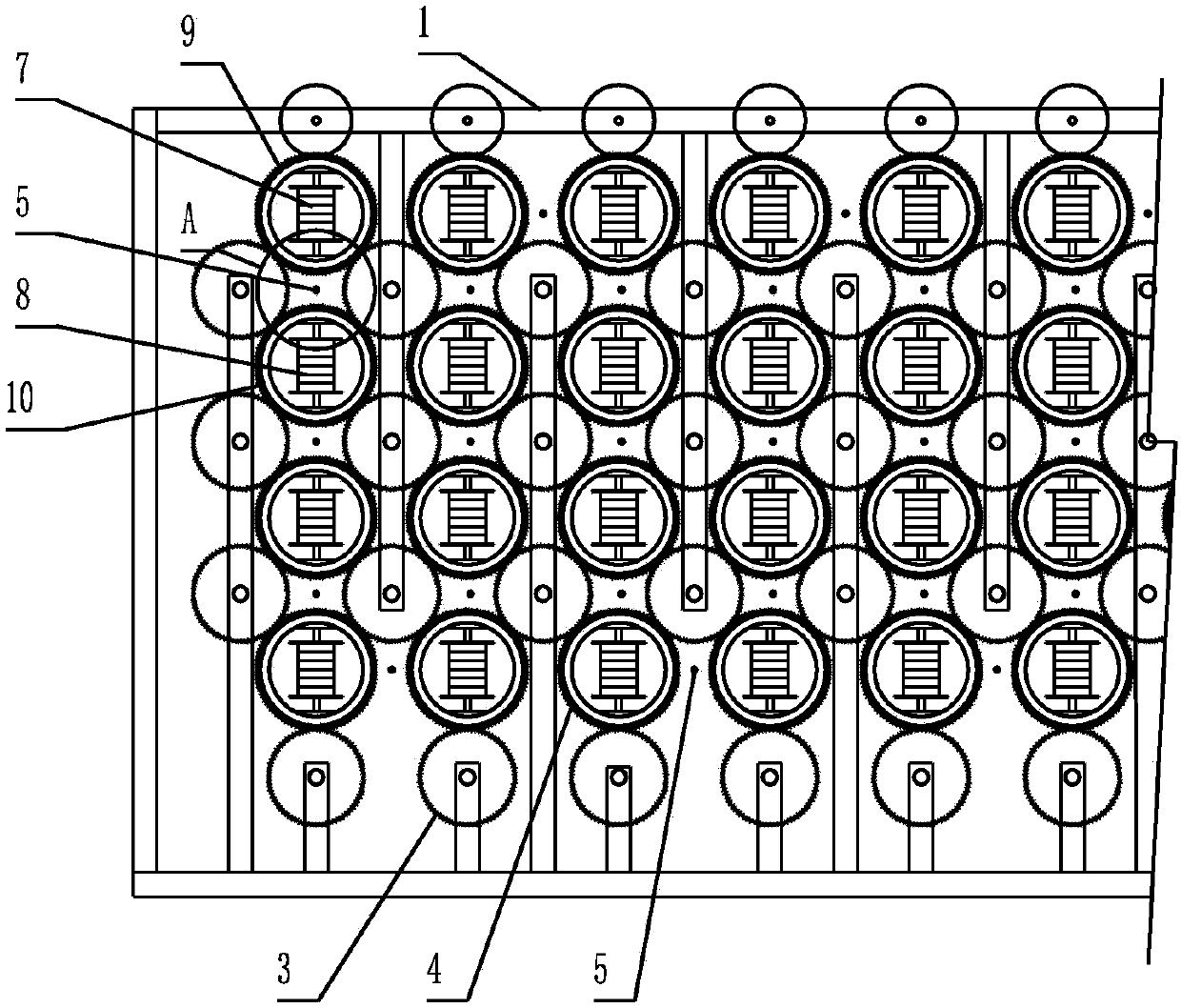

Hexagonal net automatic control efficient weaving system and use method thereof

A technology of weaving system and hexagonal mesh, which is applied in the field of automatic control and high-efficiency weaving system of hexagonal mesh, can solve the problems of influence of wire strength, production efficiency and safety, and uneven mesh, so as to improve efficiency and product quality, Guarantee quality and operation safety, avoid the effect of mesh irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

