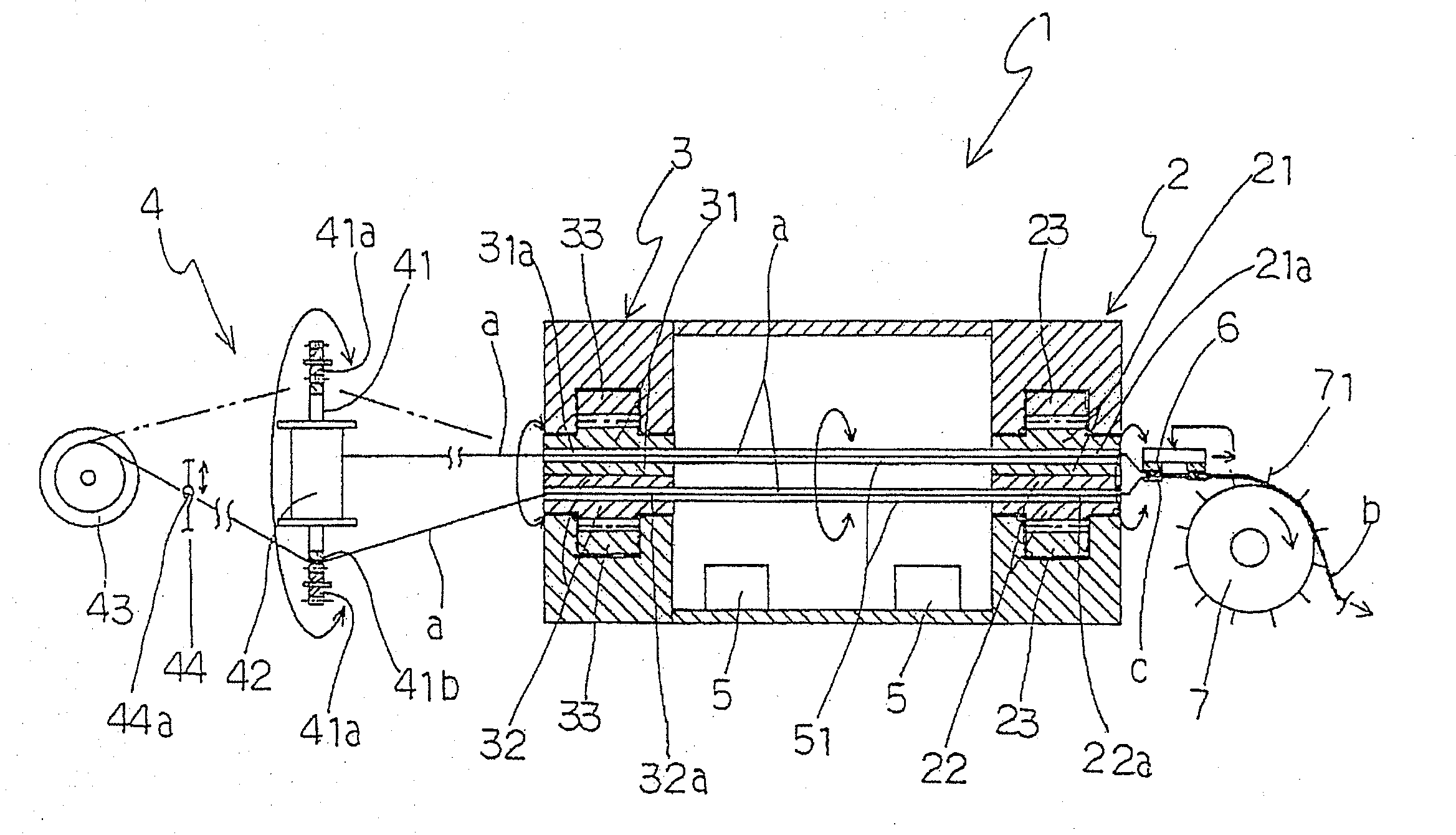

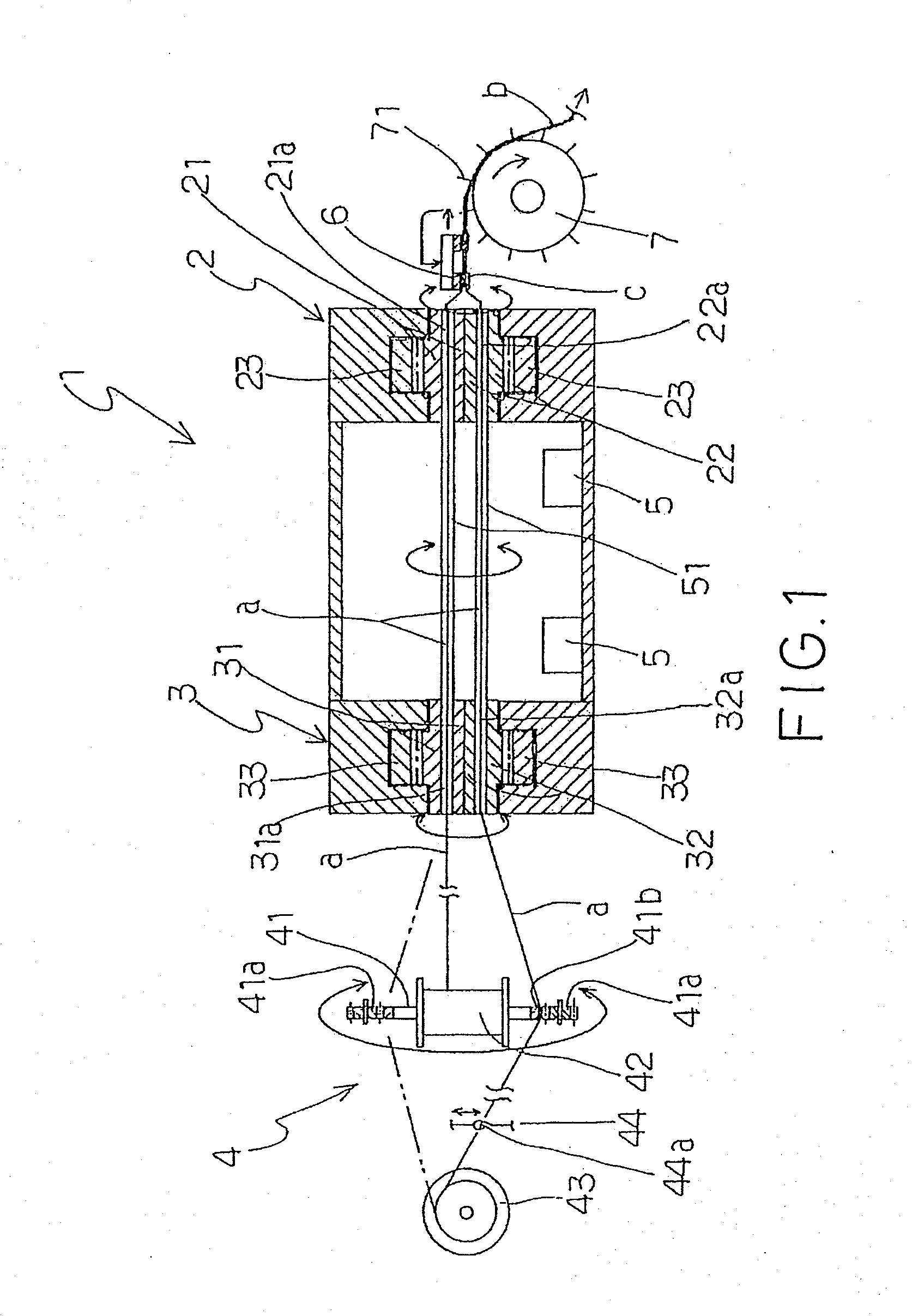

The invention discloses a twisting-free wire conveying system used for hexagonal net knitting. The twisting-free wire conveying system comprises a frame, wherein a first wire conveying device is arranged at the front end of the frame; a second wire conveying device is arranged at the rear end of the frame; a wire swinging device is arranged between the first wire conveying device and the second wire conveying device; a movable escalator is further arranged at the front end of the frame; the first wire feeding device is used for winding a net wire on a wire shaft in the second wire conveying device around a net wire on a wire shaft in the corresponding first wire conveying device when the net wire is woven; and the wire swinging device is used for swinging the net wire in the wire shaft inthe second wire conveying device in an up-down direction and a left-right direction so as to enable the net wire to be shifted from a corresponding net wire groove of a chain disc of the first wire conveying device to a net wire groove of an adjacent chain disc. By virtue of the system, manual wire twisting and penetrating is omitted, limitation of the twisting length is avoided, the maintenance is convenient, the labor intensity of workers is low, the production efficiency is high, the equipment investment cost and the maintenance cost are low, and the system is suitable for the technical field of silk screen manufacturing.

Owner:河北恒拓机械设备有限公司

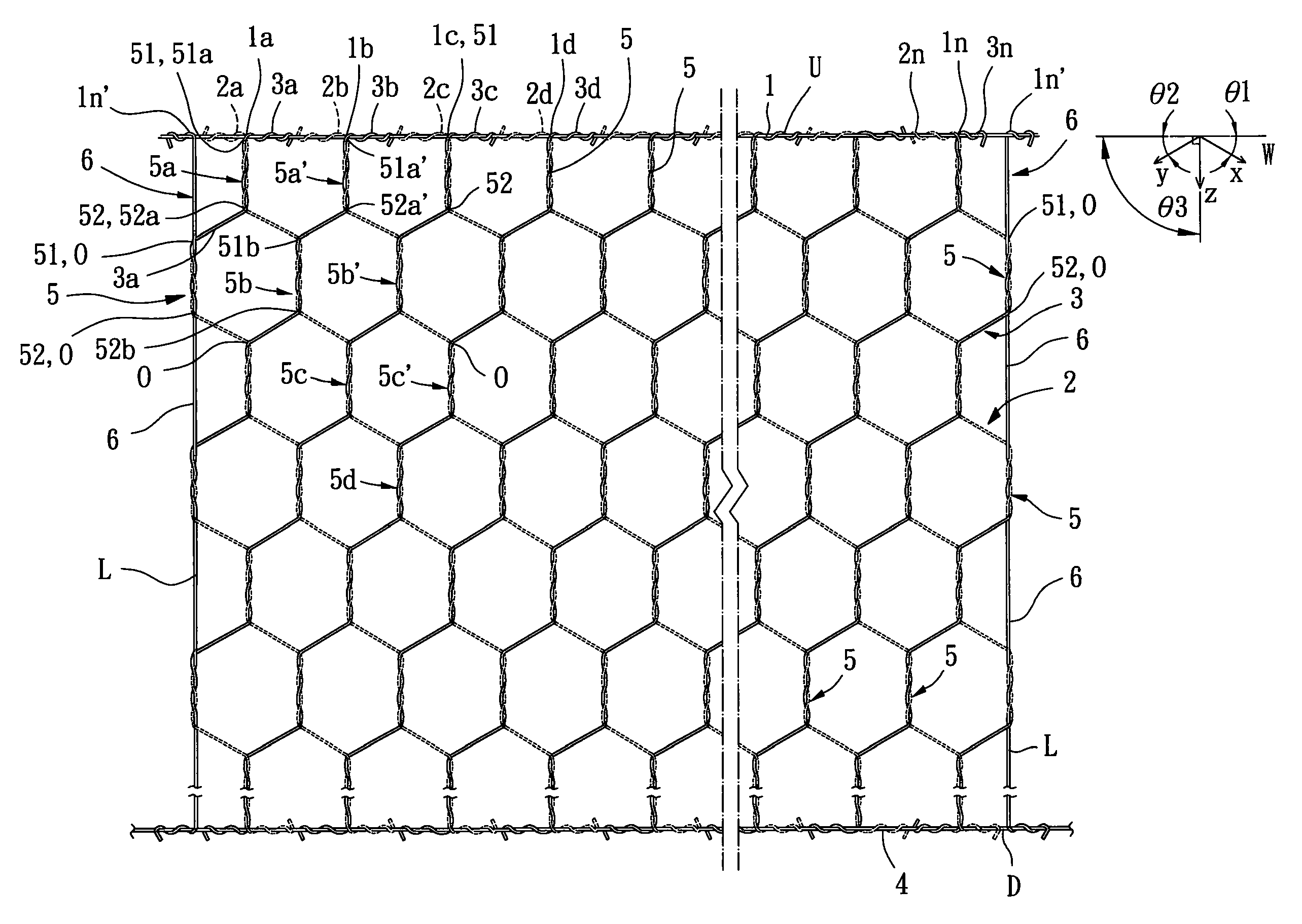

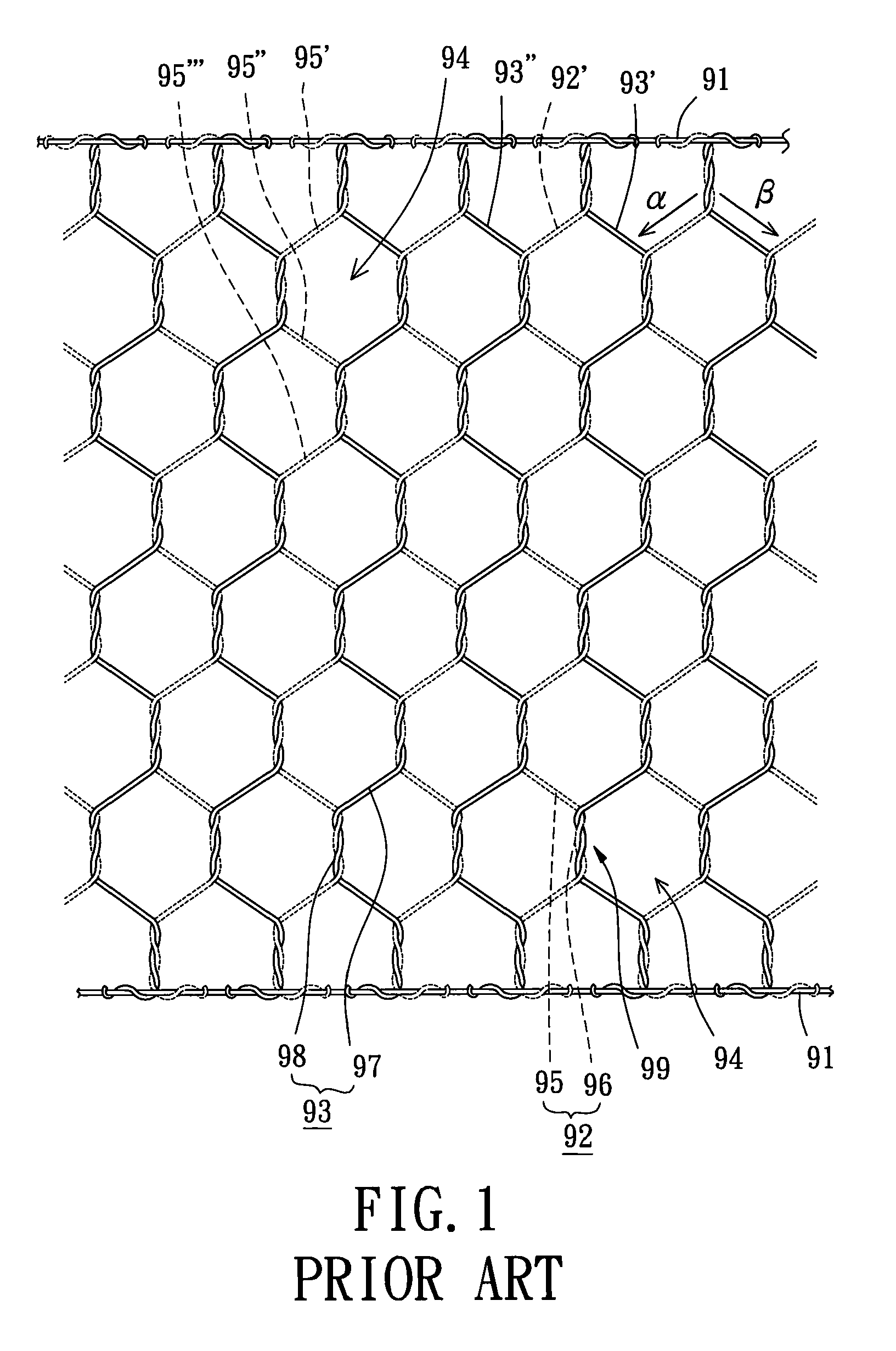

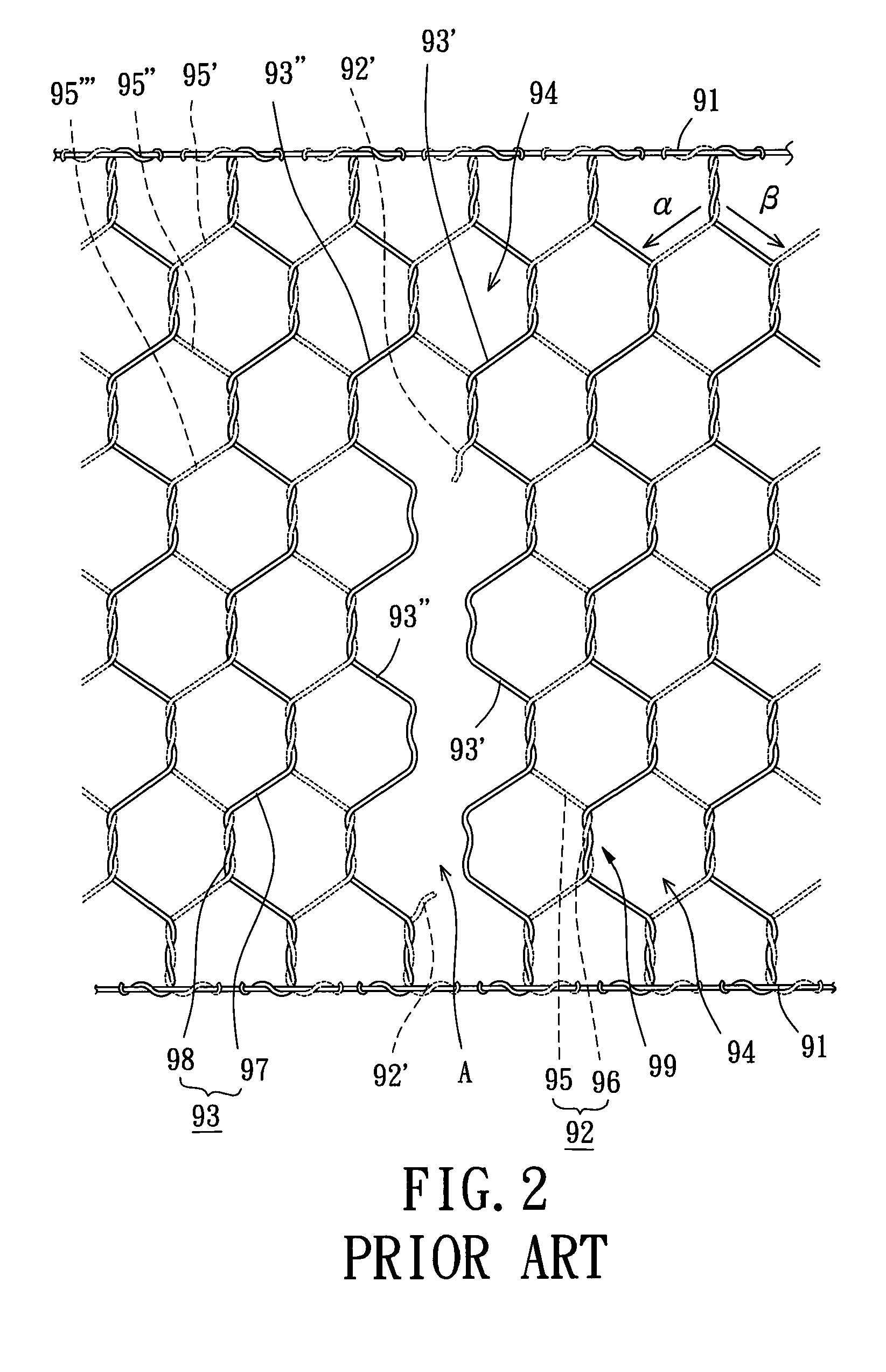

Net structure and methods of making the same

A net structure includes a plurality of metal rightwards inclined wires including, in sequence, a first rightwards inclined wire, a second rightwards inclined wire, and an N-th rightwards inclined wire. The net structure further includes a plurality of metal leftwards inclined wires including, in sequence, a first leftwards inclined wire, a second leftwards inclined wire, and an N-th leftwards inclined wire. The first rightwards inclined wires intersects, in sequence, from the first rightwards inclined wire through the N-th rightwards inclined wire at an intersection at which a twine portion is formed. The second rightwards inclined wires intersects, in sequence, from the second rightwards inclined wire through the N-th rightwards inclined wire at an intersection at which a twine portion is formed. The N-th leftwards inclined wire intersects the N-th rightwards inclined wire at an intersection at which a twine portion is formed, thereby forming a net structure with a plurality of hexagonal meshes. The net structure is made by slant weaving.