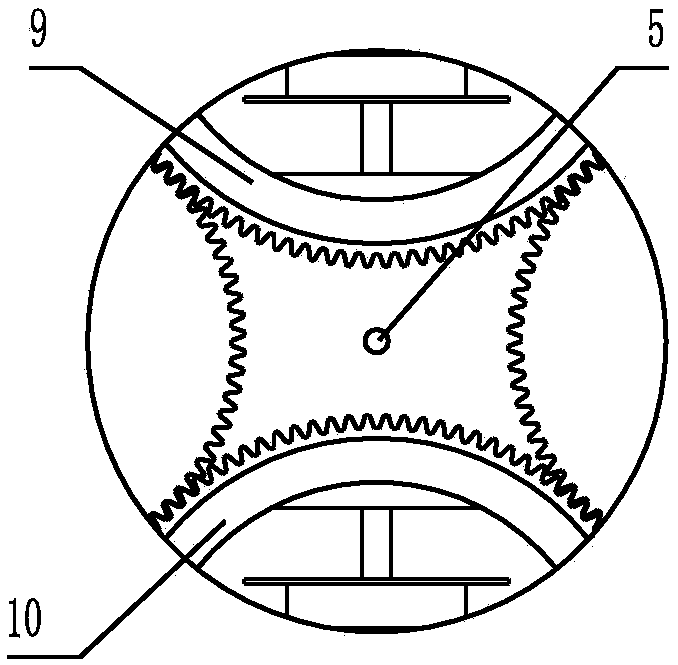

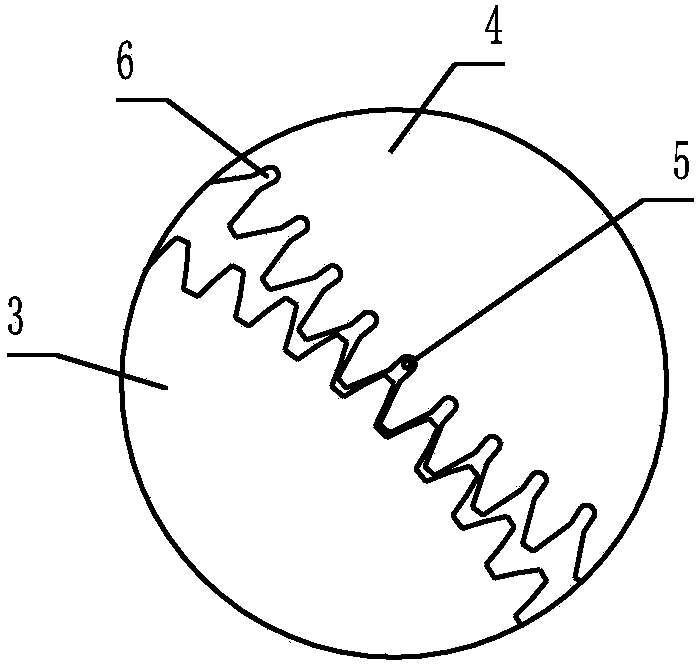

Method used

Image

Examples

Embodiment 2

[0035] Embodiment 2: A hexagonal mesh automatic control high-efficiency weaving system, a heating and setting device for hexagonal mesh weaving with plastic mesh is provided between the mesh forming device and the mesh wire winding module, and a temperature controller is provided to control the temperature , the temperature controller is controlled and connected with the PLC controller; the automatic heating system uses zoned heating to automatically control the temperature, so that the temperature difference in the temperature box is controlled within plus or minus one degree Celsius, achieving a good temperature control effect. Other structures are the same as in Embodiment 1.

[0036] The use method of the above-mentioned coding system: add the next step in the middle of the 3rd step and the 4th step of the use method in the above-mentioned embodiment: open the mesh heating device, and set the heating temperature of the thermostat; other steps and embodiment 1 is the same. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com