Owner:GANGZHAN ENTERPRISE

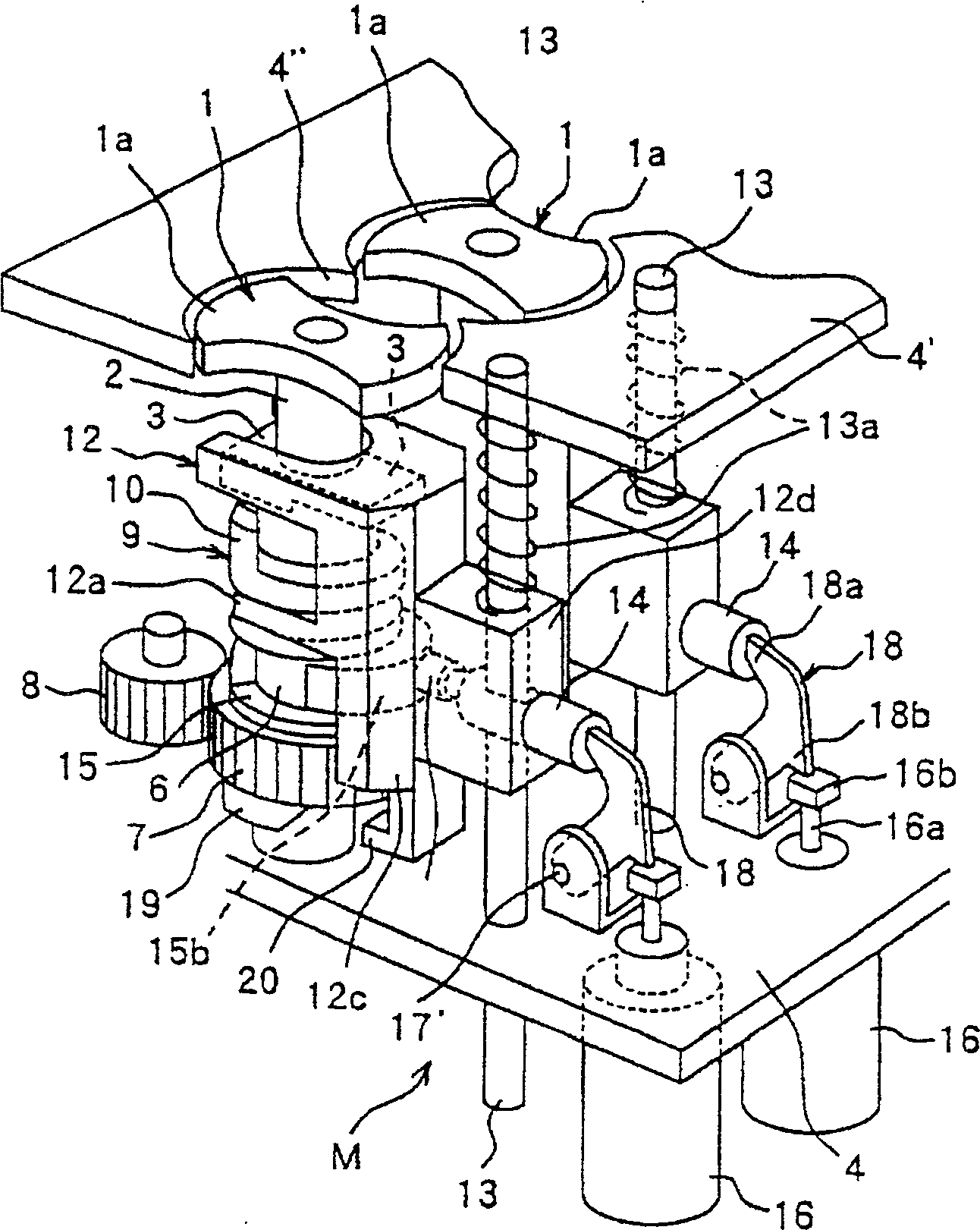

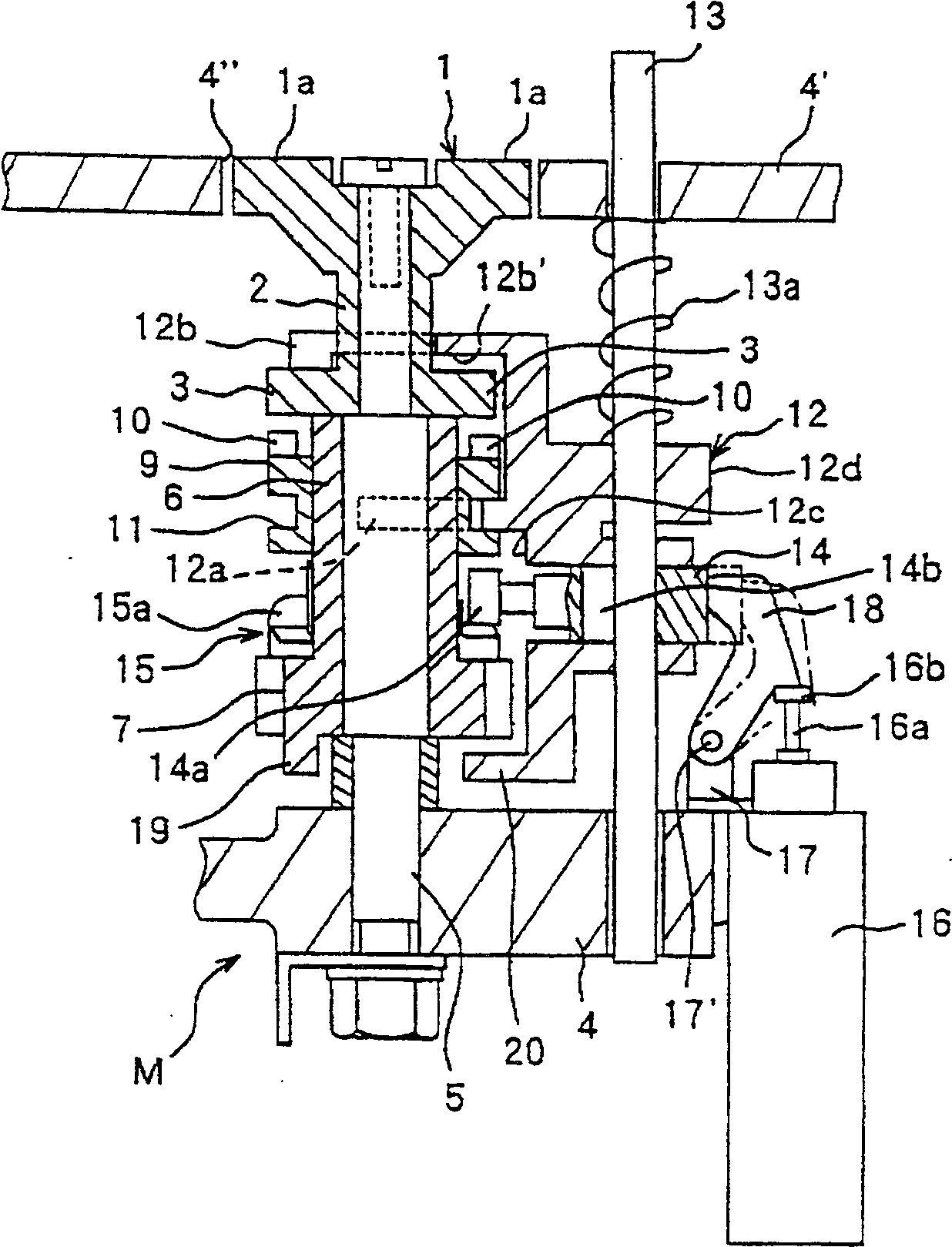

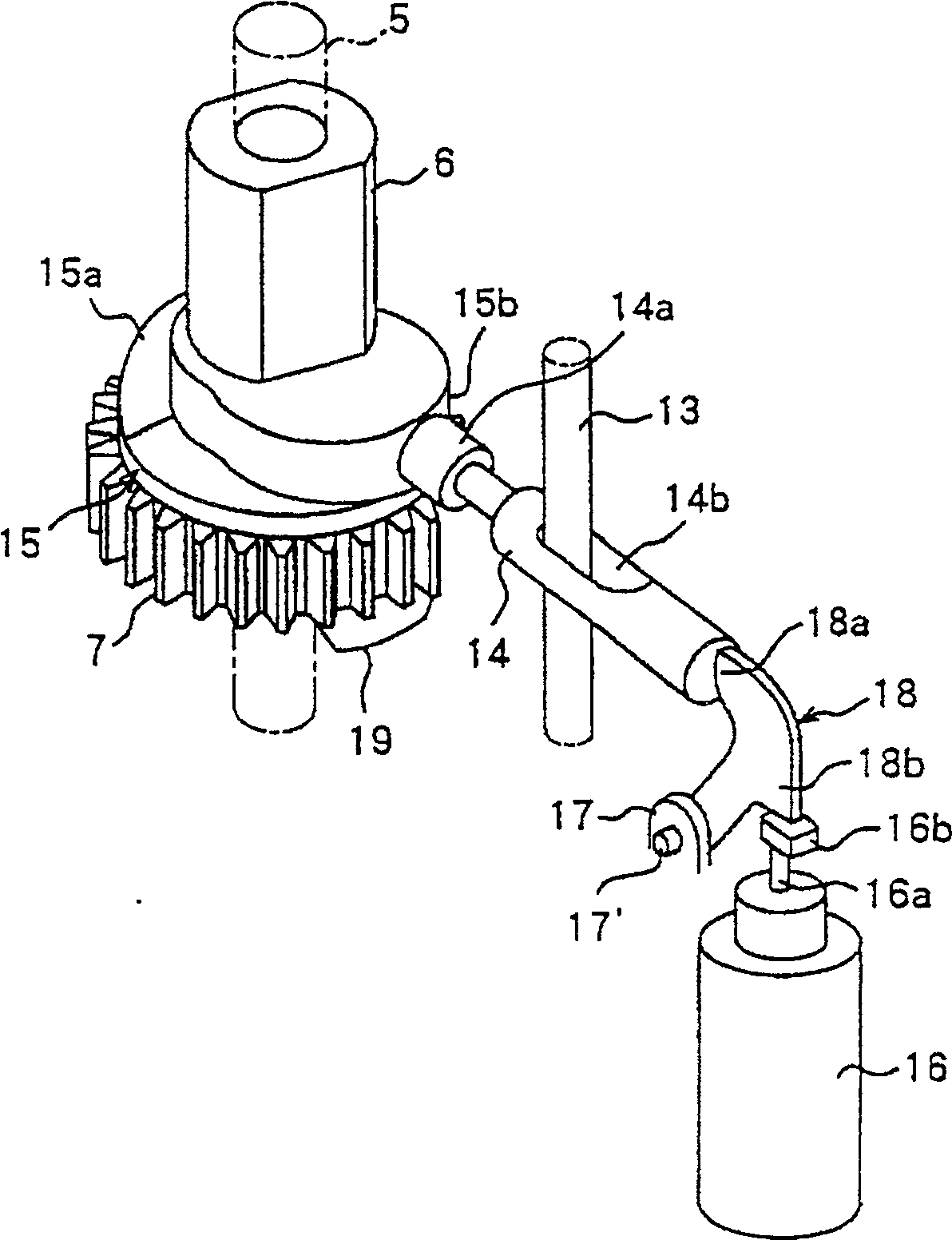

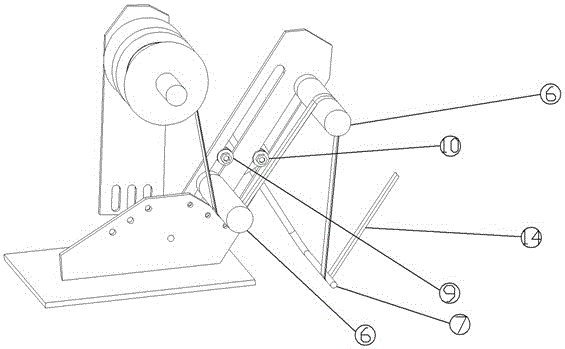

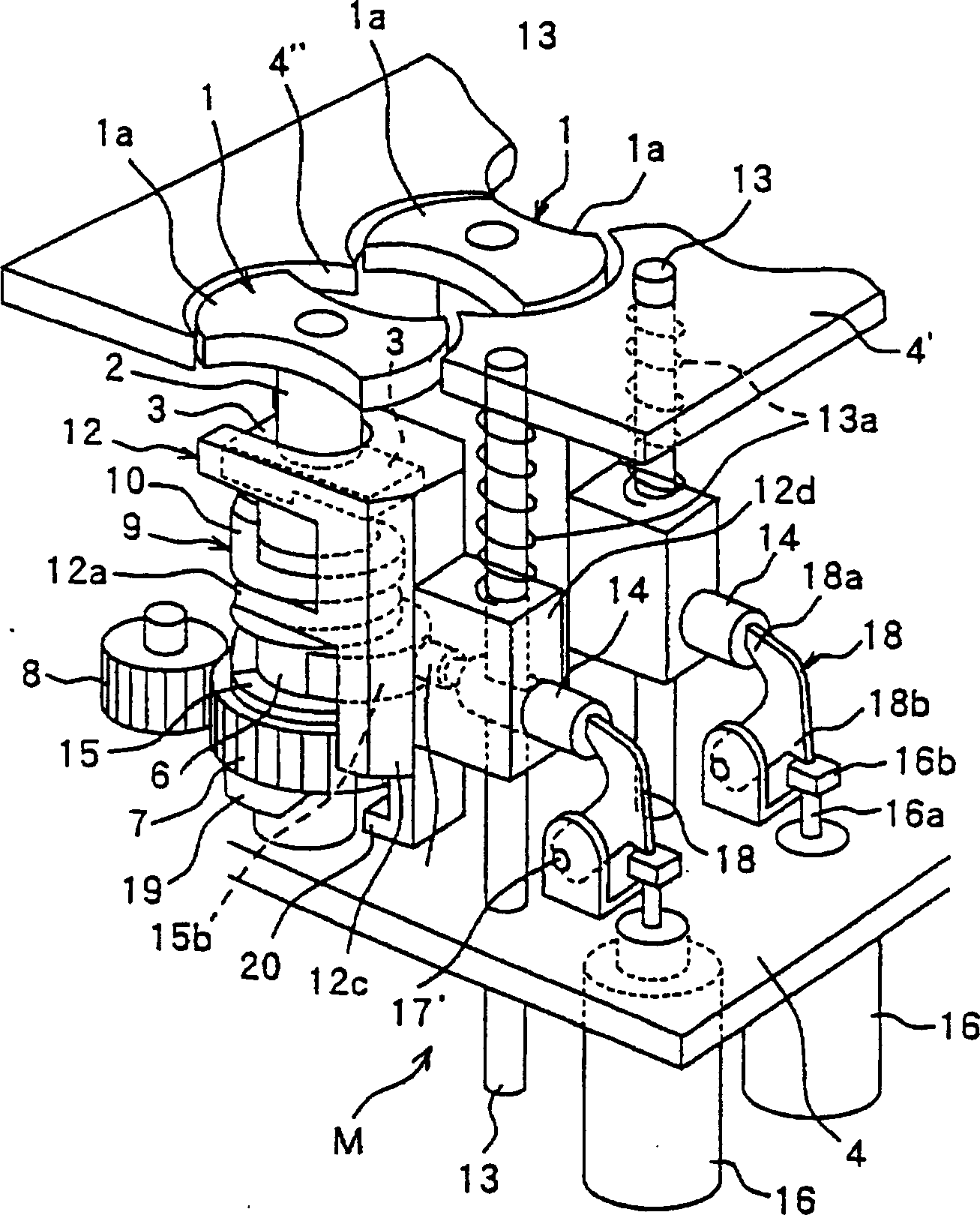

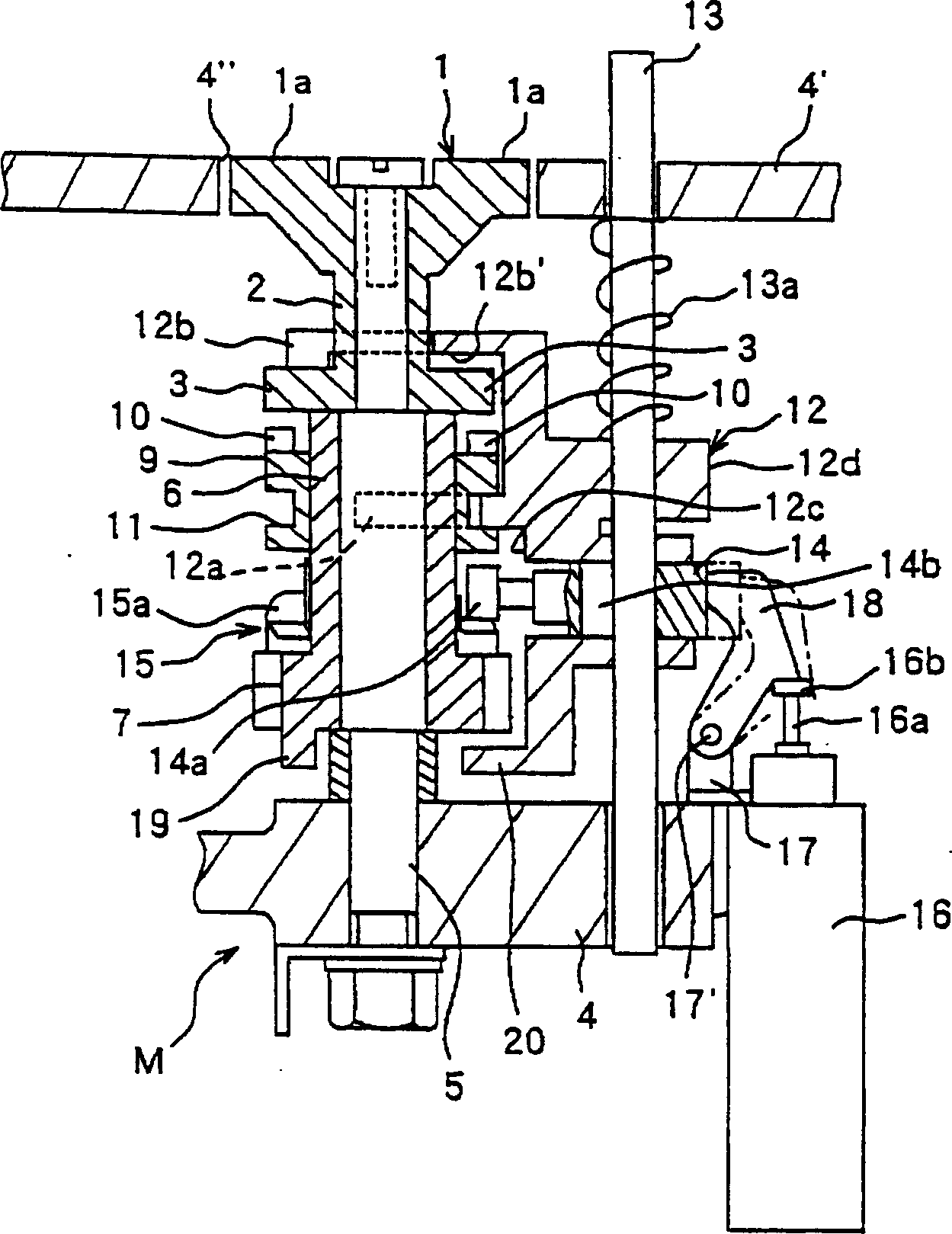

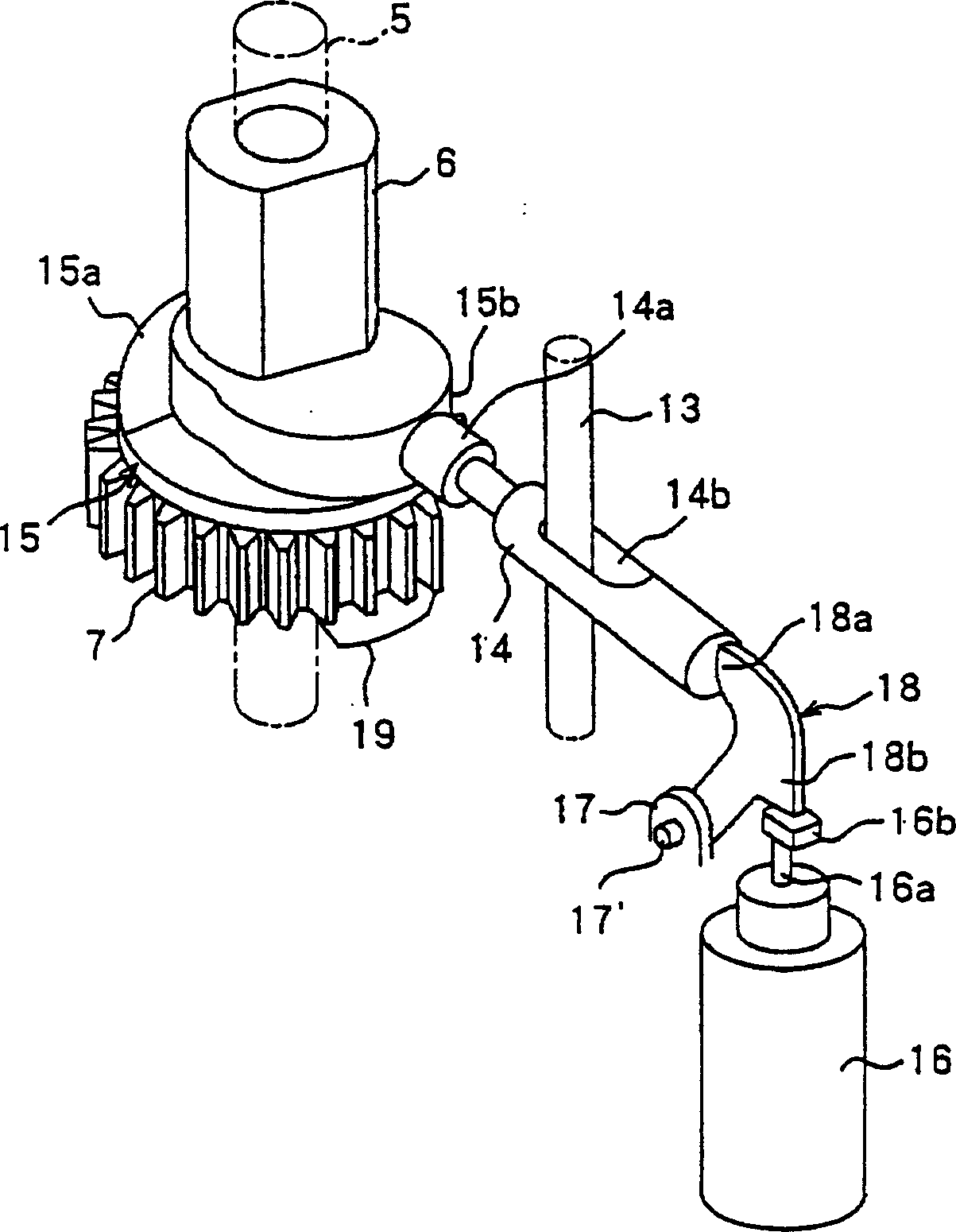

Circular braiding machine

PURPOSE: A torsion lace machine is characterized by controlling applying an electric current to a solenoid, controlling travelling of a bobbin along a hole formed on an upper frame by a rotor metal and a rotor driving shaft, forming patterns precisely, forming a first cam and a second cam into one unit(a cam plate), unifying a third cam with a gear rotated with the rotor driving shaft and reducing a cost. CONSTITUTION: A torsion lace machine comprises: a clutch(9) connected when a rotor metal(1) and a rotor driving shaft(6) are moved upward and separated when the same are moved downward; a fork member(12) which is pushed by a spring(13a), supporting the clutch(9); a slide shaft(14) penetrating a back plate of the fork member(12) and being capable of sliding horizontally; a first cam operating a cam floor installed on an inner end of the slide shaft(14) to displace the fork member(12) upward through the slide shaft(14); a solenoid(16) pushing the slide shaft(14) to send the cam floor into an applying area of the first cam; a second cam(15b) pushing the slide shaft(14) to send the cam floor out of the applying area of the first cam; and a third cam reinforcing power of the spring(13a).

Owner:ICHIKAWA IRON WORKS

Plastic open mesh net manufacturing device and machine

ActiveCN102656304BConsistent shapeConsistent strengthTwist lace-making machinesWire networkMechanical engineeringMesh grid

Owner:OFFICINE MACCAFERRI SPA

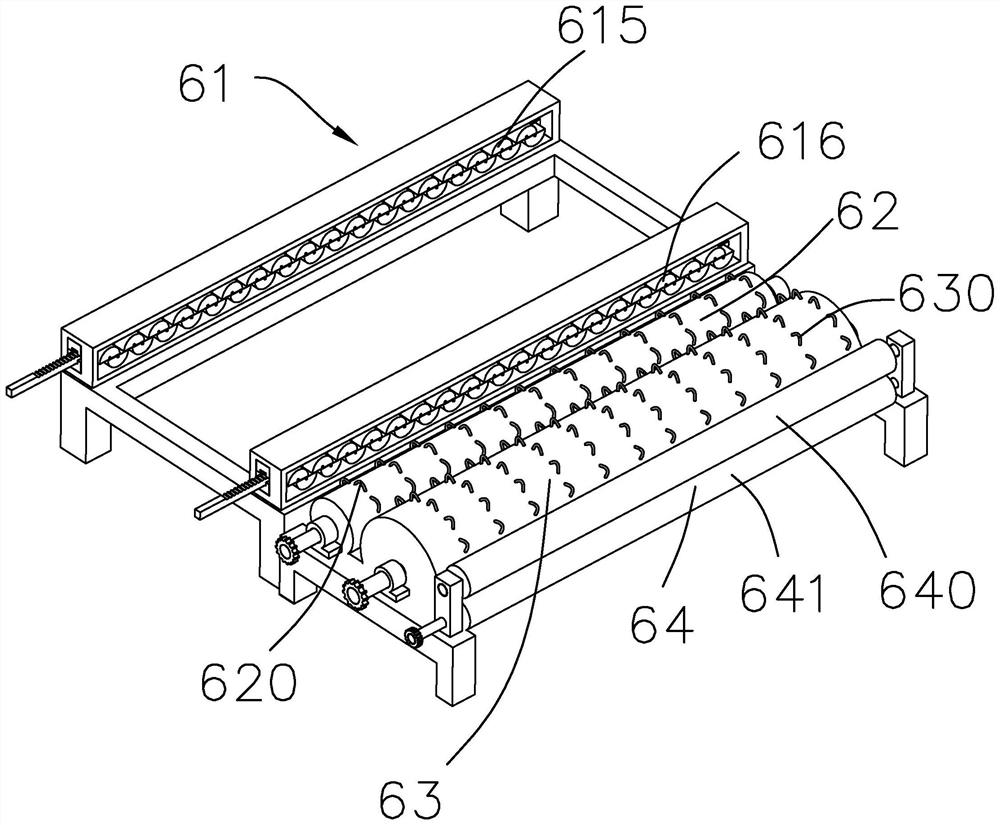

Flexible gabion mesh weaving equipment and working method thereof

PendingCN114182432ATwist lace-making machinesHeating/cooling textile fabricsPolymer scienceEngineering

The invention relates to flexible gabion mesh weaving equipment and a working method thereof. The flexible gabion mesh weaving equipment comprises a wire feeding device, a twisting assembly, a traction roller, a heating roller and an extrusion roller set which are arranged in sequence. The wire feeding device provides silk threads, and the silk threads pass through the twisting assembly and gradually form a silk screen structure with continuously-arranged diamond units under the action of the twisting assembly. The traction roller drives the formed silk screen structure to perform traction movement, so that the silk screen structure moves towards the downstream side; and the heating roller receives the silk screen structure from the traction roller, provides a heating function to heat the silk screen structure, sends out the silk screen structure towards the downstream side, and achieves a shaping function on the silk screen structure through the extrusion sending-out function of the extrusion roller set.

Owner:河北格宾五金丝网有限公司

Electronic driven jacquard apparatus and cassette for use therein

InactiveCN101050576ASmooth movementStable choice actionJacquardsTwist lace-making machinesEngineeringRetaining Pin

An electronic driven jacquard apparatus includes a cassette having a select head pivotally selectable between a contacting posture contacting a select pin and a non-contacting posture not contacting the select pin in association with a bending movement of an operational member comprised of a piezoelectric body and a retaining pin providing a pivot for the select head, a jacquard machine body for fixedly supporting the cassette and a reciprocating mechanism for reciprocating the jacquard machine body along a longitudinal direction of the select pin. An end of the select pin facing the select head has a cubically convex shape whereas an end of the select head facing the select pin has a corresponding concave portion for receiving therein the cubically convex end of the select pin.

Owner:MIYAGI LACE CO LTD

Electronic jacquard device and cassette for electronic jacquard

InactiveCN101258277AStable needle selectionJacquardsTwist lace-making machinesElectricityEngineering

Owner:MIYAGI LACE CO LTD

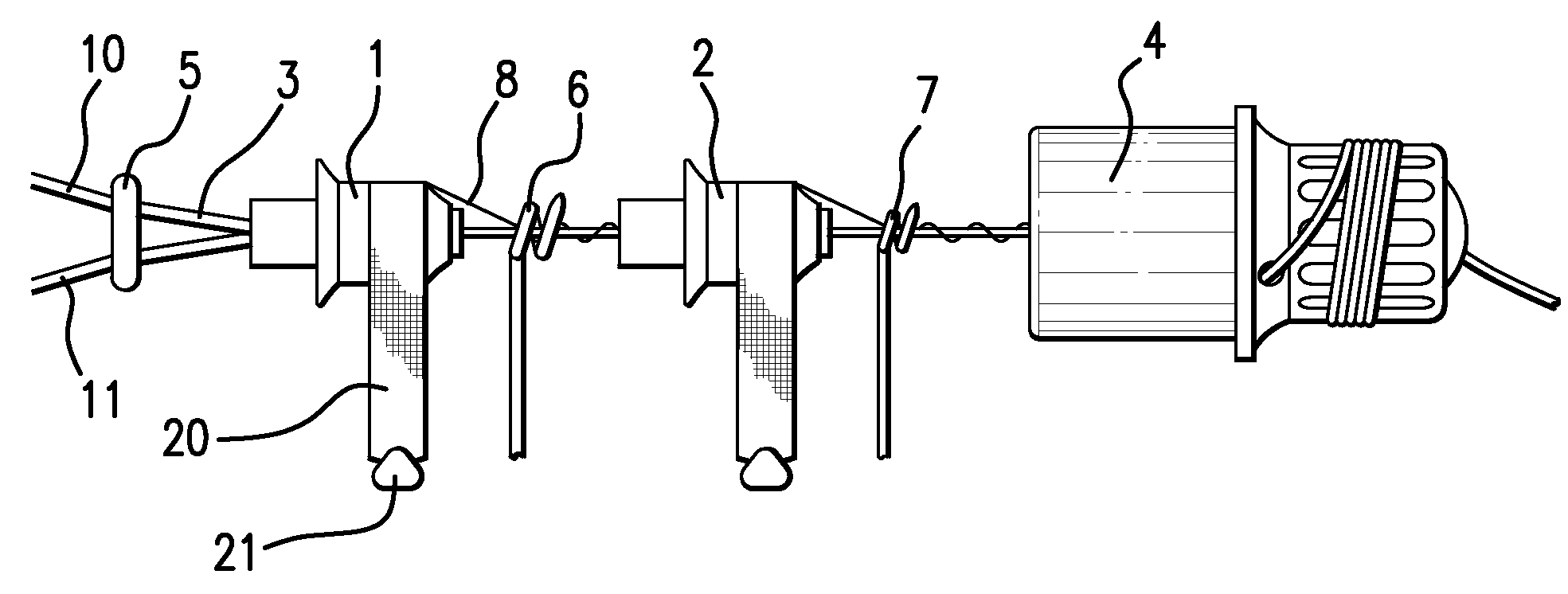

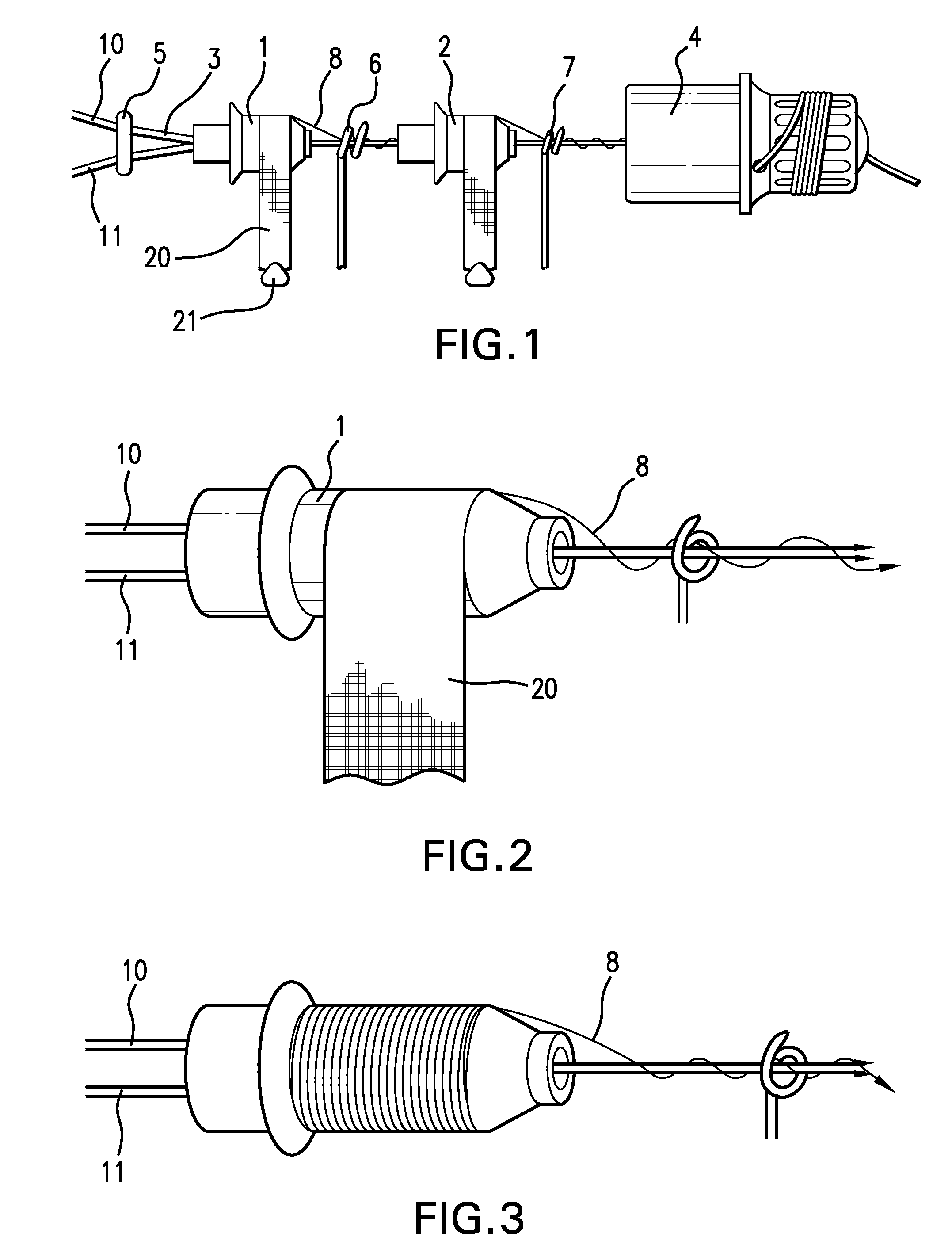

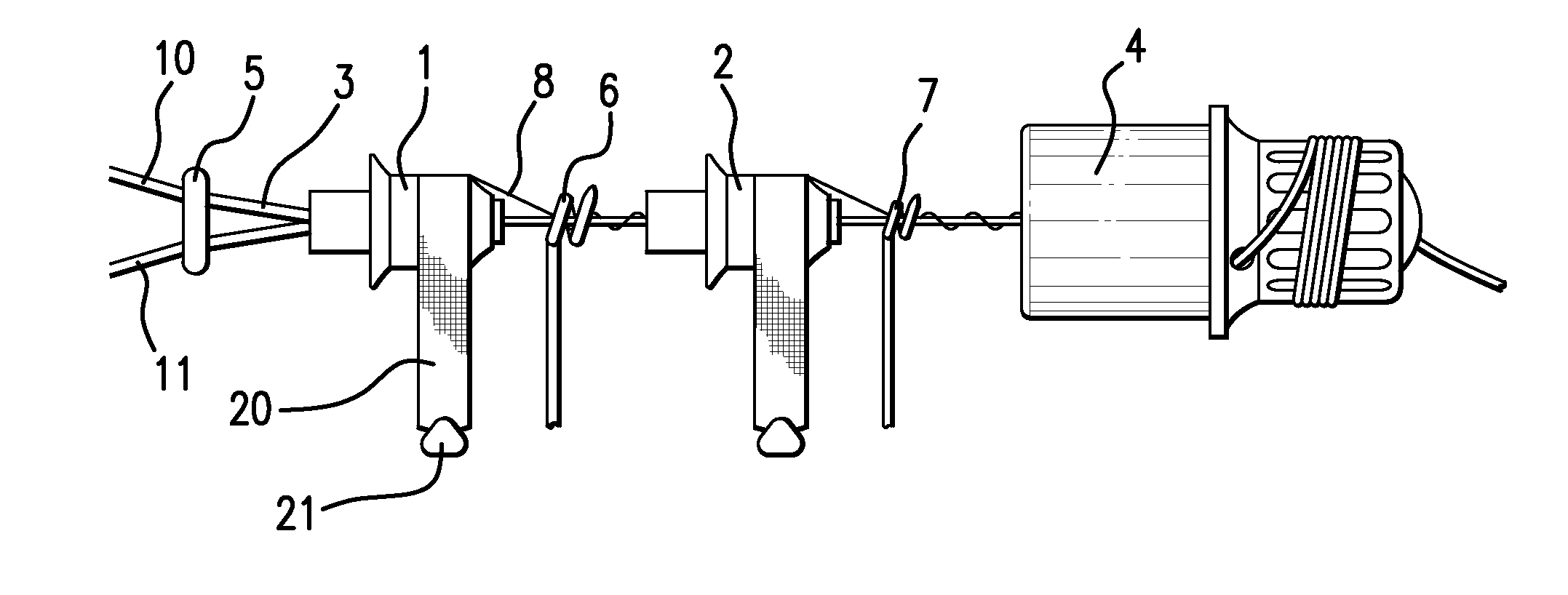

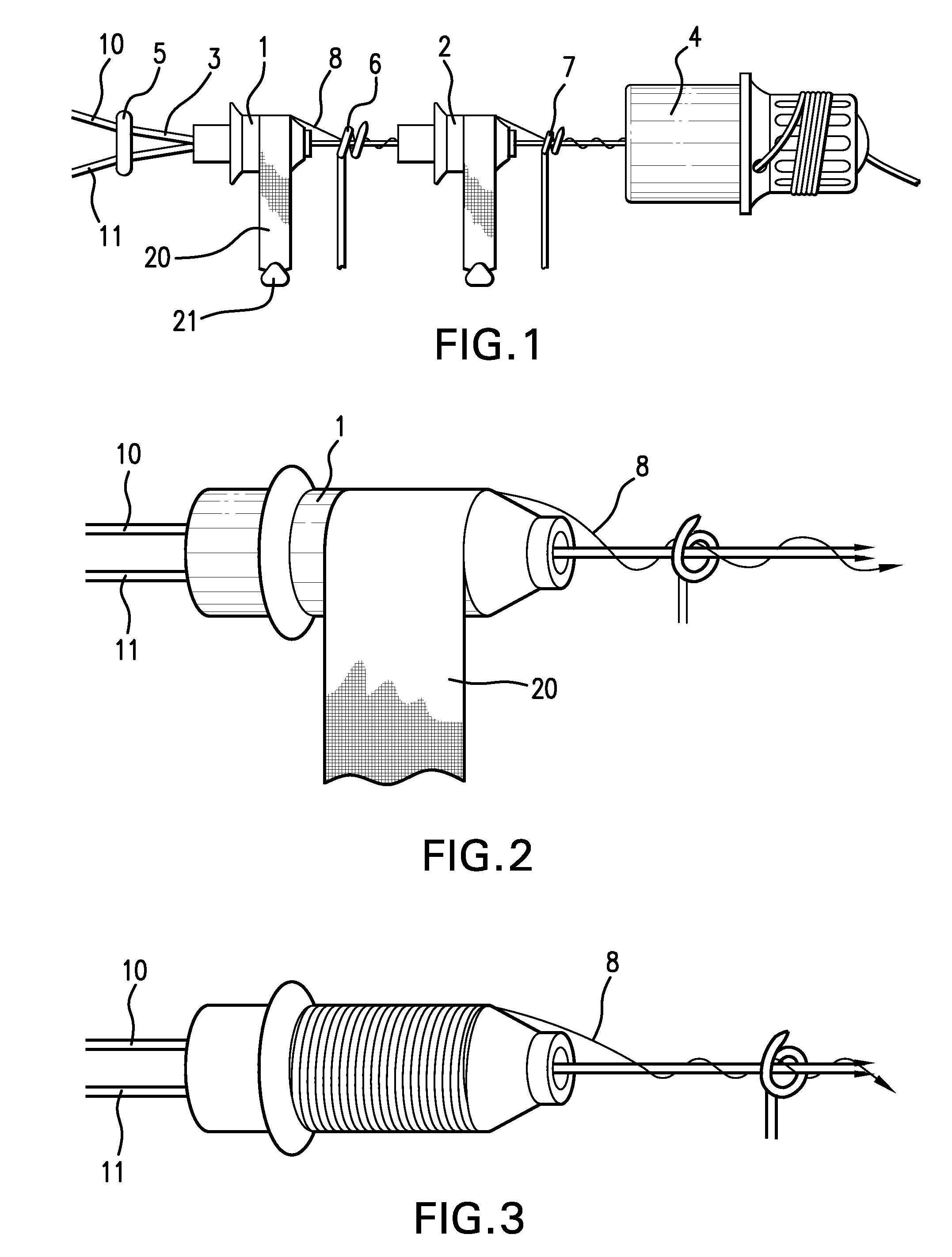

Automatic lacer for bundles of polymeric fiber

ActiveUS8171710B2Reducing clogging and potential stoppageAvoid damageTwist lace-making machinesLoomsFiber bundleMechanical engineering

An automatic lacer wraps bundles of polymeric fibers with thread, before the bundles are woven into a fabric mat and placed in a housing to form a gas-separation membrane module. A fiber bundle passes through a spool which is previously wound with thread on its outer surface. The thread is attached to the fiber bundle, so that when the bundle is moved through the spool, the thread is pulled from the spool, and automatically becomes wound around the bundle. Threads from two or more spools may be wrapped around the fiber bundle simultaneously. Lacing of the fiber bundles reduces the amount of tangling in the loom feeder, and improves the quality of modules made from the fiber bundles.

Owner:GENERON IGS

Intermediate film breakage detection device for knitting machine and control method

ActiveCN106093126ARealization of glue breaking detectionIncrease productivityTwist lace-making machinesMaterial analysis by electric/magnetic meansEngineeringSignal lines

The invention discloses an intermediate film breakage detection device for a knitting machine and a control method, wherein the device comprises a base; a support plate is mounted on the base; a first side plate and a second side plate are mounted on the support plate; a film rack is arranged on the second side plate; a guide roller, a lifting lever, a lifting lever fixing block and a detection lever are arranged on the first side plate; the lifting lever fixing block and the detection lever can be movably fixed onto the first side plate; one end of the lifting lever is in separable contact with the detection lever after passing through the lifting lever fixing block; a power source signal line is connected to the detection rod; a broken film detection signal line is connected to the shifting lever. Therefore, broken film detection of an intermediate part of a film can be realized, automatic production can be realized, and the production efficiency is improved.

Owner:NANJING ORIENTLEADER TECH CO LTD

Plastic open mesh net manufacturing device and machine

InactiveUS20120261075A1Improve evennessImprove uniformityTwist lace-making machinesWire networkEngineeringScrew thread

A device for twisting plastic wires to form a plastic open mesh net comprises a front twist mechanism and a back twist mechanism which have corresponding pairs of front and back thread-holes for receiving plastic wires to be twisted. Each couple of a front thread-hole and a back thread-hole is connected by a corresponding heat-conductive thread guide, preferably in the form of a pipe, which provides a uniform heating of the plastic wire which is guided therein. A machine for manufacturing a plastic open mesh net comprises a holding device downstream of the twisting device to maintain a uniform shape of the just formed open mesh net.

Owner:OFFICINE MACCAFERRI SPA

Leavers machine and pushing rod for the same

InactiveCN101096798AOmit positioning operationReduce replacement timeTwist lace-making machinesEngineeringGame machine

To provide a game machine capable of reducing a control load on the game control means side and increasing the time for the game control means to spend for the game control. Display control commands at least including a variation time command and a stopped pattern command are transmitted from a game control board to a display control board. Then, whether a prior notice of a ready-to-win state should be given or not, and whether a prior notice of a jackpot should be given or not are determined according to the variation time command, and further, a symbol to be replaced in the symbol replacement control is determined on the display control board side.

Owner:MIYAGI LACE CO LTD

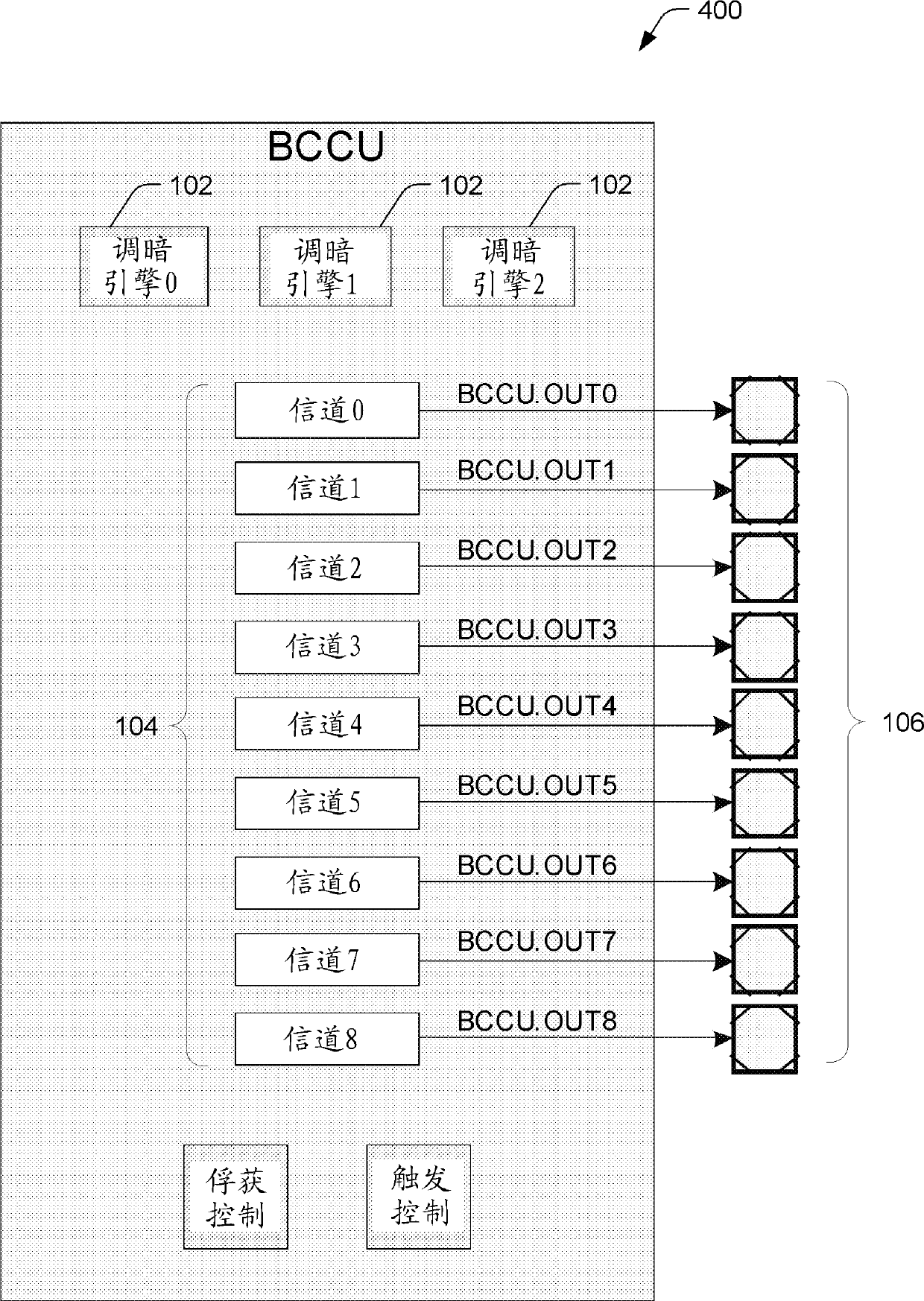

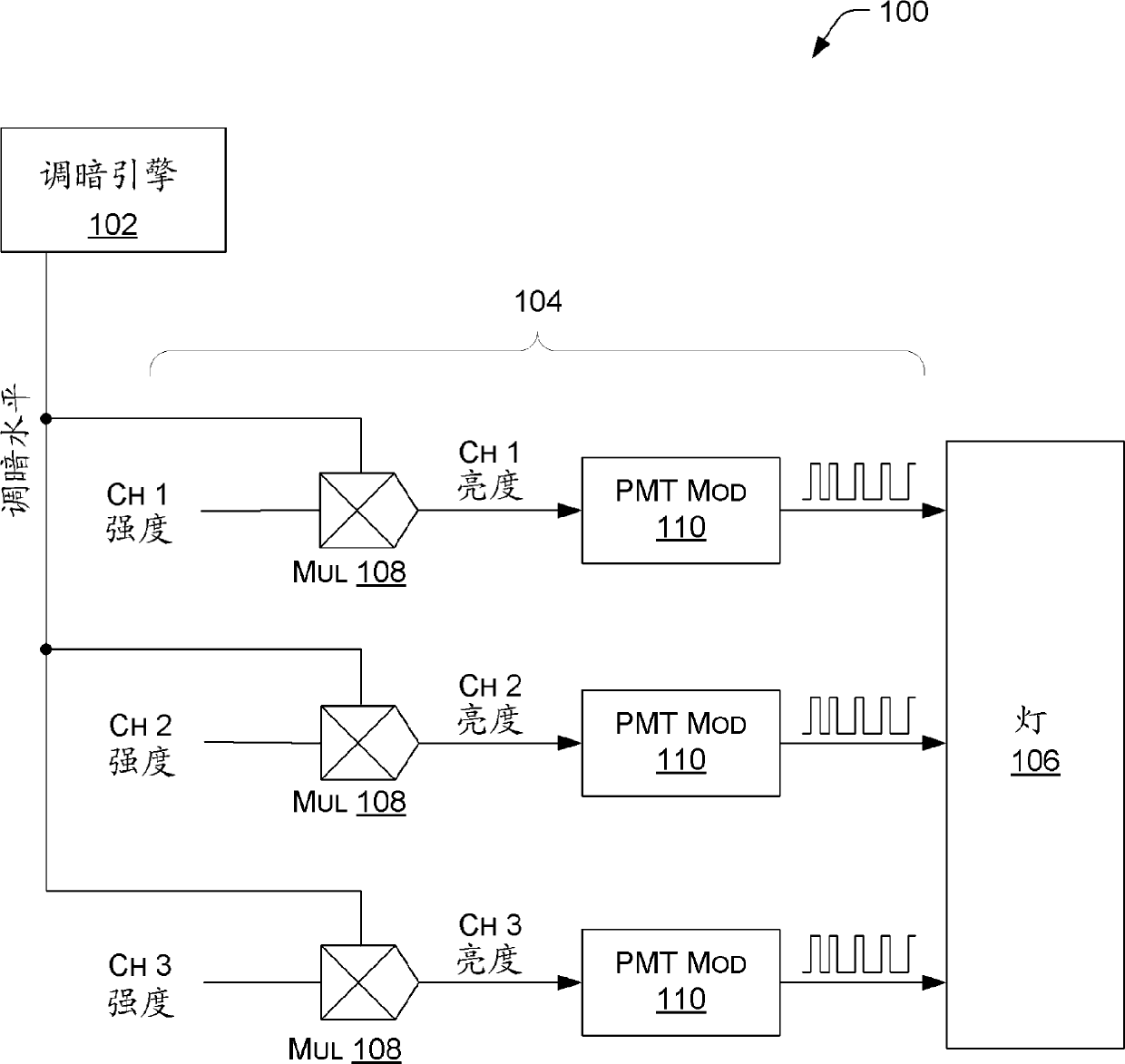

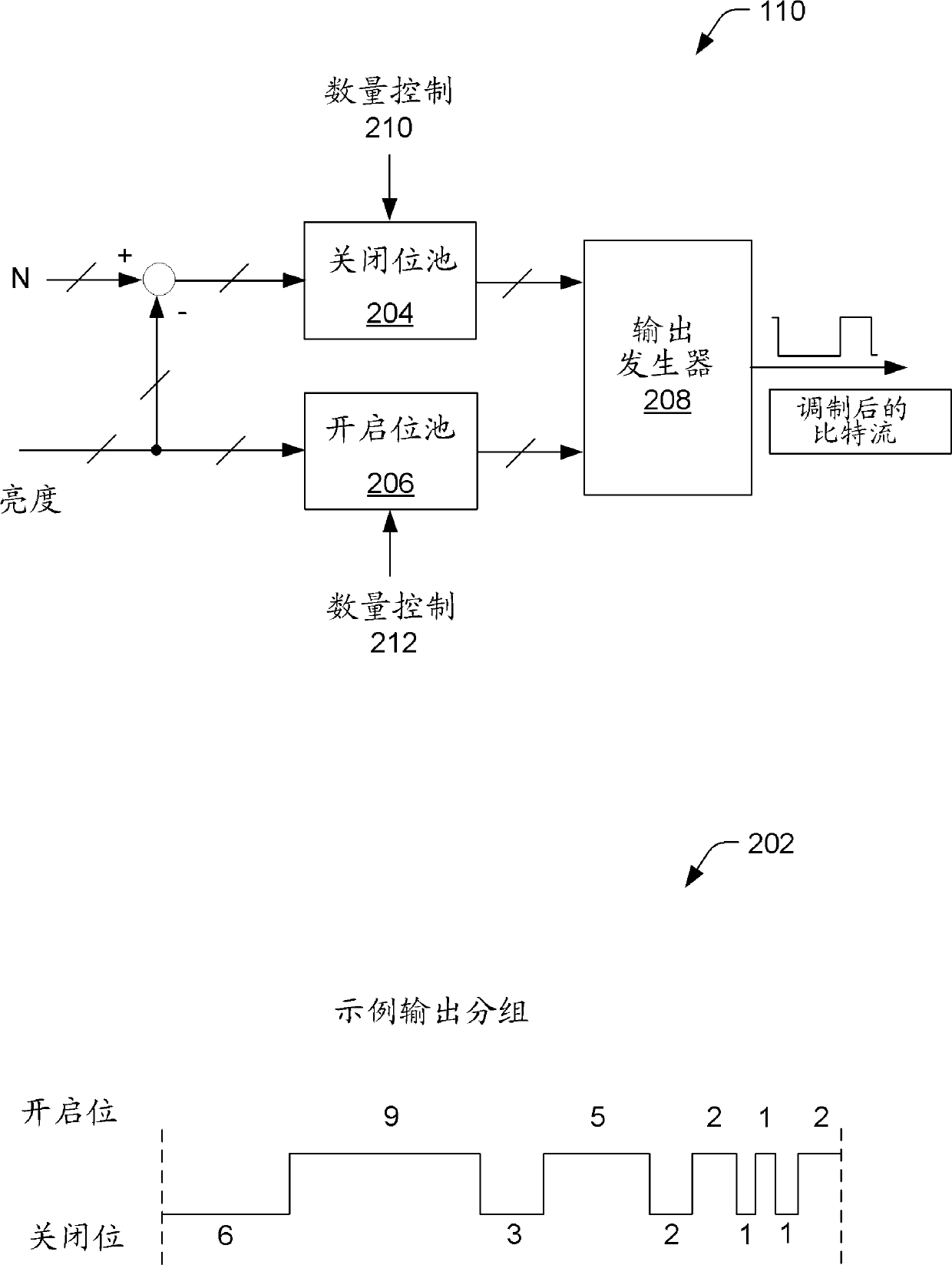

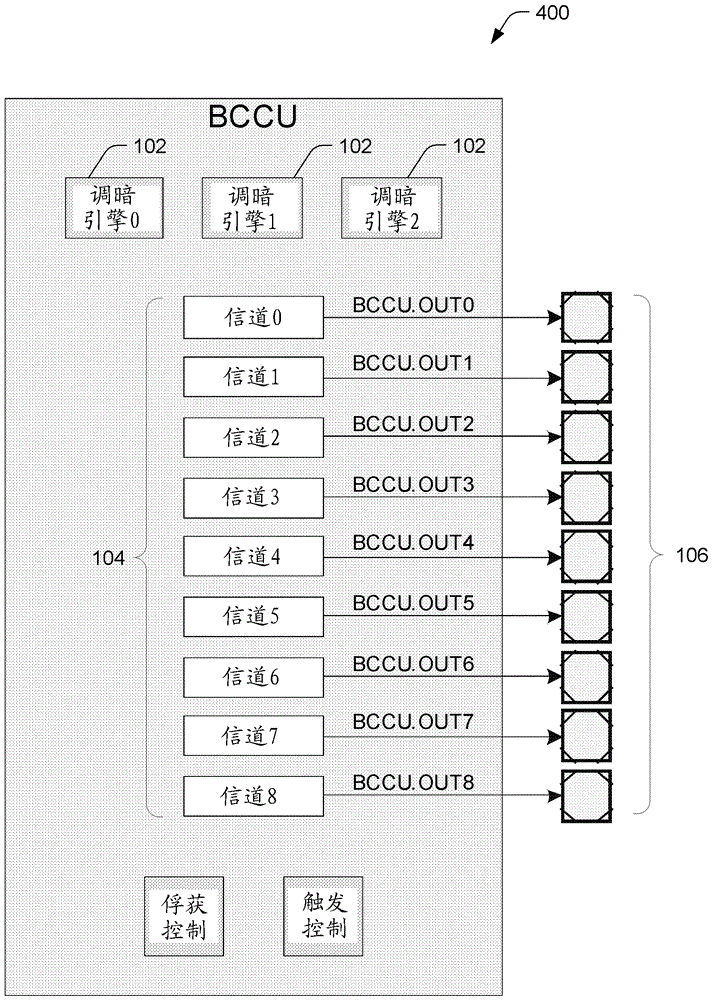

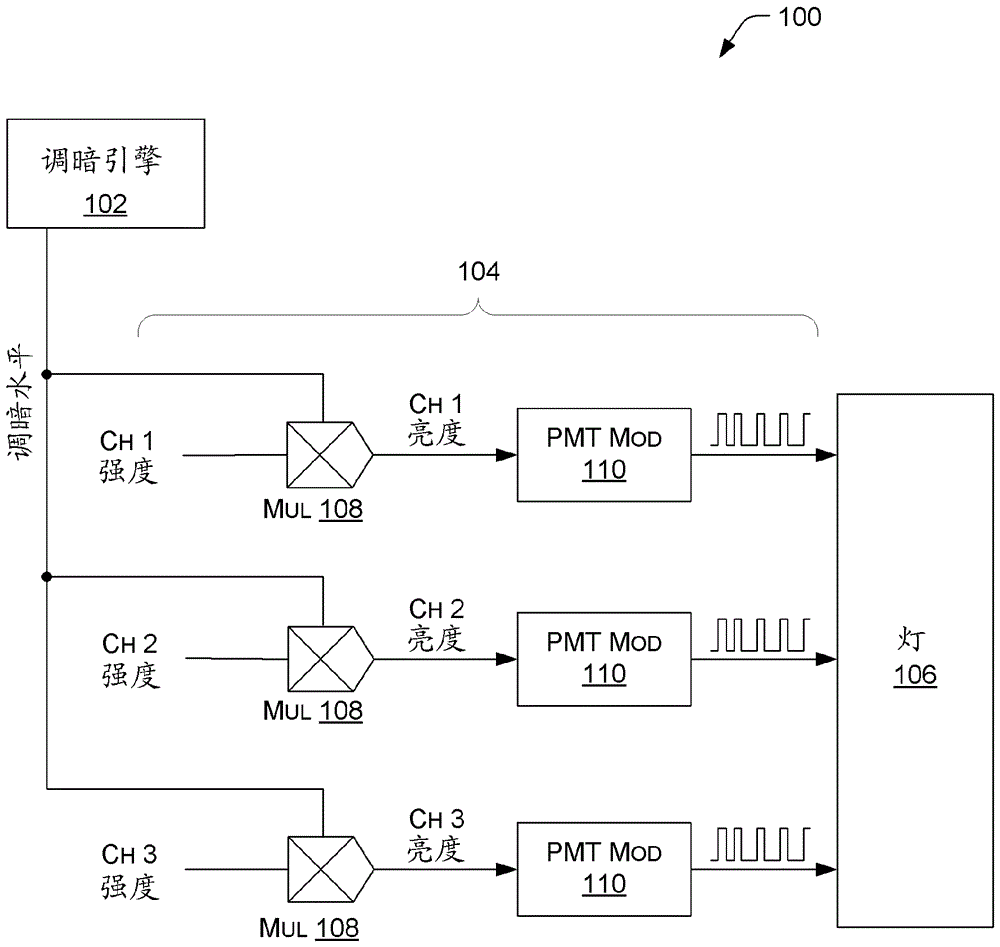

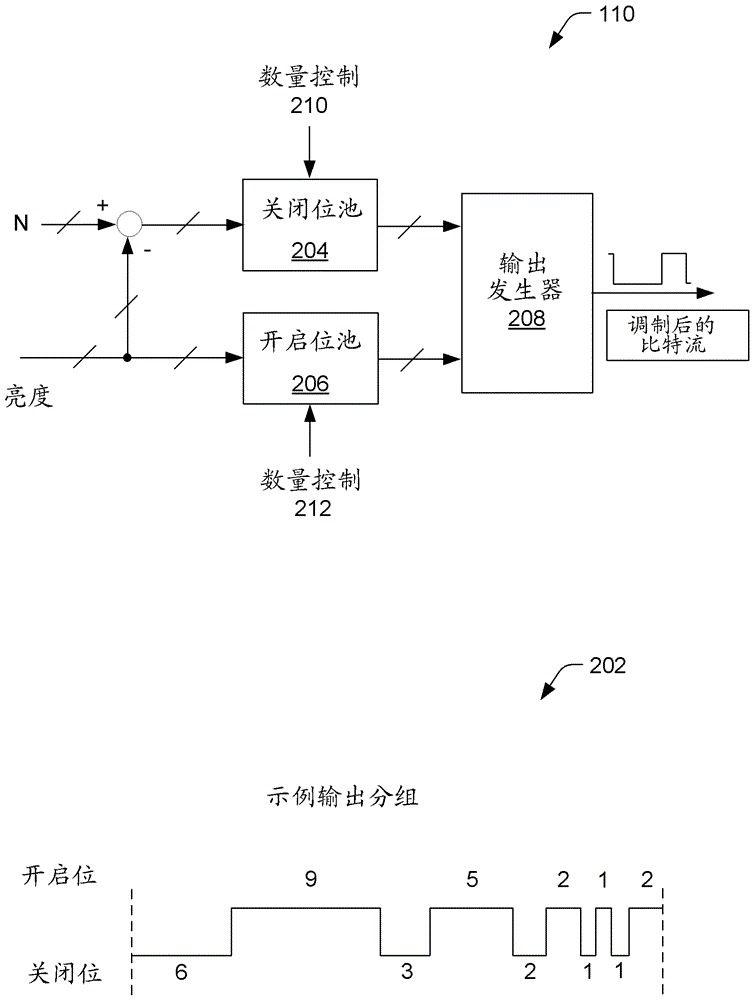

Variable load driver with power message transfer

ActiveCN104093233ATwist lace-making machinesElectroluminescent light sourcesControl signalMessage delivery

The invention relates a variable load driver with power message transfer. Representative implementations of devices and techniques provide a modulation arrangement for a control signal. The control signal is received as a digital value. A modulated control signal having a varying rate of change may be generated based on the quantity of off-bits and the quantity of on-bits of the digital value.

Owner:INFINEON TECH AG

Plastic shuttle of netting machine

ActiveCN101333725BImprove wear resistanceExtended service lifeTwist lace-making machinesKnotting netsWear resistantMetallic materials

The invention discloses a plastic shuttle of the netting machine, which comprises a plastic shuttle body and an arc-shaped bottom supporting section that is arranged at the bottom of the plastic shuttle body and is used to support a line disk. One side of the arc-shaped bottom supporting section is provided with a shuttle retaining edge; and the inner surface of the arc-shaped bottom supporting section is buried with a layer of corresponding arc-shaped metal coupon which is made of wear resistant metal material. The plastic shuttle of the netting machine has the advantages that as a layer of arc-shaped metal coupon is arranged in the arc-shaped bottom supporting section, the wear resistant performance between the arc-shaped bottom supporting section and the line disk is improved, thereby prolonging the service life of the plastic shuttle; furthermore, the arc-shaped metal coupon and the plastic shuttle are lapped reasonably and ingeniously, so stronger binding force between the metal coupon and the plastic shuttle can be assured, and strength in the inner structure will not be affected due to the arrangement of the metal coupon.

Owner:张家港市新盈模具塑化有限公司

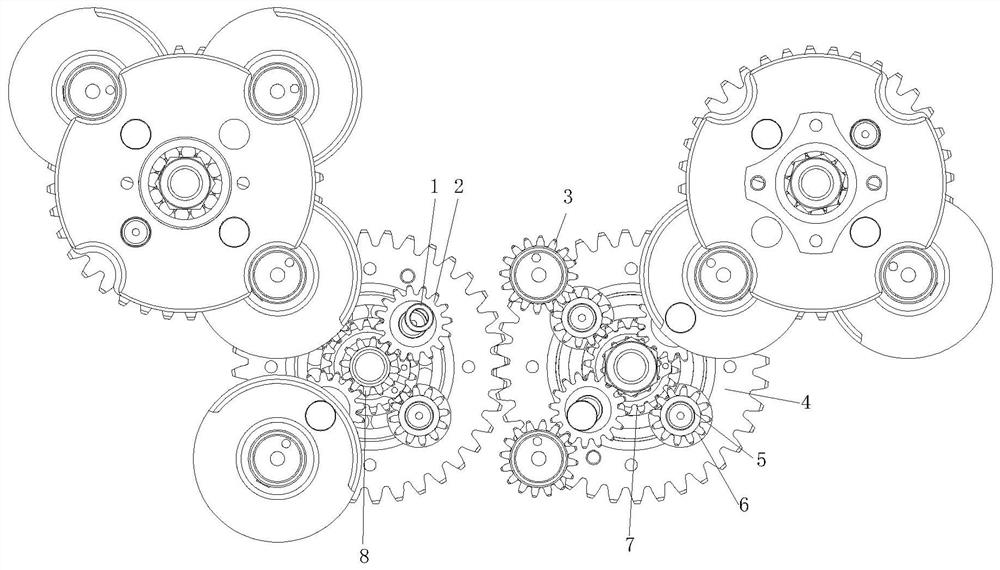

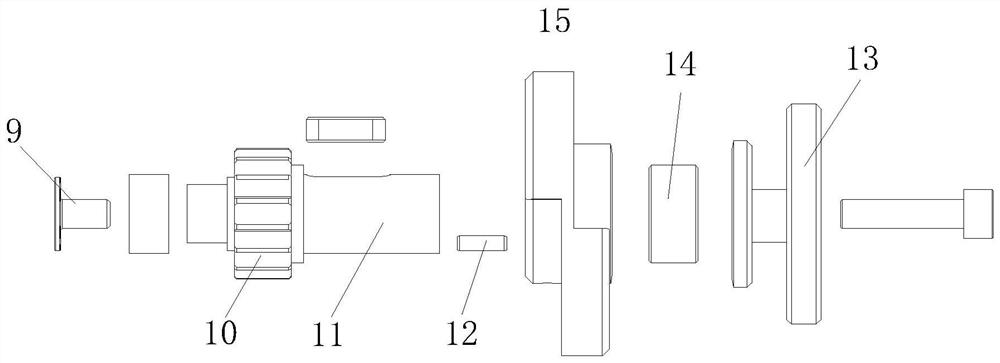

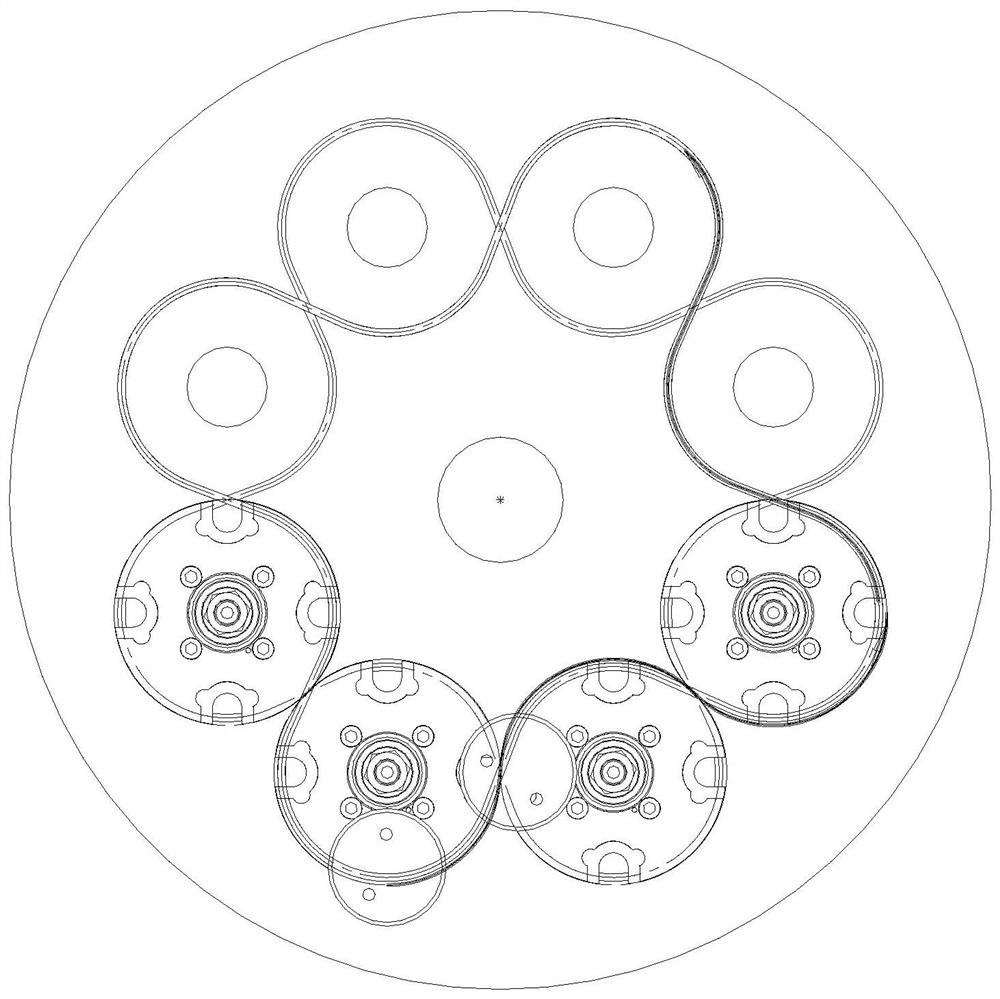

Planetary directional high-speed braiding machine

PendingCN113737386ASmall running resistanceReduce energy consumptionTwist lace-making machinesGear wheelEngineering

Owner:东莞市冠博精密机电有限公司

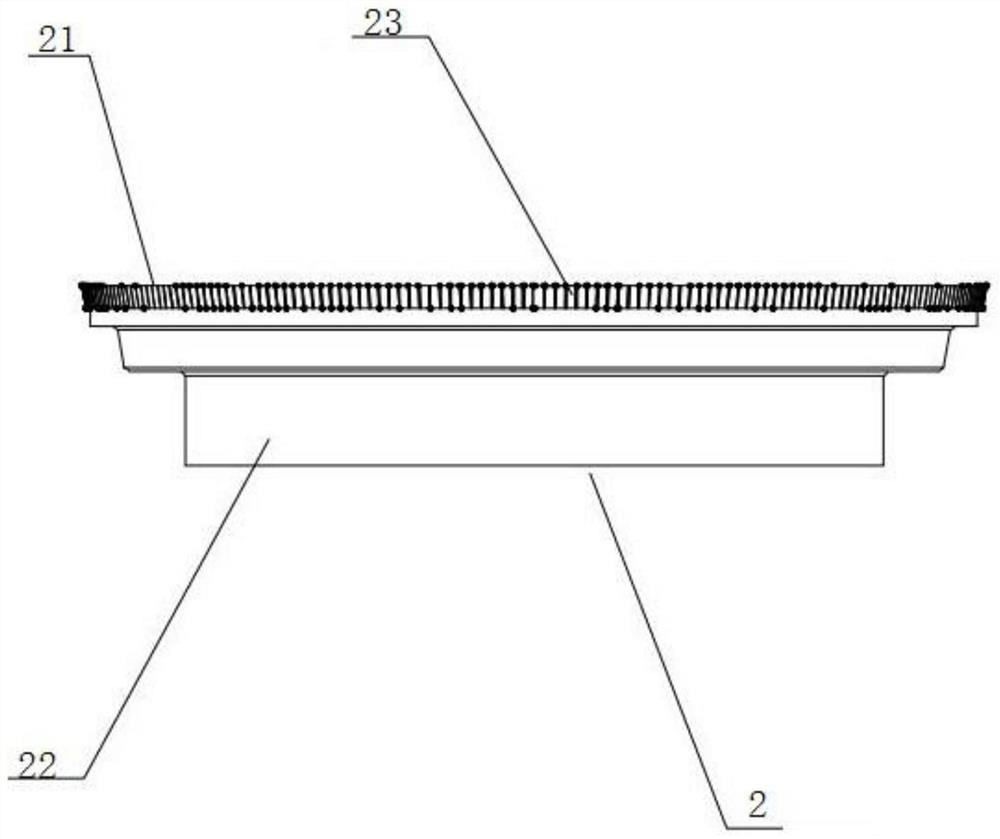

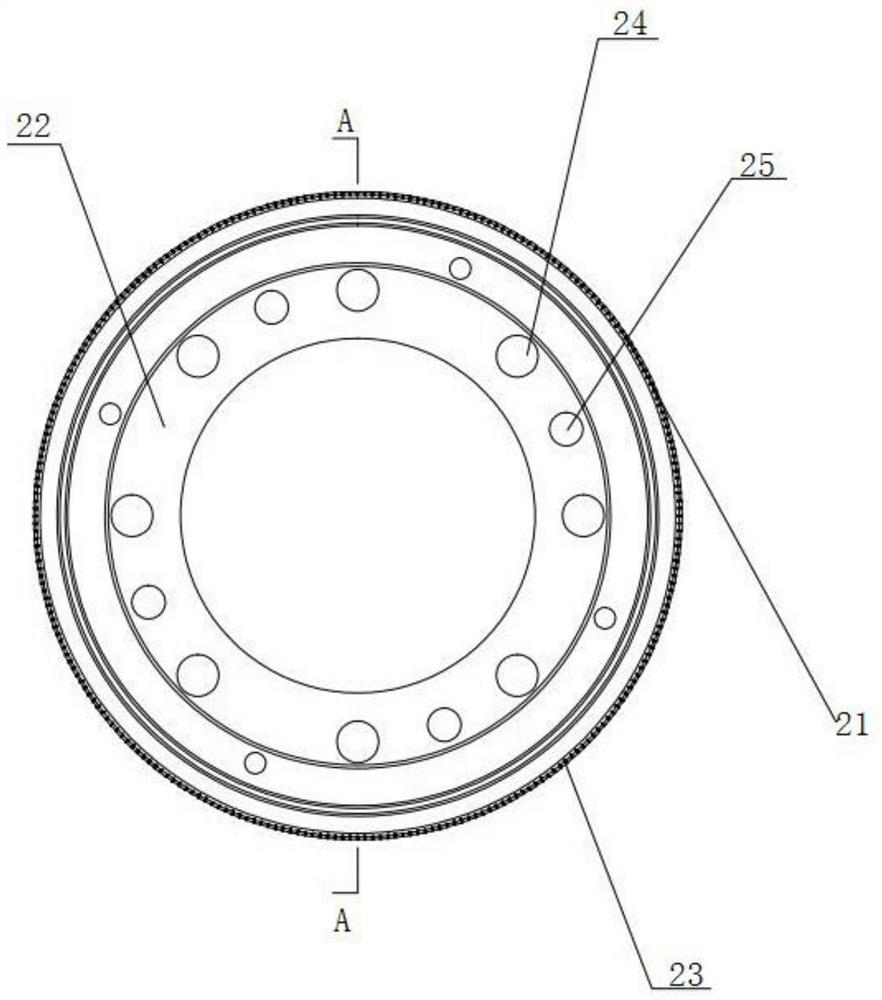

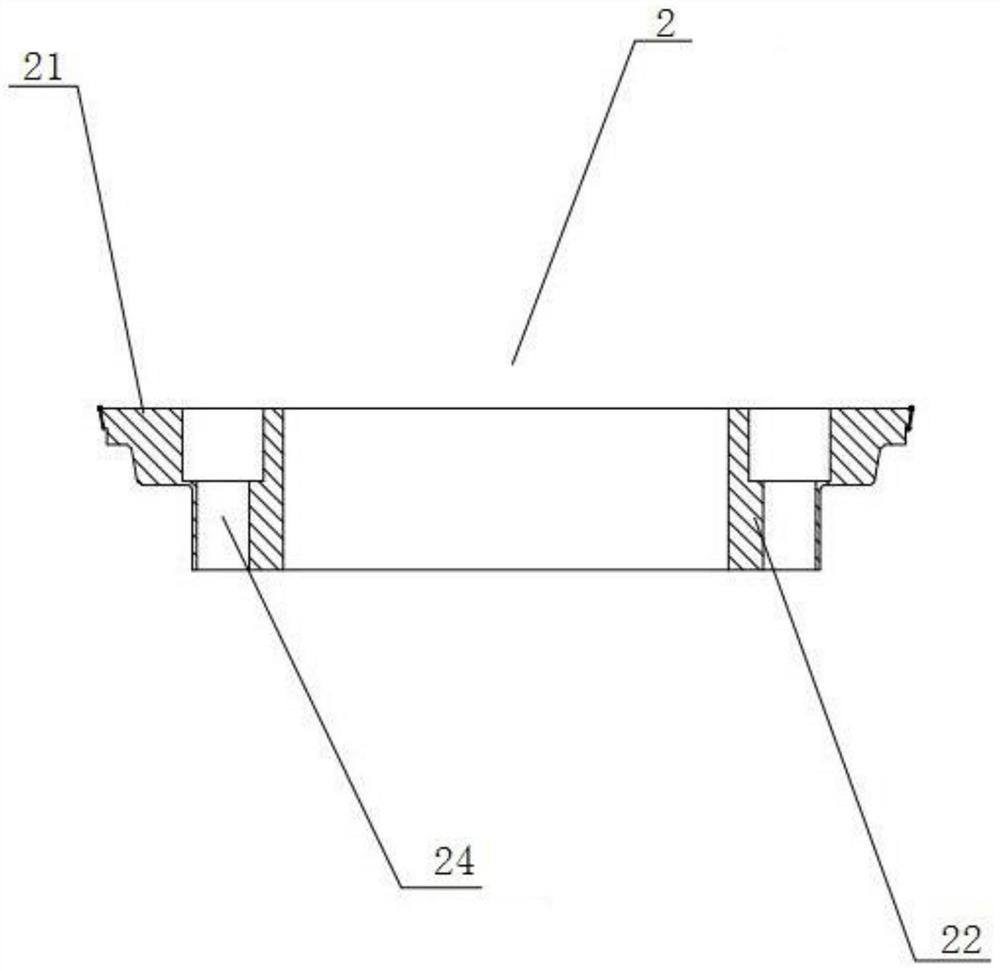

A mold for producing concentrated water net

ActiveCN111764043BEasy knittingEasy to installTwist lace-making machinesReverse osmosisWater netEngineering

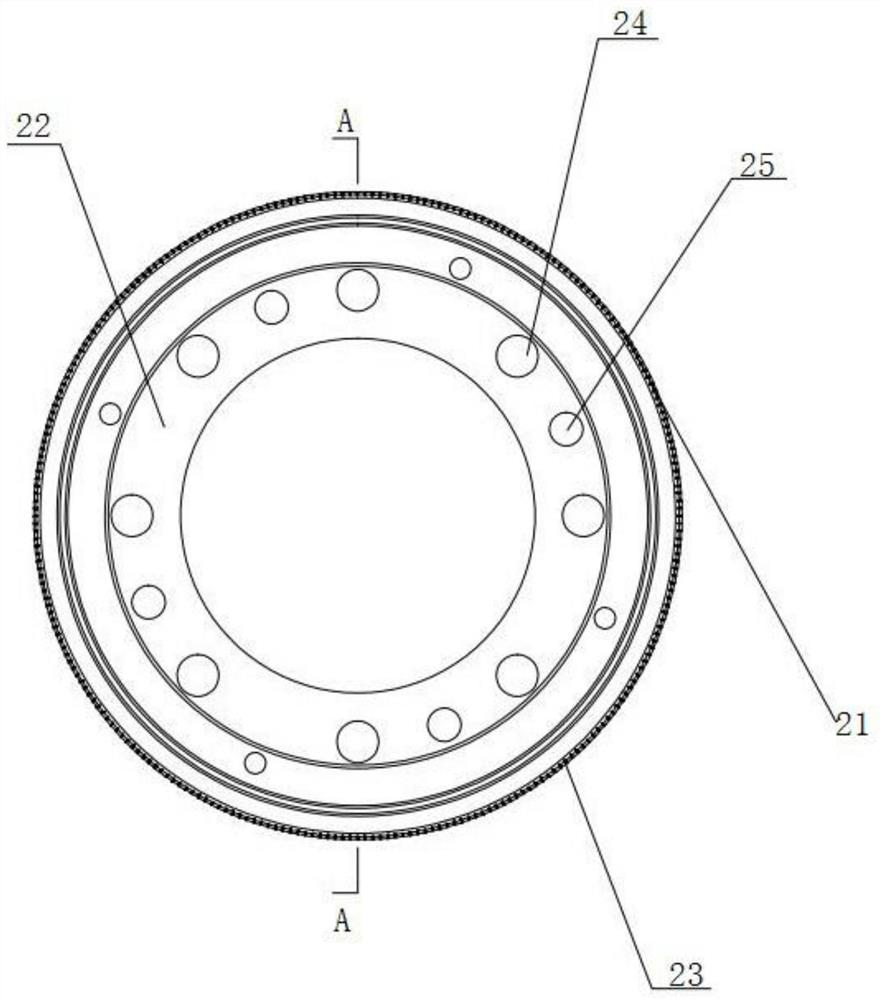

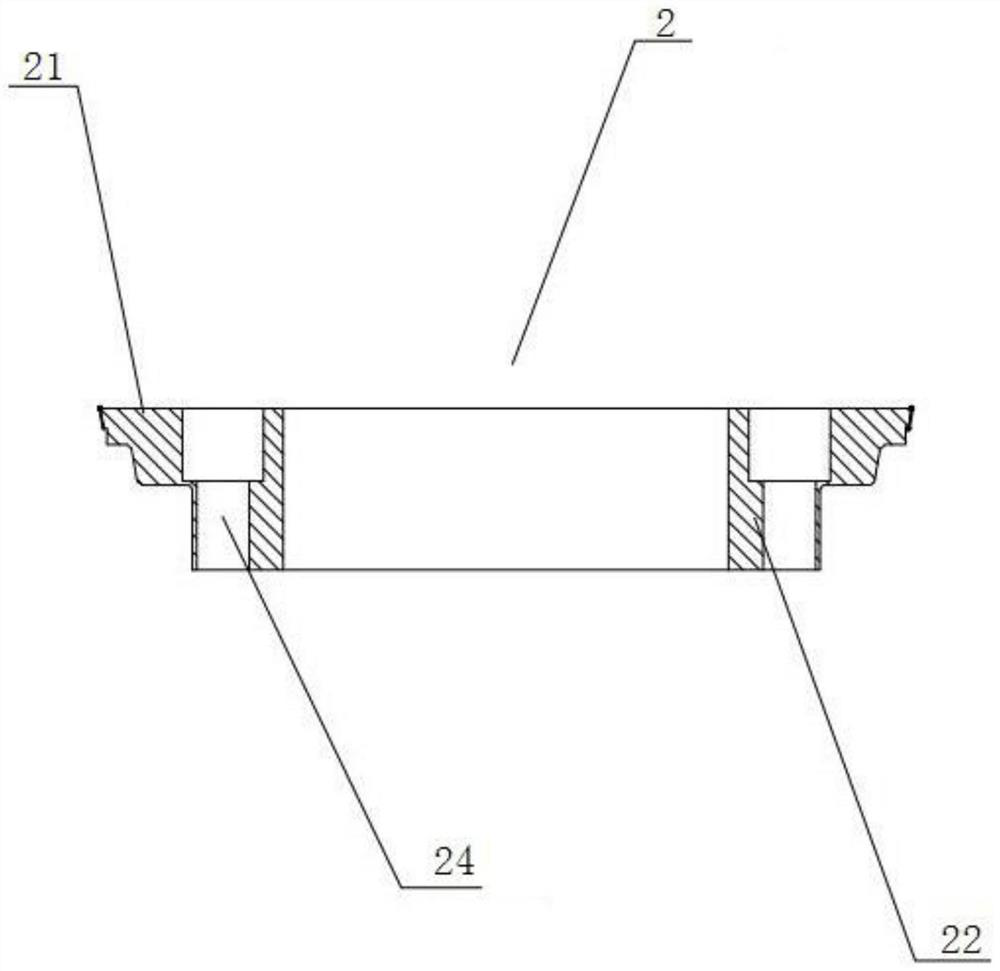

The invention discloses a mold for producing concentrated water mesh, which comprises an outer rotating body and an inner rotating body; the outer rotating body is in the shape of a hollow cylinder, and several inner grooves are opened on the inner side wall of the bottom; the inner groove 11 is inclined It is arranged on the inner side wall of the outer rotating body 1; several pairs of first fixing holes and first positioning holes are symmetrically provided on the outer rotating body; the inner rotating body includes an integrally formed base ring body and an upper ring body integrally formed with the base ring body Hollow cylinder; the height of the base ring body is consistent with the height of the inner groove; the outer wall of the base ring body is provided with several outer grooves corresponding to the inner groove; the outer groove 23 is obliquely arranged on the bottom of the base ring body 21 On the outer wall, its inclination direction is opposite to that of the inner groove 11; on the upper hollow cylinder, there are second fixing holes and second positioning holes corresponding to the first fixing holes and the first positioning holes. The invention can produce concentrated water nets, and the produced concentrated water nets have good uniformity and are easy to install and disassemble.

Owner:贵州海澄科技有限公司

Automatic lacer for bundles of polymeric fiber

ActiveUS20100132537A1Reduce cloggingReducing potential stoppageTwist lace-making machinesLoomsFiber bundleEngineering

An automatic lacer wraps bundles of polymeric fibers with thread, before the bundles are woven into a fabric mat and placed in a housing to form a gas-separation membrane module. A fiber bundle passes through a spool which is previously wound with thread on its outer surface. The thread is attached to the fiber bundle, so that when the bundle is moved through the spool, the thread is pulled from the spool, and automatically becomes wound around the bundle. Threads from two or more spools may be wrapped around the fiber bundle simultaneously. Lacing of the fiber bundles reduces the amount of tangling in the loom feeder, and improves the quality of modules made from the fiber bundles.

Owner:GENERON IGS

Leavers machine and pushing rod for the same

InactiveCN101096798BOmit positioning operationReduce replacement timeTwist lace-making machinesEngineeringGame machine

To provide a game machine capable of reducing a control load on the game control means side and increasing the time for the game control means to spend for the game control. Display control commands at least including a variation time command and a stopped pattern command are transmitted from a game control board to a display control board. Then, whether a prior notice of a ready-to-win state should be given or not, and whether a prior notice of a jackpot should be given or not are determined according to the variation time command, and further, a symbol to be replaced in the symbol replacement control is determined on the display control board side.

Owner:MIYAGI LACE CO LTD

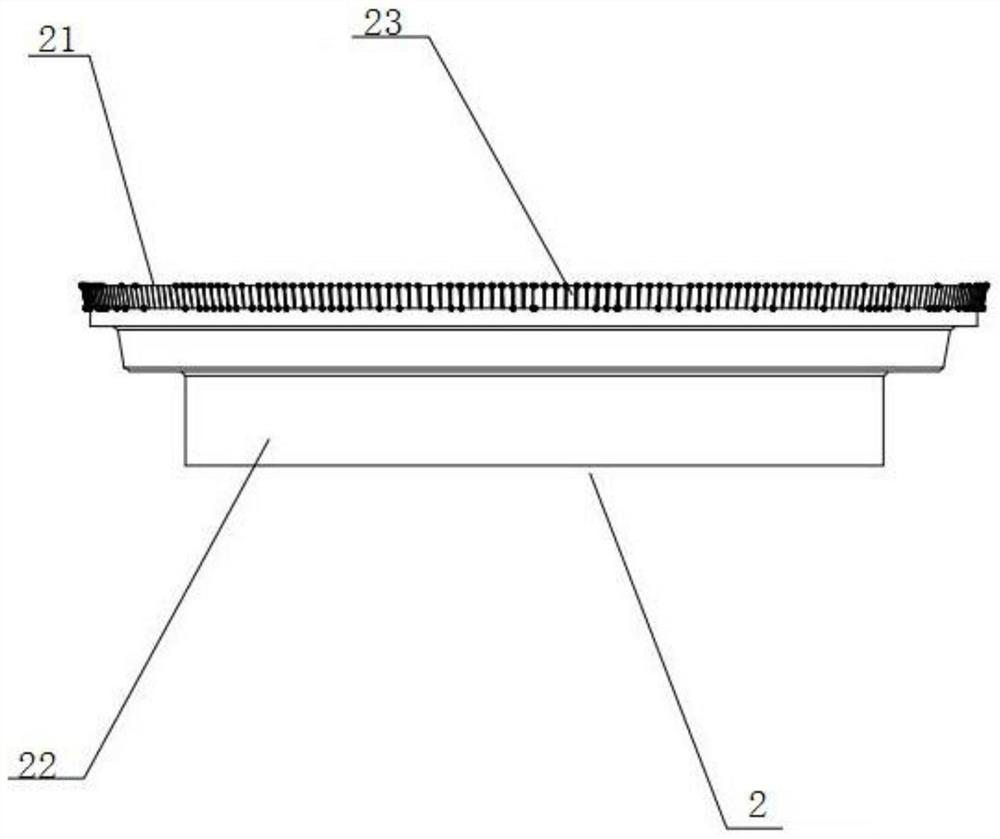

Mold for producing concentrated water net

ActiveCN111764043AEasy knittingEasy to installTwist lace-making machinesReverse osmosisHollow cylinderEngineering

The invention discloses a mold for producing a concentrated water net. The mold comprises an outer rotating body and an inner rotating body. The outer rotating body is in the shape of a hollow cylinder. A plurality of inner grooves are formed in the circumference of the inner side wall of the bottom of the outer rotating body. The inner grooves are arranged obliquely at the inner side wall of thehollow cylinder. The outer rotating body is symmetrically provided with a plurality of pairs of first fixing holes and first positioning holes. The inner rotating body comprises an integral base ringbody and an upper hollow cylinder integrally formed with the base ring body. The height of the base ring body is the same as the height of the inner grooves. A plurality of outer grooves correspondingto the inner grooves are formed in the circumference of the outer side wall of the base ring body. The outer grooves are arranged obliquely at the outer side wall of the base ring body, and the inclined direction is opposite to that of the inner grooves. The upper hollow cylinder is provided with second fixing holes and second positioning holes corresponding to the first fixing holes and the first positioning holes. The mold can produce the concentrated water net, and the produced concentrated water net has good uniformity and is easy to install and disassemble.

Owner:贵州海澄科技有限公司

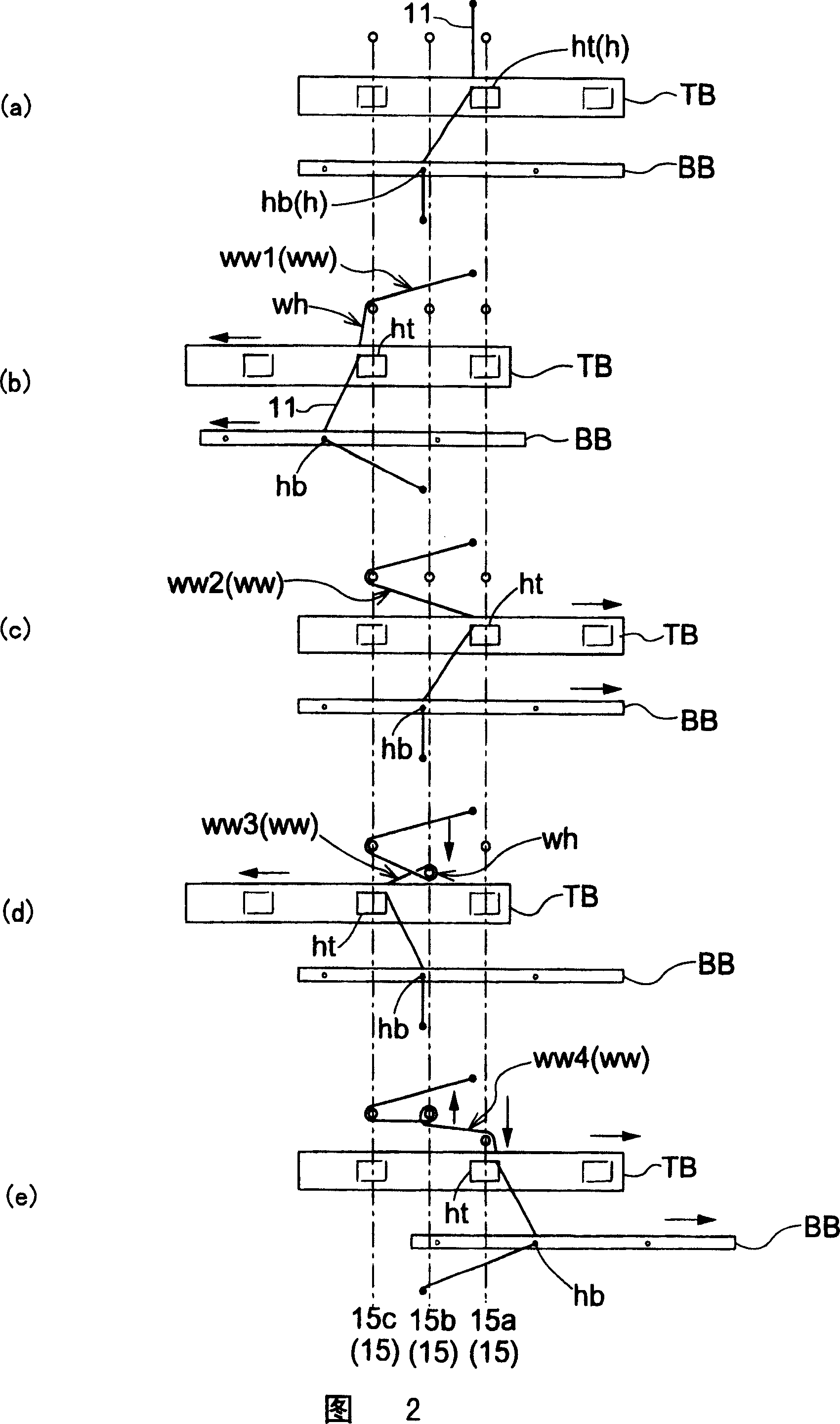

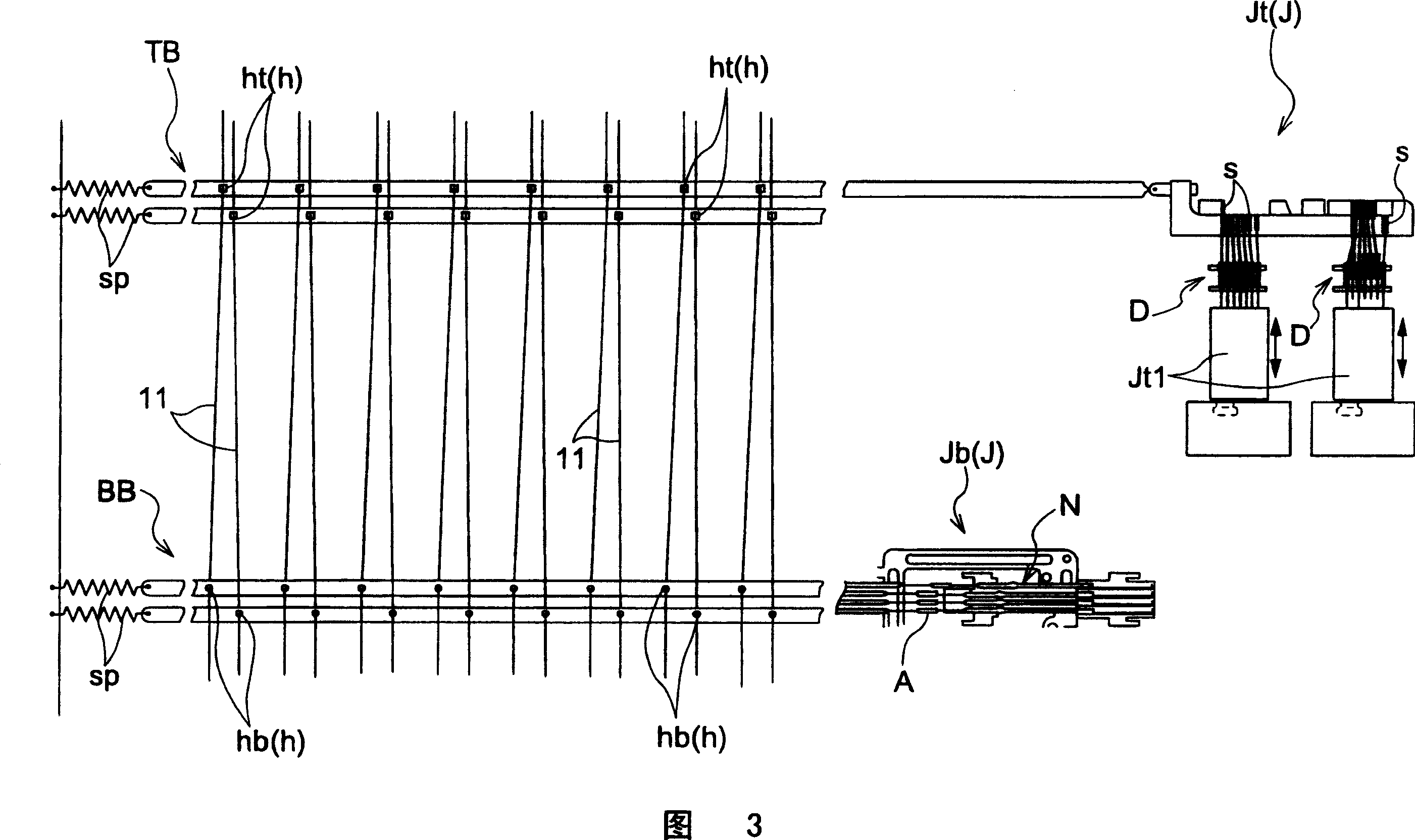

Circular braiding machine

The invention provides a torchon lace machine which halves impact noises produced on the energizing of a solenoid and can always accurately perform patterning. This torchon lace machine is characterized by disposing a clutch 9 for connecting a rotor metal 1 to a rotor-driving shaft 6, when upward moved, and separating the rotor metal 1 from the rotor-driving shaft 6, when downward moved, a fork member 12 which holds the clutch and is downward energized with a spring 13a, a slide shaft 14 horizontally slidably penetrating the back plate of the fork member , the first cam 15a which acts on a cam follower 14a disposed on the inner end side of the slide shaft to upward displace the fork member through the slide shaft, a solenoid for pushing the slide shaft to make the cam follower to approach the operation area of the first cam, the second cam 15b for pushing back the cam follower to the outside of the operation area of the first cam, and the third cam 19 for reinforcing the force of the spring for downward energizing the fork member. Patterning can always accurately be carried out by the operation of the third cam 19.

Owner:ICHIKAWA IRON WORKS

Variable Load Drivers Using Power Messaging

ActiveCN104093233BTwist lace-making machinesElectroluminescent light sourcesControl signalMessage delivery

The present invention relates to variable load drives utilizing power messaging. Representative implementations of devices and techniques provide means for modulating a control signal. The control signal is received as a digital value. A modulated control signal having a varying rate of change may be generated based on the number of off bits and the number of on bits of the digital value.

Owner:INFINEON TECH AG

Shuttle collision preventing device of netting machine

InactiveCN102031635AGuaranteed normal operationSimple structureTwist lace-making machinesEngineeringCopper

The invention discloses a shuttle collision preventing device of a netting machine, which is used for changing the warp shading time of the netting machine and comprises a shuttle box (3). The shuttle collision preventing device is characterized in that a light receptor (2) is arranged at the upper part of the shuttle box (3), the position of the light receptor is higher than that of the shuttle tail of a copper shuttle (1), and a light projector is arranged at the other end of the shuttle box (3) and corresponds to the light receptor (2). The shuttle collision preventing device disclosed by the invention has simple structure, is used for advancing the warp shading time of the netting machine so as to be staggered with the abnormal shuttle jumping time of the copper shuttle, thereby ensuring that the netting machine stops operating when abnormal copper shuttles jump occurs to guarantee the normal operation of machine equipment.

Owner:沅江市洞庭之鑫贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com